AIR COOLED HEAT EXCHANGER MANUFACTURER

Air-cooled heat exchangers (ACHEs) have become a very valuable solution in industries where cooling is critical to ensuring efficient operation. Conventional cooling systems make use of a water-based cooling medium, whereas air-cooled systems make use of ambient air to cool industrial process streams. They are especially beneficial in areas with limited or expensive access to water. Air-cooled heat exchangers are increasingly being adopted in various industries like petrochemicals, power generation, oil and gas, and chemical processing. Waterman Engineers Australia is a leader in designing innovative, customer-specific, customized engineering solutions with thorough design and construction services in this advanced cooling system.

The Mechanism and Working Principle of Air Cooled Heat Exchangers

At its heart, an air-cooled heat exchanger is based on a process of convection where the ambient air absorbs heat from the process fluid. The process commences with the flow of hot fluid through a series of finned tubes in which there is an optimization of the surface area for the heat to be transferred. Fans placed at a or a below the tubes cause airflow across the fins, where heat is carried away, thus cooling the fluid inside the tubes.

This cooling method eliminates water dependency as well as makes it possible to install the system in remote or arid locations. This renders it highly flexible. Their designs at Waterman Engineers Australia fulfill stringent thermal and mechanical standards due to the severe heat loads of industrial processes to ensure optimal performance at various operating conditions. Waterman Engineers Australia, employing advanced computational design software, ensures that every ACHE is built according to the client’s requirements and works efficiently under real-world conditions.

Key Components of an Air Cooled Heat Exchanger

Air-cooled heat exchangers constitute several critical elements that work together to achieve effective cooling. Every individual element is essential for the functionality and longevity of the exchanger:

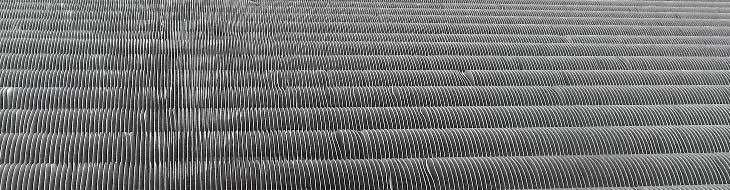

- Finned Tubes

These tubes actually work through a heat transfer process as they are designed with fins that increase the area where they interact with air. The fins therefore improve the rate of cooling so that the hot fluid of the process will dissipate heat fast as it passes through.

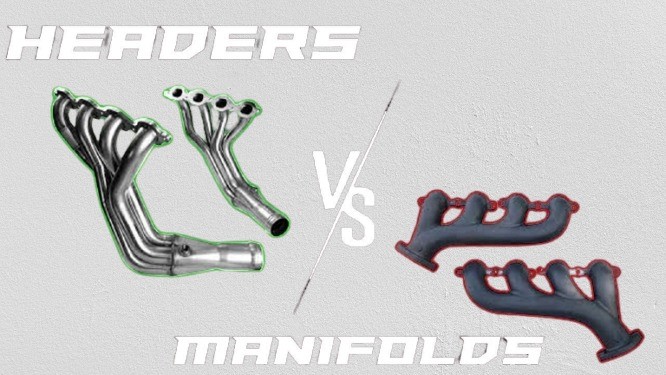

- Headers and Manifolds

Tubes end with headers that direct the process fluid into and out from the exchanger. Headers have been designed to withstand high temperatures and pressure as well as facilitate fluid distribution across the tubes.

- Fans and Fan Drives

Fans are generally mounted above or below the tube bundle to provide a continuous flow of air over the tubes. Fan drives control the fan speed, which controls airflow to optimize cooling performance. Energy efficiency and speed control for the fans can have important impacts on the overall performance and energy consumption of the exchanger.

- Plenum Chambers

These chambers house the fan and help direct airflow uniformly across the tube bundle for improved heat transfer efficiency. The design of the plenum is size-dependent; it can vary according to requirements from both cooling and installation space.

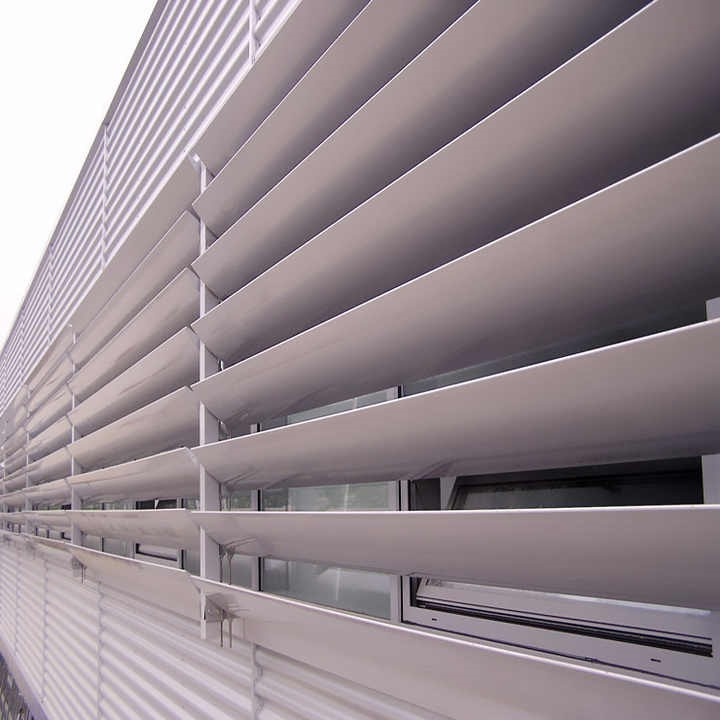

- Support Structures and Louvers

It is the support structure that keeps all of the components in place and ensures stability with high operational loads. Louvers, often relocatable, even assist in controlling airflow to mitigate environmental conditions which can impact performance, such as dust or extreme temperatures.

From finned tubes to plenum chambers, Waterman Engineers Australia goes that extra step in creating each and every component with utmost precision. Their team’s expertise includes high-quality materials for aluminum and copper, that will indeed significantly enhance the thermal conductivity in improving heat exchangers’ efficiency. Each of these elements is designed to stand up to whatever extreme environment may be around them-from savage chemical plants to high-temperature refineries.

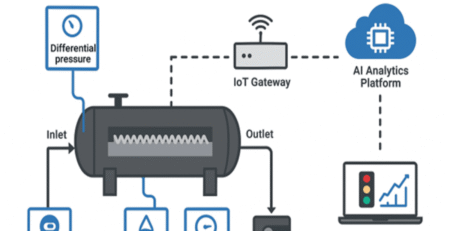

Instrumentation and Control Mechanisms

Air-cooled heat exchangers must be effectively monitored and controlled to ensure both safe and efficient operation. Instrumentation systems allow process operators to optimize cooling operations in the event of overheating or excessive pressure build-up. The main instruments and controls are usually:

- Temperature Sensors

These sensors measure the temperature of outgoing and incoming fluids and can use the data to control cooling accurately. Temperature feedback tunes the speed of fans in real time and fluid flow rates.

- Pressure Gauges

Pressure monitoring ensures the exchanger works under safe conditions, without the risk of leaks or failure.

- Fan Speed Controllers

Variable Frequency Drives (VFDs) control fan speed according to process needs, thus optimizing airflow and maintaining the required cooling levels. They, therefore contribute to saving energy since fans operate only at this necessary speed.

- Flow Meters

These measure the fluid flow rate through the tubes, which are critical to maintain constant cooling efficiency. Changes in flow can be accommodated with fluctuating process demands.

- Automatic Louvers

The amount of air entering the exchanger can be controlled by adjustable louvers that make up for variations in environmental conditions. For example, in colder climates, louvers could partially close to cut down airflow to maintain consistent cooling performance.

Waterman Engineers Australia specialises in providing clients with a high degree of operational autonomy and reliability that the implementation of advanced instrumentation and control systems offers. Their specialties include incorporating automated systems that monitor the performance of exchangers and alert operators before anomalies develop. This ensures minimal downtime and peaks in efficiency.

Applications and Benefits

ACHEs have become essential in many industrial applications because of their efficiency, adaptability, and little impact on the environment. In this section, we will discuss the various applications of ACHEs, the benefits they provide, and how Waterman Engineers Australia helps businesses maximize their cooling solutions

Diverse Applications of Air Cooled Heat Exchangers

Air-cooled heat exchangers are used across a variety of industries where high performance cooling is required. Some of the main applications include:

- Petrochemical Industry

ACHEs have been widely applied in the petrochemical plants in cooling process fluids, distillation columns, and compressor units. Their abilities in withstanding high temperature and pressure have made them suitable for refining crude oil and processing natural gas.

- Power Generation

ACHEs are major in power plants, especially those using gas turbines, which cool the turbine exhaust. Their operation is meant to keep their own efficiency in operations and also control the increase in thermal load-to-power for the plant.

- Chemical Processing

Many chemical plants require exothermic reactions to be cooled. In this way, ACHEs provide a good method for temperature management in reactors and other process equipment, allowing for much safer and efficient chemical manufacturing.

- Manufacturing

There are also many manufacturing processes that involve high usage of ACHEs for the cooling of production lines, machinery, and products, especially in the food and beverage industries. The helpful versatility of these exchangers adds flexibility to the specific demands within manufacturing settings.

- HVAC Applications

ACHEs in the HVAC systems cool circulating water and air by providing a measure of controlling indoor climate in large buildings and industrial facilities and saving energy.

- Mining and Metal Processing

ACHEs are used in mining operations and metal processing plants to cool equipment that produces a great deal of heat. This means that they work within their optimal limits and are safe to do so, especially where water may be scarce.

Waterman Engineers Australia is well-equipped to deliver, with vast experience in the design and supply of ACHE’s for such applications. They work closely with their client on understanding the specific cooling requirements of the process and deliver customized solutions to promote operational efficiency.

Advantages of Air Cooled Heat Exchangers

The advantages of using air-cooled heat exchangers are considerable, especially when compared with traditional, water-cooled systems. Those key benefits include:

- Reduced Water Usage

ACHEs can’t be water-cooled systems, and hence areas that face sources and/or usage limitations are excellent candidates for such devices. Water-based cooling is increasingly getting expensive along with the sharp regulations with respect to pollution.

- Lower Operating Costs

Though the initial investment in ACHEs may be greater than that of water-cooled systems, they tend to cut their operational costs over the long run. Since they consume much less water and require minimal maintenance, they result in great savings.

- Environmental Benefits

By using air as the cooling medium, ACHEs limit the environmental impacts arisen by the water drawn and discharged. This is in accordance with best practices in modern industries that follow the principles of corporate social responsibility.

- Flexibility in Installation

ACHEs can be built at remote sites where water supply could be limited. Their design can fit into any particular site constraints, thus very adaptive to operational environments.

- Improved Safety

The absence of water in cooling systems reduces the chances of leaks and associated hazards. ACHEs eliminate the possibilities of thermal shocks that occur in water-cooled systems with steep temperature changes.

- Longevity and Reliability

Air-cooled heat exchangers are designed to resist adverse environmental conditions, which guarantee extended service life and consistent performance in the long run. Waterman Engineers Australia makes sure that all its ACHEs are designed using materials of high quality, improving their reliability and minimizing repeated replacement.

Waterman Engineers Australia is proud to present robust and reliable air-cooled heat exchangers to clients, lasting long term and performing well, with quality assurance and compliance by national and international standards to ensure each unit lasts.

Custom Design and Engineering Support

One of the key features of Waterman Engineers Australia is that they guarantee tailor-made engineering solutions, beginning each project with a comprehensive review of what the client actually needs followed by a detailed design process to consider these aspects:

- Thermal Load CalculationsCalculations by engineers will be based on assessing heat loads that the ACHE is supposed to handle for optimal sizing and performance.

- Material SelectionBased on the intended application, Waterman Engineers Australia settles on material inputs for the best thermal conductivity, corrosion resistance, and strength to ensure that the heat exchanger acts well under the demands of operations.

- Site-Specific ConsiderationsBecause ambient air temperature and humidity levels are taken into account during the designing stage, the solution presented would be more effective as well as compliant with environmental regulations.

- Performance TestingSuch prototype models, if put to some stringent performance tests before installation, can assure clients that their cooling solution will indeed be efficient and fully functional.

Through the knowledge and expertise in engineering, it is evident that Waterman Engineers Australia ensures optimization of the constructed air-cooled heat exchanger that meets performance standards, suited for the needs of the specific industry to be served..

Advanced Process Mechanisms

The increase in complexity and the advancement of stringent environmental standards have resulted in the development of ACHEs. This design and the mechanisms through which such structures operate make cooling an eco-friendly process for industries, while allowing the same industries to save water usage and reduce general costs in operation.

Waterman Engineers Australia provides custom ACHE units that cater exactly to the specific demands of industries ranging from petrochemical plants to power-generating stations using the latest and advanced engineering practices and specialized technologies. Advanced process mechanisms and potential technical benefits of ACHEs form the focus of this section, emphasizing its significance in modern industrial applications.

- Process Mechanisms

The principle of air-cooled heat exchangers is fairly straightforward compared to other cooling systems, but the actual design is associated with particular cooling demands and environmental conditions at a site. Such systems are designed to be sensitive to changes in operational and ambient conditions to ensure continuous performance. Some of the more advanced mechanisms used in ACHEs are:

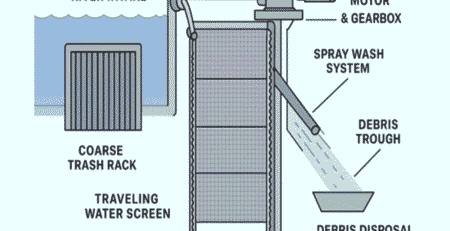

- Forced and Induced Draft Systems

In forced draft ACHEs, fans are installed on the bottom of the equipment to blow air acriss the finned tubes. It is helpful in applications where dust and debris could degrade the exchanger because there is small possibility of fouling. For their part, induced drafts assume fans mounted atop the tubes to pull air down through the finned surfaces. This configuration brings several advantages for high-temperature applications. The temperature experienced at the fan components will be less. Hence, the fan operational life will improve.

- Variable Fan Speed Control

The fan speed adjustment enables ACHE units to respond to the changes in process demands and ambient temperature. Optimizing airflow further helps in the precise control of cooling and energy efficiency. Waterman Engineers Australia equips its ACHE units with VFDs to allow flexible fan speed control for consistent performance without useless energy consumption.

- Counterflow and Crossflow Arrangements

Air-cooled heat exchangers can be arranged either in a counterflow or crossflow as determined by process requirements. In the case of a counterflow configuration, air and fluid flow in opposing directions, ensuring the greatest possible temperature gradient that enhances the transfer of heat. Crossflow configurations where air and fluid pass through each other are primarily beneficial in installing them where space is limited. Waterman Engineers Australia would evaluate every project to select the ideal configuration for its clients.

- Dehumidification and Anti-Frost Mechanisms

Dehumidification and anti-frosting techniques are necessary in cold climates to avoid efficiency loss in the exchanger. Moisture condensing on finned surfaces increases readily and builds up as frosts; preheating air before it is admitted to an ACHE unit can assume a ‘preheated air intakes’ or ‘auto defrosting’ form so as not to damage equipment and maintain continuous operation.

The waterman engineers in Australia deliver technical competence and environmental sustainability since they ensure that air-cooled heat exchangers provide a proper balance between efficiency and environment friendliness. Every ACHE unit is designed so as to produce constant cooling performance that serves the energy as well as environmental needs. Having high-quality quality testing and precision design allows the exchangers to run with a potential free flow across a wide range of industrial conditions, thereby making them a very suitable option for industries looking to increase cooling efficiency without adding to higher costs.

Technological Innovations

Most industries will, therefore, implement effective and sustainable operation. Technology, on air-cooled heat exchangers, is thus updated to reflect high performance, efficiency, and environmental friendliness. The latest trends in the design of air-cooled heat exchangers have been discussed on seeing how Waterman Engineers Australia can develop innovative solutions for their clients.

- Advanced Design and Material Innovations

Improved Finned Tube Configurations Super-efficient finned tubes in modern ACHEs provide optimized surface geometry for better heat transfer improvement. Advances like helical wound fins and greater density of the fins improve the exchanger’s potential for efficient heat dissipation. This can definitely be very effective for industries operating with cooling requirements due to their ability to create smaller and more efficient designs.

- Corrosion-Resistant Materials

The corrosion might be a significant problem to some ACHEs especially in those industries using aggressive chemicals or working indoors. Waterman Engineers Australia uses some advanced materials like aluminium alloys and stainless steel, which possess higher thermal conductivity as well as greater corrosion resistance capabilities. Adoption of more durable materials extends the operation life in ways such as reducing any form of maintenance cost and increased reliability.

- Noise Reduction Techniques

In an effort to minimize operational noise particularly in urban or sensitive environments—a new ACHE designs have resorted to integrating sound-dampening technologies. This ranges from quieter fan models, modification of fan blade shapes, and implementation of isolation from vibrations. These advancements ensure air-cooled exchangers come within regulatory noise limits concerning efficiency.

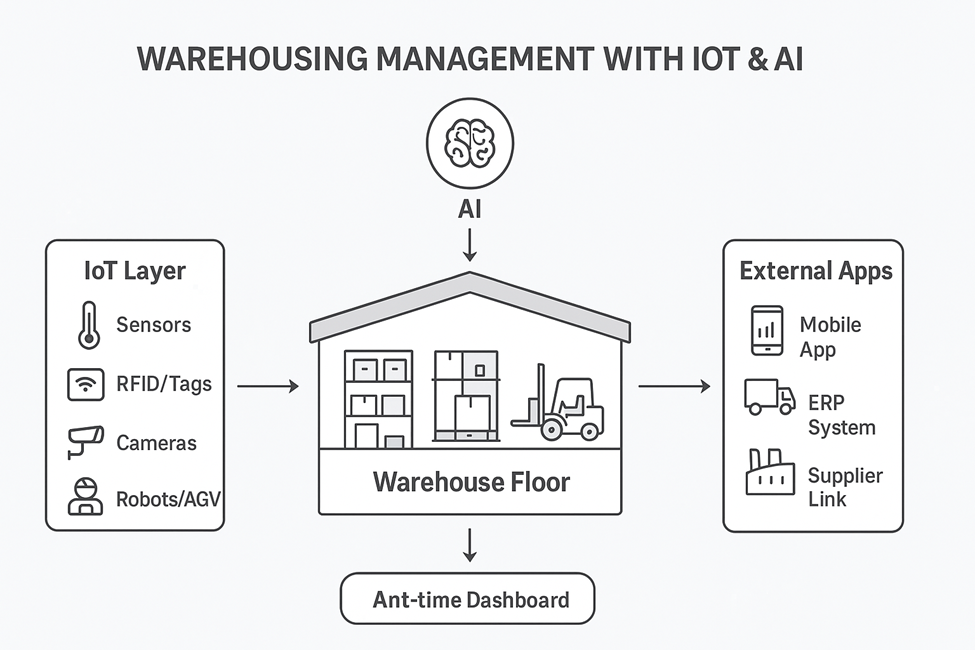

- Integration of Digital and Automated Control Systems

Automation and digital monitoring systems change the mode with which air-cooled heat exchangers work, allowing real-time control and proactive maintenance:

- IoT-Enabled Sensors

IoT sensors are the backbone of most modern ACHE systems. They continuously monitor temperature, pressure, flow rates, and fan speeds. The sensors may send an operator raw, real-time data allowing them to detect inefficiencies or problematic issues before they actually become major problems.

- Predictive Maintenance

Predictive maintenance is proactive wherein data analytics are utilized to predict potential failure before its occurrence. The predictive algorithms, through the trend of a series of operational data that can identify abnormal patterns, prompt maintenance checks. Waterman Engineers Australia incorporates predictive maintenance technology in systems to help clients reduce downtime and extend the lifespan of equipment.

- Remote Monitoring and Control

Remote monitoring is the ability to monitor a number of ACHE units at multiple locations from a central system. Remote control functions will permit operators to change, for instance, fan speed or louver position depending upon alteration of process conditions or ambient conditions. Such a feature helps to control more facilities with extensive cooling.

Waterman Engineers Australia maintains innovative digital applications in the ACHE systems so that its clients have up-to-date and advanced tools for control, efficiency, and insight. Their team offers custom automation solutions, thereby giving industries options that are tailored to their needs when it comes to monitoring and controlling their systems.

Future Trends in Air Cooled Heat Exchangers

As industries head towards sustainable operations, a number of trends defines the future of air-cooled heat exchanger technology.

- Energy Efficiency Optimization

New models of ACHE are built in more energy-efficient ways. So, such products can help manufacturers build exchangers that achieve the same cooling but use less energy. They are actually the big leap toward making industries reduce their carbon footprint and expenditure on energy.

- Hybrid Cooling Systems

Hybrid systems combining both air and water cooling will come into use to fill the gap between ACHEs and conventional cooling towers. In hybrid systems, air cooling is the dominant mode, but water-based cooling is added in extreme conditions. Such an approach also allows industries to minimize the use of water while maintaining effective cooling even during high ambient temperatures.

- Enhanced Environmental Compliance

Future ACHEs are supposed to have features that are consonant with stricter environmental regulations. They include noise pollution reduction, superior efficiency in the usage of energy, and the use of sustainable materials in construction. Waterman Engineers Australia is committed to being environmentally friendly, and thus any solution would be timely and within regulatory standards, surely guiding this to a sustainable future.

- Compact and Modular Designs

As industries are expanding and running out of space, there is a growing need for compact and modular ACHE units that can easily be integrated into the existing setup. Modular designs of ACHE offer more flexibility to make installation options very flexible and scalable. Waterman Engineers Australia can also provide for modular options to allow clients to adapt to expand their cooling capacity as their needs change.

Conclusion

They could constitute a more solid and eco-friendly cooling alternative at the best for modern industries, addressing the challenge of water scarcity, adding value to the operations, and reducing environmental adversities. Continuous improvements in designs, materials, and digital integration present an excellent prospect for ACHEs to be extremely efficient, adaptive, and environmentally friendly.

Waterman Engineers Australia is committed to the development of supporting clients with innovative ACHE solutions that precisely incorporate the requirements of different specific industries. This makes the strength of quality, sustainability, and innovative engineering ensure that clients receive serviceable, high-performance equipment that will prove efficient in the long run. Waterman Engineers Australia thus embarks on integration of the latest technology in helping its clients perform at their best in cooling and towards a future of more consumptive industrial processes.

FAQs related to Containerized Sea Water Desalination Plant

- What is an air-cooled heat exchanger (ACHE)?

An air-cooled heat exchanger is a piece of equipment that absorbs heat from the process fluids by transferring it to ambient air using fan-driven airflow over finned tubes. It is applied wherever water cooling is not possible or is not economical.

- Where are air-cooled heat exchangers commonly used?

ACHEs are installed in almost all the petrochemical, power generation, chemical processing, HVAC, and manufacturing facilities among many other types. They can be particularly helpful where water is scarce or expensive.

- What are the main benefits of using air-cooled heat exchangers?

The primary advantages of ACHEs are water savings, lower operation costs, environmental sustainability, flexible installation, and enhanced safety. All these features make ACHEs a popular cooling solution for most industries.

- How do air-cooled heat exchangers differ from water-cooled heat exchangers?

The ACHE uses atmospheric air as the cooling medium, which does not require a continuous water supply, quite in contrast to water-cooled exchangers. This is what makes them ideal for locations with limited access to water sources and minimizes environmental impact related to water discharge.

- What are finned tubes, and why are they important in ACHEs?

Finned tubes are heat transfer elements whose surfaces have been extended with fins to enhance the process fluids-air heat interchange area. A finned tube exchanger, therefore, has enhanced cooling efficiency and is an integral part of the ACHE design.

- How does Waterman Engineers Australia customize ACHEs for different industries?

Waterman Engineers Australia tailors ACHEs to specific needs of an industry by carrying out detailed assessments on thermal load, site conditions, and the demand made at site conditions. The waterman engineering team ensures every unit is designed in accordance with industry standards and client specification.

- What materials are used in air-cooled heat exchangers to prevent corrosion?

In order to increase durability and minimize corrosion, ACHEs may utilize in their particular applications stainless steel, aluminum alloys, and other corrosion-resistant metals. These materials help to endure more effectively against challenging environments, especially in chemical and petrochemical activities.

- What role do fans play in an air-cooled heat exchanger?

Fans blow air across the finned tubes-a heat transfer component-process heat dissipation. More advanced designs and materials of fans support higher efficiency and lower noise, which can make for better ACHE performance in various applications.

- How does digital monitoring improve the performance of ACHEs?

IoT sensors in the digital monitoring systems could track temperature, flow rate, and pressure in real time. Such information will aid predictive maintenance, thereby reducing downtime and ensuring that the ACHE runs with a best efficiency.

- Does Waterman Engineers Australia offer automated solutions for ACHEs?

Yes. Waterman Engineers Australia does provide customized automation options that can include IoT-enabled sensors, remote monitoring, and predictive maintenance systems. Such advanced features ensure efficient and reliable operation and also allow clients to remotely control the ACHE unit.

- What are the environmental benefits of using air-cooled heat exchangers?

ACHEs save water, reduce water effluent pollution, and encourage energy-efficient cooling, all of which is in line with environmental sustainability objectives. Waterman Engineers Australia designs ACHEs in an eco-friendly manner, thus helping industries reduce their footprints on the environment.

- Can air-cooled heat exchangers be used in power plants?

Indeed, ACHEs are extensively applied in power plants to cool the turbine exhaust while maintaining operating efficiency. They assist in lowering the thermal load and contribute to enhancing the output power in gas turbine-based power generation facilities.

- How does Waterman Engineers Australia ensure the reliability of its ACHEs?

Utilising quality materials, rigorous testing, and international standards, it ensures reliability in Australia. Reliability By Waterman Engineers Australia The final product is robust due to quality control, lasting long and showing dependable performance in a challenging environment.

- Are there any innovative trends in air-cooled heat exchangers?

It includes an application of high-efficiency finned tubes, hybrid cooling systems, compact designs, and increased automation applied for the purpose of predictive maintenance. Waterman Engineers Australia puts forward all these trends in its solutions in order to cater to Industry’s changing needs through a modern, efficient, and adaptable ACHE.

- What support and services does Waterman Engineers Australia provide for air-cooled heat exchangers?

Waterman Engineers Australia provides full turnkey package service, starting from a tailormade design and engineering to installation, digital monitoring, and after-sales service. Their experience with different applications ensures that clients benefit from fully comprehensive solutions according to specific cooling requirements.