Ultrafiltration Plants on Hire for Mining Sites

Ultrafiltration Plants on Hire for Mining Sites

FOR AUSTRALIAN CLIENTS ONLY

Ultrafiltration (UF) is a pressure-driven membrane separation process that removes suspended solids, colloidal particles, bacteria, viruses, and large organic molecules from water. UF membranes typically have pore sizes ranging from 0.01 to 0.1 microns, providing a physical barrier that ensures high-quality effluent suitable for reuse or further polishing by downstream processes like reverse osmosis (RO).

In mining, UF is increasingly deployed as a critical treatment step — either as standalone treatment for solids removal or as pretreatment to protect downstream desalination or ion exchange units.

Why Use UF Plants on Hire for Mining?

Mining operations frequently face variable feedwater conditions, temporary needs, and remote site challenges. Hiring a UF plant addresses these constraints by providing:

- Rapid Deployment: Containerized UF skids can be delivered and installed within weeks.

- Flexibility: Modular units can be scaled up or down to match fluctuating flows.

- Mobility: Easily redeployed to new pits, camps, or sites.

- No Major CAPEX: Costs shift to operational expenditure, freeing capital for core mining activities.

- Guaranteed Performance: Reputable rental providers offer performance guarantees and handle maintenance.

Typical Applications in Mining

UF plants on hire serve a range of applications, including:

- Pretreatment for RO: Removing turbidity and fouling agents to protect high-pressure membranes.

- Clarification of Tailings Pond Water: Reclaiming process water to reduce freshwater intake.

- Pit Dewatering: Treating mine pit inflows with suspended solids.

- Stormwater Treatment: Managing runoff that contains sediments and organic debris.

- Temporary Filtration for Compliance: Assisting sites to meet discharge limits during high-flow or high-load events.

How Hired UF Systems Are Configured

- Containerized Modular Skids:

Most UF hire plants are housed in standard 20-foot or 40-foot containers. Each container includes:

- UF membrane modules (hollow fiber or tubular, depending on solids loading).

- Feed pumps, backwash pumps, and chemical dosing systems.

- Control panels with PLC automation.

- Clean-in-place (CIP) system for membrane cleaning.

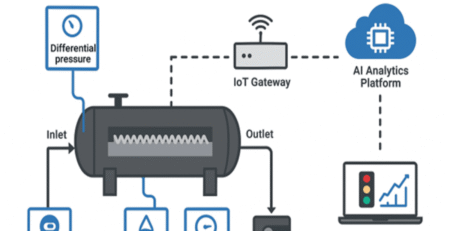

Instrumentation (flow meters, pressure gauges, turbidity sensors).

- Scalability:

Providers offer modular skids that can be connected in parallel or series to handle flow rates from 50 m³/day to several thousand m³/day. This is vital for mines with seasonal or unpredictable flows. - Plug-and-Play Setup:

UF hire plants come with standardized pipe connections, flexible hoses, and quick electrical hook-ups for fast installation and commissioning.

Design Considerations for UF in Mining

Mining waters can pose challenging feed conditions:

- High Turbidity: Solids loading can vary widely due to rainfall or excavation activities.

- Variable pH and Metals: UF membranes must be compatible with varying pH and potential fouling by metals.

- Chemical Compatibility: Materials must resist corrosion from mine water chemistry.

- Cleaning Requirements: Regular backwash and periodic chemical cleaning (CIP) must be designed into the system.

To address these, hire plants are typically equipped with:

- Automatic Backwash: Programmable backwash cycles using filtrate water.

- Chemical Dosing: Coagulant or flocculant dosing upstream to improve solids removal.

- CIP Skids: Allowing operators to restore membrane performance quickly.

- Remote Monitoring: Data logging and alarms for transmembrane pressure (TMP), flow, and turbidity.

Operation and Maintenance

One of the key benefits of a hired UF plant is that the service provider usually supplies:

- Spare parts and consumables (e.g., membranes, chemicals).

- Periodic membrane integrity testing.

- Remote monitoring support.

- Optional site operators or training for client staff.

- Replacement modules if performance declines.

Benefits Specific to Mining Clients

✅ Reduced Downtime: Downtime during unexpected surges in solids can be mitigated by swapping modules.

✅ Environmental Compliance: Consistent effluent quality supports discharge permits.

✅ Water Reuse: Treated water can be recycled for dust suppression, ore processing, or cooling.

✅ Adaptability: As pits expand, plants can be relocated with minimal disruption.

Example: Typical Hired UF Plant Specification

| Parameter | Typical Range |

| Flow Capacity | 50–2,000 m³/day (modular) |

| Feed Turbidity | Up to 500 NTU |

| Filtrate Quality | <0.1 NTU |

| Operating TMP | 0.5–2.0 bar |

| Backwash Frequency | 20–60 mins |

| Materials | SS 316, HDPE, PVDF membranes |

| CIP Frequency | Weekly to monthly |

| Power Supply | 380–415 V, 3-phase |

Real-World Example

Case Study: A mid-tier gold mine faced seasonal pit flooding during the rainy season, resulting in turbid water exceeding discharge limits. By deploying a 1,000 m³/day UF plant on hire:

- The mine reduced freshwater imports by recycling pit water.

- Rapid commissioning (10 days from delivery) kept the mine in compliance.

- The plant was demobilized and redeployed to another pit when no longer needed.

Conclusion

Ultrafiltration plants on hire offer mining operations an agile, cost-effective, and reliable way to manage solids and deliver high-quality treated water for reuse or safe discharge. Their modular, containerized design, combined with professional O&M support, makes them an attractive solution for mines dealing with unpredictable flows, seasonal changes, or temporary treatment needs.

✅ Benefits of Containerised UF Plants for Mining Sites

Containerised ultrafiltration systems bring unique advantages for challenging and remote mining operations:

- Rapid Deployment & Mobility

- Delivered as plug-and-play modules in standard shipping containers (20 ft / 40 ft).

- Minimal civil works required — just a level pad and utility connections.

- Easy to move between pits or satellite sites as mining progresses.

- Space Efficiency

- Compact design maximises treatment capacity per footprint.

- Ideal for mines with limited available space near pits, tailings ponds, or camps.

- Robust Protection

- Containers protect membranes and equipment from harsh weather, dust, and wildlife.

- Insulated or climate-controlled options for extreme temperatures.

- Security & Compliance

- Locked containers safeguard equipment on remote sites with minimal supervision.

- Enclosed design reduces the risk of spills or environmental incidents.

- Ease of Operation & Maintenance

- All treatment units, pumps, controls, and CIP skids are integrated inside the container.

- Standardised modules simplify training, spares, and remote troubleshooting.

- Flexible Scalability

- Multiple containers can be added in parallel or series to match changing flow rates.

- Systems can be upgraded or modified without disrupting site operations.

- Cost Control

- No permanent civil infrastructure or buildings needed.

- Easy demobilisation avoids costly decommissioning works.

How Containerised Ultrafiltration Plants Save Downtime and Space on Mining Sites

🔹 1. Factory-Assembled, Pre-Tested Modules

- Containerised UF plants are fully assembled, integrated, and tested at the manufacturer’s facility before delivery.

- This plug-and-play design eliminates complex site installation, welding, or fit-outs.

- Result: No delays waiting for onsite construction or multiple contractors — reducing commissioning time from months to days.

🔹 2. Minimal Civil Works

- The only requirement is a level foundation or compacted gravel pad with utility connections (power, feed lines, discharge lines).

- No need for purpose-built buildings, large concrete slabs, or additional structural enclosures.

- Result: Significant time and space savings compared to traditional stick-built plants.

🔹 3. Rapid Relocation

- Once a pit or section of a mine is dewatered, the same containerised UF module can be lifted and moved to the next site.

- No dismantling of pipes, tanks, or equipment piece-by-piece.

- Result: Zero downtime between sites — treatment capacity stays available when and where it’s needed.

🔹 4. Compact, Integrated Footprint

- All treatment components — membranes, pumps, backwash systems, chemical dosing, CIP skid, and control panels — are housed inside the container.

- Vertical skids and compact layouts maximise membrane area per square metre.

- Result: No sprawling treatment pads or additional shelters — freeing up valuable operational land for mining activities.

🔹5. Faster Maintenance & Less Downtime

- Standardised, enclosed design means all equipment is easy to access in a controlled environment.

- Built-in CIP (clean-in-place) units allow operators to clean membranes onsite without removing them.

- Remote monitoring systems flag fouling or performance drops early.

- Result: Planned maintenance can be done quickly and efficiently inside the container, minimising plant shutdowns.

🔹 6. Weather Protection

- The container shell protects sensitive membranes, pumps, and instruments from dust, rain, extreme heat, or cold.

- Reduces equipment failures that can lead to unplanned downtime.

- Result: Higher reliability, especially at remote or harsh mining sites.

Containerised UF plants help mining companies maintain continuous operations and maximise productive land by combining:

- Fast deployment

- Small footprints

- Low on-site construction

- Simple relocation

- Weatherproof operation

- Rapid maintenance turnaround

Together, these advantages directly reduce downtime and land use, delivering clear operational and financial benefits to mining operators.