Use of IoT & Artificial Intelligence in Mining Industry for Smart Energy Management

How IoT (Internet of Things) and Artificial Intelligence (AI) are used in the mining industry for smart energy management, with detailed system components, workflows, and benefits

✅ 1. Why Smart Energy Management Matters in Mining

Mining is an energy-intensive industry, with operations consuming energy across:

- Drilling & blasting

- Haulage (diesel-powered and electric fleets)

- Crushing, grinding, and ore beneficiation

- Pumping (dewatering, slurry transport)

- HVAC systems in underground mines

- Lighting, ventilation, compressors, and processing plants

Energy costs can account for 25–40% of operating expenses. Hence, optimizing energy use with IoT sensors and AI algorithms is critical for reducing costs and carbon footprint while ensuring uninterrupted operations.

🛰️ 2. IoT Applications in Smart Energy Monitoring

A. Smart Energy Metering

- IoT-connected energy meters (electricity, diesel, gas) installed at:

- Substations, MCC panels, gensets, compressors

- Remote mining equipment

- Ore processing plants

- Monitors:

- kWh, kVA, Power Factor

- Voltage and current imbalance

- Load patterns

B. Diesel Fuel Monitoring

- IoT fuel level sensors on:

- Haul trucks, loaders, excavators, and generators

- Monitor:

- Fuel fill, consumption, and refueling cycles

- Leak detection and theft prevention

C. Thermal and Vibration Sensors

- Track energy loss from motors, drives, belts, and heat exchangers

- Installed in crushers, conveyors, mills

D. Environmental Sensors

- Monitor temperature, humidity, pressure to optimize HVAC and ventilation in underground operations

🧠 3. AI Applications for Energy Optimization

A. Predictive Load Management

- AI models forecast peak load times based on:

- Shift schedules

- Equipment operating cycles

- Historical consumption

- Enables load leveling and demand response strategies (e.g., turning off non-critical loads during peak tariffs)

B. Energy Usage Pattern Recognition

- AI clusters and classifies energy profiles for:

- Inefficient vs optimal machine cycles

- Operator behavior affecting energy use

- Abnormal spikes indicating leaks or faults

C. Predictive Maintenance for Energy-Draining Equipment

- Anomaly detection on:

- Overheating motors

- Low-efficiency compressors

- Leaky pumps

- Reduces unplanned energy-intensive breakdowns

D. Smart Scheduling of High-Load Equipment

- AI algorithms optimize operating schedules:

- Crusher, ball mill, ventilation fans

- Charging stations for EV mining trucks

- Based on tariff windows, solar/wind availability, and productivity targets

E. Integration with Renewable Energy Sources

- AI manages microgrids by:

- Balancing diesel gensets with solar PV, wind, and batteries

- Prioritizing clean energy use while maintaining power quality

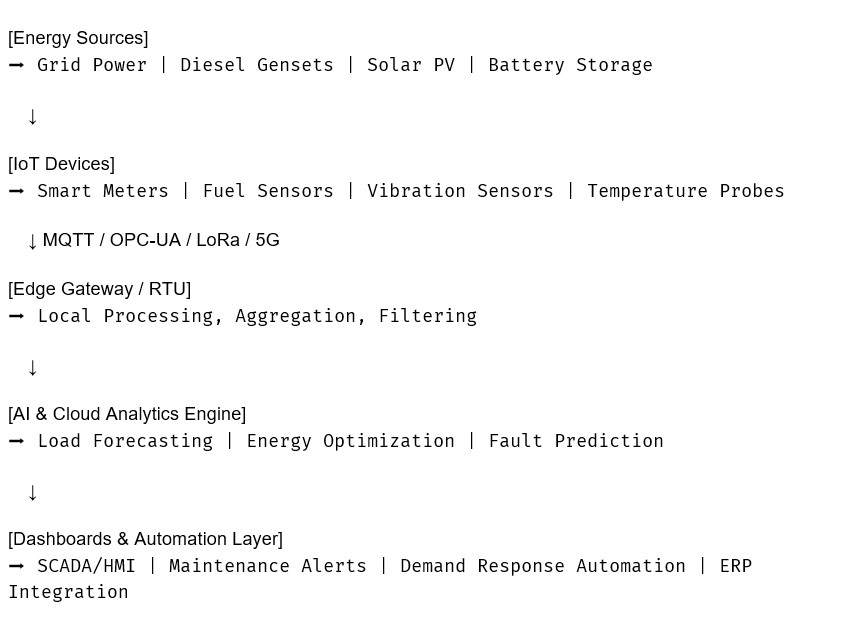

🏗️ 4. System Architecture for Smart Energy Management

📊 5. KPIs Tracked Using IoT & AI

| Metric | Description |

| Energy Intensity (kWh/ton of ore) | Tracks energy efficiency of production |

| Power Factor | Ensures efficient use of electricity |

| Fuel Usage per Equipment Hour | Identifies overconsumption and leaks |

| Energy Cost per Operation Cycle | Links cost to specific machines/processes |

| Carbon Footprint (kg CO₂-eq) | For ESG & sustainability reporting |

🧩 6. Integration with Other Systems

- EMS (Energy Management System) for overall control

- SCADA systems for supervisory control

- Maintenance platforms (CMMS) to trigger corrective actions

- Enterprise systems (SAP, Oracle) for reporting and procurement

Carbon accounting platforms for ESG compliance

🔁 7. Use Case Example: Smart Diesel Monitoring in Open-Pit Mining

Problem:

Fuel theft and inefficiency in haul trucks lead to 20% excess energy cost.

IoT + AI Solution:

- IoT fuel sensors installed on all haul trucks

- AI models detect anomalous fill patterns and fuel drain

- Real-time fuel consumption dashboards per trip, per operator

- System automatically alerts for:

- Unauthorized refueling

- Idling beyond set thresholds

- Leaks

Result:

- 30% reduction in fuel theft

- 15% improvement in fuel economy

- Real-time dashboards for operations & finance

✅ 8. Benefits of IoT and AI in Energy Management

| Benefit | Explanation |

| 🔋 Energy Cost Reduction | Real-time monitoring and predictive control |

| 📉 Peak Demand Avoidance | Load shedding during peak tariff hours |

| 🔧 Efficient Equipment Operation | Detects and corrects inefficient machines |

| ♻️ Lower Carbon Emissions | Optimized energy use and renewable integration |

| 📈 Operational Efficiency | Enables data-driven maintenance and scheduling |

| 📊 Regulatory Compliance | Automated carbon and energy reporting for ESG |