Wastewater Treatment Techniques in Textile, Mining and Pharmaceutical Industries

Waste Water Treatment Techniques

When organic matter released from industrial effluents reaches bodies of water untreated, it becomes a food supply for the bacteria that live inside. When such tiny microorganisms break down contaminants, they draw DO from the water. Hence more contaminants are in the water bodies, the higher their oxygen demand would be. Inorganics released are also difficult to decompose. They stay in lakes and rivers if they get into them through untreated wastewater. The water quality will become a concern for humans and other animals when their concentrations rise across time. Hence it is mandatory for the industries to have waste water treatment plants so that quality of water shouldn’t become a concern for the environment. The primary goal of wastewater process is to reduce as many suspended particles as practicable before returning the leftover water to the environment, and do Wastewater Recovery. Different industries have their own waste water treatment techniques or Effluent treatment plants, according to their requirements and the type of effluents.

WASTE WATER TREATMENT TECHNIQUES IN TEXTILE

There are three categories of effluent treatment techniques:

1. Primary Treatment

Primary treatment in Effluent Recycling Systems is projected to eliminate as many suspended particles as feasible after removing abrasive particles, coarse solids, and copious amounts of residual oil. It relies on sedimentation, in which particles are separated from water in a series of cells. Some primary treatment techniques are following:

| TREATMENT TECHNIQUE | ENACTMENT | BENEFITS |

| Filtration Technique

|

reverse osmosis, nano-filtration, microfiltration, ultrafiltration | Protects machinery and tools by reusing lubricants |

| Chemical Coagulation and Mechanical Flocculation

|

Using a clariflocculator, eliminate finely dispersed suspended particles. | remove sludge and

cleanse the water |

| Screening

|

Screens and fine screens are used to remove fibers | Maintenance is little to negligible |

| Equalization

|

In a sump pit, sewage streams have also been caught

Frequently, rotating agitators or pressured air from below can be used. |

constant effluent discharge flow rate |

| Sedimentation | For eliminating effluents, cross-flow sedimentation tanks and center-feed circular filtrations are used | low-cost and simple to use |

2. Secondary Treatment

Secondary treatment’s main aim in Effluent recycling plants is to eliminate more BOD than could be extracted by traditional sedimentation. This also removes a considerable percentage of pigment, phenol, scattered and dispersed organic molecules, oil from untreated wastewater. Some secondary treatment techniques are following:

| TREATMENT TECHNIQUE | ENACTMENT | BENEFITS |

| Trickling Filters | Waste water is spilled on the gelatinous sheet, where bacteria oxidize it | efficient, easy to use, and uses less electricity |

| Aerated Lagoons | Mechanical equipment is used to aerate the effluents for 2-6 days | low energy consumption, low cost, and simple to use |

| Activated Sludge Process | Trash is biologically degraded by aerobic bacteria, which produces water and carbon dioxide | effluent water recovered is of great quality and is inexpensive |

| Oxidation Ditch

|

the waste water is dumped into an oxidation ditch for treatment | weir overflow rates should be kept to a minimum, and recurrent effluent surges are avoided |

| Anaerobic Digestion

|

Anaerobic bacteria slowly ferment or digest the components of the sludge | Low-energy approach |

3. Tertiary Treatment

The final phase of wastewater treatment in textile effluent treatment is tertiary water treatment. Inorganic chemicals, viruses, bacteria, and parasites are all removed during this stage. The treated water is safe to recycle, reuse, or discharge into the environment after these dangerous substances have been removed. Some tertiary treatment techniques are following:

| TREATMENT TECHNIQUE | ENACTMENT | BENEFITS |

| Ion Exchange Method

|

Anions and cations are removed | filtered water at a high flow rate |

| Electrolytic Precipitation & Foam Breakdown

|

At gas-liquid interactions, surface-active solutes build, and foam separation is a research instrument | metals are recycled |

| Oxidation Technique

|

oxidative chemicals are utilized | quick reaction rates |

| Photo Catalytic Degradation

|

decolorizing a wide spectrum of colors | low cost method |

| Thermal Evaporation

|

oxidizing decolorization of dyes | environmental friendly |

WASTE WATER TREATMENT IN MINING INDUSTRY

The wastewater treatment techniques in mining industry are following:

1. PH Adjusters

For treating mining wastewater, among the first steps is to return the water’s pH to its initial level. pH adjusters can help decrease the acidity of mining wastewater and restore it to a balanced pH level. It’s advisable to raise the pH of mining water to 8 or higher before proceeding with further treatment methods.

2. Flocculants and Coagulants

One utilizes coagulants and flocculants to assort the tiny metal pieces and suspended matter in wastewater into larger clumps after adjusting the pH levels. This makes mechanically filtering and removing them easy. They are developed to enhance mining treatment process and minimize operating costs.

3. Additional Chemicals

Specific applications necessitate the use of additional chemicals to safeguard the processes or perhaps to prepare the wastewater for filtering. They include the following:

- Ion exchangers and water softeners

- Biocides and Algaecides

- Corrosion inhibitors

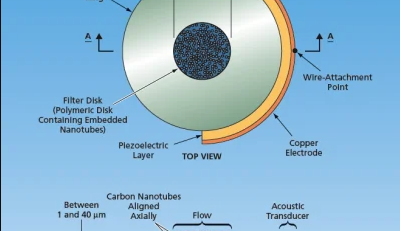

3. Filtration

Mechanical filtering methods can eliminate any suspended material or certain forms of organic matter after maximized the grade of water with correct chemicals. While there are a variety of devices to choose from, the following are the most common types of mechanical filtering equipment:

- Filter Presses

- Centrifuges

- Belt Presses

WASTEWATER TREATMENT TECHNIQUES IN PHARMACEUTICAL INDUSTRY

1. Primary Treatment

Sedimentation and Coagulation

It is preferred to materialize in cost-effective coagulating sedimentation processes. When suspended particles in wastewater get agglomerated in water, they lose their stability, cohesiveness, and large fragments sink. This approach, which is commonly treated with coagulation, not only successfully reduces the concentration of contaminants, but also improves the biodegradability of wastewater.

Flotation

Flotation uses a carrier of highly scattered small bubbles to bind to wastewater contaminants. It realized the water to float towards the solid-liquid and liquid-liquid division because it was less dense than water. Flotation can be used as a pretreatment for wastewater with high suspended particles content, requiring less expenditure, lower energy, a simple procedure, and high reliability.

2. Secondary Treatment

The secondary water treatments are explained below:

| TREATMENT | ENACTMENT | BENEFITS |

| Aerobic Treatment | conventional stimulated sludge method | Low pollution cost |

| Anaerobic Treatment | high-concentration organic wastewater treatment | Adapted at room temp, low pollution cost |

| Combined Treatment | micro electrolysis-anaerobic hydrolysis acidification process-SBR series

pretreatment UBF contact oxidation – BAF hydrolysis acidification UASB-SBR |

Efficient |

3. Tertiary Treatment

Incineration

Incineration of wastewater ought to be cleaned with an overabundance of oxidizing air in the incinerator burning process, such that contaminants in the wastewater are eliminated at a high temperature oxidative breakdown, is an integrative and high-temperature procedure of profound oxidation reactions. Incineration can significantly decrease waste quantity of water while also removing many of these hazardous compounds and recovering heat. The COD elimination efficacy of this approach is 99.5%.

Supercritical Water Oxidation Technology

It involves raising the water pressure and temperature to the critical point (T=374°C, p=22.1Mpa.G) at which water forms supercritical water and hydrogen water ceases to occur. The oxidation of organic material can be done out in a homogeneous oxygen-rich stage following supercritical water produces oxygen when supercritical water dissolves well. Furthermore, a 400-600°C temperature speeds up the reaction rate, allowing organic materials in waste water to attain high disintegration efficiency in a matter of seconds and finish the process. Organic matter is changed to, N2, H2O, CO2, and H2. Cl chloride ions to a metal salt and the nitro group to N2 is converted to sulphate. SCWO has a 99.99 percent organic matter removal rate.