The Benefits and Challenges of Implementing a Zero Liquid Discharge System in Industrial Settings

Zero liquid discharge (ZLD) processes are designed to maximize water recovery by removing salts and other solids, thus reducing discharges from industrial wastewater.

ZLD systems include thermal evaporators, crystallizers and brine concentrators that reduce waste disposal and increase water recovery. These technologies are used in a variety of industrial wastewater treatment facilities worldwide.

Cost Savings

Zero Liquid Discharge Systems (ZLD) are becoming more and more popular in industrial settings as an environmental approach to wastewater treatment. These technologies reduce the amount of liquid waste that is sent to sewers and other sources while allowing plants to reuse water for other purposes, saving on water costs.

The cost of implementing a ZLD system depends on the type of contaminants and how much volume of wastewater is to be treated. This is due to the fact that different technologies are used for each contaminant. Some of these technologies include membrane systems, filtration, evaporation, and crystallization.

Some of these technologies are capital-intensive and require a significant amount of equipment, while others have lower upfront costs but high operating costs. The cost of equipment also depends on the level of automation required for a ZLD system, shipping costs, environmental regulatory fees, and taxes.

Another factor that can affect the cost of a ZLD system is the size of the plant. Larger facilities have higher water volumes, which means larger piping and equipment needs. Therefore, a larger ZLD system will be more expensive than a smaller one.

Nevertheless, the costs of implementing a ZLD system are still significantly lower than if you simply send your wastewater to a sewer or other waste disposal site. In addition, some ZLD systems can be designed so that waste can be recycled or reused instead of sending it to landfills.

Many power plants are looking to implement zero liquid discharge as a way to meet new federal standards that limit harmful pollutants in their fly ash transport water, bottom ash transport water, and flue gas mercury control system wastewater. With these tighter rules, it’s more important than ever to be able to effectively eliminate toxic pollutants from your industrial process.

As global freshwater scarcity becomes increasingly prevalent, the market for ZLD systems will continue to grow. This trend is largely driven by stricter regulations and public awareness regarding the negative impacts of wastewater discharge. Additionally, the capability of ZLD to recover wastes is expected to drive its growth.

Environmental Benefits

In an increasingly water-scarce world, Zero Liquid Discharge (ZLD) is becoming a popular strategy to manage industrial wastewater. Similar to membrane-based processes, ZLD aims to recover and reuse water as much as possible.

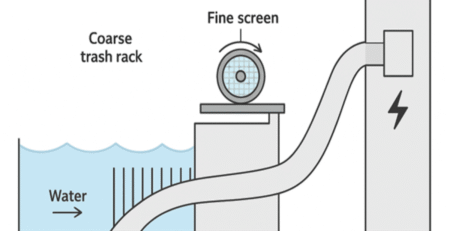

Typically, a ZLD system is comprised of a series of advanced wastewater treatment technologies and processes. The sequence of these steps is determined by a number of variables, including waste water composition and source water characteristics. These factors, along with site-specific operating costs, foot print availability, and pollutant loading concentrations, determine the most optimal treatment design for a particular industrial setting.

A basic ZLD system includes a pre-concentration step using membrane brine concentrators or electrodialysis technology, followed by a robust evaporation/crystallization stage that completely eliminates the produced wastewater. With this robust step, the process enables maximum recycling of water and reduces liquid waste volumes to the minimum allowed by regulatory agencies.

The main drivers for implementing a Zero Liquid Discharge System are strict regulations, water scarcity and rising public awareness of the negative impact that wastewater discharge has on the environment. As a result, these regulatory forces are driving many companies to implement zero liquid discharge strategies as a means to limit their environmental liabilities and enhance sustainability.

In addition to the environmental benefits of a ZLD system, other important considerations are reducing energy consumption and costs associated with disposal. This can be accomplished by utilizing innovative ZLD designs that minimize residual waste products and minimizing the subsequent evaporation/crystallization phase, resulting in decreased energy requirements and lower operation expenses.

However, despite these advantages, ZLD is not without its challenges, as it also generates solid waste that must be treated and/or disposed of. This solid waste can pose its own challenges and costs, so implementing a ZLD solution requires careful thought and planning.

The emergence of ZLD is a welcome development to a world where water supplies are under pressure. The increased availability of ZLD solutions, in combination with ongoing advancements in water recovery technologies, will help to meet this global demand for environmentally sound and sustainable solutions. As a result, it is expected that the ZLD market will continue to grow over the next decade.

Energy Savings

Zero Liquid Discharge (ZLD) is a wastewater management strategy that aims to reduce water pollution, conserve resources, and extend water supply by reducing the volume of liquid waste generated in an industrial process. It is also a key step for complying with environmental regulations.

Increasing water scarcity, decreasing water availability, and increasing effluent regulations are driving many industrial facilities to pursue strategies that maximize efficiency and sustainability while still meeting treatment requirements. Several approaches to this challenge have emerged over the years, including wastewater reuse and recycling and Zero Liquid Discharge.

One of the most important considerations when implementing a Zero Liquid Discharge System is energy consumption and costs. In general, ZLD systems require more energy than traditional thermal wastewater treatment and disposal methods because of the high concentrations of salt in the feedwater. However, certain ZLD processes can use lower-grade renewable energy, such as geothermal energy.

Brine is a major contributor to many industrial processes, especially in power plants where wet gas scrubbing, coal pile run-off, and leachate from gypsum stacks produce wastes that contain high concentrations of salts. Traditionally, these wastes are discharged to surface water and the sea or to wastewater treatment plants, which can damage the local environment.

Modern zero liquid discharge (ZLD) technologies aim to minimize the amount of brine produced by these processes, and therefore to avoid its discharge. This can be achieved by incorporating a variety of different ZLD technologies, including mechanical vapour recompression, reverse osmosis, evaporation/crystallization, and fractional electrodeionization.

These advanced systems are often able to produce cleaner, purified water with low levels of salt, as well as a solid product for landfill disposal or recovery as valuable salt byproducts. They have also been shown to improve water quality and reduce greenhouse gas emissions when compared with conventional technologies.

However, it is important to remember that even with advanced technologies and best practices, there are still some challenges to overcome when implementing a ZLD system. For example, storage ponds can leak or negatively impact local wildlife, while disposed solid wastes can cause toxic chemicals to leach into groundwater. This can make a ZLD system less environmentally friendly than conventional technologies that do not produce such wastes.

Safety

In recent years, water conservation and waste water treatment have become increasingly important as the global population grows, and the cost of disposing of contaminated wastewater in the aquifers and sewers continues to rise. The benefits associated with zero liquid discharge include lower capital investment, a smaller footprint on the environment, and reduced operating costs as well as increased operational flexibility to meet changing requirements.

The best way to determine the most efficient and practical ZLD solution is to conduct a thorough wastewater characterization study. This will identify the most important water quality defining factors for a plant, which will help to optimize the system design and performance.

Optimal design is achieved through the proper balance of a number of considerations such as the amount of solids to be treated, a comprehensive analysis of the waste water chemistry and the available site and equipment space. A system of the appropriate size and capacity will deliver the desired benefits while maintaining a safe operating environment and an optimal return on investment. The most effective systems are a close collaboration between an experienced engineering team and a facility’s management and maintenance teams. The best systems are designed to the highest standards of safety and reliability, utilizing state-of-the-art technology to protect human life and property from the hazards of liquid discharge, while preserving valuable resources such as water and energy.