API, Use of Oil Seperator in Waste Water Treatment

An API oil-water separator is a machine that segregates oil and colloidal matter from industrial effluents. These effluents produced by petrochemical industry, oil manufacturing plants, natural gas processing plants, and from other oil – based waterbodies. These treatment plants mainly work on the standard that is American petroleum institute so we called API waste water treatment plant.

Principle of API Separator Plant

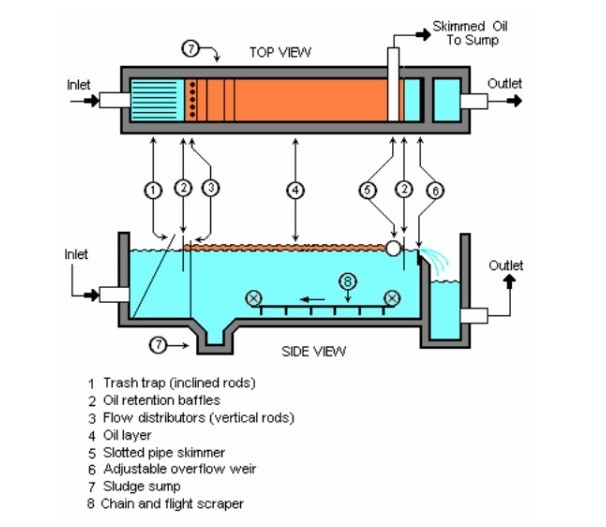

The API separator is generally a gravity separation instrument that usually works on the principle of Strokes Law. According this the rise in the velocity of oil droplets is based on the density, weight and water properties.

The specific gravity difference between oil and contaminated water is smaller than the specific gravity difference between suspended solids and water. The separator’s concept is based on that difference. According to this concept oil will present on the top of the separator. In the middle region waste water is present while in the suspended sediments layer are present. Once the oil and suspended solids are removed the middle phase again sent in most refineries waste water treatment plants.

The oil top, which may contain absorbed water and associated particles, is normally skimmed off continuously. This oily layer can also process to extract valuable components or may be discarded. A chain and flight scraper and sludge pump generally used to remove the thicker bottom sediment layer.

Performance Factors of API

The water temperature, horizontal velocity, density, size of the oil droplets, and the amount and characteristics of the colloidal matter are all important factors that affect API separator efficiency.

API separators are designed to separate oil droplets of size 0.015 cm in diameter (150 microns). The API separator are also used to maintain laminar flow. This device also used to remove both free oil and suspended particles of concentration between50 and 200 mg/L. Removal of large amounts of free oils, greases, and suspended particles from reduces overloading and other downstream mechanism

Design and Operation of API Separator Plant

The API oil-water separator is a gravity-based separation instrument. It utilizes Stokes Law to determine the increase velocity of oil droplets depending on size and density. Since the specific gravity discrepancy among oil and wastewater is probably lower than that of the specific gravity discrepancy between suspended solids and water. The API oil-water separator is designed around that disparity. The majority of the suspended solids will settle to the bottom of separator as a layer of sediment. The oil will rise to the surface of the separator, as well as the wastewater will become the middle layer between both the oil on top as well as the solids on the bottom, according to that selection criterion.

The oil layer is usually skimmed off and later thrown off or reprocessed. The bottom sediment layer is scraped away using a flight and chain scrapper and a sludge pump. Then the water layer is treated with a dissolved air flotation machine to remove any remaining oil. It is followed by a biological treatment unit to remove any unwanted absorbed chemical compounds.

Design Criteria for API Separators

The API separator’s design guidelines are thoroughly specified. The following are some of the most essential design specifications for API separators:

- Depth to Width Ratio

A least depth to width ratio should be 0.3 to 0.5 is advised to keep separation units from being too deep, allowing oil droplets to come to the top in less time.

- Length to Width Ratio

To retain operational conditions as near to plug flow as practicable, a minimum size to width ratios of 5:1 is suggested across all API separator designs, minimizing the chance for short circuiting.

- Oil Particle Size

Typically, refinery wastewaters contain oil particles that are 150 microns or bigger. As a result, API separator system design for removing oil particles of such a size is devised. Unless adjustments are made in the size of the API separator to eliminate tiny particles, particles smaller below 150 micron will generally leave an API separator and will have to be eliminated by downstream treatment procedures.

- Horizontal Velocity

It has been found that keeping a horizontal velocity with no or more 3.0 ft/min reduces turbulence and its influence on obstructing the extraction of oil from effluent.

- Maximum Width and Depth of Channel

The maximum width and depth of an API separator channel are 20 feet and 8 feet, respectively.

- Inlet Distributions

Reaction jet baffles have been suggested to distribute permeate streams all across width and depth of API separator to mitigate the influence of high wastewater intake velocities into API separator and probable short-circuiting related with all these high velocities.

Advantages of API Separator Plant

- Ability to manage wastewater containing high oil concentrations of up till 10,000 parts per million and high TSS concentrations of up till 20,000 parts per million

- Corrosion-resistant, non-metallic collector components are simple to install.

- Removal of concentrated oil

- Simple design

- Low maintenance on daily basis

- Resistance to plug with solids

API Separator Applications

There are following API separator application that are mentioned here

- Oil/water separation

- Refinery wastewater

- Removal of solids and grits

- Removal of oil from waste waters

- Power plant operations

Limitations in Design

The following conditions affect the working of separators and gravity tanks. These conditioned are mentioned here

- The size of oil droplet is less than 150 microns

- The density of oil is greater than 925kg/m3

Suspended solids are attaching to the oil thus the ‘actual’ oil density is more than 925 kg/m3 - The water temperature is less than 50C that limits the work API separator

- The large amount of dissolved hydrocarbons also limits or reduced the working of API separator

Additional Treatment of Water Discharges From API

Water released by API type separators typically requires numerous increased computational stages due to performance limits before it can be released or recycled. Water treatment is next used to effectively remove droplets less than 150 microns, embedded materials as well as heavier oils, hydrocarbons, and other impurities that the API did not remove.

Some secondary treatment technologies are following:

- DAF

- Anaerobic and Aerobic biological treatment

- Parallel Plate Separators

- Hydrocyclone

- Walnut Shell Filters

- Media filters

Waste Water Treatment Frequently Asked Questions

1) What does an API separator do?

An API oil-water separator is a machine made to separate oil and suspended solids in large quantities from industrial wastewater produced in petrochemical plants, chemical plants, natural gas processing facilities, and other sources of oily industrial water.

2) What is an oil water separator used for?

An oil water separator is what? Simply, an oil water separator separates oil and suspended solids from water so that they can be skimmed off, as implied by the name. Oil tends to float to the top because it is lighter than water.

3) What is API separator sludge?

Sludge from a wastewater treatment facility is used to treat wastewaters from the cleaning of oil storage tanks and is known as API separator sludge.

4) When should an oil separator be used?

On big air conditioning systems up to 150 tones and on low or ultra-low temperature refrigeration systems, oil separators are crucial. Most two-stage compressor manufacturers mandate the installation of oil separators.

5) Where are oil separators used?

In refrigeration systems where it is challenging for the oil to return from the evaporator, oil separators are used. These often include ultra-low temperature systems and field built-up systems, like those found in supermarkets. The discharge pipe for the compressor and compressors has oil separators fitted.