All about Zero Liquid Discharge System (ZLD System)

A Zero Liquid Discharge System is a treatment process for wastewater that is not discharged to the environment. Instead, the unit produces solid waste and treats it. As a result, the treated effluent is not discharged into the environment. It also maintains a Zero Liquid Discharge. The environmental impact and cost of using a Zero Liquid Discharge System are just some of the benefits of this system.

Water Recovery

A Zero Liquid Discharge System (ZLD) is an engineering approach to wastewater treatment that recovers all the water from a facility. As one of the best ZLD suppliers, Zero liquid discharge systems also reduce contaminants to solid waste. Various types of ZLD systems are available. The best solution depends on the wastewater composition, the streams to be treated, and operating costs and footprint availability. Listed below are the advantages of zero-liquid discharge systems.

ZLD systems are based on membrane technology. Membranes can separate a variety of complex fluid mixtures and can recycle solvents in Zero Liquid Discharge Systems. These systems often result in zero liquid discharge and are more costly. This is because these wastewater recovery systems use a complex process to separate non-volatile Solutes from their solvents. The liquid is then filtered to recover the solute and remove all contaminants.

The Zero Liquid Discharge System allows for the recycling of wastewater in many industries. Zero Liquid Discharge systems recover as much water as possible for reuse and recycle it as a valuable by-product. In addition to recovering water, Zero Liquid Discharge systems also minimize the environmental footprint associated with wastewater disposal. It is also an excellent way to reduce operating costs. Zero Liquid Discharge systems are especially popular in countries where the environment is strictly enforced.

During the water recycling process, the resulting concentrated liquid is pumped back into the process. The water is then dewatered using an evaporator. This dewatered liquid is then pumped into a filter press, which traps solids and keeps the heated tank clean. After the press, the resulting liquid is pumped to a large hopper, where it is reused.

Solid Waste Production

Zero liquid discharge is highly efficient means of wastewater treatment, but it has numerous factors also to check. It requires large capital investments and operating costs and generates significant greenhouse gas emissions. Additionally, it leaves behind a dry sludge that contains a high concentration of hazardous chemicals and heavy metals. This zld water treatment plants, waste treatment method requires a high level of engineering expertise and careful planning to reach zero discharges. Listed below are the factors to look in for zero liquid discharge.

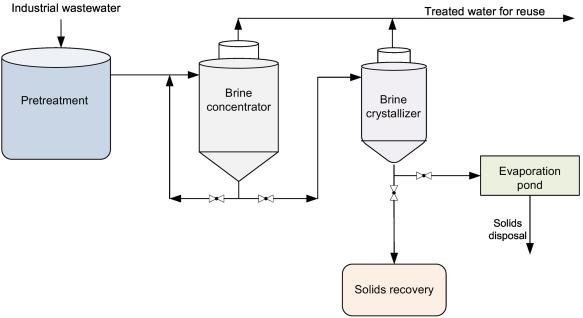

To produce zero liquid discharge, the first step in the treatment process is to utilize membrane technology and ultra-filtration. The goal of pre-treatment in ZLD System is to separate the clean water from the polluted water. This separation results in a concentrate. This concentrate is then treated further, filtered, and enters a brine concentrator. This equipment uses heat and vapor compression to evaporate the brine solution. The remaining waste is then converted into solid waste by a crystallizer. The high-pressure steam used in the crystallizer aids in the formation of solid waste.

While a ZLD process can be beneficial for some applications. It requires additional equipment, chemicals, and sludge disposal. The downsides of a ZLD system include a high installation and operational cost. For example, if you have a small-scale production plant, the ZLD process is not cost-effective. Nonetheless, it allows the use of cheaper alloys for major process equipment.

Zero liquid discharge is becoming a mainstream technology in the manufacturing industry. Increasing public awareness and tighter environmental regulations are forcing manufacturers to adopt the technology. Zero liquid discharge is a valuable waste reduction technique, and Samsco Corporation has the necessary experience and equipment to implement it. So, it is time to get started on zero liquid discharge. If you’d like to make a difference in your environmental impact, adopting this zero-discharge system technology can help you save money.

Environmental Impact of Zero Liquid Discharge System

Developing a Zero Liquid Discharge System (ZLDS) requires careful planning and analysis. There is no “one-size-fits-all” solution, as each site has its own unique set of factors. The optimal system is site-specific, taking into account the type and composition of waste water, different streams to be treated, operating costs and available footprint. Here are some points to keep in mind when planning a zero liquid discharge system.

In developing a zero liquid discharge system, waste water is treated and recycled within the system. The treated water is then released into the environment by means of heat and crystalizers. The zero liquid discharge process has been used in the power industry for nearly 50 years, and the U.S., Australia, China, India are leading markets for this technology. As wastewater treatment costs continue to rise, zero liquid discharge can help companies reduce their water costs and avoid adverse environmental impacts associated with wastewater discharge.

Although ZLD is a very efficient way to treat wastewater, there are some unintended consequences of this technology. The wastewater treatment process requires large amounts of energy and produces a significant amount of Green House Gas (GHG). ZLD technology can be particularly energy-efficient if the system is powered by renewable energy sources. Further, ZLD systems can be a good fit for large-scale chemical production plants.

The process for achieving a Zero Liquid Discharge System involves pre-treatment, concentration, and thermal treatment. During this process, wastewater is processed using membrane technologies such as electrodialysis and reverse osmosis. After the evaporation stage, dissolved solids precipitate as crystals, and these are removed from the wastewater through a filter press or centrifuge. Reuse of condensate water is another way to use wastewater.

Cost of ZLD Technology

The Zero Liquid Discharge (ZLD) process is a relatively new method of water treatment that uses only water to produce electricity. This technology is a relatively high-tech and capital-intensive alternative to traditional FGD treatment. However, some organizations have already made the transition to zero liquid discharge and are selling or reusing the solids that are produced. Lithium, for example, is recovered from oil-field brines and salars in the United States. Gypsum, meanwhile, can be recovered from mine water and flue gas desalination wastewater and sold for use in drywall manufacturing.

There are several advantages to ZLD technology. The first of these is that it allows companies to use lower-cost alloys in major process equipment. The second is that it eliminates the high cost of waste disposal and allows companies to recycle wastewater. Besides, it has a high capacity for increasing productivity. ZLD is becoming more popular as it has many advantages. Zero Liquid Discharge System Cost is a factor in determining the ZLD system cost for your facility.

The ZLD cost depends on the amount of wastewater being treated. The capital cost of the entire system can vary depending on its size and characteristics. If your waste stream is extremely large, ZLD might not be a cost-effective solution. So, if you want to build a ZLD facility, consider the following:

The cost of a ZLD treatment system is an important factor in deciding whether or not to purchase it. The cost will depend on how many components you need and whether or not you want to install an evaporation pond. Additionally, ZLD systems can be shipped to your facility. However, freight costs can vary depending on the time of year and your location. To reduce the cost of a zero liquid discharge system, it may be wise to install a membrane system.

ZLD System Applications

A Zero Liquid Discharge System is a process that concentrates waste water to its solubility limit, where the salts can be collected for reuse. In contrast to other systems, a ZLD requires less capital and complexity. The advantages include the use of less expensive alloys for the major process equipment, which reduces operating costs. Here are a few of the benefits of this technology. They also enable more efficient wastewater treatment and recycling.

A Zero Liquid Discharge System is a process for recovering water and desired solvents from wastewater. After the process, the remaining constituents are dehydrated to form pure water. As a result, zero liquid discharge creates zero waste. Currently, water and chemical processes are highly dependent on liquids. Most of this waste is disposed of in landfills, but some of it is partially or fully recyclable.

With stricter discharge guidelines, the power industry is increasingly moving towards the use of ZLD. ZLD systems can also help reduce contaminants like mercury and selenium to part-per-trillion levels. This is particularly important for the power industry, which consumes large amounts of water for operations. These plants have to find effective methods of reusing their waste water. If these systems can reduce these levels, then the energy and environmental costs of the power plants will be reduced.

ZLD stands for Zero Liquid Discharge, a system that is used to treat and reuse wastewater in a closed-loop system. The following are some common features of ZLD systems:

- Pre-treatment: The first step in a ZLD system is pre-treatment, which involves removing solids and other contaminants from the wastewater. This is typically done using a sedimentation tank, a filter, or a clarifier.

- Evaporation: After pre-treatment, the wastewater is subjected to evaporation, which removes water from the waste stream and concentrates the remaining contaminants. This is typically done using multi-effect evaporators or thermal evaporators.

- Crystallization: In some ZLD systems, the concentrated waste stream is subjected to crystallization, which further removes water and results in a solid waste product that can be disposed of or processed further.

- Recycling: The purified water from ZLD systems can be recycled back into the industrial process, reducing the need for fresh water and helping to conserve water resources.

- Energy recovery: ZLD systems often use energy-intensive processes, such as evaporation and crystallization. However, these processes can also generate heat and other forms of energy that can be recovered and reused, reducing the overall energy consumption of the system.

- Monitoring and control: ZLD systems are typically equipped with monitoring and control systems that help to optimize the performance of the system and ensure that it is operating within design parameters.

By incorporating these features, ZLD systems can effectively treat and reuse wastewater, reducing the need for fresh water, conserving water resources, and improving the overall sustainability of industrial processes.

ZLD System Frequently Asked Questions

1) What is a zero liquid discharge system?

A strategic wastewater management method called zero liquid discharge (ZLD) makes sure that no industrial effluent will be released into the environment. It is accomplished by first recycling wastewater, followed by recovery and reuse for industrial purposes.

2) Why is zero liquid discharge important?

A water treatment method called Zero Liquid Discharge (ZLD) aims to eliminate all liquid waste from a system. ZLD focuses on producing clean water that may be used again (for example, irrigation), reducing wastewater in an inexpensive manner, and protecting the environment.

3) What is the purpose of discharge analysis?

A patient’s or client’s progress toward goals, status at discharge, and future self-management plans are all summarized in the discharge document.

4) What is zero liquid discharge and why is it important?

A strategic wastewater management method called zero liquid discharge (ZLD) makes sure that no industrial effluent will be released into the environment. It is accomplished by first recycling wastewater, followed by recovery and reuse for industrial purposes.

5) Why is zero waste management important?

Why is Waste Zero Important? We want to do our share to lessen our influence on the environment, thus striving towards zero waste is crucial. Climate change is a result of waste that winds up in our landfills, oceans, and incinerators.

6) How does wastewater affect the environment?

Restrictions on human enjoyment, drinking water intake, and shellfish consumption can result from bacteria, viruses, and disease-causing pathogens contaminating beaches and shellfish populations; Metals including mercury, lead, cadmium, chromium, and arsenic can have harmful effects on species in both the acute and chronic phases.