Ecological hazards in Textile Industries

Did you know that Australia is the second-highest consumer of textiles per person in the world? Also, this sector constitutes the largest percentage of waste in the country generating 800,000 tons of textile waste every year.

A textile sector of an industry is a unique combination of growth, development, and export performance and in today’s competitive world export and domestic textile, markets are progressing at a great pace. This fast-changing global competition has put the textile industrial sector as the focus of attention. Nowadays, green parties insist more upon manufacturing, processing, and final disposal of textile products by taking environmental norms under consideration.

In addition to this, traditional consumers are more conscious about the ecological aspects of textile production right from fibre to the end of the chain. The commercial decision in this global business is strongly dependent on how conscious we are to protect our environment. With the increase in environmental awareness, the world has become more ecologically conscious and therefore the concept of green textile has emerged in facilitating eco-management in the textile arena.

Generally, one of the most noticeable hazards in the textile industry is noise pollution.

Over the past few years, considerable progress has been made in the weaving sector of the textile industry. The vibrations transmitted in the weaving sector as a result of running looms to a building can, produce nuisance among the local population and cause damage to the nearby buildings. Usually, 100 to 120 dB noise level is expected in the weaving rooms depending upon the design, fitting, type, number of looms used, erection, building type, fabric type, etc.

Mostly, noise levels of 70 to 100 dB are recorded commonly in the yarn production workrooms. Generally, high spindle speeds of new machines (rotor speed up to 110000 rpm and ring spindles up to 20000 rpm) generate a great deal of noise.

Typical values of the noise level in different processes have shown in the table below.

Table 1: Annual Noise level values in different sections of the textile industry

| Process | Noise level (dB) |

| Texturizing plant | |

| Compressor house | 99.50 |

| Texturizing section | 94.80 |

| Filament take-up section | 93.20 |

| Spinning | |

| Two for one twister | 100-110 |

| 20 Open-end rotor spinning i.e. 3840 rotors in operation | 100 |

| Rieter M2/1 Rotor spinning (individual) | 86 |

| Ring spinning | 80 |

| Weaving Section | |

| Weaving | 100-120 |

Excessive noise produced from the textile manufacturing process may pose life-threatening impacts on the lives of the workers and the population living in the nearby residential areas and even may lead to permanent hearing loss. It is reported that this type of extreme noise can be the cause of many psychological effects and physical damage such as loss of concentration, irritability, increased pulse rate, and loss of concentration among workers.

Another important hazard in the textile industry is Air pollution. Generally, different air pollutants are produced in different stages of fabric production including volatile organic compounds, sulphur dioxide, nitrous oxides, aniline vapours, chlorine dioxide, chlorine, carrier hydrogen sulphide, etc.

Normally, the workers working in the spinning plant of a textile mill are exposed to such a working environment in which they have to inhale dust and fibrous plastic for the whole day. Even in certain areas, the air exchange is not proper thus causing inconvenience and suffocation among workers. Small fibrous plastics are generally inhaled by workers during weaving activities in the weaving section of the textile industry. Also, air polluted with fly and dust causes respiratory ailments like chronic bronchitis, byssinosis (lung disease).

Moreover, ten percent of the greenhouse gas emissions are generated by the textile industry. Usually, the emission of different types of greenhouse gases emission takes place during the manufacturing and transportation of apparel.

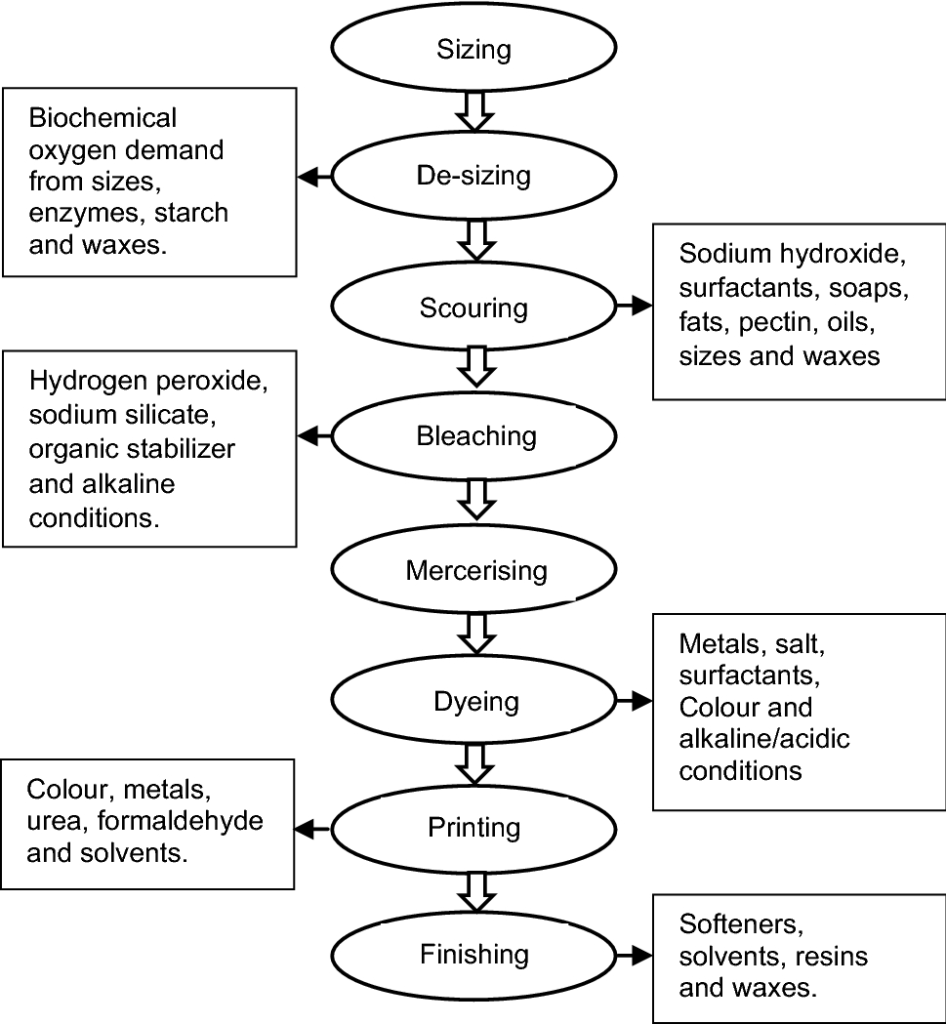

Chemical pollution is known to be another important ecological hazard in textile mills. Generally, more than two thousand chemicals are used in the textile industry ranging from dyes to transfer agents. The figure below shows chemicals produced in each step of fabric processing.

Figure 1: Main Pollutants and chemicals discharged at different steps of textile processing

After the finishing process, when the final product is ready some chemicals and dyes become part of textile industry effluents, causing environmental and health problems by contaminating the nearby sediment, soil surface, and groundwater thus becoming a major global environmental pollution challenge. Traditionally fabrics consist of residuals of chemicals that get evaporated into the air we breathe or absorbed through our skin. About forty percent of the globally used colorants contains organically bound chlorine which is also a known carcinogen. The majority of the chemicals used are carcinogenic and sometimes may be the cause of harm before birth and can trigger allergic reactions in some people.

Also, as a result of chemical pollution, a disturbance in the normal function of cells takes place which may pose alteration in the biochemical mechanisms and physiology of animals, therefore, resulting in impairment of essential functions such as osmoregulation, respiration, reproduction, and even cause death. Moreover, incompletely treated or untreated textile effluent can be damaging to both terrestrial and aquatic life as it can pose harmful effects to the natural ecosystem, therefore, causing chronic health effects.

Furthermore, Water pollution in the textile industry is also a noticed hazard of concern because this industry is regarded as the number one polluter of clean water after agriculture on this earth. Generally, discharge of untreated effluent and toxic chemicals like chlorine, formaldehyde, heavy metals (mercury and lead) produced especially during the processing of textile is a critical environment and for human health.

The effluent produced causes significant environmental degradation because it drastically decreases the concentration of oxygen due to the presence of hydrosulphide. In addition to this, it blocks the passage of light through the waterbody which poses adverse impacts on the water ecosystem. The high temperature and pH of the effluent pose extremely detrimental consequences.

Additionally, the textile industry consumes a large amount of water in its processing operations. For instance, around five hundred gallons of water are used for the production of enough fabric to cover a sofa. More than half a million people already living in the regions are prone to chronic drought. This number will be like to increase five-fold to one-third of the entire population by 2025.

The textile industries are also a known cause of soil pollution, for example, grazing of the goats for their wool adds excessive chemicals for getting the textile fibres. In addition, these fibres from fossil fuels are playing a known role in making this industry extremely energy-intensive. It takes about seventy to a hundred million trees every year for the production of textile fibres. According to the recent research in 2022, around forty-eight percent of the fashion supply chain is associated with deforestation and whatever comes along with it i.e., endangered biodiversity, greenhouse gas emissions, etc.

Ecological Hazards in Textile Industries Frequently Asked Questions

1) What are the environmental issues in textile industry?

Water, air, and solid waste contamination are the main environmental issues brought on by the textile sector.

2) What are the common hazards in the textile sector?

They consist of musculoskeletal stressors, chemical exposure from material processing and dyeing, exposure to cotton and other organic dusts, and noise exposure.

3) What are the environmental problems and polluting effects from textile organic dye?

One of the main reasons why soil’s physical and chemical qualities change, water bodies deteriorate, and flora and fauna in the ecosystem suffer is because of toxic textile dyes. The soil microorganisms die as a result of harmful dyes, which reduces agricultural yield.

4) How is textile dyeing harmful to the environment?

The biochemical and chemical oxygen demand (BOD and COD), impairment of photosynthesis, inhibition of plant growth, entry into the food chain, recalcitrance and bioaccumulation, and potential for toxicity, mutagenicity, and carcinogenicity are all considerably compromised by textile dyes.

5) How can we reduce the environmental impact of textiles?

Along with lowering overall consumption, a change to a circular textile production and consumption system with longer uses, more reuse, and recycling could lessen those effects.