Designing Heat Exchangers for Floating Production Storage and Offloading (FPSO)

Introduction:

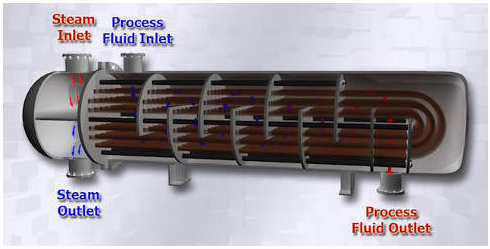

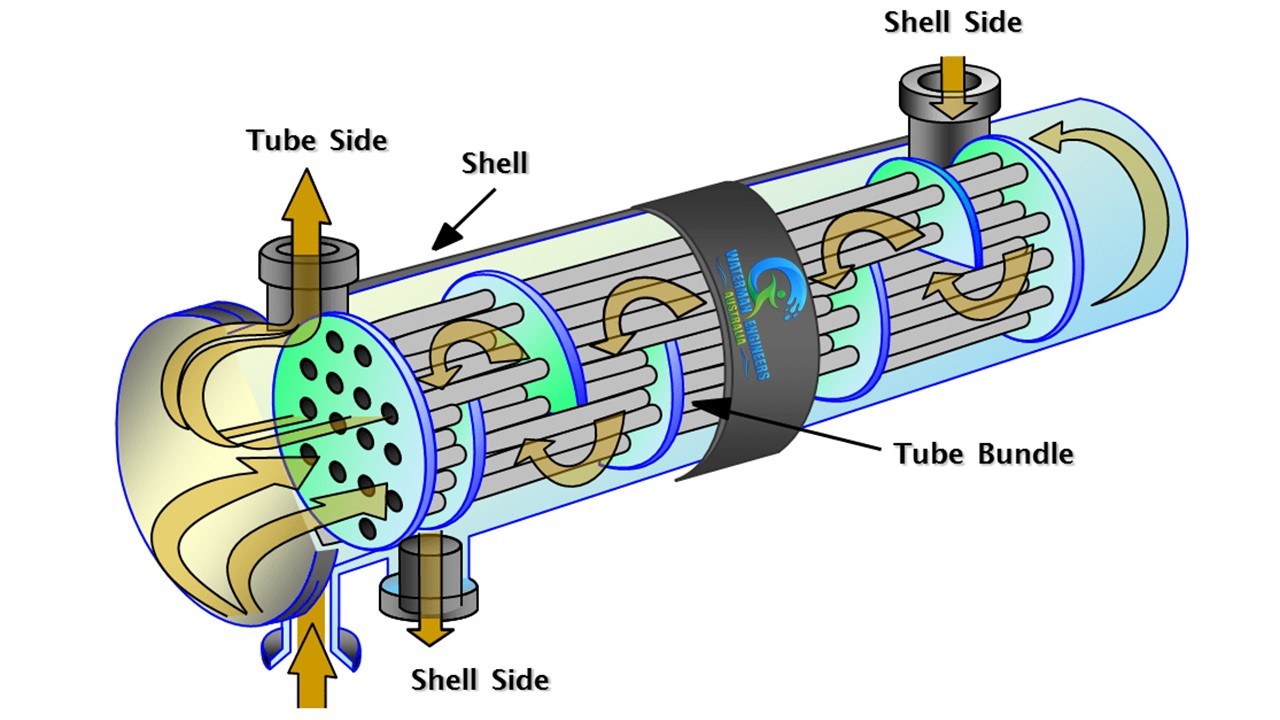

A mechanical device called a heat exchanger is used to move heat, or thermal energy, between two or more fluids that are at different temperatures. Effectively exchanging heat from a hotter to a cooler fluid, or vice versa, without letting the two fluids mix, is the goal of a heat exchanger. This thermal energy transfer is widely employed in daily applications as well as industrial operations for a variety of functions, such as heating, cooling, condensation, and evaporation.

A heat exchanger’s basic idea is to increase the surface area of contact between the two fluids in order to promote effective heat transfer. There are many different kinds of heat exchangers, each having unique advantages and applications depending on the needs of the process. These include shell and tube heat exchangers, plate heat exchangers, finned tube heat exchangers, and more.

Heat exchangers are essential components of Floating Production, Storage, and Offloading (FPSO) systems because of the particular difficulties associated with offshore oil and gas operations. Heat exchangers are necessary for FPSOs for the following reasons:

- Facilities for processing hydrocarbons, such as natural gas and crude oil, that are drawn from offshore wells are installed on FPSOs. Heat exchangers play a critical role in processes like treating and separating hydrocarbon streams, condensing vapours, and regulating temperature at different stages of processing.

- Temperature control is essential to FPSO operation efficiency. In order to maintain the ideal range for processing and storage conditions, heat exchangers assist in controlling the temperature of process fluids.

- For machinery and other equipment like gas compressors, FPSOs frequently need cooling systems. Equipment overheating is avoided via heat exchangers, especially air coolers and finned tube heat exchangers, which dissipate excess heat produced during compression.

- Boilers are usually used by FPSOs to produce steam, which is necessary for a number of operations, including heating and power generation. These boilers’ feedwater is preheated by heat exchangers, which increases energy efficiency and lowers fuel usage.

- Common FPSO tasks include processing generated water, separating gases, and condensing vapours. Heat exchangers play a crucial role in these procedures by guaranteeing effective heat transfer and enabling the phase shifts required for treatment and separation.

- Weight and space restrictions pose serious problems for FPSOs. Heat exchangers must be made to be lightweight, small, and able to withstand the demanding thermal requirements of the vessel’s numerous processing units.

- FPSOs work in harsh offshore conditions with exposure to saltwater, strong winds, and possible wave movement. It is necessary to use materials and coatings in the design of heat exchangers that are resistant to corrosion and degradation under these circumstances.

- Strict safety requirements and standards must be followed by FPSOs. Heat exchangers are essential for preserving safe working conditions, and in order to assure compliance and prevent accidents, safety features must be incorporated into their design.

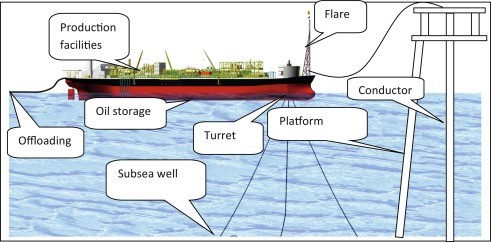

In offshore oil and gas production, floating production, storage, and offloading (FPSO) boats are essential because they provide a flexible platform for the processing and storage of hydrocarbons. The intricate process of designing heat exchangers for floating production and storage units (FPSOs) necessitates a deep comprehension of the particular difficulties presented by offshore environments, strict safety regulations, and the particular needs of hydrocarbon processing. We will explore the complexities involved in creating heat exchangers specifically for FPSO applications.

Overview of FPSO Operations

In essence, FPSOs are floating facilities that integrate the processes of producing, storing, and unloading gas and oil. These boats are situated in offshore fields where it is not feasible to have permanent infrastructure. Hydrocarbons are delivered to FPSOs from undersea wells, where they undergo onboard processing, store the generated oil, and then discharge it onto shuttle tankers for refinery delivery.

Separation units, gas compression systems, water injection systems, and utilities like electricity generation are typical examples of the processing facilities on an FPSO. Heat exchangers play a crucial role in these systems by performing functions such as heating, condensing, and chilling different process streams.

Key Considerations in Heat Exchanger Design for FPSOs

- Environmental Challenges

FPSOs work in challenging offshore conditions with exposure to saltwater, strong winds, and possible wave movement. In order to guarantee lifespan and dependability, the heat exchangers must be built to endure these circumstances, using materials that are resistant to corrosion and protective coatings.

- Space Limitations

Since there is a limited amount of space on an FPSO, heat exchanger architecture optimization is essential. It is crucial to use compact designs that optimise heat transfer efficiency within a limited space. - Weight Constraints

In order to ensure stability, weight is a crucial component in FPSO design. Lightweight materials must be used in heat exchanger design without sacrificing efficiency, safety, or structural integrity. - Safety Standards and Regulations

Strict safety requirements and standards must be followed by FPSOs. In order to ensure compliance with industrial and regulatory standards, heat exchanger designs must have safety elements to prevent mishaps such as leakage, overpressure, or fouling. - Heat Exchanger Types for FPSOs

On FPSOs, a variety of heat exchanger types are used, such as:- Heat exchangers with shell and tubes These exchangers, which are widely utilised in high-temperature and high-pressure applications, are efficient and adaptable.

- Plate heat exchangers are small, effective, and appropriate for applications with limited area.

- Air coolers can be used to cool particular process streams or in scenarios where water is limited.

- Applications where a larger surface area is needed for improved heat transmission are best suited for finned tube heat exchangers.

- Fluid Characteristics

When designing heat exchangers, it is essential to comprehend the characteristics of the fluids being processed. FPSOs deal with a range of fluids, such as chemicals, water, natural gas, and crude oil. Temperature variations, corrosiveness, and possible phase shifts must all be taken into consideration in the design. - Operational Flexibility

Since FPSOs are made to function in a variety of environments, the heat exchangers need to be flexible in their operation. This involves having the capacity to deal with changes in fluid composition, temperature, and flow rates. - Maintenance Accessibility

An important factor in the design of an FPSO heat exchanger is accessibility for maintenance and inspection. To reduce downtime, parts should be accessible for regular inspections, cleanings, and repairs.

Steps in Designing Heat Exchangers for FPSOs

- Define Operational RequirementsClearly state what the heat exchangers’ particular operating requirements are. This entails being aware of the ranges of pressure and temperature, the flow rates, and the kinds of fluids being handled.

- Environmental AnalysisAnalyse the operating environment of the FPSO in detail. Take into account elements including exposure to saltwater, wind loads, and wave movement. Choose coatings and materials that won’t corrode or deteriorate under these circumstances.

- Fluid Dynamics and Thermodynamics AnalysisAnalyse thermodynamics and fluid dynamics to find out what is needed for heat transmission. Recognize the viscosity, thermal conductivity, and specific heat of the fluids involved in the heat exchange process.

- Type and Configuration SelectionChoose the right heat exchanger type and configuration based on the operating requirements and analysis. Think of things like weight restrictions, space restrictions, and heat transfer efficiency.

- Materials SelectionSelect materials that are resistant to the aggressive properties of hydrocarbons and the corrosive impacts of seawater. To increase durability, materials like coatings and alloys resistant to corrosion are frequently used.

- Safety Features IntegrationInclude safety measures like temperature sensors, corrosion monitoring systems, and pressure relief valves in the heat exchanger design. Make that the design conforms to industry safety requirements and guidelines.

- Optimization of FootprintMake the heat exchangers’ footprint as little as possible on an FPSO because of the space constraints. Investigate small designs that don’t sacrifice functionality to maximise the amount of space available.

- Weight OptimizationThink about optimising weight without sacrificing structural stability. To fulfil weight restrictions without sacrificing effectiveness or safety, use lightweight materials and creative design techniques.

- Flexibility in OperationIt is important to plan the heat exchangers to account for changes in fluid composition, flow rates, and temperature as well as other operational factors. This guarantees adaptability to various situations.

- Accessibility for MaintenanceMake sure that maintenance and inspection may be done with ease thanks to the design. It is important that parts are easily accessible for regular inspections and any required maintenance.

Implementation of FPSO Heat Exchangers

A project including the design and construction of heat exchangers for an FPSO working in the treacherous waters was recently undertaken by Waterman Engineers Australia. The undertaking comprised:

- Rigorous Environmental examination of the challenging offshore environment to establish corrosion prevention strategies and material requirements.

- Making use of sophisticated computational fluid dynamics (CFD) models to maximise the heat exchanger arrangement in the limited area of the FPSO.

- using lightweight materials to satisfy strict weight restrictions without sacrificing structural strength.

- putting in place safety measures like corrosion monitoring systems and pressure release valves to guarantee adherence to industry safety requirements.

- creating heat exchangers with flexible operating designs that could adapt to changes in fluid characteristics, flow rates, and temperatures.

- ensuring that parts were made to be easily accessed, making regular maintenance and inspections easier.

- The dependability and general efficiency of the FPSO’s processing capabilities were greatly enhanced by the effective installation of these heat exchangers.

It takes a multidisciplinary approach to design heat exchangers for FPSOs, including materials science, fluid dynamics, thermodynamics, and safety engineering. Because of the particular difficulties presented by offshore locations, environmental considerations, weight restrictions, and space constraints must all be carefully taken into account. Waterman Engineers Australia is a prime example of successful implementation because of its dedication to safety standards, environmental studies, and innovative design processes. Heat exchanger design and optimization will be critical to improving productivity, guaranteeing safety, and advancing offshore hydrocarbon production as FPSO operations develop.

Choose Waterman Engineers Australia Heat Exchangers for Floating Production Storage and Offloading (FPSO) that elevate your industrial processes to new heights. Contact us today to explore how we can optimize your heat transfer applications and contribute to the success of your operations.