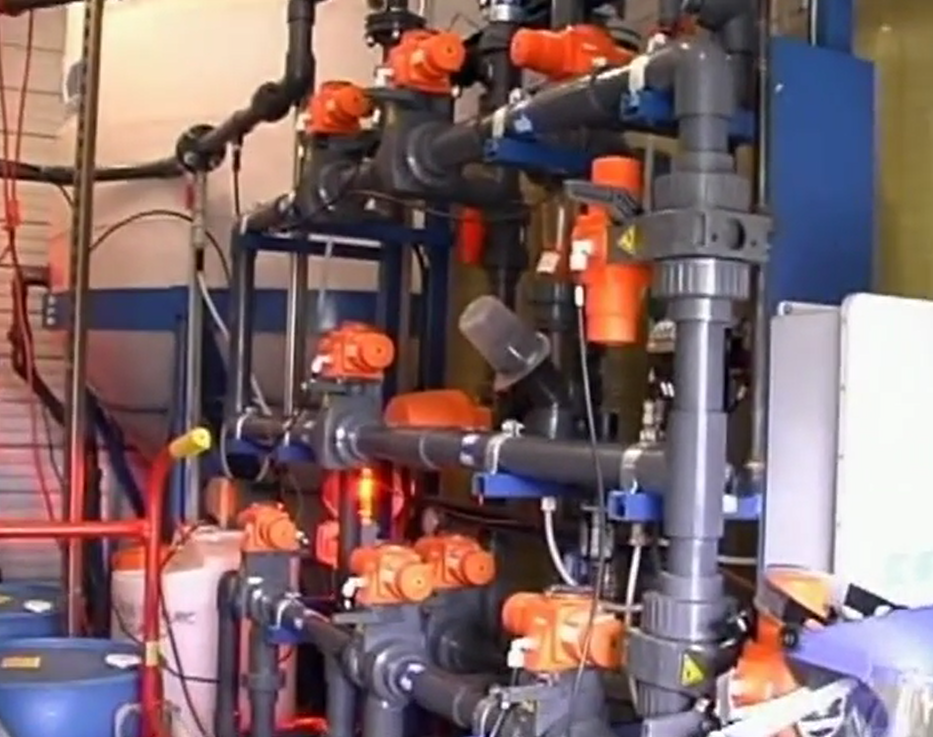

Arsenic Removal System and Its Different Components

Arsenic Removal Systems are specially designed to remove arsenic from drinking water, while maintaining the purity of the water. These systems contain several different elements, including Reverse Osmosis filters, Adsorbent arsenic reduction media, and exchange filters. These filters are very effective in removing arsenic from water, and they are also easy to use.

What are the Benefits of Anionic Exchange Filter for Arsenic Removal?

Amongst the many different types of treatment systems for arsenic removal, Ion-Exchange is the most cost effective. It is a type of reverse osmosis system that removes a variety of ions at once. The process uses a tank filled with a special ion exchange material. Ion-Exchange is effective against several different contaminants, including anions, alkalinity, dissolved solids, nitrates, and metals.

The effectiveness of IX is based on the pentavalent state of As(V). In order for the unit to remove As(V), the As(V) must first be converted to the pentavalent state by oxidation. Anions that are negatively charged and not naturally pentavalent are regenerated with sodium carbonate, lime, caustic potash, or ammonia. The regenerated anion resin beads are then washed out with waste brine. This brine can contaminate surface water supplies and groundwater supplies.

Anion exchange units may also be used with post-treatment systems. These post-treatment systems will help you comply with quality regulations.

An anion exchange unit requires periodic regeneration. This regeneration process is mainly enforced using co-current and counter-current regeneration techniques. The brine solution released from the regeneration process contains contaminants that are removed from the water by the exchange resin. This waste brine can contaminate surface water supplies. The brine from an anion exchange unit can also foul groundwater supplies.

These systems are also used to remove a variety of other contaminants from water. In addition to arsenic, these systems can be used to remove nitrate, sulphate, manganese, magnesium, fluoride, and iron. These systems also remove organic compounds.

Reverse Osmosis Filter in Arsenic Removal Plants

Reverse Osmosis Filter in Arsenic Removal Plants

Using a Reverse Osmosis filter for arsenic removal system is a good way to reduce the levels of arsenic in your water supply. However, you’ll need to make sure that you choose a system that can meet your needs. Arsenic is a toxic substance that can cause diarrhoea, blindness, and nausea.

Reverse Osmosis is an effective water purification process that can remove most contaminants, including arsenic. It uses a semipermeable membrane that is filled with microscopic pores. Water is heated to the boiling point, then forced through the membrane. Because the pores are too small to allow water molecules to pass, the arsenic is trapped and removed.

The best way to determine whether your water contains arsenic is to use a water tester. If the results show a level of arsenic that is above the USEPA’s recommended limit of 10 parts per billion (ppb), you need to have your water filtered.

There are several types of arsenic removal systems that you can purchase. Some systems can be installed at the point-of-entry, meaning that all the water that is used through the tap will be treated. Other systems, including ion exchange systems, are designed to remove arsenic from water.

Reverse Osmosis systems can remove most contaminants, including arsenic, chlorine, lead, and iron. However, they do require some maintenance. They must be cleaned and replaced regularly.

An arsenic removal system is a great way to protect your family from the harmful effects of arsenic. The best system for you depends on your needs and budget. There are several different systems available, ranging from inexpensive units to highly expensive models.

An Arsenic removal system is one of the cheapest methods to reduce the level of arsenic in your water.

An arsenic removal system should be able to reduce arsenic by at least 80-90%. You’ll need to change your filters regularly to maintain the best performance. The filters also must be changed according to the instructions in the user manual.

If you have a large family, or you have a lot of arsenic in your water, you may need to buy multiple filters. You’ll also want to consider purchasing an activated carbon block post-filter to catch volatile organic compounds.

Adsorbent Arsenic Reduction Media for Arsenic Removal

Adsorbent Arsenic Reduction Media for Arsenic Removal

Choosing an adsorbent arsenic reduction media is one of the first steps in designing an arsenic removal system. Media used in these systems are specifically designed to remove Type III and Type V arsenic.

The type of adsorptive media used for arsenic reduction depends on the concentration of arsenic in the water. Activated alumina and iron oxide are commonly used as adsorbents. They can be treated with a caustic solution to strip the arsenic. However, these two types of media tend to behave differently under different conditions.

Arsenic reduction media can be used with an automated system to reduce the time spent on monitoring.

Adsorbent arsenic reduction media have an excellent reputation for efficiency. In addition, they are simple to operate. They require little operator attention and can last for several years. For this reason, they are ideal for point-of-entry systems. Nevertheless, there are additional factors that can have a moderate effect on their performance.

Adsorbent arsenic removal media are a cost-effective solution for small water systems that produce high concentrations of arsenic. They also have the advantage of not requiring disposal when they are exhausted.

Adsorbent arsenic elimination media can be manufactured to remove arsenic, but it is important to remember that these technologies require periodic backwashing. Media replacement accounts for 80% of the total operational cost. The replacement rate is dependent on the flow rate and the volume of water treated. The flow rate is also dependent on the type of media used.

The Bottom Line

Various technologies for arsenic removal include reverse osmosis, nanofiltration, ion exchange, precipitation, coagulation-flocculation, electrolysis, and membrane techniques. The removal efficiency of each technology depends on the raw water quality, the type of media used, and the type of treatment unit. These are some of the main factors to consider when choosing an arsenic reduction media.

If you are looking for an arsenic removal system for your water, then you may have to look into a few different types. The most common methods that are used in this area of water treatment are adsorption and flocculation. In this article, you will learn more about the two methods, as well as some of the challenges that may be faced when it comes to removing arsenic from water.

Why Adsorption is the Most Widely Used Technique in Arsenic Removal Plant?

Adsorption is a common technique used for the removal of arsenic ions from water. Arsenic is a naturally occurring chemical that is toxic to human health and aquatic life. It can be found in groundwater and surface water.

A wide variety of techniques for removing arsenic from water are available. Some of these techniques have been developed over a period of time, while others have only recently gained prominence. Choosing the best technology for removing arsenic from water depends on several factors. The cost of capital expenditures, waste stream costs, and efficiency are some of the factors that are used to decide on a technology.

In addition to conventional technologies, new adsorbent materials are also being researched. Activated carbon and metal oxides are two of these novel adsorbents. These adsorbents have the potential to be useful in low-cost systems.

Iron oxy-hydroxides are an effective arsenic adsorbent. They can be easily synthesized. Several studies have been conducted to determine the effect of pH, initial concentration of As(III), and adsorption rate.

Another technique for removing arsenic from water is the reverse osmosis process. This process is one of the most effective methods for removing the metal ions from water.

Other techniques for removing arsenic include electro-dialysis, membrane separation, and precipitation. Among these methods, adsorption is often the most effective and is inexpensive to operate.

In the context of climate change, arsenic levels in drinking water are becoming a concern. There is a need for innovative and environmentally sound solutions to this problem.

Innovative technologies for arsenic removal should be sustainable and efficient. Cost-benefit balances should be maintained and the quality of the end product should meet the most stringent standards.

Oxidation of Arsenite with Oxygen is a Slow Process

Arsenic is a common contaminant of groundwater. It is highly toxic, and can cause arsenicosis and other diseases. Various treatments are available to reduce the concentration of arsenic to acceptable levels.

There are several types of oxidants that can be used to oxidize arsenic. The most widely used oxidant is atmospheric oxygen. However, it is a slow process. Another oxidant that is commonly used in developing countries is hypochlorite.

An ion exchange technique is another approach that has been developed for arsenic removal. However, this method requires a pre-oxidation step. This means that arsenite must first be oxidized to asthenate before it can be removed by ion exchange.

In ion exchange, negatively charged ions are attached to flocs via electrostatic attachment. This makes the colloids larger. Flocs can be separated from the solution through membrane filtration.

Plain sedimentation is another treatment method. This type of treatment can be effective in removing arsenic from water. However, the amount of arsenic that is reduced depends on the water’s composition and quality.

One of the most well-known techniques for arsenic removal from water is flocculation. This method involves the formation of flocs with the aid of a coagulant. As a result, the negatively charged ions are neutralized by the coagulant.

This process can also be applied to solids. If the iron or manganese content in the water is high, it can lead to membrane fouling. For this reason, it is recommended to filter the water through a gravel/sand bed.

Another technique that can be used for arsenic removal is adsorption. Adsorptive media for arsenic removal include activated alumina, bauxite, and iron-manganese coated sand. These Adsorptive media are usually mixed with an oxidising agent to induce the sorption of arsenic on the media.

MF and Flocculation to Remove Arsenic from Water

Arsenic is a contaminant that affects public health. It has been found to cause hyperpigmentation, hyperkeratosis and much more. There are a number of methods used to remove arsenic from water. Some of them are discussed below.

Membrane filtration (MF) is an important method for the removal of arsenic from water. MF works on the principle of electrostatic attachment of small particles to larger ones. The efficiency of MF is dependent on the pH of the contaminated water. At a high pH, arsenate has a negative charge. This results in a lower adsorption capacity than at the optimum pH.

Another membrane process is ultrafiltration. In this method, dissolved compounds with molecular weight above 300 g/mol are removed. For this purpose, a high pressure membrane such as reverse osmosis is used.

Aeration-filtration is another membrane technique used to remove arsenic from water. Adsorptive media, such as activated alumina and kaolinite clay, are also used. These media can be adapted for different compounds.

Metal Organic Frameworks (MOF) is a class of porous materials that can be easily modified for targeted compounds. They are characterized by a large surface area and tunable pore sizes. Their thermal stability and adsorption capacities are superior. MF can be used to remove arsenic, as well as other contaminants.

Nanoparticles are a promising alternative to MF. These materials are readily available and are easily regenerated. They are also inexpensive to prepare. However, they may not retain their adsorption capacity.

Coagulation and flocculation are other processes that can be used to remove arsenic from water. Coagulation involves the use of an iron-based coagulant to promote co-precipitation of arsenic with metal hydroxides.

Arsenic Removal System Global Demand and Supply and Market Growth of Asia Pacific

The global arsenic removal market is estimated to be worth USD 684.8 million by 2023. This growth is mainly due to increasing demand for safe water treatment solutions. Moreover, growing health awareness is anticipated to boost market growth during the forecast period.

Asia Pacific is expected to be the largest region for the global arsenic removal market. With rising industrial activities and rapid urbanization, the demand for products is projected to increase in the next seven years. In addition, the easy availability of raw materials is also predicted to accelerate the market.

Middle East & Africa is the third largest market for the arsenic removal industry. With the increased government initiatives for the safe water supply, the market is predicted to expand rapidly. Increasing consumer disposable income is estimated to drive the market during the forecast period.

Europe is the second largest market for the arsenic removal market. With the increasing need for testing for arsenic levels, the market is also anticipated to expand. Furthermore, the rising use of drinking water systems is also predicted to promote market growth. Moreover, the compactness of the device is also estimated to support market growth during the forecast period.

North America is the leading market for the arsenic removal industry. Major companies operating in this industry include Waterman Engineers Australia.

Asia Pacific is anticipated to grow at a rapid pace during the forecast period. The major factors that are likely to drive the market’s expansion are the increasing industrial activity, increasing need for safe water, and increasing need for cleaner and healthier water.

Market Structure and Projections

Increasing awareness about health risks caused by arsenic is expected to drive the growth of global arsenic removal system market. Rapid industrialization and the increasing demand for water treatment solutions are predicted to accelerate the growth of the market. The rising demand for safe, clean and readily available water is also predicted to boost the growth of the industry.

Among all the market segments, the drinking water treatment segment is anticipated to account for the highest share of the market. This is mainly due to the growing industrialization and the increasing need to improve the water supply chain.

The growth of the market is predicted to be boosted by the increasing government initiatives to increase the supply of safe water.

Various factors that are projected to contribute to the global arsenic removal market include the increasing need to eliminate microparticles, the availability of raw materials, and the rising demand for healthier water. Besides these, industrial applications of arsenic removal system, and the increased awareness about the benefits of healthy water is also expected to fuel the growth of the industry.

Among the regions, the Asia Pacific region is predicted to be the fastest growing market. During the forecast period, the market is estimated to grow at a significant CAGR.

Arsenic Removal System Frequently Asked Questions

1) What are the methods of removing arsenic contamination?

Oxidation, coagulation-flocculation, and membrane methods are commonly used to remove arsenic species. Additionally, significant developments in the use of different nanoparticles for the cleanup of contaminated water have been made.

2) How much arsenic does reverse osmosis remove?

According to studies, RO is up to 85 – 95% effective at removing the most typical type of arsenic that is regularly detected in well water in Marine.

3) What filters filter out arsenic?

The most effective water filtering methods for eliminating arsenic from drinking water are reverse osmosis (RO) systems. Reverse osmosis, or RO, is a process that uses pressure to pass through a certain semi-permeable membrane to rid water of dissolved impurities.

4) What is not removed by reverse osmosis?

RO systems can’t completely rid water of all pollutants. Most organic chemicals, bacteria, chlorine byproducts, and dissolved gases including carbon dioxide, methane, and radon cannot be efficiently removed by reverse osmosis systems.

5) Does activated alumina remove arsenic?

The most used adsorbent for removing arsenic from aqueous solutions is activated alumina (AA). But typical porous substances, like AA, have poorly defined pore structures, have modest adsorption capacities, and behave slowly under kinetic conditions.

6) How many types of adsorptive media are there?

Iron oxide and activated alumina are two popular forms of adsorptive medium for the removal of arsenic.

7) What are the advantages of ion exchange method?

Compared to other water treatment techniques, ion exchange offers a number of benefits. Since the resin may be vigorously recycled, the ion exchange process is inexpensive and produces high production.

8) How does ion exchange remove arsenic?

Arsenic is removed from water using anion exchange by exchanging it for a non-toxic chemical connected to the resin bed as the water travels through the bed. The mechanism backwashes with brine to replenish the resin bed once all of the available area has been filled.

9) Why ion exchange is better than zeolite?

Zeolite and ion exchange processes are different in that the former uses the mineral zeolite as the resin for absorbing cations in hard water, whereas the latter may use a variety of resins for the ion exchange.

10) What are the methods of removing arsenic contamination?

Oxidation, coagulation-flocculation, and membrane methods are commonly used to remove arsenic species. Additionally, significant developments in the use of different nanoparticles for the cleanup of contaminated water have been made.