Confectionary Industry Effluent Treatment

Introduction

One of the biggest and most significant sectors in the world is the confectionery sector. It produces sweets, such as chocolate confectionery and gum goods, which are distinguished by the substantial amounts of sugar and sugar alternatives, cocoa, lipids, emulsifiers, and flavour used in the manufacturing process.

The growth of numerous industry areas has significantly improved people’s quality of life in a variety of ways. However, as industrial facilities multiply, they start to significantly pollute the water.

When sewage is, for example, discharged into rivers without first being treated, it pollutes the water and causes eutrophication due to the high amounts of phosphate and nitrogen. Drinking water can then be made from this water. Sewage inflow-related water deterioration poses a serious threat to both people and animals.

Large volumes of organic compounds present in industrial waste are biochemically broken down by oxygen dissolved in water. Sewage may not be able to receive any water at all due to its excessive oxygen consumption. This adds to the emergence of anaerobic conditions, which lead to the extinction of aerobes and impede the oxygen-dependent self-cleansing of sewage. Furthermore, living organisms suffer from water de-oxidation.

Sustainable Development Goal (SDG 6)

The defence of water against industrial contaminants is one of the cornerstones of sustainable development. To do this, industrial effluent must be purified more effectively and with the aid of environmentally friendly technology. Water pollution can be effectively managed by monitoring industrial sites that release sewage into municipal waterways. But oftentimes, especially in heavily industrialized areas, the work is prohibitively expensive. The expenditures associated with a production unit emitting sewage of poor quality are frequently very expensive. As a result, factories are utilizing various sewage pre-treatment techniques more frequently.

Confectionary Industry Wastewater Characteristics

The amount of sewage produced depends on how frequently the installation is cleaned, which is the main source of sewage in the confectionery industry. Its content and quantity fluctuate daily and seasonally as a result of these causes. How it gets disposed of is affected by this. Each month, the confectionery manufacturers discharge between 300 and 500 m3 of technical effluent.

As sewage from such industries is biodegradable and predominantly composed of organic compounds and suspensions, it harms the high COD and BOD. The COD index typically ranges from 1000 to 12000 mg/L, while the BOD ranges from 500 to 8000 mg/L. Wastewater primarily contains sugars, lipids, and colors as its organic constituents. Sewage from confectioneries frequently includes cleaning and disinfection agents, which can change the pH and increase the amount of nitrogen and phosphorus compounds.

How to Treat Confectionary Wastewater?

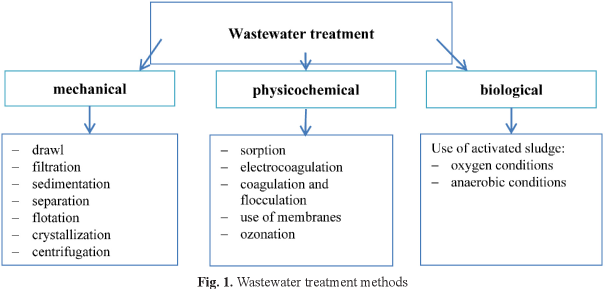

Mechanical Treatment

Larger floating and dragging solids, granular particles larger than 0.1 mm in diameter, easily falling suspensions, oils, and fats are all objectives of mechanical wastewater treatment, the so-called first step of purification. To accomplish this, grate and screen devices are employed to capture and separate solids from the wastewater’s main body. It is currently commonplace to carry out procedures like filtration, drainage, sedimentation, and flotation. In turn, this makes it possible to reduce the number of organic compounds in wastewater by a few percent.

Physical Treatment

Sorption

Two phenomena are involved in the sorption process. Adsorption is the first one; it entails molecules attaching to the surface of a solid or liquid. The second is absorption, which is the process by which one material is absorbed by another to form any continuous phase. Adsorption-based methods are among the most competitive since they are straightforward and don’t require high operating temperatures.

An excellent material for adsorbing organic molecules is activated carbon. Its high surface area, porosity, and resistance to chemical and thermal changes are to blame for this. It is the most adaptable adsorbent utilized in the wastewater treatment process because of this. More than 90% of the BOD and COD readings are decreased. The high cost of production, regeneration and disposal issues are its primary drawbacks. Scientists are therefore looking for less expensive, more environmentally acceptable sorbents that have characteristics similar to carbon. Solids having a lot of surface area, porosity, inertness, and good physical and chemical properties are the best adsorbents. Natural minerals (such as bentonite, kaolinite, zeolites, and silica beads), as well as agricultural waste (such as eggshells, corn cobs, chicken feathers, rice husks, and coconut shells), industrial by-products, bio sorbents (such as chitosan, peat, and biomass), and other materials (such as starch, cyclodextrin, and cotton), have all been tested as low-cost.

Additionally, it has been discovered that materials like wool, sawdust, cocoa shells, sugar beet pulp, distillery sludge, or maple sawdust can help reduce metals and improve aerobic conditions in wastewater. Furthermore, wastewater with a high content of organic compounds can benefit considerably from the addition of metakaolin and carbon derived from dates, nuts, and tamarinds when the pH is neutral. Additionally, it was demonstrated that an active carbon made from waste almond and orange peels makes an excellent absorbent.

It was discovered that the highly developed pore structure of the active carbon obtained from the activation of olive stones with phosphoric acid (H3PO4) will lead to a high level of pollutant absorption. To prepare active carbon, low-cost absorbents like coconut tree sawdust, silk cotton hull, sago waste, maize cob, and bananas were also used. To remove high-density metals and colors from aqueous solutions, it was developed. The experiment’s findings demonstrate that all types of carbon were successful in cleaning up water contamination. The use of powdered activated charcoal as an absorbent in studies to clean the sewage from the production of sweets and ice cream was successful. It has been demonstrated that this type of carbon can greatly increase sewage’s oxygen levels. Additionally, it was demonstrated that biological wastes from the processing of squid can lower BOD values by 90–95%.

Coagulation and Flocculation

These techniques are generally utilized in wastewater treatment to get rid of organic compounds and suspended particles. The selection of an appropriate coagulant determines how effective a process will be. Active silica and salts of aluminium and iron are the most widely used. When used as a coagulant in wastewater from the food sector, ferrous sulphate can reduce BOD from approximately 33% to 58% and COD from around 30% to 53%. While the use of limes improved the aerobic conditions (BOD: 34%-66% and COD: 32%-59%), the improvement was not as great. Following biological treatment, the coagulants lime, alum, polymer, and dried leaves were further examined for their ability to reduce BOD and phosphorus in wastewater. It has been demonstrated that the materials do not alter pH but have significantly decreased the concentration of phosphorus and the BOD ratio by up to 80–90%. Organic substances, such as “chitosan,” which is found in some crab shells, can also be effective coagulants. They might be employed to get rid of organic stuff that raises BOD levels.

Electro-coagulation

An electrochemical technology called electrocoagulation (EC) is being employed more and more in the treatment of wastewater. Anodes that have been electrolytic allies dissolved, such as iron or aluminium, are frequently employed in the straightforward and effective EC process. There is no need to add any chemical coagulants or flocculants because the coagulating agent is produced in situ through the electro-oxidation of a sacrificial anode.

The COD, BOD, and total solids content of wastewater from the sugar sector were significantly reduced when electrocoagulation using zinc electrodes was used in a bipolar system, according to the study. While an electrochemical procedure using hybrid iron and aluminium electrodes results in a 90% decrease in COD and a 93.5% reduction in color after treatment. Turbidity, color, and COD can be reduced by approximately 96%, 98%, and 39%, respectively, by the integrated electrocoagulation process using aluminium sacrificial anodes and the sand filtration process as a pre-treatment of effluent from the chocolate factory. Hybrid electrodes are also cost-effective and safe to use.

However, the electrocoagulation process for wastewater treatment has significant initial capital expenses and is predicted to have annual running costs of USD 140,000 and USD 40,000, respectively.

Ozonation

Since ozone is a potent oxidant and readily soluble in water, it is employed in the techniques used to remediate wastewater. For wastewater that has been properly diluted, ozonation works best. This procedure can only be utilized as the first stage of the complete treatment process in wastewater with a high concentration of organic components.

The raw wastewater’s color can be reduced to almost 10% under these circumstances, and the overall amount of TOC decreases by no more than 60%.

Membranes

Membranes can be thought of as selective barriers that let some components from the mixture pass through while keeping others in. The gradient of a potential, such as pressure, temperature, concentration, or electrical potential, is what propels transportation. This technique relies on physical separation, typically without the inclusion of chemicals, which is one of its unique features. Reverse osmosis, microfiltration, ultrafiltration, and other pressure procedures are the most widely used membrane treatment technologies.

Case Study:

Wastewater from the calamari processing line had an extremely high BOD value (1000–5000 mg/L), thus it was treated using the membrane test. Since proteins and other organic compounds may pass through the membrane during the first stage of the experiment, it was evident that the single-stage test using an ultrafiltration membrane (UF) could not efficiently reduce BOD. The Nanofiltration membrane received the permeate from the first step (NF). The BOD was lowered as a result to roughly 300 mg/L.

The BOD indicator dropped by almost 90% in the two-stage method. Wastewater from restaurants that offered traditional Malay cuisine was also treated using ultra-filtration and Nanofiltration membranes. Depending on the membrane type, extremely strong elimination of BOD5 (86.8%) and conductivity (82.3%) as well as very high reductions of COD (up to 97.8%) and turbidity (99.9%) were discovered. The proprietor of the restaurant may additionally benefit from the reuse of treated wastewater for non-drinking uses. The drawback of membrane systems is that they only recover around 75% of the water, which leaves roughly 25% of the leachate behind.

Biological Methods

Use of Activated Sludge

One of the most widely used technologies for wastewater treatment uses activated sludge under aerobic conditions, although the costs of procurement and operation are frequently too high for industrial applications. Physical and metabolic activities coexist in the biological system known as activated sludge. It appears as a suspension of flocculating clusters of heterotrophic bacteria under the microscope.

Physical processes based on the adsorption of organic substances take place on the surface of flocks, causing them to break down into smaller pieces. After being taken up by the microbial cells, they continue to change there. Enzymes produced by bacteria in activated sludge catalyse a sequence of biochemical events that lead to the breakdown of both inorganic and organic components in the wastewater. Many confectionary manufacturers employed activated sludge for wastewater treatment.

Case Study:

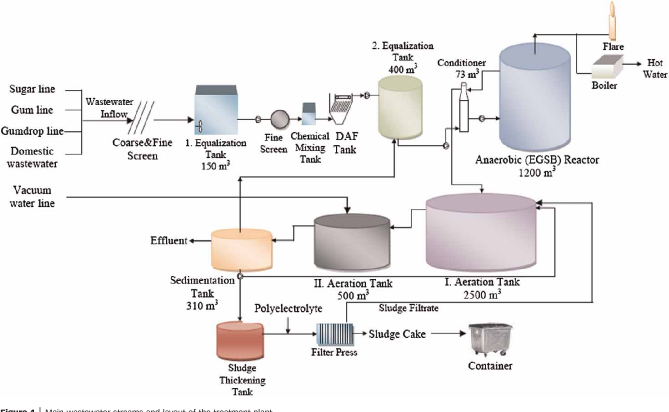

An integrated pilot plant for wastewater treatment from the production of gums and sweets was designed as part of an experiment. It included an equalizer, a chemical mixer, an aerator, a clarifier, a disinfectant tank, and a sand filter. The BOD index dropped from 3200 mg/L to 70 mg/L and the COD from 5000 mg/L to 100 mg/L following the purification process. Additionally, laboratory tests on the use of periodic operating reactors to treat wastewater with activated sludge were conducted (SBR). The aeration and sedimentation phases were carried out by three reactors in two-day cycles. The analysis findings revealed a COD and BOD elimination effectiveness of above 95%. When compared to the permissible values for sewage entering the sewage system, the values of these indices in treated wastewater were much lower.

The main drawbacks of the technologies mentioned are their exorbitant costs, difficult technology, and the eradication of compacted microorganisms in the activated sludge /L.

Treatment through Anaerobic Conditions

Using carefully chosen bacterial strains, the anaerobic treatment uses a microbiological procedure like methane fermentation to turn the organic waste in sewage into biogas (methane and CO2). Anaerobic sludge contains the granular and flocculent bacteria required for the process.

Anaerobic technologies are used in several wastewater treatment procedures. In addition to treating many other forms of trash, – aerobic digestion was also employed to treat biosolids.

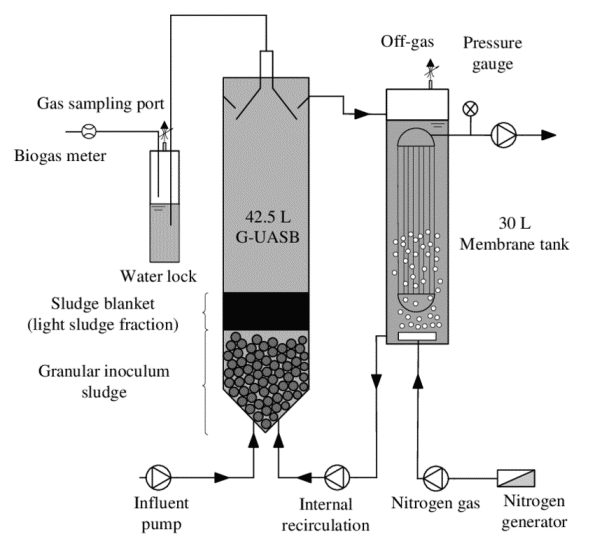

In recent years, the Up-flow Anaerobic Sludge Blanket (UASB) reactor has gained a lot of popularity and is frequently used for the treatment of diverse wastewater types. High removal efficiency even at low temperatures, low energy consumption, and minimal space requirements are benefits of employing this reactor.

Anaerobic Bioreactor

The majority of anaerobic reactors are comparable to aerobic reactors, but maintaining an anaerobic environment requires some special considerations. This reactor is easy to build, has a high loading rate, and can handle hazardous and organic compounds in high concentrations.

The fundamental idea behind anaerobic bioreactors is the employment of methanogens, which are specialized bacteria used to promote anaerobic processes that tend to form immobilized granules that sink at the bottom as sludge. The UASB reactor is constructed using this operating principle.

It is possible to create an anaerobic fluidized bed with a biofilm as the mixer of microorganisms, which grows on carrier particles and is fluidized with energy from the feed stream. The substrate eventually diffuses out into the bulk liquid after passing through the biofilm and being transformed into volatile fatty acids and CH4. The density and concentration of the particles decrease as the biofilm thickens and the particles inside the reactor get larger and exit the reactor.

Economic Analysis

The anaerobic reactor is straightforward, has straightforward mechanical equipment, incurs minimal additional operating and maintenance expenses for the wastewater treatment system, and is simple enough for the existing crew to operate.

By minimizing the energy requirements in the active sludge system and generating electricity from biogas, the removal of organic matter by the anaerobic process permitted electricity savings of roughly 1800 kWh/day=657,000 kWh/year or 105374$/year.

According to laboratory titration studies, the amount of hydrochloric acid required to bring dairy wastewater’s pH level to neutrality was at least 0.5 L of HCl 2N for every m3 of industrial effluent. The buffering ability of the carbon dioxide in the biogas and the system’s adaption to higher pH levels reduce the cost of acquiring the required hydrochloric acid by 21075 USD per year. According to the aforementioned information, the plant should pay for itself in around 7 years.