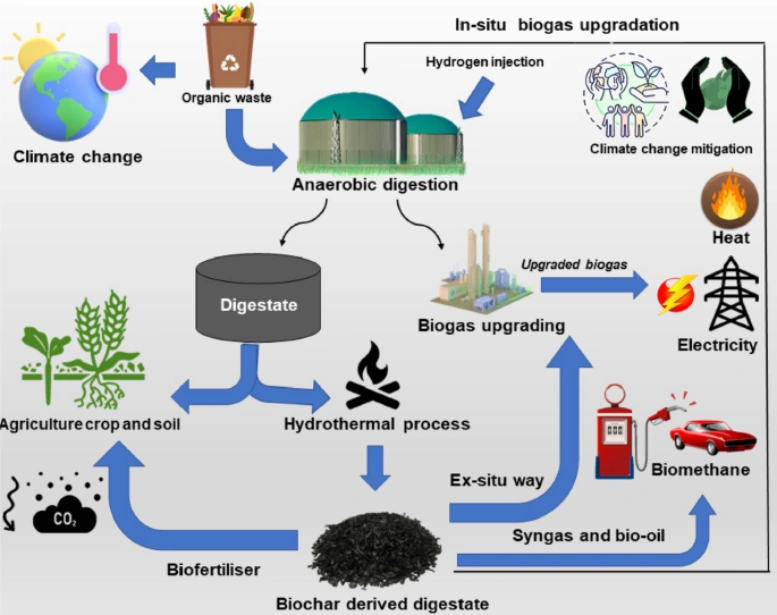

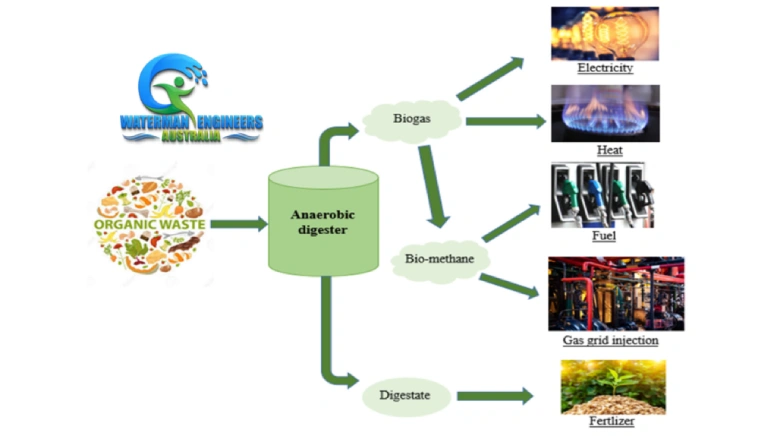

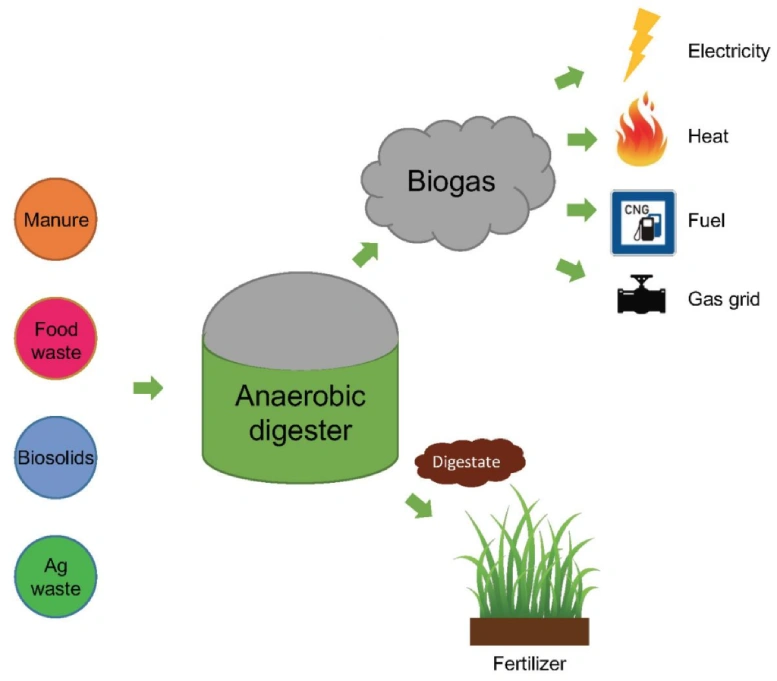

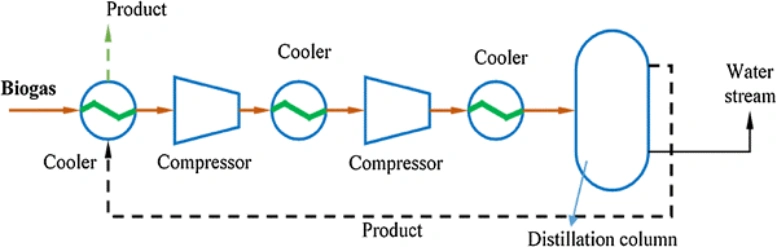

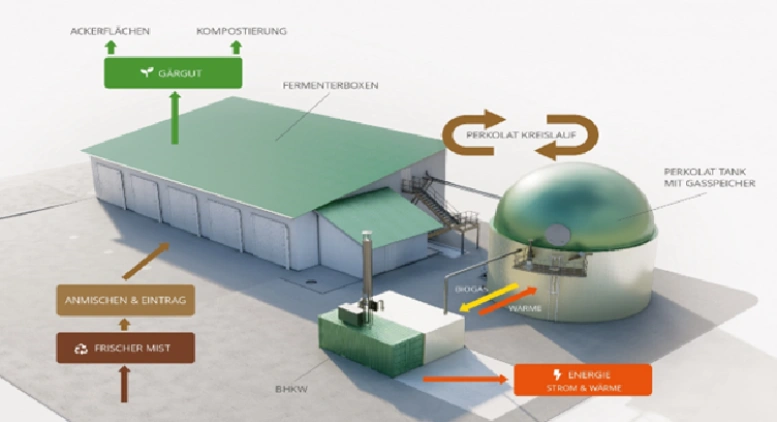

Anaerobic digestion is a natural biological process that turns organic matter into biogas. Biogas is a flexible and long-lasting source of renewable energy. A process called anaerobic digestion uses microbes to break down food without oxygen. As a byproduct, biogas is made. A lot of people are interested in this eco-friendly technology because it looks like a good way to deal with organic waste and make useful energy at the same time.

Anaerobic Digestion Process

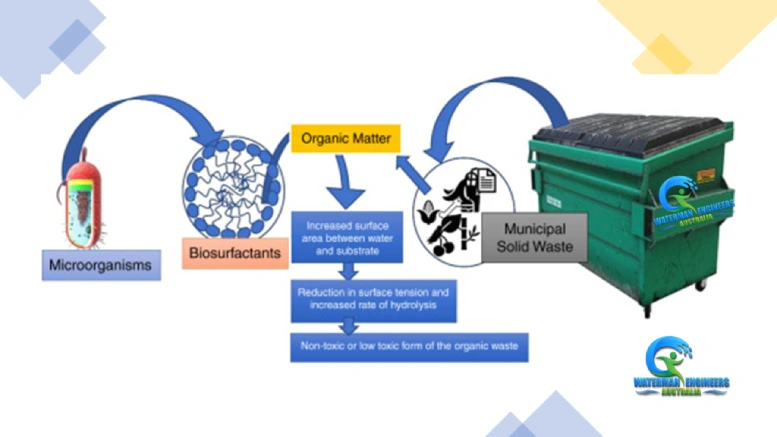

Microorganisms break down organic matter without oxygen, which is called anaerobic digestion. This biological process takes place in anaerobic digestors, which are sealed containers that are made to make the best conditions for the microbes that break down the food.

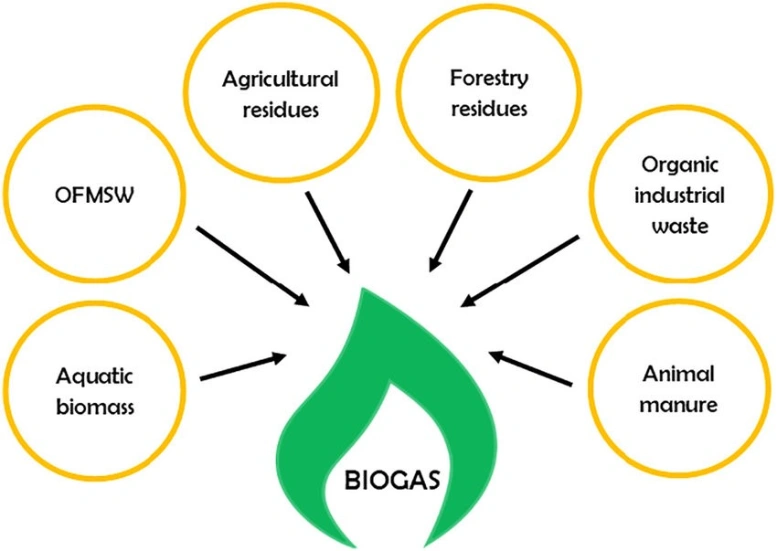

Feedstock Sources

Biogas can be made from many different types of organic materials, such as agricultural waste, municipal solid waste, animal manure, wastewater sludge, and energy crops. The type of feedstock used depends on what is available locally, how waste is managed, and what the biogas is going to be used for in the end.

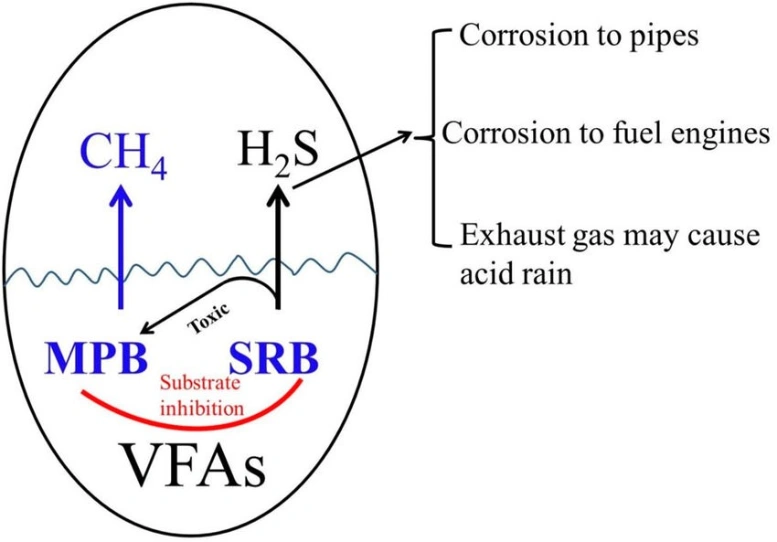

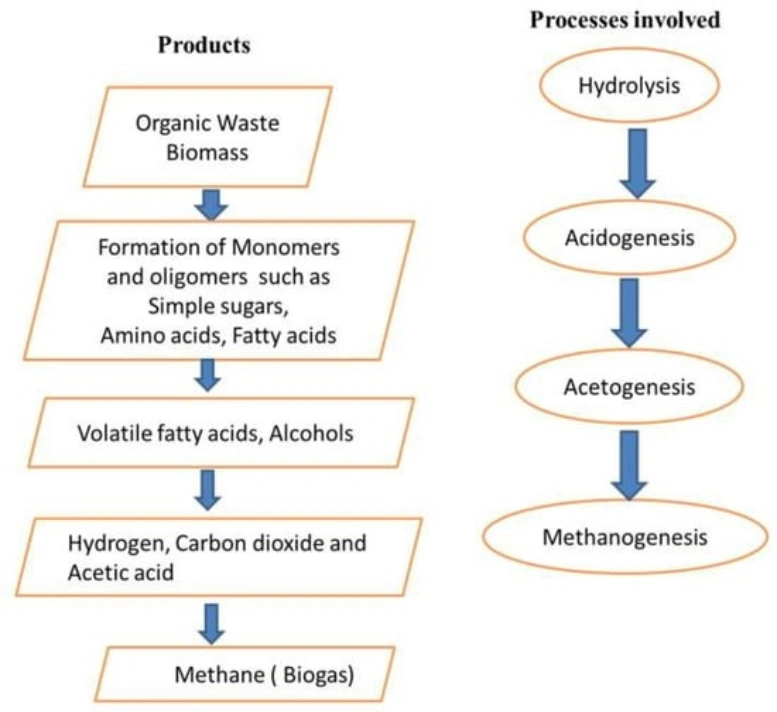

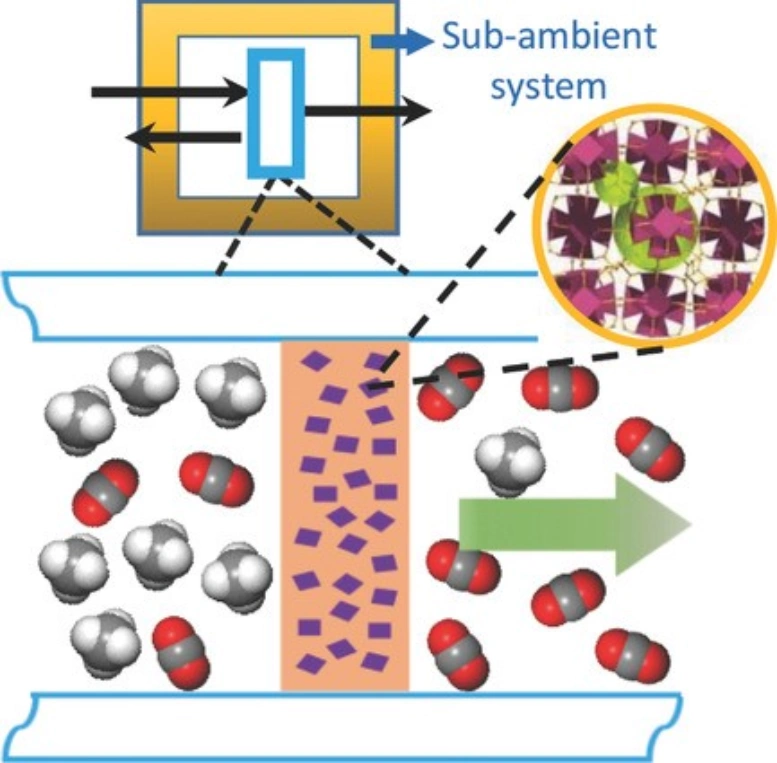

Microbial Activity

Different types of microorganisms work together to break down complex organic compounds into simpler molecules during anaerobic digestion. The main steps in microbial activity are hydrolysis, acidogenesis, acetogenesis, and methanogenesis. These reactions produce biogas that is high in methane.

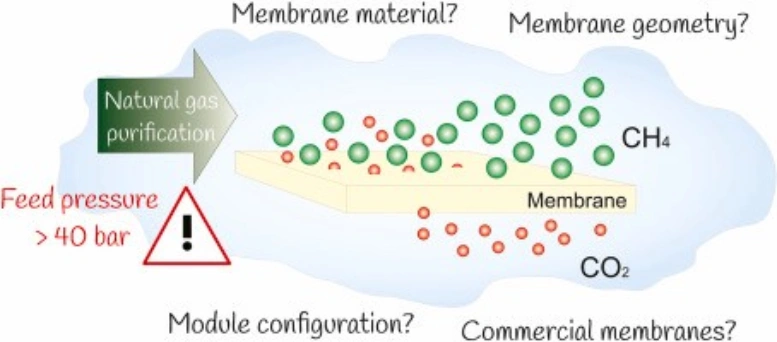

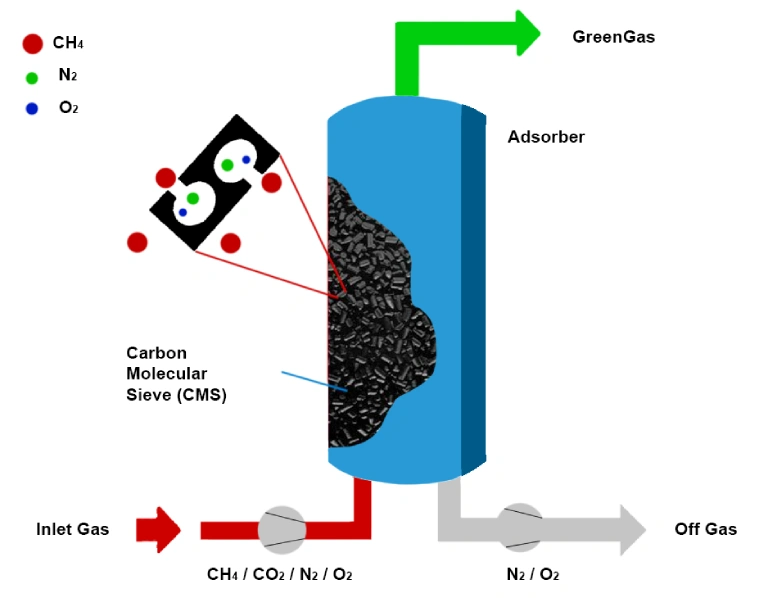

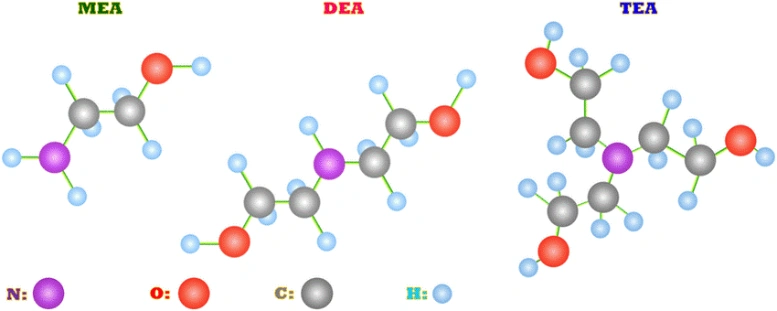

Biogas Composition

Biogas is mostly made up of methane (CH4) and carbon dioxide (CO2). It also has small amounts of hydrogen sulphide (H2S), nitrogen (N2), and water vapour. The amount of methane in biogas is very important because it determines how much energy it has and how it can be used.