Energy drinks comes in soft drink category and include a wide range of carbonated drinks, fruit and vegetable juices, bottled water, sports drinks, beverage concentrates, ready-to-drink tea, and ready-to-drink coffee. They are a popular supplement for teens and adults. They contain a high level of stimulants like caffeine, taurine, ginseng, guarana, and others. They help enhance physical activity and mental alertness. As manufacturers of Energy Drink Manufacturing Plant, Energy drinks are produced and bottled by using high-end manufacturing and filling machines like Energy Drink Filling Machine, energy drink making machine, etc. Additionally, we are reputable exporters of an unrivalled selection of soft drink manufacturing equipment’s.

Working of energy drink manufacturing machine:

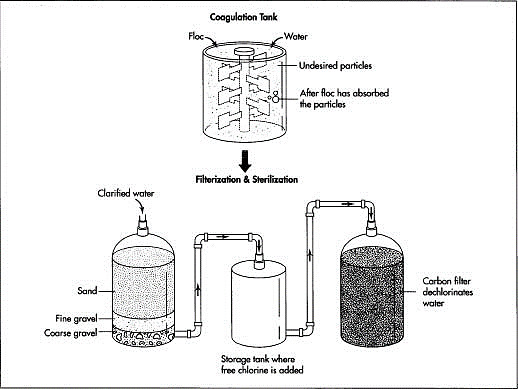

Clarifying water in Soft Drink Manufacturing Plant:

The success of the drink depends upon the quality of the water. Impurities like bacteria, suspended particles, organic matter, etc. can degrade the taste and color of the water. These impurities are removed through a series of coagulation, filtration, and chlorination during the energy drink manufacturing process. In coagulation, a gelatinous precipitate or floc is mixed into water that absorbs suspended particles and makes them larger. These large particles are easily trapped by filters of equipment for manufacturing energy drinks. Alkalinity is adjusted during the clarification process by adding lime to reach desired pH level.

Filtering, sterilizing, and dechlorinating the water in Energy Drink Plant:

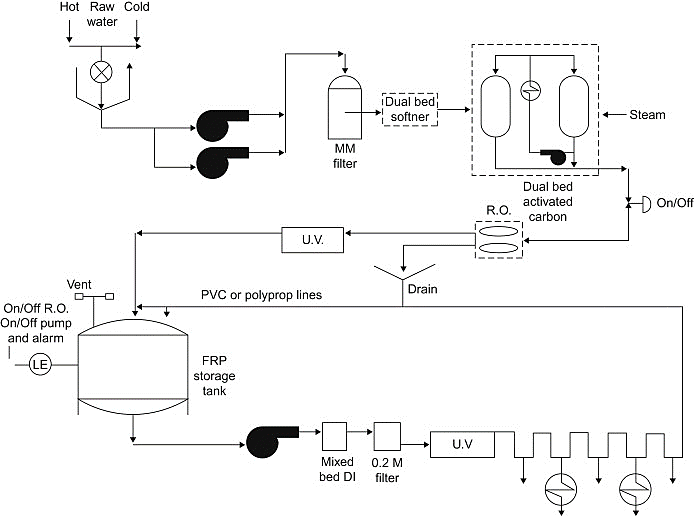

The fine particles of a floc are removed by pouring water through a sand filter by Energy Drink Machinery. The particles are captured by passing water through sand and courser beds of gravel. Bacteria and organic matter that can spoil the taste and color of the water are removed through the process of sterilization. This is done by pumping water into a storage tank and adding a small amount of free chlorine. The water must remain in the storage tank for two hours for the reaction to complete. Dichlorination of water is done by activated carbon filters. This helps in the removal of organic matter. Deaeration of water is done by a vacuum pump before it passes into a dosing station of the Energy Drink Production Line.

Mixing the ingredients with Energy Drink Machinery:

According to the compatibility, dissolved sugar and flavor concentrate are pumped into the dosing tank in a predetermined sequence. The ingredients are then conveyed into a batch tank where they are mixed. Ultraviolet radiation and flash pasteurization are used to sterilize the syrup. Then, proportion carefully combines the syrup and water. Proportioners regulate the flow rate and ratios of the liquids. Aeration of the mixture is prevented by pressurizing the vessels with carbon dioxide.

Carbonation with Soft Drink Plant Machinery:

In cold drink manufacturing machine carbonation can either be added to the finished product or mixed in the water at an earlier stage. As carbon dioxide solubility increases with the increase in temperature, the temperature of liquid must be carefully controlled. For this purpose, the carbonators are equipped with cooling systems. To facilitate the movement into the storage tank, the beverage is slightly over-pressured with carbon dioxide. And, as suppliers, our top priorities have been to comprehend client needs and provide the best solutions possible to satisfy them consistently and affordably.

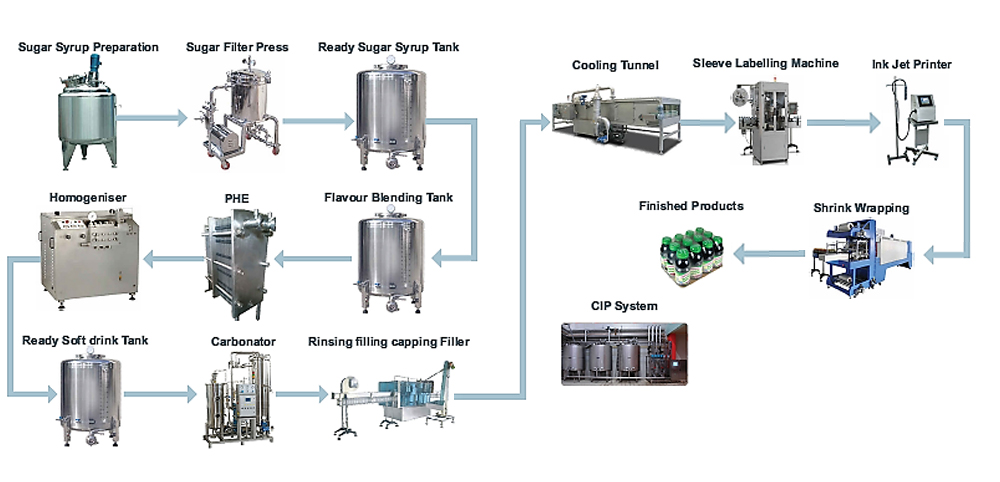

Energy Drink Filling and Packaging Machines:

The finished product is transferred into cand and sealed with pressure-resistant closures. After this labeling is done and containers are packed into cartons. Our Energy Drink liquid filling and packaging machines are made to adapt to the industry's evolving demands. We offer the best equipment to manage your Energy Drink filling requirements and achieve your production targets.

Energy Drink Production Line:

Energy Drink Manufacturing Plant Design:

The energy drink manufacturing plant consists of:

- Clean in place (CIP)

- Dosing

- Filtering

- Sanitation

- Controls

- Automation

- Refrigeration

- Packaging

- Bottling

- Storage vats and tanks

- Monitoring

- Central utility plants

- Palletizing/material handling

- Blow molding / bottle-making

- Carton filling

Soft Drink Mixing Machine:

- Voltage: 300V

- Stainless steel

- Power: 3KW

- Dimensions: 2200*1600*2100

- Capacity: 500Liter/hour-10000Liter/h

Soft Drink Filling Machine:

- Structure: Rotary

- Filling speed: Adjustable

- Production capacity: 5PCs per month

Energy Drink Machine Advantages:

- Cost effective

- Efficient

- Sturdy

- Environmentally friendly

Energy Drink Manufacturing Plant Frequently Asked Questions

Q. How does an energy drink manufacturing plant operate?

A. Energy drink manufacturing plants follow a standardized process to produce energy drinks. First, ingredients are mixed together in specific proportions. Then, the mixture is pasteurized, carbonated (if required), and filtered. The final step involves packaging the energy drink into cans or bottles, which are then sealed, labeled, and ready for distribution.

Q. How are carbonated drinks manufactured in a plant?

A. Carbonated drinks, such as soda, are produced in a manufacturing plant through a process called carbonation. Initially, syrup is prepared by mixing water, sweeteners, flavourings, and other ingredients. The syrup is then combined with carbonated water, which adds the characteristic fizziness. The mixture is carefully blended and cooled before being packaged into bottles or cans. The containers are sealed and labeled for distribution to consumers.

Q. What are the main considerations in setting up a sports drink manufacturing plant?

A. When setting up a sports drink manufacturing plant, several considerations should be considered. Firstly, you need to determine the formulation of your sports drink, including the specific electrolytes, carbohydrates, and flavors you want to include. Then, you'll need to establish a production process that ensures accurate blending and quality control. Additionally, it's important to consider the packaging materials and design, as well as develop effective marketing strategies to target athletes and fitness enthusiasts.

Q. What are the key steps involved in manufacturing ready-to-drink tea and coffee?

A. The manufacturing process for ready-to-drink tea and coffee involves several important steps. First, the base ingredients (tea leaves or coffee beans) are carefully selected and processed to extract their flavors and aromas. The extracted tea or coffee is then mixed with water and sweeteners, if desired, in specific ratios. Afterwards, the mixture is pasteurized, filtered, and sometimes carbonated. Finally, the ready-to-drink tea or coffee is packaged in bottles or cans, labeled, and prepared for distribution to consumers.

Q. What are the packaging considerations for a beverage manufacturing plant?

A. Packaging considerations in a beverage manufacturing plant include selecting appropriate packaging materials (such as bottles, cans, cartons, or pouches) that suit the product and its shelf life requirements. Factors to consider include packaging design, branding, labeling compliance, convenience for consumers, and environmental sustainability.