Activated Sludge Process for Wastewater Treatment Technologies

Did you know that using recycled wastewater can save around 50 to 60% on domestic water use?

Water is what allows life to exist on this planet. Water is required for practically all of our activities. However, human actions can have an impact on water quality. The majority of our hazardous industrial and household waste mixes with pure water, polluting it and causing a slew of terrible illnesses. In Australia, water crisis and drought conditions are two major concern that needs to be addressed before it’s too late. Australia is on track to run out of clean water resources shortly due to unsustainable water consumption and rising demand. Many scientists and specialists are looking for solutions to this problem. Reusing wastewater is one viable method among several to solve this problem. In Sydney, over 70% of wastewater is discharged from houses. This wastewater can be reused by making it clean and safe to use again.

Contaminated wastewater is a possible environmental danger, and it must be treated before being discharged to avoid negative consequences. Treatment solutions that really can tackle the rising concerns about water contamination are urgently required. Various wastewater recovery treatment technologies or Waste water treatment plants can be used to address this issue few of which are discussed below:

Activated Sludge Process

In 1913, Arden and Lockett proposed a wastewater treatment technique, the Activated sludge process (AS) which is a treatment technique for industrial and domestic wastewaters. This process uses microorganisms such as bacteria to treat wastewater aerobically. In the industrialized world, activated sludge (AS) technology is now the most frequently used biological wastewater treatment. It is often used for secondary wastewater treatment i.e. removal of biodegradable organic matter. Treatment using activated sludge is appropriate for facilities that generate organic waste. Municipal wastewater treatment plants, petroleum refineries, textile mills, factories, and chemical manufacturing plants are just a few examples.

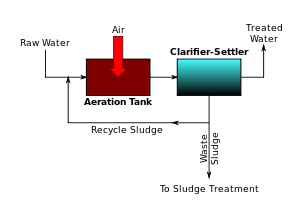

A typical AS process consists of three steps;

- Aeration

- Sludge settling

- Return Activated sludge equipment

Design

Although there are many different designs, all AS have three main components: firstly, an aeration tank will function as a bioreactor. Then, the solid material in the sludge is separated from the treated water through a settling tank, also known as the final clarifier. In the last step, a return activated sludge (RAS) equipment will carry settled AS from the clarifier to the aeration tank’s influent. Organic pollutants in wastewater supply the energy and carbon needed for microbial growth and production.

Procedure

In this process, air/oxygen is pumped into agitated sewage which breaks down solids in the wastewater. Sludge liquor is poured into an active sludge chamber after the sewage is bubbled. Dead bacteria rise to the surface of the tank, while active bacteria descend to the bottom. The active bacteria are then returned to the digesting chamber while the clean water is discharged into the watercourse or stored away.

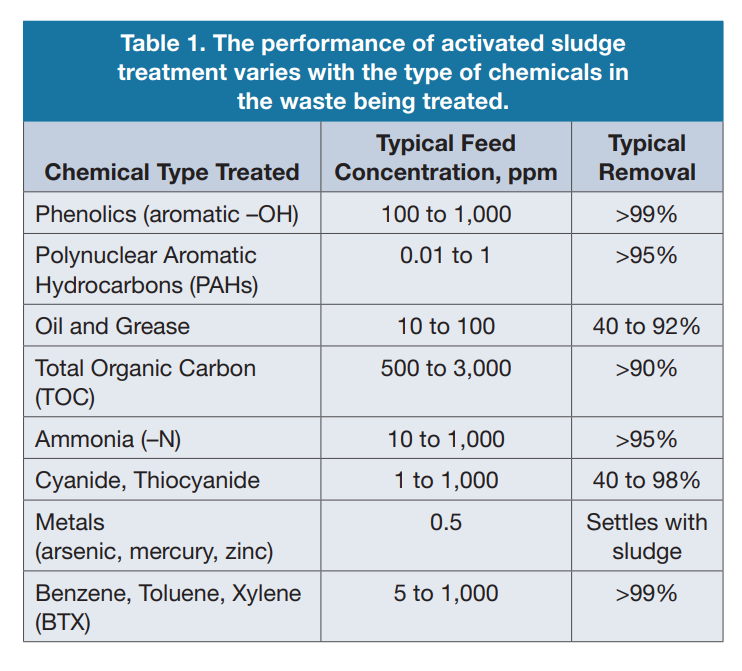

An activated sludge process can treat a range of chemicals present in water. Its efficiency depends upon the type and concentration of the pollutant present. Table 1 contains a list of chemicals along with their percentage removal that could be treated with AS procedure.

Variables of AS procedure

The following are the most critical factors in the AS process:

- Flow scheme

- Mixing process

- Rate of loading

Conventional Activated Sludge (CAS)

The Conventional Activated Sludge technology is an activated sludge method that is used to reduce the amount of organic debris in wastewater. It entails the oxidation of biological materials containing carbon in order to reduce organic contaminants present in wastewater.

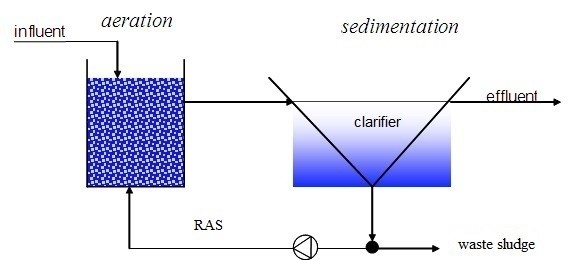

A CAS comprises two parts

- An aeration/biological tank

- A sedimentation tank (secondary clarifier)

Procedure

In this system, an aeration tank is utilized for biodegradation. The air is combined with wastewater in the aeration tank. When organisms collide while digesting wastewater, bigger particles called flocs emerge, which have a greater potential to destroy the wastewater’s biological components. After that, microorganisms sink due to their adsorbed organic material in the sedimentation tank which is a secondary clarifier that separates the sludge from the treated wastewater. The sedimentation tank, also known as a secondary clarifier,’ separates the particles from the liquid. The clarifier’s water is transferred to purification and discharge facilities, or for further tertiary treatment regarding additional purification i.e. filtration and/or UV disinfection).

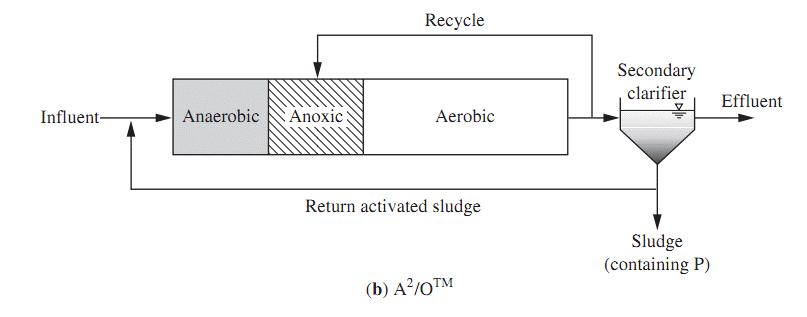

Anaerobic-Anoxic-Aerobic (A2O)

In the wastewater treatment process, the anaerobic-anoxic-aerobic (A2O) technique is one of several activated sludge treatment technologies. This is a type of sewage treatment that eliminates nitrogen and phosphorus and is an improvement over the traditional activated sludge process.

Design

The A2O method includes an anoxic tank for de-nitrification, an anaerobic tank for removal of phosphorus and absorption, and anaerobic tank for organic matter decomposition.

Procedure

A2O-activated sludge systems consist of three processes i.e. anaerobic, anoxic, and aerobic to conduct the nitrification and denitrification in wastewater along with phosphorus removal. This process has an internal recycling process for sludge. The internal recycling is carried out in an anoxic tank which is between an aerobic and anaerobic tank that is employed for phosphorous removal through nitrification. For the denitrification process, nitrate is recirculated to the anoxic zone from the aerobic tank. Phosphorus is released in the anaerobic tank by utilizing the organic matter from the wastewater. Due to the absence of oxygen in anaerobic tanks, microorganisms and activated sludge become less active which eventually releases phosphorus. Sludge from anaerobic tanks is then transported to anoxic tanks after phosphorus is released. The nitrate ion in the nitrate-rich liquid obtained from the aerobic tank is pumped into the anoxic tank decomposes because microorganism preferring anaerobic conditions devours oxygen in the tank.

Stirred sewage and nitrifying bacteria in the aerobic tank break down ammonium nitrogen-rich waste fed from the anoxic tank and transform it into nitrate ions. Nitrogen is released into the atmosphere as nitrogen gas as oxygen is taken up by the nitrate ion as the breakdown process occurs. The last settling tank receives sludge (activated) and phosphorus-consuming bacteria. After going through the disinfection process, the clarified water in the settling tank is released. As returned sludge, a portion of the settled sludge is returned to the reaction tank. Because nitrification and denitrification occur simultaneously while a nitrate-containing liquid is cycled, this nitrogen removal technology is also known as a recirculating denitrification system.

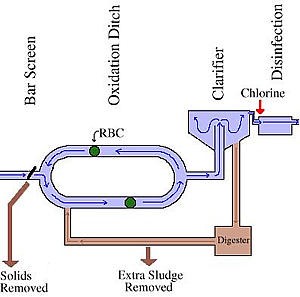

Oxidation Ditch

An oxidation ditch is an enhanced process of activated sludge technology that is used to remove biodegradable organic matter. In this system, the bar screen is usually the only pre-treatment employed. Wastewater runs straight in the oxidation ditch after passing past a bar screen. Water travels through the oxidation ditches after pre-treatment, where RBCs and microbes in the returned activated sludge decompose the biological oxygen demand. The sludge is then removed in a clarifier, and the water that remains is disinfected.

Sequencing Batch Reactors (SBR)

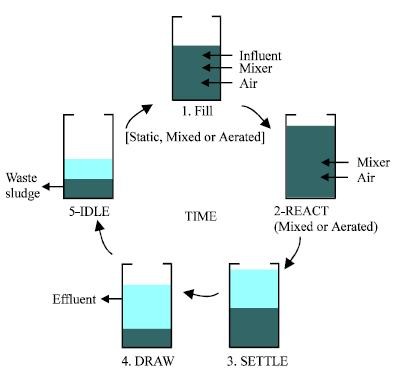

One of the most often used aerobic treatment systems for wastewater is the sequencing batch reactor (SBR). The SBR process uses a single basin to perform all of the functions which makes it different from traditional activated sludge technology.

Procedure

Filling, reacting, settling, decanting, and idling are the five processes that make up the fill-and-draw concept that regulates the operation of an SBR. These methods might be tweaked to meet varied operational requirements.

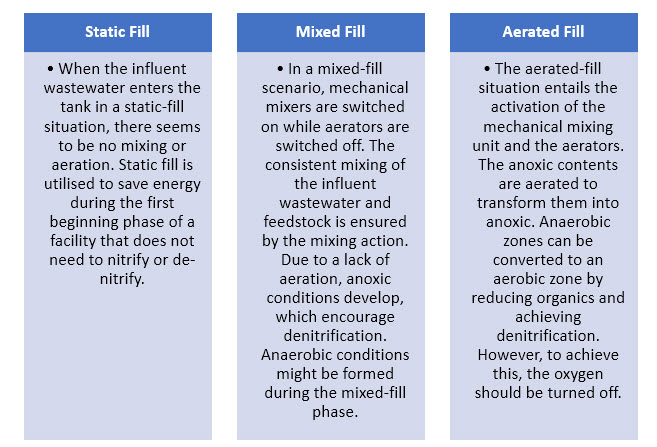

Fill Phase

During the fill phase, the basin gathers influent wastewater. The influent feed the microorganisms in the sewage, enabling biochemical reactions to proceed. During this step, aeration and mixing are carried out with variation forming three different situations;

- Static Filling (without mixing and aeration)

- Mixed Filling (mechanical mixing occurs but no aeration)

- Aerated Filling

React Phase

The react phase is when the majority of the carbon-containing BOD is removed. During this time, no wastewater is allowed to enter the basin, and the mechanical blending and aeration systems are activated. The levels of organic elimination rise since there are no increased volumes or organic loadings.

Settle Phase

Activated sludge is resettled under controlled situations throughout this phase, there is no flow into the basin, no stirring, and no aeration. A distinctive barrier is formed by the activated sludge with the liquid portion as a flocculent mass settle. This mass of sludge is also called a sludge blanket. This is a necessary element of this process. However, if the particles do not settle rapidly, a part of the sludge will be scraped off during the decant phase that follows, decreasing effluent quality.

Decant Phase

In this phase, the residual effluent is extracted through a decanter. When the phase in which the sludge settles is over, a signal is transmitted to the decanter to start the effluent-discharge valve opening.

Idle Phase

The idle phase occurs in between the fill phase and decants phase. During this phase, a little portion of sludge (activated) from the bottom of the SBR basin is pumped out and this procedure is called wasting.

Activated Sludge Process Frequently Asked Questions

1) What is activated sludge treatment process?

A biological floc made up of bacteria and protozoa is used in the activated sludge process, a form of biological wastewater treatment method, to treat sewage or industrial wastewaters.

2) What are the types of activated sludge process?

The traditional ASP, contact stabilization plant, total mix plant, and step aeration plant are some examples of different ASP types [251]. By microbially breaking down the organic material in the wastewater, this biological treatment removes biological waste from the water.

3) What are three stages in activated sludge system?

The aeration rate of the air is one. 2) Sludge waste through used sludge is another. The third option is sludge recirculation, which can be done for nutrient removal either through internal mixed liquor recycling or return activated sludge.

4) What are the advantages of activated sludge process?

The process of treating activated sludge has advantages.

- There is less undesirable muck present.

- The sewage treatment facilities replenish their populations of helpful microorganisms.

- The extended emptying intervals are made possible by the activated sludge treatment procedure.

- The method is really trustworthy.

- The procedure is easier.

5) What are the characteristics of activated sludge?

The rheological, sedimentation, filtration, and compression characteristics of activated sludge are taken into account in this review. These are the physical characteristics that have significant engineering implications for wastewater treatment facility design and operation.