Traveling Water Screens in Hydroelectric Power Plants

Traveling Water Screens (TWS) for hydroelectric power plants, These are a specialized type of fine screen widely used in hydropower and thermal power stations.

🔹 Traveling Water Screens in Hydroelectric Power Plants

1. Introduction

A Traveling Water Screen is a continuously moving fine screen designed to filter water entering a hydropower station. It removes debris, weeds, fish, and floating matter that pass through coarse trash racks.

Unlike stationary fine screens, traveling screens are mechanized and self-cleaning, ensuring continuous water flow with minimal manual intervention.

They are critical at intake structures, where uninterrupted, debris-free water supply is needed for:

-

- Turbines (main hydropower generation)

- Cooling systems (generator bearings, lubricating oil systems, auxiliary pumps)

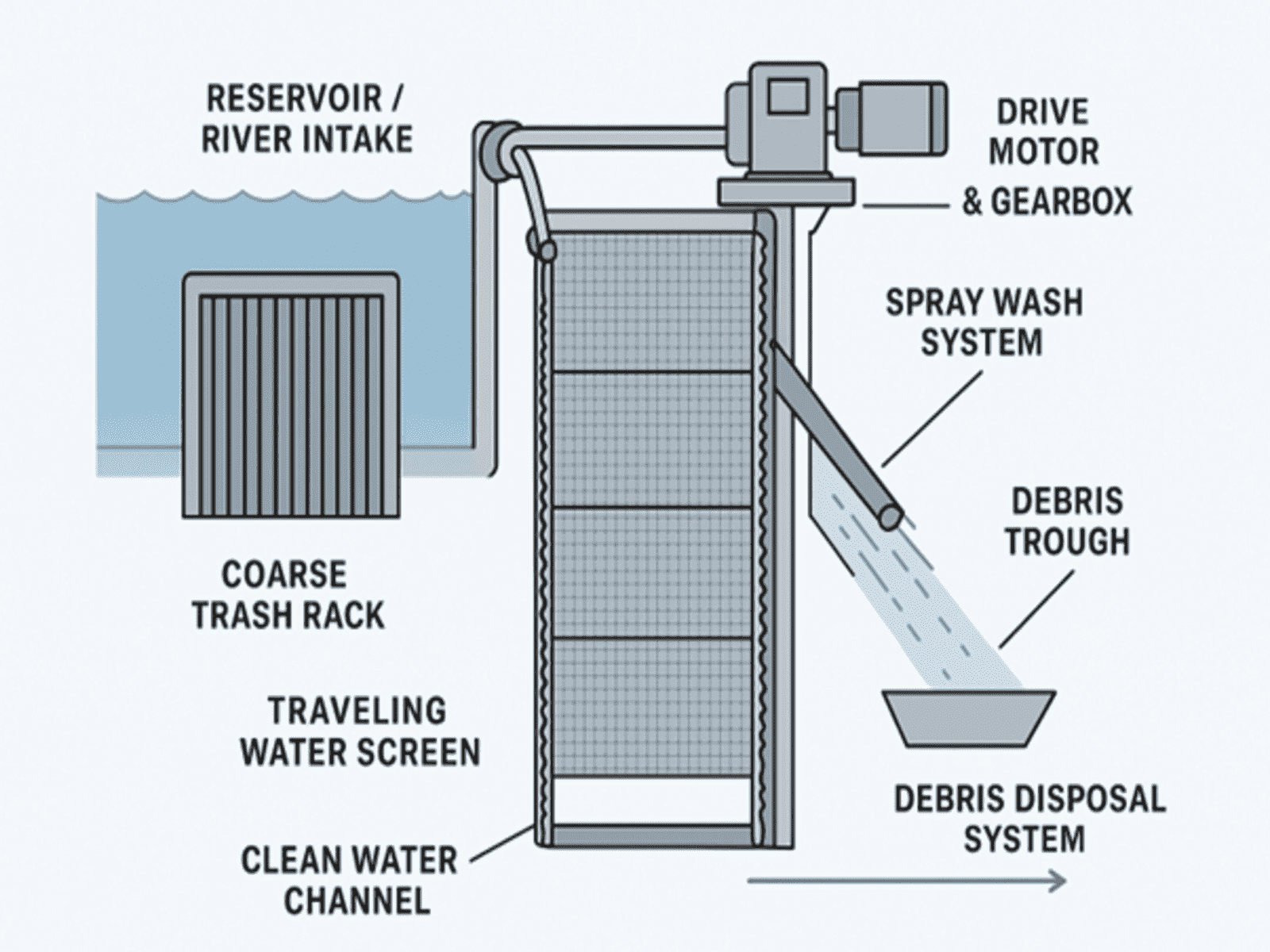

2. Construction

A typical traveling water screen consists of:

- Screen Panels / Baskets → Wire mesh, perforated plates, or bars (3–20 mm openings). Mounted on chains or a frame.

- Chain & Sprocket Mechanism → Moves the screen continuously in a vertical loop.

- Guide Tracks → Ensure smooth movement.

- Drive Motor & Gearbox → Powers the chain system (often variable speed).

- Spray Wash System → High-pressure water jets clean debris off screen panels.

- Debris Trough → Collects removed waste for disposal.

3. Working Principle

-

- Water from the reservoir passes first through the coarse trash rack (removes large debris like logs).

- The partially cleaned water flows to the traveling screen.

- Screen panels, moving in a continuous loop, trap smaller debris, fish, and aquatic vegetation.

- As the panels rotate upward, high-pressure spray jets wash off collected material into a debris trough.

- Clean water passes through the screen into the penstock or cooling system.

- The system operates automatically and continuously, ensuring no clogging.

4. Key Functions in Hydropower

- Protects turbines from trash, weeds, and abrasive debris.

- Prevents clogging of cooling water systems.

- Improves turbine efficiency by maintaining steady hydraulic flow.

- Reduces downtime and manual cleaning needs.

- Fish protection: Some traveling screens are designed with fish-friendly buckets and bypass systems to safely guide fish back to the river.

5. Design Considerations

- Screening capacity → Must match intake flow (m³/s).

- Screen mesh size → Typically 3–20 mm depending on debris load and turbine requirements.

- Head loss → Low resistance is critical to avoid energy loss.

- Screen speed → Adjustable; higher during debris-heavy seasons (spring, floods).

- Self-cleaning efficiency → Depends on spray jet design and water pressure.

- Structural durability → Must withstand continuous operation, sediment abrasion, and ice loads (in colder regions).

6. Types of Traveling Water Screens

- Vertical Traveling Screens → Most common; mounted vertically at intake.

- Inclined Traveling Screens → Installed at an angle, easier for fish bypass systems.

- Dual-Flow Traveling Screens → Water flows from both sides through the screen panels, increasing efficiency.

7. Advantages

✅ Continuous automatic cleaning

✅ Reduces turbine wear and damage

✅ Handles variable debris loads (seasonal leaves, floods, algae blooms)

✅ Compatible with IoT & automation for monitoring screen load and optimizing cleaning cycles

✅ Environmentally friendly when equipped with fish diversion systems

8. Challenges & Maintenance

- High initial cost compared to stationary screens

- Requires power for motors and wash system

- Maintenance of chains, sprockets, and nozzles essential

- Corrosion resistance needed (often stainless steel) due to continuous water exposure

9. Integration with IoT & AI

Modern hydropower plants integrate traveling screens with smart monitoring systems:

- Sensors detect head loss across the screen (clogging indicator).

- AI algorithms predict optimal cleaning intervals, reducing water wastage from unnecessary washing.

- Remote monitoring ensures minimal manual labor at unmanned hydropower stations.

- Predictive maintenance alerts operators before mechanical failure occurs.

10. Typical Application in Hydropower Plant Intake

- Reservoir / River Intake

- Coarse Trash Rack (150–50 mm spacing) → Stops large debris

- Traveling Water Screen (3–20 mm spacing) → Removes finer debris, fish, weeds

- Clean Water Channel → Flows into penstock & cooling water pumps

- Debris Disposal System → Conveyors or collection bins

✅ In summary:

Traveling water screens are self-cleaning, continuous screening systems that form the second line of defense after trash racks in hydroelectric power plants. They safeguard turbines, optimize plant performance, and can be designed to be fish-friendly and IoT-enabled for smart, low-maintenance operation.