Zero Liquid Discharge System – Global Market Insights

Using a Zero Liquid Discharge System in your office or home is a great way to reduce waste. It is also one of the most efficient ways to purify water and other beverages.

How Reverse Osmosis Work in Zero Liquid Discharge System?

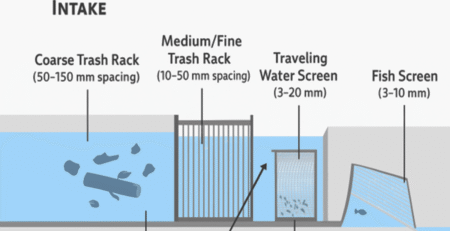

Several industrial processes require ultrapure water. This is achieved by using reverse osmosis for liquid discharge systems. This process removes dissolved solids, such as salts, cations, and organic compounds. It is used in a variety of applications, including metal finishing, ion exchange polishing, and distillation. It can also be used for small-scale hydrogen production.

The reverse osmosis for liquid discharge system works by pumping brackish water across a semi-permeable membrane. The solution is forced through the membrane, which allows the solvent to pass through while removing the dissolved solids.

Reverse osmosis is particularly useful in power generation. It has low operating costs and produces highly purified water. In addition, it helps to lower crystallization and drying costs. It has been increasingly adopted by power producers as well as for desalination.

Reverse osmosis for liquid discharge systems may also be part of a water reuse process. This is especially helpful in industries that require water at a high purity, such as the semiconductor industry. It is also used in the dairy industry.

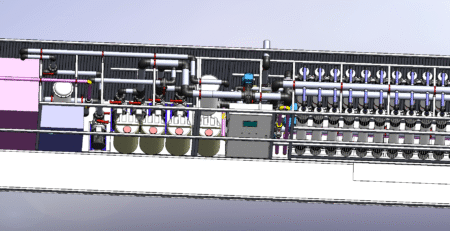

The ZLD plant features seven parallel high-pressure trains. The water enters the plant from a storm drain, which is then used for landscape irrigation and industrial cooling.

The ZLD plant features seven parallel high-pressure trains. The water enters the plant from a storm drain, which is then used for landscape irrigation and industrial cooling.

The reverse osmosis system includes a cross-flow filter. This allows the water to sweep contaminants from the membrane and helps to keep it clean. A carbon filter is installed to protect the membrane elements from chlorine damage.

A two-stage reverse osmosis process reduces the brine’s water content by approximately 70%. The concentrate is fed to the next RO vessel. The feed spacers can vary according to design factors.

A complete reverse osmosis system is equipped with additional water treatment stages, such as ultraviolet light or ozone. The purity of the water is determined by the selection of the membrane, the recovery ratio, and the feed water salinity.

A thin film composite (TFC) membrane is one of the best options for reverse osmosis. This type of membrane is made from synthetic material, providing good mechanical strength and a high rejection rate. The TFC membrane is also more resistant to the effects of chlorine. Its reject rate is typically 95-98%.

What is Ultrafiltration in Zero Liquid Discharge System?

What is Ultrafiltration in Zero Liquid Discharge System?

Unlike other waste water treatment techniques, Zero Liquid Discharge uses a combination of ultrafiltration and thermal processes to treat wastewater. It has been used in industries that consume large volumes of water. This approach is a cost-effective way to process water and reuse it.

The ZLD process is designed to produce lime sludge that contains about 50 percent dry solids. The process requires chemicals. It also requires additional equipment. Membrane-based technologies are often used in ZLD schemes.

In order to successfully design and operate a Zero Liquid Discharge system, sound water chemistry is key. The process involves a pre-treatment step. Waterman Engineers Australia can help you design a Zero Liquid Discharge System that is appropriate for your application.

Ultrafiltration, also known as UF, is a separation process that is ideal for removing bacteria and colloidal particles from water. It can also be used as a pre-treatment for reverse osmosis plants. Its benefits include high selectivity, lower turbidity, and removal of most pathogenic organisms.

The membranes are made of polymers such as polysulfone or polyimide. They have a porous sub-layer and a dense layer. They have pore sizes in the range of 0.1 to 0.001 microns. They have a high permeation rate, and are ideal for removing dissolved contaminants. They can be manufactured from inorganic materials, such as alumina, or organic materials, such as polyetherimide.

These technologies can recover up to 95 percent of the filtered water. They are used in many water recycle/reuse schemes. Power plants and coal pile runoff often produce wastewaters with salts. Brine concentrators can handle higher salt concentrations than reverse osmosis.

When designing an optimal UF system, factors such as the waste composition, the various streams to be treated, and the foot print availability must be considered. Among the benefits of UF are a high recovery ratio, reduced energy consumption, and less waste disposal costs.

Some of the other benefits of ultrafiltration are its ability to remove heavy metals, oils, and pollutants in the discharge. In addition, it is a low-cost, simple-to-operate system. It has been developed to maintain the highest quality of treatment while allowing for easy monitoring.

Application of Zero Liquid Discharge System

Increasing water and wastewater costs have compelled industrial operations to limit the amount of water they use. This has led to a growing demand for zero liquid discharge. There are a variety of ways to achieve this goal. The application of zero liquid discharge depends on the type of water and wastewater, as well as the type of system and equipment required.

There are two major types of systems: membrane-based and thermal technologies. Both of these systems are capable of achieving zero liquid discharge. These systems have different advantages and disadvantages.

The main advantage of evaporation-based systems is that they can handle a wider range of waste streams. They also require less labour and equipment than other methods. These benefits make them a good choice for water recycling.

These systems are able to remove most of the dissolved solids in the wastewater and can produce a solid product. Ultimately, these systems are capable of producing a clean, high-quality water stream suitable for reuse in processing plants.

The traditional approach to zero liquid discharge involves filtration technology. This technique typically sends the wastewater to an evaporator, where the evaporator concentrate is sent to a crystallizer. However, this process is costly.

The traditional approach to zero liquid discharge involves filtration technology. This technique typically sends the wastewater to an evaporator, where the evaporator concentrate is sent to a crystallizer. However, this process is costly.

The most expensive equipment is the crystallizer. This is a large-scale piece of equipment that can be very costly. It is also prone to corrosion and scaling. It is possible to remove the solvents from the sludge using a solvent stripper.

Optimal designs for these systems depend on many factors, including the composition of the waste stream, the number of streams to be treated, the foot print of the facility, and the operating costs. The design must also take into consideration the location of the waste stream.

The power industry has seen a growing shift toward ZLD in recent years. This is because of stricter guidelines for waste water discharge and public concern about the environmental impact of these discharges.

Global Market of ZLD System

Currently, there is no “one size fits all” solution in the zero liquid discharge systems market. This is due to a number of factors. Some of the key drivers include water economics, water shortages, and environmental laws. The need for better water reuse is expected to boost the market in the future.

Another factor driving the demand for zero liquid discharge systems is the rapid worldwide industrialization. These industries eject a large amount of wastes that are harmful to the environment. Therefore, many companies have mandated the implementation of a zero liquid discharge system.

The global zero liquid discharge systems market is dominated by Asia-Pacific, which makes up a significant share of the global chemical output. This region is also expected to exhibit strong growth in the forecast period. The largest economy in this region is India.

Among the major players in the zero liquid discharge systems market, Waterman Engineers Australia is among the major players. These players are implementing strategic initiatives to increase the production of zero liquid discharge systems.

Leading manufacturers of the zero liquid discharge systems like Waterman Engineers Australia is implementing technologically advanced production processes. Moreover, we are providing an extensive range of membrane technologies to meet the high purity water requirements of various applications.

Increasing concerns about water scarcity have led to the recycling of waste water. Hence, the use of zero liquid discharge systems is expected to expand in the coming years. In addition, the public is concerned about the impact of wastewater discharges.

In addition, the increased urbanization and industrialization has posed more stress on the world’s freshwater supply. Hence, the need to decrease environmental pollution drives the revenue growth of the market.

In order to address these challenges, the leading manufacturers of the zero liquid discharge systems are focusing on protecting their operations and supply chains. This will ensure sustainable growth of the zero liquid discharge systems market.

In the coming years, the global zero liquid discharge systems market is expected to expand at a steady pace. The market is expected to grow at a CAGR of 9.83% in the forecast period.

In Conclusion

The application of ZLD can be cost-effective, depending on the type of system and the volume of waste being processed. In addition, the end result is a clean, reusable water source that meets the stringent regulatory standards.

Zero Liquid Discharge System Frequently Asked Questions

1) How does zero liquid discharge work?

A strategic wastewater management method called zero liquid discharge (ZLD) makes sure that no industrial effluent will be released into the environment. It is accomplished by first recycling wastewater, followed by recovery and reuse for industrial purposes.

2) What are the major zero liquid discharge technologies available for industrial wastewater management?

Zero liquid discharge is a cutting-edge approach to wastewater treatment that combines fractional electrode ionisation, ultrafiltration, reverse osmosis, and evaporation/crystallization.

3) How does zero liquid discharge work?

A strategic wastewater management method called zero liquid discharge (ZLD) makes sure that no industrial effluent will be released into the environment. It is accomplished by first recycling wastewater, followed by recovery and reuse for industrial purposes.

4) What is your proposal for zero liquid discharge of TWW?

The system goals for a zero liquid discharge system include eliminating the discharge of liquid wastewater, producing solids for reuse or disposal in landfills, and recycling high-quality water that can be usefully reused.

5) What is importance of Zero Liquid Discharge System work?

For an industrial process or facility, aiming for zero liquid discharge has a variety of advantages: Reduced trash quantities lower the expense of waste management. Reduce the cost and risk of water acquisition by recycling water on the spot.