Adsorption/ Bio-oxidation for Industrial Wastewater Treatment

Adsorption/ Bio-oxidation Overview

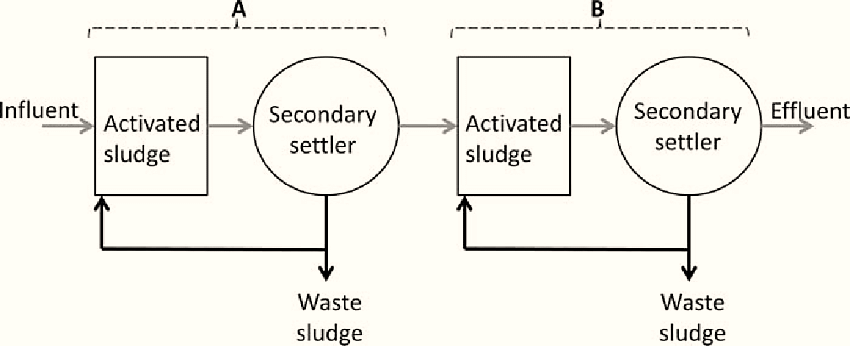

A two-stage modification of the Activated Sludge Process (ASP), used for wastewater treatment is considered as Adsorption/ Bio- oxidation process. There are two stages to it: a high-loaded A stage and a low-loaded B stage. The entire process is based on an A-stage fully dynamic biological system, which eliminates the need for a primary clarifier. Both the A and B stages feature their own settling tanks and sludge collection lines, allowing for distinct microbial communities in each reactor.

Professor Botho Böhnke of RWTH Aachen University devised adsorption/bio-oxidation in the middle of 1970, based on the results of German engineer Karl Imhoff. He stated in his findings that 60-80% treatment efficiency could be achieved by the action of highly loaded ASP basins. Professor Böhnke originally published an essay on adsorption/bio-oxidation in 1977, and the approach grew in popularity in the early 2000s as a result of increased study and interest in wastewater energy recovery.

Operating Principle

The Adsorption stage (A- stage) is the most important or innovative part of the process, not preceded by the primary treatment.

Flocculation or sorption process is used typically in A- stage for the removal of influent organic matter due to high loading rates and low sludge detention time. Biodegradability of the B-stage influent is improved by the occurrence of hydrolysis of complex organic molecules. Low sludge detention time and high loading rates enhance the development of dynamic biocoenosis with a large microorganism’s fraction present in the exponential growth phase. Variety of organic compounds is increased by the diverse sludge biocoenosis that can be degraded in the A-stage and keep the process more stable and avoidable towards the shock loads. The A-stage is capable of removing over 80% of the influent organic materials. In comparison to the traditional Activated Sludge method, the requirement for oxygen supply and reactor volume is significantly lower.

The Bio-oxidation stage (B- stage) is usually a low-loaded activated sludge process where the remaining organic matter is degraded by biodegradation. By alternating aerobic, anoxic, and anaerobic zones in the reactor, this step can be tailored for nitrogen/phosphorus removal.

Operational Conditions

| Parameter | Stage-A | Stage-B |

| MLSS, g/L | 1.5 – 2 | 3 – 4 |

| SRT, d | 0.2 – 0.5 | 14 – 20 |

| HRT, h | 0.5 | 2 – 4 |

| Loading rate, g BOD. Gvss-1. d-1 | 2 – 10 | 0.05 – 0.3 |

| Dissolved oxygen, mg/L | 0.2 – 0.7 | 0.7 – 1.5 |

Advantages of industrial Wastewater treatment

- Low energy consumption due to low aeration requirements and 20% reduction in aeration costs as compared to typical single stage ASP plant.

- 40% reduction in the volume of aeration tank as compared to single stage ASP plant.

- Enhancement of biogas production in the digester due to increased sludge production in the A-stage.

- Higher organic load can be received by the A-stage as in conventional ASP.

- Effluent concentrations are more constant.

- A-stage removed all the heavy metals and thus comply with the agricultural standards.

Disadvantages of industrial Wastewater treatment

- Incomplete denitrification occurs in the B-stage if the C/N ratio is low.

- If a WWTP is not occupied with anaerobic digestion of sludge, high sludge output in the A-stage is a disadvantage because it increases sludge treatment expenses.

- Poor settling properties of A-stage Sludge.

- Increased need for additional reactors arises due to high retention time to maintain equipment costs.

Nutrient Removal Efficiency

- Because nitrogen from organic compounds is integrated in up flow anaerobic sludge blanket (UASB) reactor sludge, nitrogen removal in the A-stage can reach 30-40%.

- Coagulation with ferric and aluminium salts, such as FeCl3 or Al2(SO4)3, can be used to remove phosphorus in the B-stage.

Commercial Adsorbents

- Active carbon is the most commonly used adsorbent, suited for the elimination of apolar compounds.

Active Carbon is added to aerobic and anaerobic wastewater purification systems in powder form or can be added to physico- chemical wastewater processes. The added active carbon is removed and treated together with the produced sludge in this case.

- Natural/Synthetic Zeolites, a lot more selective than active carbon.

- Natural Clay minerals, used for very polar organic and inorganic matter.

- Silica Gel and Activated Aluminium, used for the elimination of water from a nonpolar medium.

- Silicic acid

Applications for industrial Wastewater treatment

Adsorption is one of the advanced and widely used industrial separation technologies in water purification. It involves the interphase collection of dissolved adsorbates (pollutants) onto the solid adsorbent surface from an aqueous solution. The direct relation lies in the surface area and the adsorbent. Activated carbon, natural clay particles and many different synthetic adsorbents have been tested in order to remove organic dyes.

The adsorption/ bio-oxidation process is used conventionally for treatment of industrial wastewater with high COD in following industries:

- Paper and Pulp Industry

- Textile Industry

- Food/ Dairy Industry

- Pharmaceutical Industry

- Leather tanning Industry

In a research study in India, a combined approach of ozone- based oxidation and adsorption by activated char was applied for the treatment of a pharmaceutical industrial effluent. Ozone is a selective oxidant there and addition of H2O2 produced in situ hydroxyl radicals, which is a non- selective stronger oxidant than ozone. Effluent obtained from the industry was composed of anti- cancer drugs, anti- psychotic drugs, and some pain killers. The peroxone process had COD reduction efficiency of 75- 88.5% at pH 5-11 in almost 3 hrs. Adsorption by activated char further decreased the COD to 85.4- 92.7% for pH 5-11 in almost 2.5 hrs.

Adsorption with active carbon is used for the removal of organic micro-pollutants and COD as a tertiary purification as well as the removal of metals in organic complexes from wastewater.

- Active carbon adsorption is used for groundwater purification in soil remediation, chlorinated hydrocarbons and PAH.

- It is used in the textile sector, for the removal of colorants; which are difficult to degrade.

- It is used in the chemical processing industry for the removal of pesticides from partial flows as well as from biological wastewater purification systems.

- In the dry-cleaning sector, it can be used for the removal of PER from wastewater.

Environmental Considerations

In Industrial Wastewater treatment, when active carbon is used as an adsorbent, it must be regularly generated at a high temperature. If this is not economically applicable, it must be annihilated in an incinerator.

Other adsorbents can also be regenerated, if possible, otherwise processed anywhere else.

Adsorption/Bio-oxidation Frequently Asked Questions

1) What is adsorption process in wastewater treatment?

The process of selectively transferring one or more chemicals (adsorbents) from a gaseous or liquid stream to the surface of a porous solid is known as the adsorption technique (adsorbent).

2) What is the most commonly used adsorbent in wastewater treatment?

Water is purified using the adsorption process, which uses a variety of materials as adsorbents. These materials include activated carbon, chitosan, zeolite, clay minerals made from plant and industrial wastes, and others. The most common technique and the oldest adsorbent known to science is activated carbon.

3) What are the applications of adsorption?

Applications of Adsorption

- Air pollution masks

- Adsorption chromatography

- Ion exchange method

- In metallurgy

- Separation of noble gases by Dewar’s flask process

- Purification of water

- Removal of moisture and humidity

4) Why adsorption is used for wastewater treatment?

Adsorption is most frequently employed as a tertiary cleaning step following biological water purification to remove non-degradable organic compounds from groundwater, drinking water preparation, process water, or other water sources. When liquid molecules attach to the surface of a solid, the process is known as adsorption.

5) How is oxidation used in wastewater treatment?

Chemical oxidization is used as a pre-treatment method to either reduce the amount of sludge produced by partially oxidizing the sludge or to break down components that are difficult to degrade and make them amenable for biological degradation. In chemical oxidization, oxidants are produced or added to the wastewater.