Sewage Water Treatment

What is meant by sewage

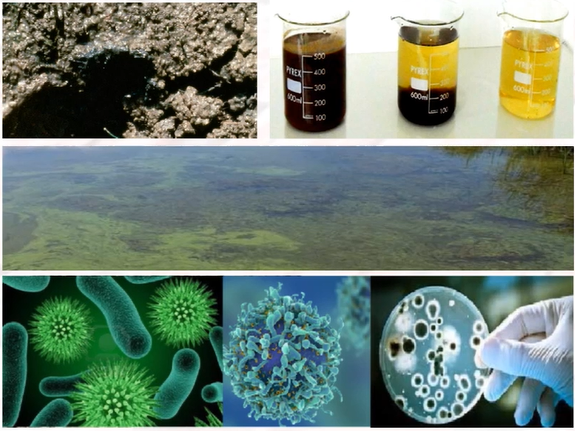

Sewage is a mixture of domestic and industrial wastes, and it is a carrier of disease. It is harmful and includes a number of various types of wastes as follows.

- Kitchen waste

- Hospital waste

- Electronic waste

- Agricultural waste

- Ions and harmful micro-organisms etc.

- some ions and metals like chlorides, sulphides, and mercury

In importance of treatment

Sewage water doesn’t have any use to reduce the threat of water pollution. So, sewage water should send it to the sewage water treatment process, before discharged into the rivers.

Phases of wastewater treatment

- Pre-treatment

- Primary treatment

- Secondary treatment

Pre-treatment is the first step of treatment and is used to remove large objects and non-degradable objects equipment’s which are involved in pre-treatment example,

- Bar screen removes brakes, bottles, and rocks

- Grid chamber removes rocks, broken glasses, plastic bags, syringes, combs towels,

In primary treatment, it includes the removal of solids and oils from the effluence.

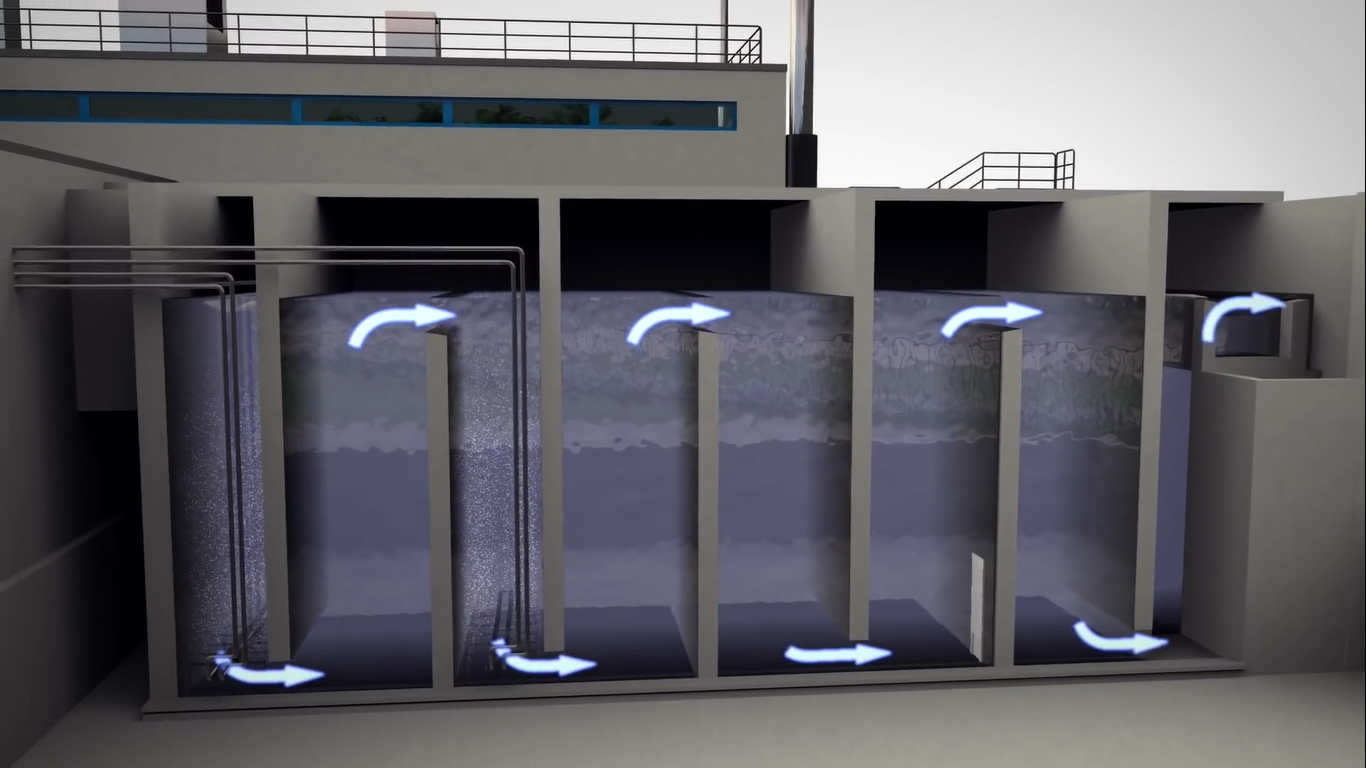

Microorganisms that break down organic materials in the sewage are used in secondary treatment. It is also known as a biological process.

Sewage treatment plant contains

- Bar screen

- Grid chambers

- Primary settling tanks

- Activated sludge basins, trickling filters

- Sludge digesters

- Drying beds process

Process Involved

Collect sewage water from various sources to treatment plant. Bar screens will remove bricks, bottles and rocks and then passed on to grit chambers. Grit chambers will remove rocks, broken glasses, plastic bags, syringes, combs, and towels. Primary settling tanks reduces the suspended solids and the BOD of the wastewater.

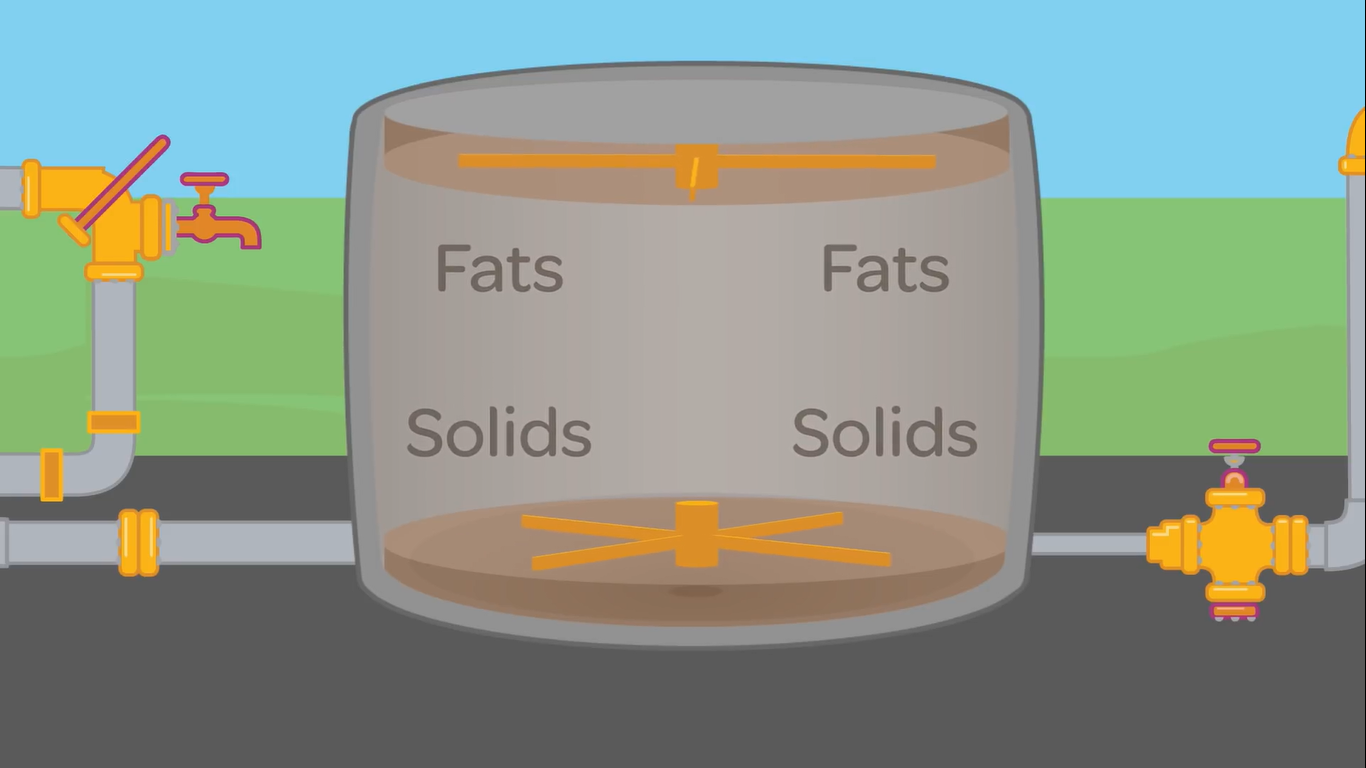

Large tanks are used for this purpose, and the settleable materials are removed as sludge while the oil rises to the surface and is skimmed off. Secondary treatment involves moving the effluent from first treatment to a chamber where microorganisms will further break down the organic materials. The sludge that was collected during the waste removal process was transported to the sludge Digester.

Sludge digester is going to treat the waste by anaerobic fermentation. Then it is transported to drying beds. After treatment, water is discharged into landfills and rivers.

Where does the water go?

We deliver water to over 1.6 million people. Which adds up to delivering over 350 million litres of clean fresh drinking water to everyone. Once the water has been used, we collected again to clean and treat collecting 330 million litres per day.

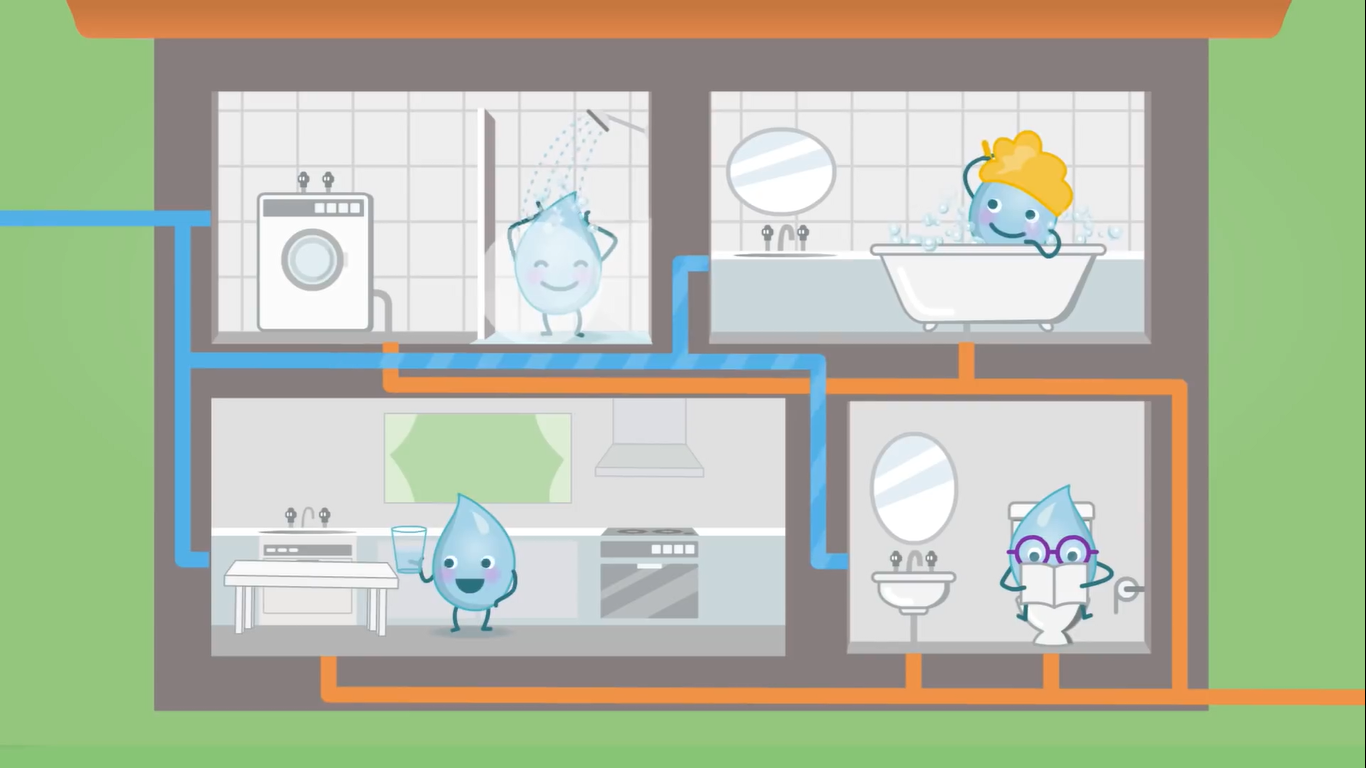

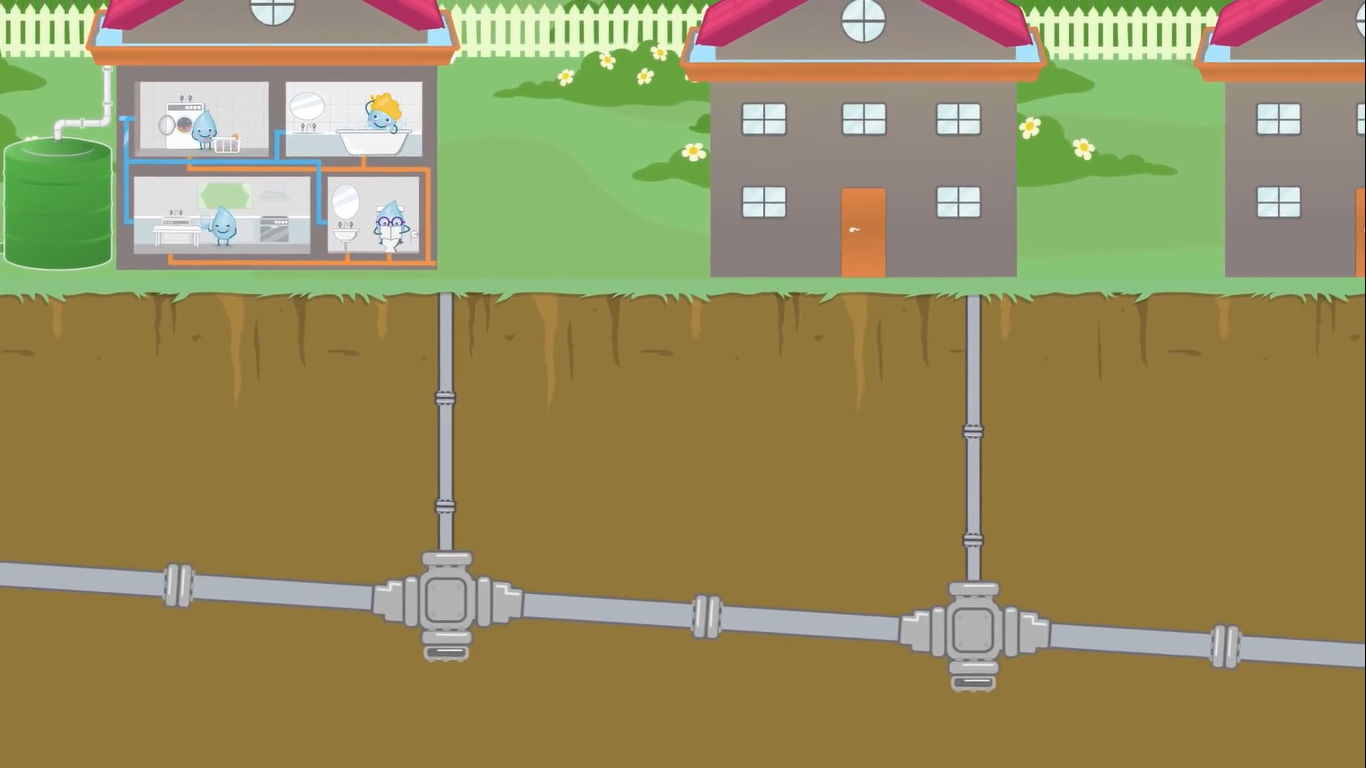

We have to make sure our pipes aren’t leaking or blocked to make sure no one goes without water. Because having a steady supply of clean fresh water is so precious, a dam was built up in the hills a long way from the city. This protected catchment built away from any roads or buildings, collects and stores the water when it rains. The dam holds the water there until we need to use it for things like drinking, taking a shower, washing our clothes, watering our garden, and flushing the toilet. Once you’ve finished using it, we take the dirty water called sewage away.

We have to make sure our pipes aren’t leaking or blocked to make sure no one goes without water. Because having a steady supply of clean fresh water is so precious, a dam was built up in the hills a long way from the city. This protected catchment built away from any roads or buildings, collects and stores the water when it rains. The dam holds the water there until we need to use it for things like drinking, taking a shower, washing our clothes, watering our garden, and flushing the toilet. Once you’ve finished using it, we take the dirty water called sewage away.

There is more than just toilet sewage. Everything that utilises water in your home will exit through a single sewage pipe, which will connect to a system of pipes under our roads. However, since doing so would poison the environment and harm the ocean, these pipes don’t merely go there. The sewage pipes instead lead to a sewage treatment facility where the water is cleaned before being recycled or returned to the ocean. A vast network of pipes transports the sewage from your home to a sewage treatment facility.

Similarly, to how a river runs from the mountains to the sea, gravity is responsible for this movement. Pump stations send sewage back to the surface when the conduit becomes too deep. Thus, it can proceed to flow downhill into the treatment facility. However, occasionally undesirable items make their way into the sewer systems. No one wants their pipes to become clogged due to debris like diapers, oils, food, and even toys, which inevitably find their way in there.

Similarly, to how a river runs from the mountains to the sea, gravity is responsible for this movement. Pump stations send sewage back to the surface when the conduit becomes too deep. Thus, it can proceed to flow downhill into the treatment facility. However, occasionally undesirable items make their way into the sewer systems. No one wants their pipes to become clogged due to debris like diapers, oils, food, and even toys, which inevitably find their way in there.

- There are four distinct processes that take place once sewage reaches the treatment facility. Filtering out the trash is the first step, as this is where the bulkier objects, such soiled diapers, wet wipes, cotton swabs, and fruit stickers, are extracted from the sewer.

- The next step is to remove debris like dust and grime. When a vortex is formed in sewage, all of the heavier particles are pushed to the outside, where they eventually settle to the bottom.

- The next step is sedimentation, which gets rid of the particles like faeces and toilet paper that make up sludge.

Sewage is let to settle so that the oils rise to the top and the solids fall to the bottom. Sludge is removed from the tank by scraping the inside and outside using blades. The sludge is then transported into a digester where bugs eat all the yucky things out. Bacteria, viruses, and algae are just some of the critters that help the sewage system do its job of decomposing garbage. Our faeces and the sewage system are home to these organisms. Like a banana that has been left in your backpack over the break and has begun to rot. These helpful bugs are so tiny that you’ll need a microscope to spot them, yet they perform an excellent job of digesting the sewage they find. After 16 days, when we open the digester, we find what looks like soil, which is then dried out and buried on the spot.

Sewage is let to settle so that the oils rise to the top and the solids fall to the bottom. Sludge is removed from the tank by scraping the inside and outside using blades. The sludge is then transported into a digester where bugs eat all the yucky things out. Bacteria, viruses, and algae are just some of the critters that help the sewage system do its job of decomposing garbage. Our faeces and the sewage system are home to these organisms. Like a banana that has been left in your backpack over the break and has begun to rot. These helpful bugs are so tiny that you’ll need a microscope to spot them, yet they perform an excellent job of digesting the sewage they find. After 16 days, when we open the digester, we find what looks like soil, which is then dried out and buried on the spot.

Phase three at the treatment facility involves using beneficial bugs to decompose the remaining dirty water in order to remove the remaining contaminants. Additionally, we employ bugs found in the sewer system. The sewage then passes through different tanks with different sorts of good bugs dwelling in them. Tanks with lots of air bubbles through them allow the bugs to break down and consume the contaminants like we do with soap and shampoo, leaving behind nearly pure water.

In the final, fourth phase, the water is filtered through ultra-filtration membranes. We next add a dose of chlorine, like in a swimming pool, and use UV light from the Sun to kill any bacteria and bugs that is left in the water.

Disinfection marks the end of the treatment procedure, and the water can then be safely recycled to some homes, businesses, and farms throughout the city.

Disinfection marks the end of the treatment procedure, and the water can then be safely recycled to some homes, businesses, and farms throughout the city.

Recycled Water

Recycled water always comes from a purple pipe or tap. You can’t drink or shower with it. But there are many things it is safe to do with it. You can water your garden, flush your toilet, and wash your car with it. It can also be used to water crops on farms and keep for years green. Nature has its own water cycle where it recycles water over and over again and serve recycling water is our way of doing the same thing. By recycling water. We can keep using water outside, even when we don’t get much rain and leave out precious, clean water for drinking.

How Do We Pump Sewage

How Do We Pump Sewage

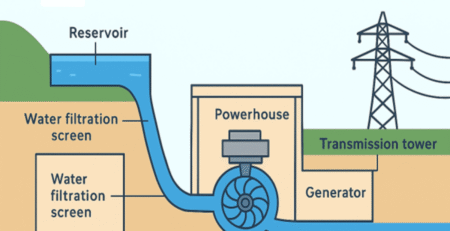

We don’t typically release raw sewage into waterways anymore and crossness has long been decommissioned after newer treatment works were built in the 1950s. But even though we have more sophisticated ways to treat wastewater before discharging it into streams and rivers, there’s one thing that hasn’t changed, we still use gravity as the primary way of getting waste to flow away from homes and businesses within the sewers below ground and eventually we need a way to bring that sewage back up to the surface of the earth. But that’s not as easy as it sounds. We’re talking about sewage lift stations.

Most sewers move gravitationally from each residence or establishment to a wastewater treatment facility. Despite being placed as pipelines, sewers typically only flow partially full, much like stench-filled water slides or subterranean creeks and rivers. This is practical as we don’t have to pay a hefty bill each month and it seldom ever goes out during a rainstorm. Sewage is forced downward by a constant, free force.

But because there’s gravity only pulls in one direction; sewers must always slope meaning they often end up well below the ground surface especially toward their downstream ends and that can be problematic. Sewers are almost always installed in open excavations also known as trenches. This might seem obvious, but the deeper a trench must be dug the more difficult, dangerous, disruptive, and ultimately expensive construction becomes, in some cases just stops being feasible to chase the slope of a sewer farther and farther below the ground surface.

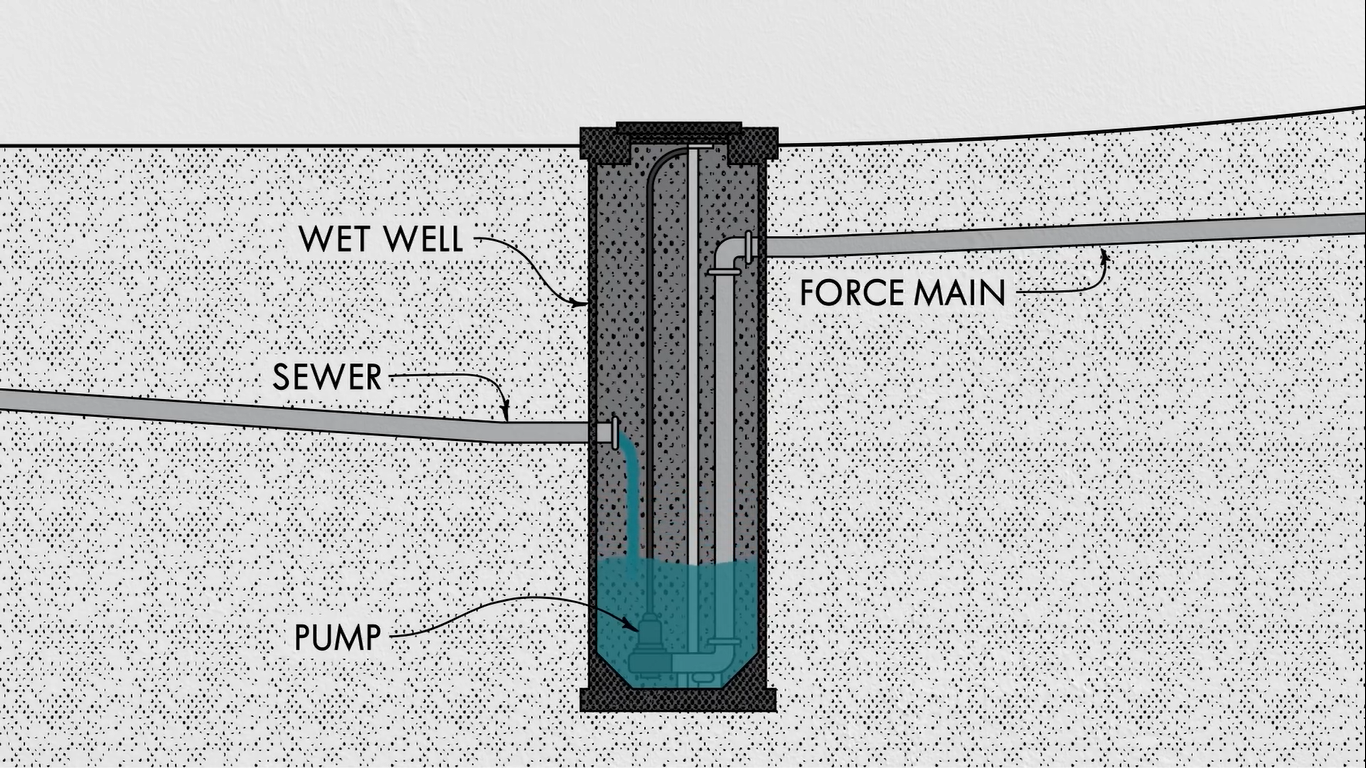

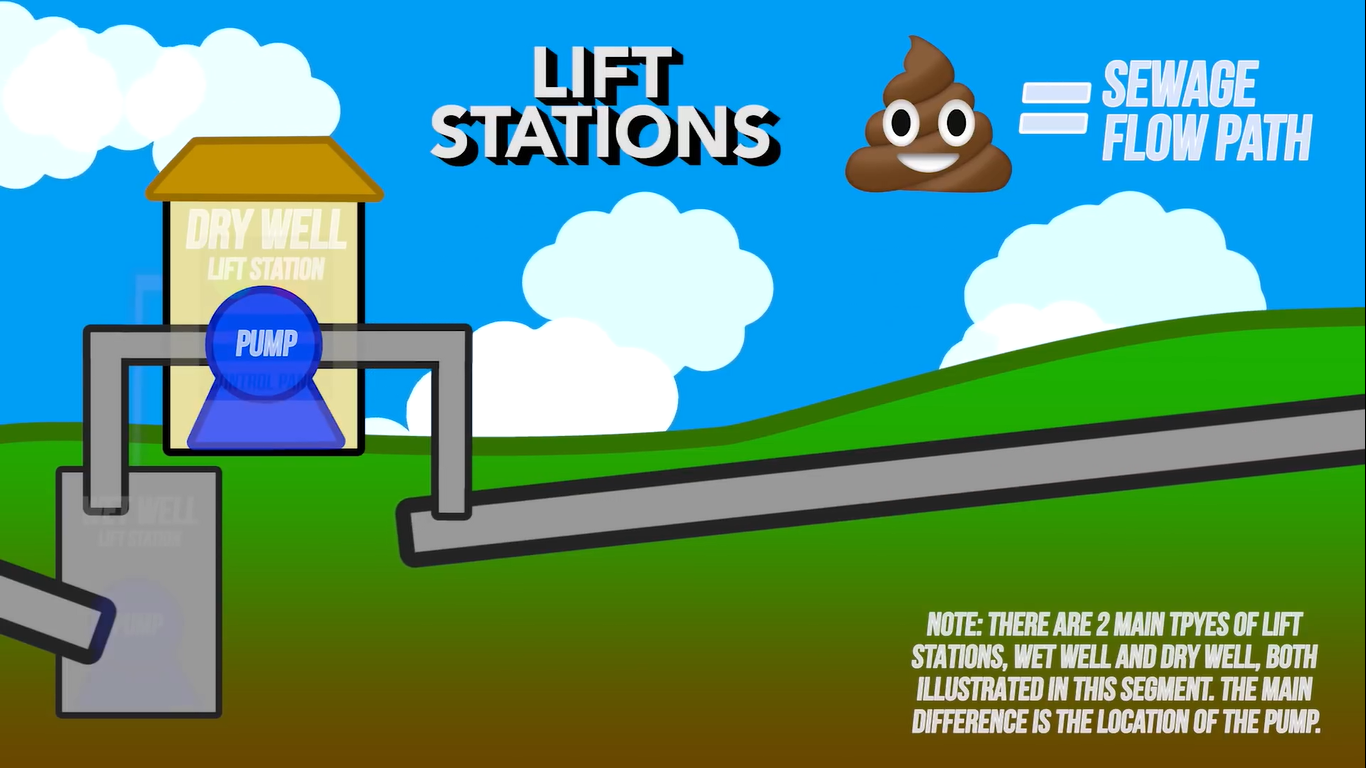

Lift Station

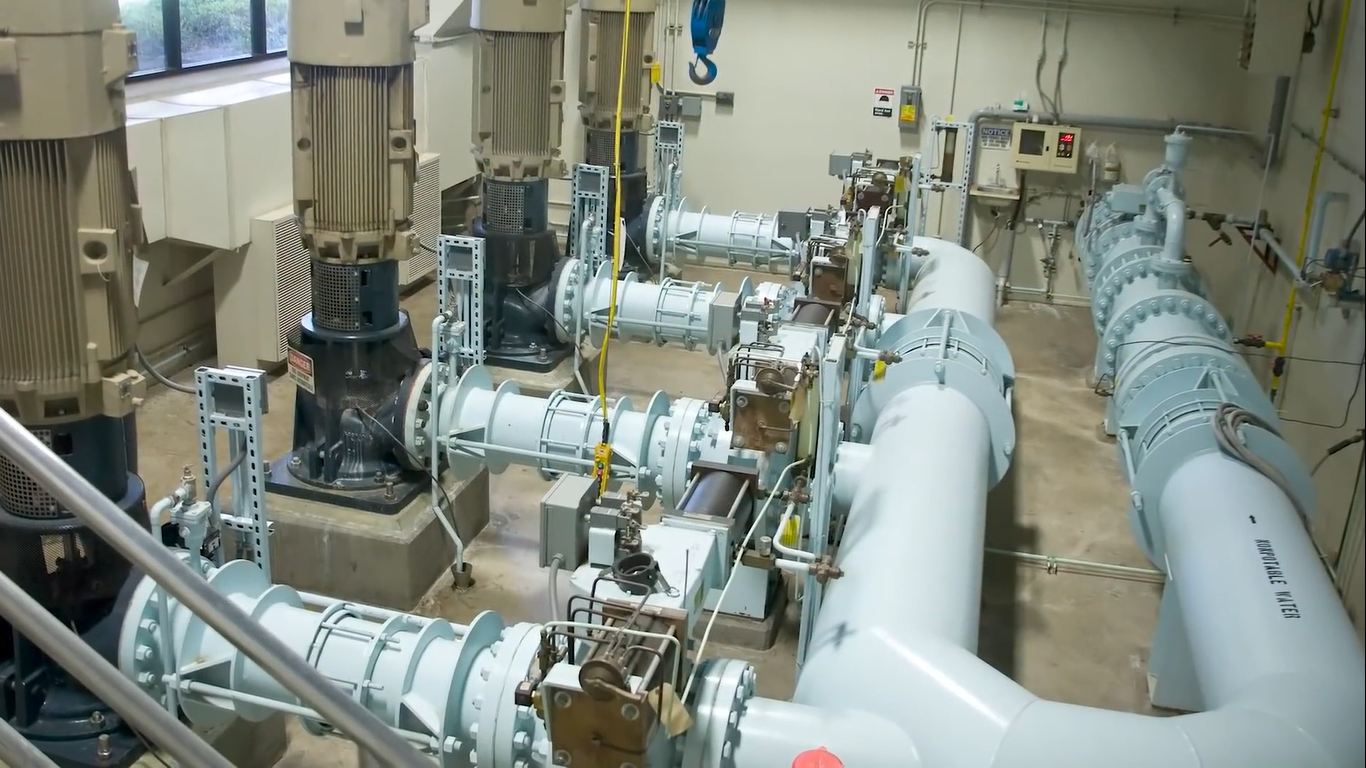

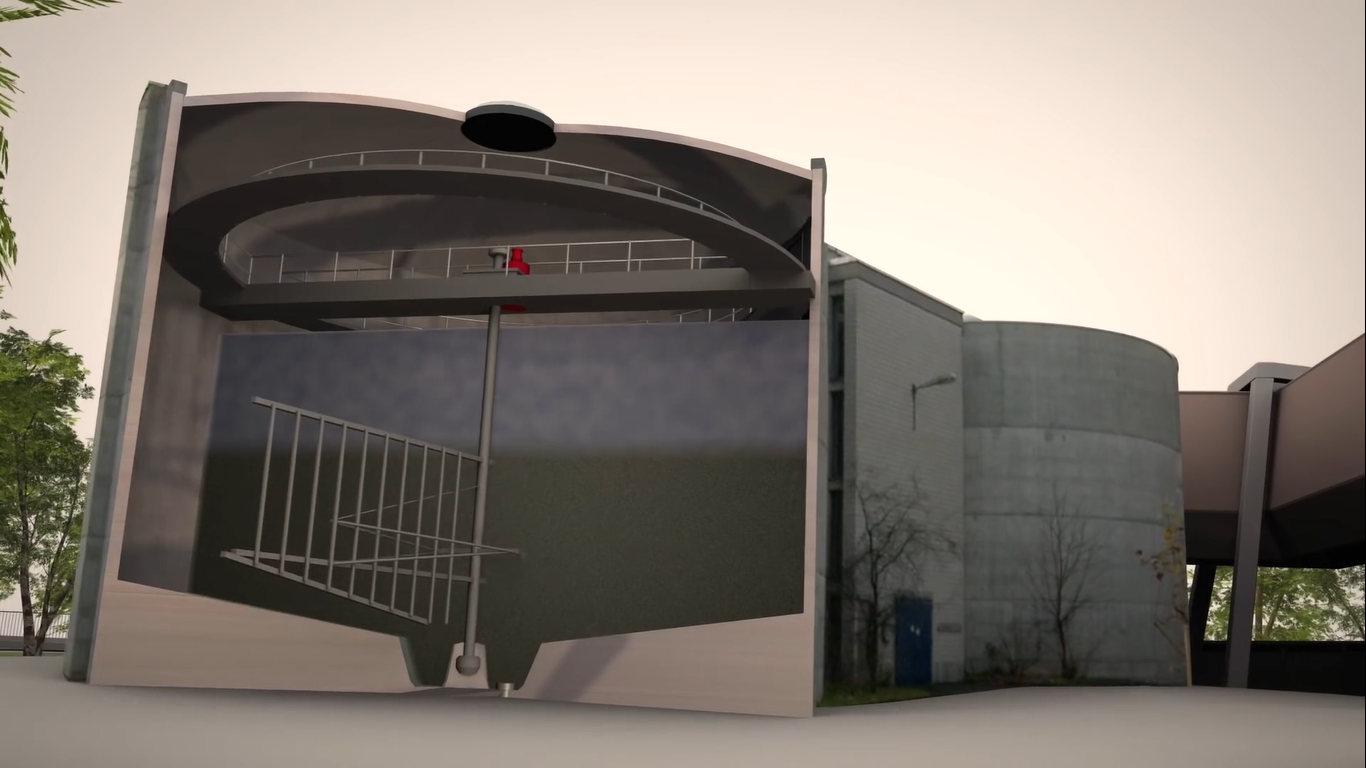

A good alternative is to instal a pumping station that can lift raw sewage from its depth back closer to the surface lift stations can be small installations designed to handle a few apartment complexes or massive capital projects that pumped significant portions of the city’s total wastewater flow. A typical lift station consists of a concrete chamber called a wet well sewage flows into the wet well by gravity filling it over time.

Once the sewage reaches a prescribed depth. A pump turns on pushing the wastewater into a specialised sewer pipe called a force mean you always want to keep the liquid moving swiftly and pipes to avoid the solid settling out, so this intermittent operation makes sure that there are no slow trickles during off peak hours. The sewage travels under pressure within the force main to an uphill manhole where it can continue its journey downward via gravity once again.

Once the sewage reaches a prescribed depth. A pump turns on pushing the wastewater into a specialised sewer pipe called a force mean you always want to keep the liquid moving swiftly and pipes to avoid the solid settling out, so this intermittent operation makes sure that there are no slow trickles during off peak hours. The sewage travels under pressure within the force main to an uphill manhole where it can continue its journey downward via gravity once again.

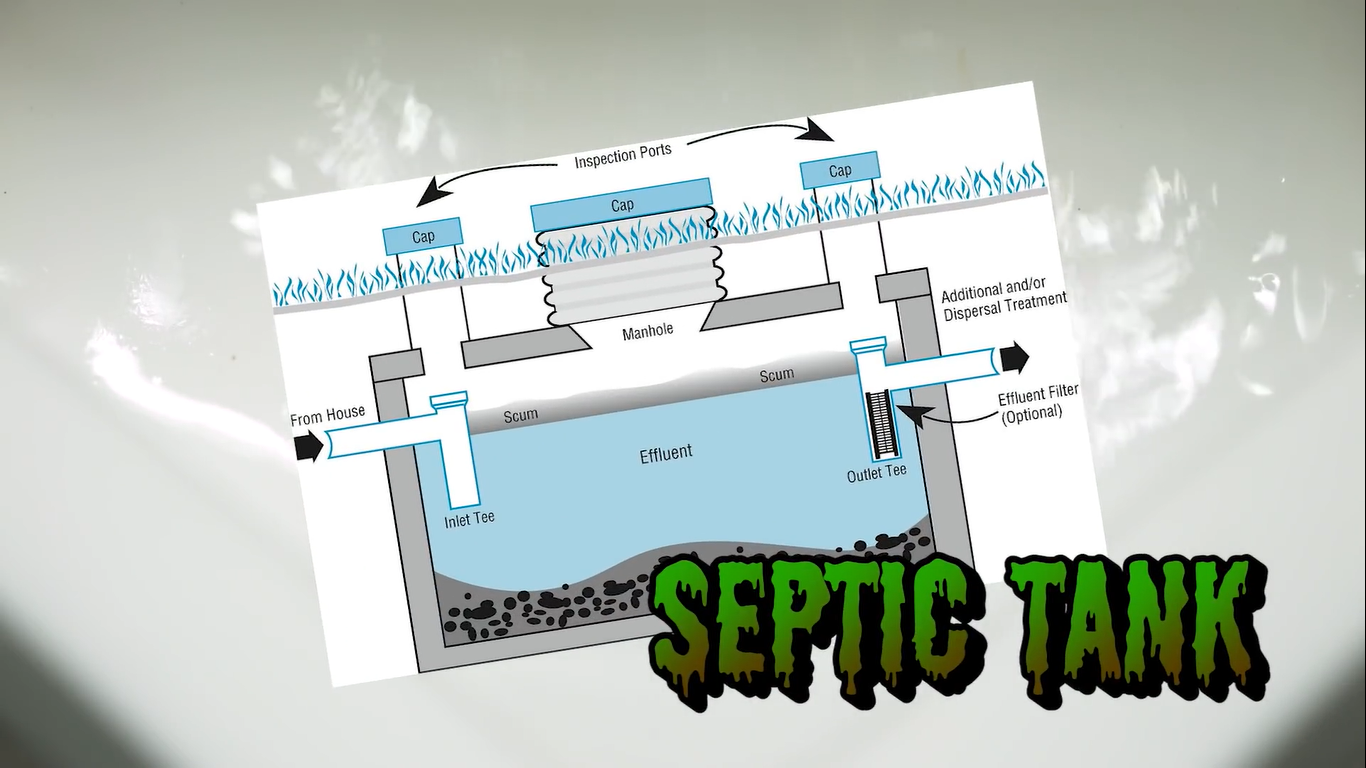

Another important location for lift stations is at the end of the line. Once wastewater reaches its final destination, there are no magical underground sewage outlets. Septic systems get rid of wastewater through leach fields that infiltrate the subsurface but they’re designing for individual buildings and aren’t feasible on a city scale that would require enormous areas of land to get so much liquid to soak into the soil, not to mention the potential for contamination of the groundwater. Ignoring for now the fact that we need to clean it up first, we still need somewhere for our sewage to go.

Another important location for lift stations is at the end of the line. Once wastewater reaches its final destination, there are no magical underground sewage outlets. Septic systems get rid of wastewater through leach fields that infiltrate the subsurface but they’re designing for individual buildings and aren’t feasible on a city scale that would require enormous areas of land to get so much liquid to soak into the soil, not to mention the potential for contamination of the groundwater. Ignoring for now the fact that we need to clean it up first, we still need somewhere for our sewage to go.

In most cases, that’s a creek river or the ocean, meaning we need to lift the sewage up to the surface of the earth one last time. Rather than build a wastewater treatment plants and underground layers like stinky superheroes. So, we only pump clean water, it’s much easier just to lift the raw sewage up to the surface to be treated and eventually discharged. That means we have to send some pretty gross stuff sewage, through some pretty expensive and sophisticated pieces of machinery, the pumps and that comes with some challenges. We often think of sewage as its grossest constituents, human excrement, you know, poop, but sewage is a slurry of liquids and solids from a wide variety of sources.

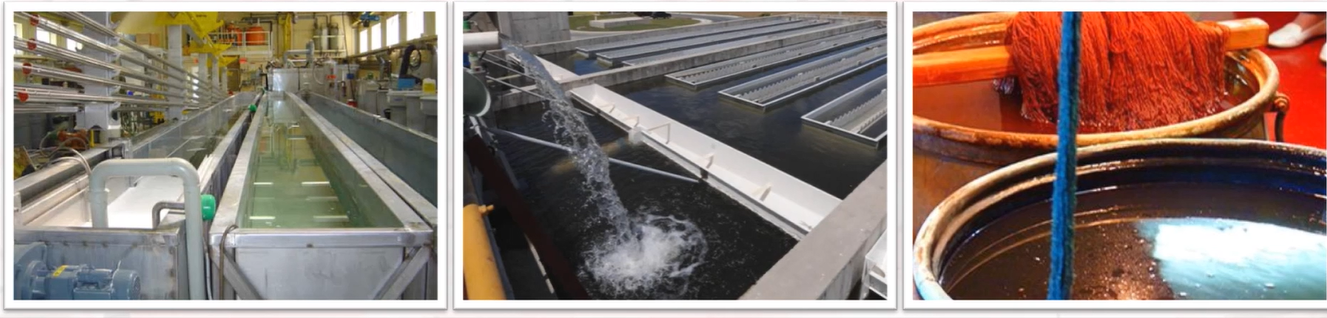

Lots of stuff ends up in our wastewater stream including soil soap, hair, food, wipes, grease and trash. These things may make it down the toilet or sink drain and through the plumbing in your house. But in the sewer system, they can be conglomerated into large balls of grease rags and other debris sometimes called pigtails or fat birds by wastewater professionals. In addition, with many cities putting efforts into conserving water, the concentration of solids and wastewater is trending upward. Conventional pumps handle liquids just fine but adding solids in the stream increases the challenge of lifting raw sewage.

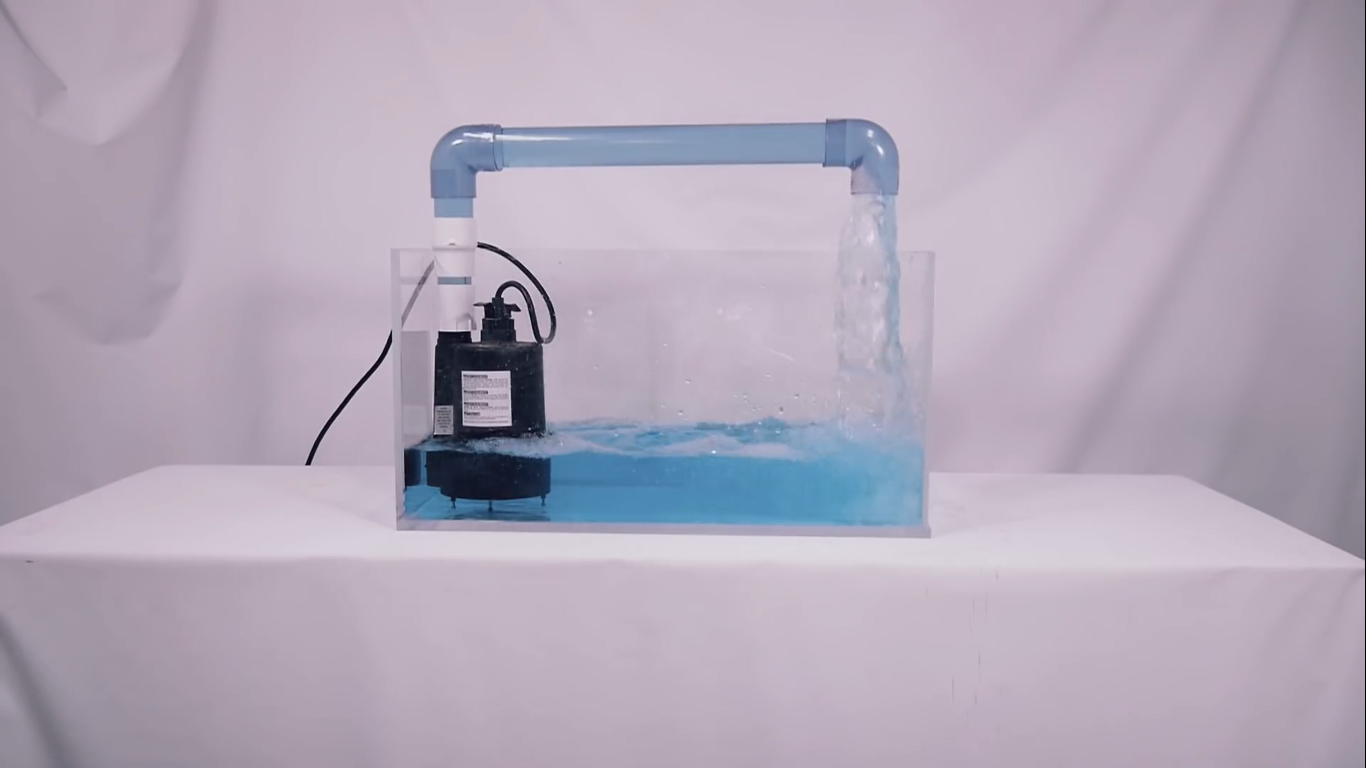

This is a small submersible pump designed for moving water out of basements or pools. It’s nothing fancy just an electric motor with a small impeller inside a moulded plastic case I took off the screen so we can really see how much it can handle the submersible pump loose, clear water just fine. Toilet paper is no issue even for the small pump, it can break apart the paper with no problem. It can even manage small, suspended solids like these plastic balls, the particles stay in solution forming a slurry like raw sewage.

This is a small submersible pump designed for moving water out of basements or pools. It’s nothing fancy just an electric motor with a small impeller inside a moulded plastic case I took off the screen so we can really see how much it can handle the submersible pump loose, clear water just fine. Toilet paper is no issue even for the small pump, it can break apart the paper with no problem. It can even manage small, suspended solids like these plastic balls, the particles stay in solution forming a slurry like raw sewage.

Clog the Pump

However, larger solids in the stream can easily clog the pump. Anything bigger than the spaces in the impeller just won’t make it through and clogging really becomes a problem with stringing debris. These are quote unquote flushable whites. They may make it past a toilet, but you can easily see why these types of wipes are a problem in a wastewater stream. I really don’t feel like pouring a bunch of grease in my demonstration here but I’m sure you can imagine how congealed fats and oils would only exacerbate the problem of clogging this pump. It’s clear that appropriately sized centrifugal pumps can handle certain types and sizes of suspended solids just fine.

Sewage pumps are designed for the extra wear and tear. The impellers have fewer veins to avoid snags and the openings are larger so that solids can freely move through them.

Different manufacturers have proprietary designs to minimise obstructions to the extent possible, but no sewage pump is clogged proof, especially with today’s concentrated wastewater full of wipes that have been marketed as flushable clogs and lift stations can be a daily occurrence removing a pump clearing it of debris and replacing it is a dirty and expensive job, especially if you have to do it frequently.

Different manufacturers have proprietary designs to minimise obstructions to the extent possible, but no sewage pump is clogged proof, especially with today’s concentrated wastewater full of wipes that have been marketed as flushable clogs and lift stations can be a daily occurrence removing a pump clearing it of debris and replacing it is a dirty and expensive job, especially if you have to do it frequently.

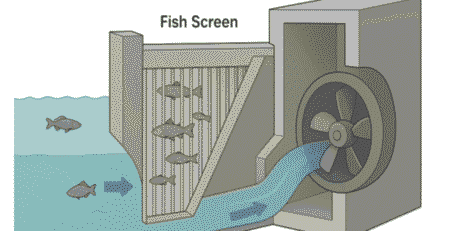

Most lift stations have an alarm when the level gets too high. But if a clog doesn’t get cleared fast enough, raw sewage can back up into houses and businesses or overflow the wet well potentially exposing humans and wildlife to dangerous biohazards. A seemingly obvious solution to the problem of clogging is to use a screen in the lift station well to prevent trash from reaching the pumps what screens have a limitation they can clog up to. By adding a screen you’ve traded pump maintenance for another kind of maintenance, removing and hauling away debris.

Smaller lift stations with bar or baskets screen can get away with maybe a once a week visit from a crew to clean them. Larger pump stations often feature automatic systems that can remove solids from the screen into a dumpster that can be hauled to a landfill every so often. Sometimes using a screen is an effective way to protect against clogging but it’s not always convenient, especially because it creates a separate waste stream to manage.

For example, if a lift station is remote, where it’s inconvenient to send crews for service and maintenance, you might prefer that all the solids remain in the wastewater Stream. After all treatment plants are specifically designed to clean wastewater, they have better equipment and consistent staffing.

For example, if a lift station is remote, where it’s inconvenient to send crews for service and maintenance, you might prefer that all the solids remain in the wastewater Stream. After all treatment plants are specifically designed to clean wastewater, they have better equipment and consistent staffing.

So, it often just makes sense to focus the investments of time and effort at the plant rather than individual lift stations along the way.

Grinding the Solids into Smaller Pieces

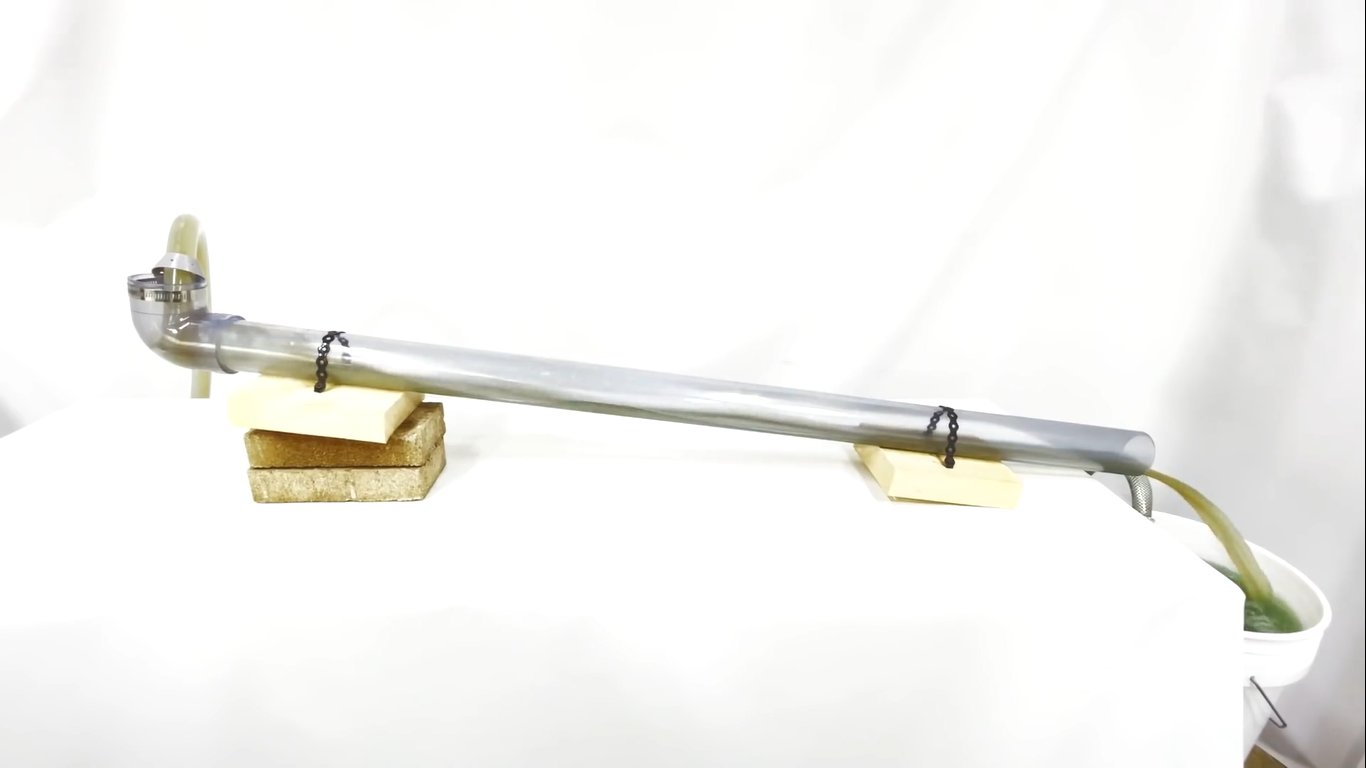

In these cases, there’s another option for minimising pump clogs, grinding the solids into smaller pieces. There’s a nice equivalent to a lift station grinder that can be found under the sinks of mini home as the garbage disposal this common household appliance saves you the trouble and smell of putting food scraps into the wastebasket.

It works like a centrifugal pump with a spinning impeller, but it also features a grinding ring consisting of sharp blades and small openings. As the impeller spins the solids, they scrape against the grinding rain shearing into smaller pieces that can travel through the waste plumbing. Our garbage disposal can handle all of the solids I tested with the submersible pump with no issues with clogging. The wipes gave it a little trouble, but it was still able to chew them up.

Some lift stations feature grinding pumps that are remarkably like under sink garbage disposals. Others use stand-alone grinders that simply chew up the solids before they reach the pumps grinders are often required at medical facilities and prisons where fibrous solids are more likely to find their way into the wastewater Street. Large grinders are also used where storm drains and sewers are combined. Because those systems see heavier debris loads from rainwater runoff a grinder is another expensive piece of equipment to purchase and maintain at a lift station, but it can offer better reliability fewer clogs, and thus decrease maintenance costs.

Some lift stations feature grinding pumps that are remarkably like under sink garbage disposals. Others use stand-alone grinders that simply chew up the solids before they reach the pumps grinders are often required at medical facilities and prisons where fibrous solids are more likely to find their way into the wastewater Street. Large grinders are also used where storm drains and sewers are combined. Because those systems see heavier debris loads from rainwater runoff a grinder is another expensive piece of equipment to purchase and maintain at a lift station, but it can offer better reliability fewer clogs, and thus decrease maintenance costs.

Clogging is not the only practical challenge of operating a sewage lift station when you depend on electromechanical equipment to provide an essential service you always have to plan for things to go wrong. Lift stations usually feature multiple pumps so they can continue operating. If one fails, they often have backup generators so that sewage can continue to flow even if grid power is lost.

Another issue with lift stations is air bubbles getting into force mains and constricting the flow. Automatic air release valves can purge force mains of these bubbles but venting sewer gas into populated areas isn’t usually a popular prospect. Although our urban lives depend on sewers to carry waste away before it can endanger public health.

How to Clean Sewage with Gravity

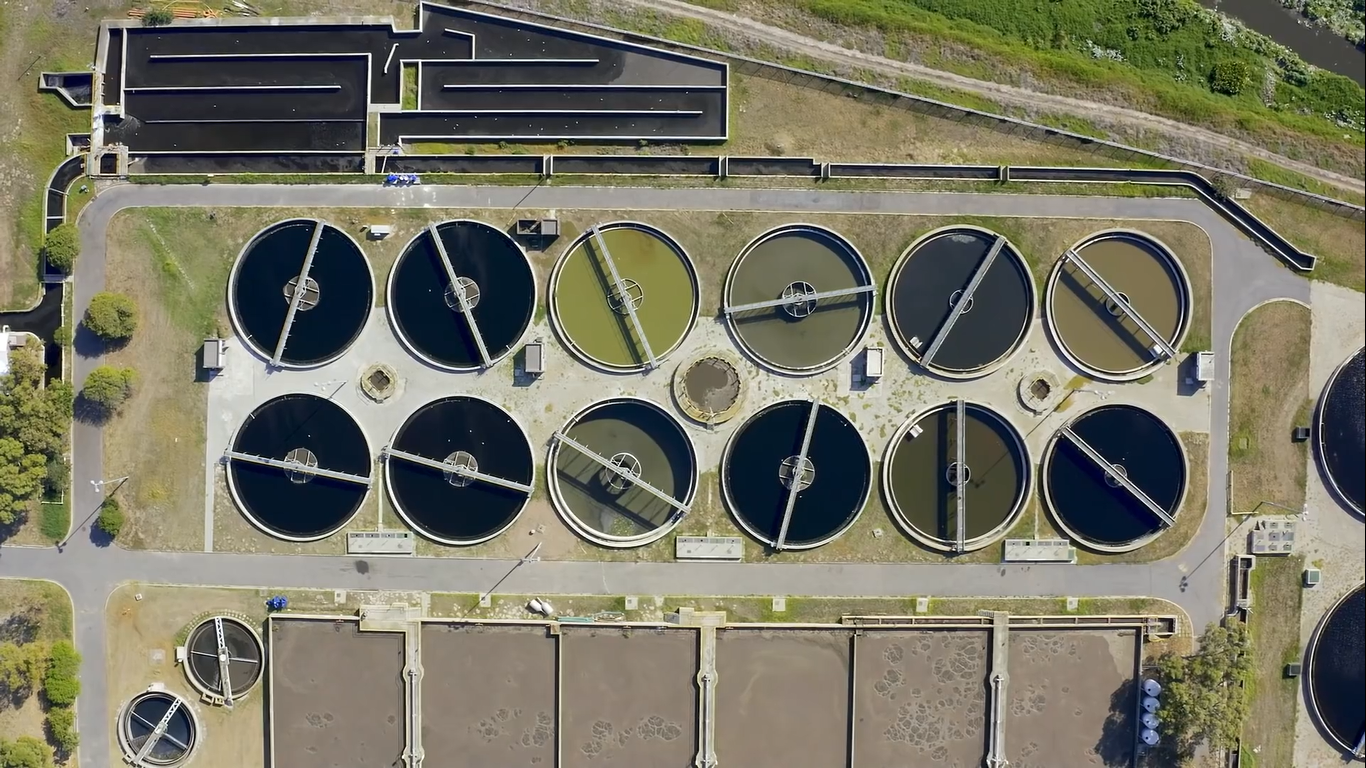

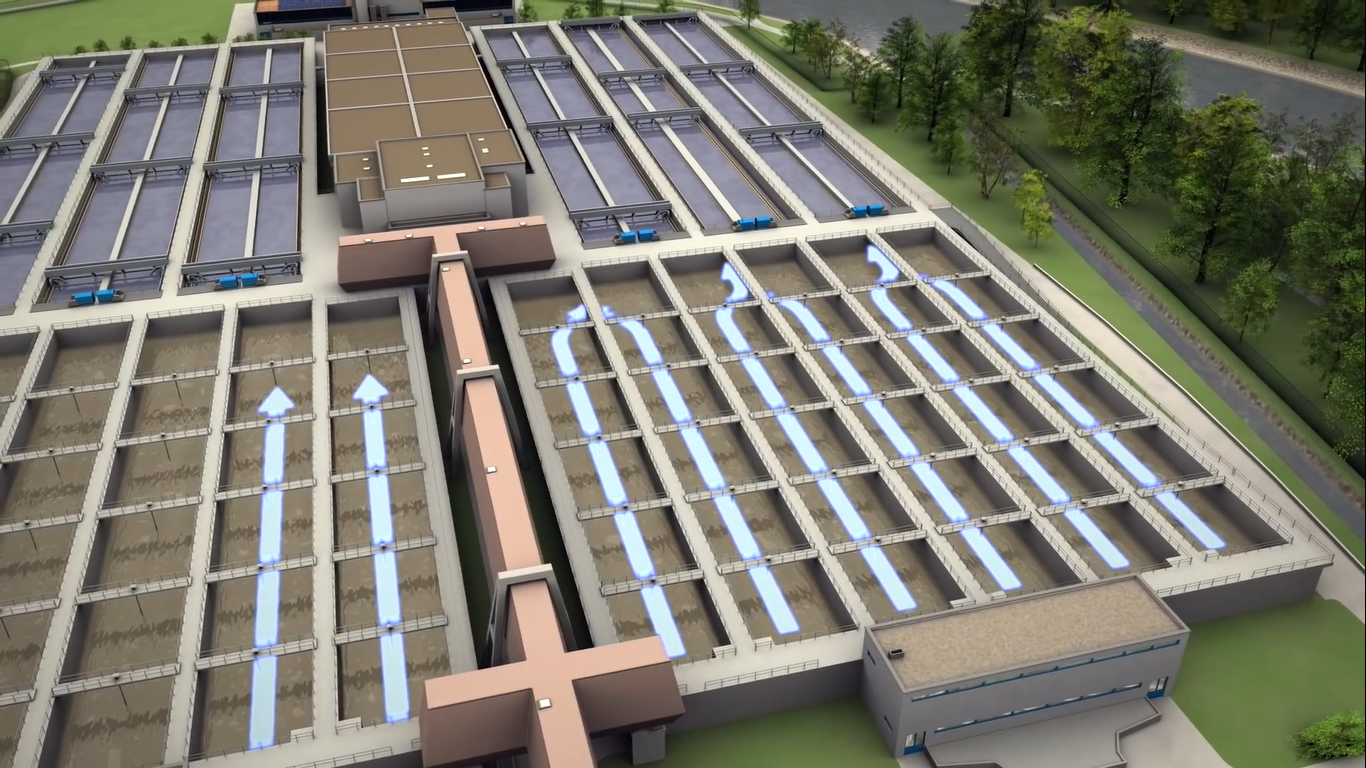

We serve more than 2 million people converting all their showers, flushes, and dirty dishwater plus the waste from countless commercial and industrial processes into water safe enough to discharge into the adjacent Canal. It all adds up to around 700 million gallons, or two and a half billion litres of sewage each day and the plant can handle nearly double that volume on peak days. There are more than enough Olympic-sized swimming pools and, in fact, aeration tanks to treat all of the sewage naturally.

Even though there are quite a few reasons you shouldn’t, however, flanking those big rectangular basins or rows of circular ponds, and smaller rectangular basins that have a simple but crucial responsibility in the process of treating wastewater. We often use chemicals, filters, and even gigantic colonies of bacteria to clean sewage on such a massive scale. But the first line of defence in the fight against dirty water is usually just gravity.

Even though there are quite a few reasons you shouldn’t, however, flanking those big rectangular basins or rows of circular ponds, and smaller rectangular basins that have a simple but crucial responsibility in the process of treating wastewater. We often use chemicals, filters, and even gigantic colonies of bacteria to clean sewage on such a massive scale. But the first line of defence in the fight against dirty water is usually just gravity.

We’re taking a deep dive into a few of the most interesting parts of converting sewage into clean water. The job of cleaning water contaminated by grit, grime and other pollutants is really a job of separation. Water gets along with nearly every substance on Earth. That’s why it’s so useful for cleaning and a major part of why it does such a good job carrying our waste away from homes and businesses in sewers, but once it reaches a wastewater treatment plant, we need to find a way to separate the water from its inhabitants wastes so it can be reused or discharged back into the environment.

Some contaminants chemically dissolve into the water and are difficult to remove at municipal scales. Others are merely suspended in the swift and turbulent flow and will readily settle out if given a moment of tranquillity. That’s the trick that wastewater treatment engineers use as the first step in cleaning wastewater.

Some contaminants chemically dissolve into the water and are difficult to remove at municipal scales. Others are merely suspended in the swift and turbulent flow and will readily settle out if given a moment of tranquillity. That’s the trick that wastewater treatment engineers use as the first step in cleaning wastewater.

Slow Down the Flow Velocity

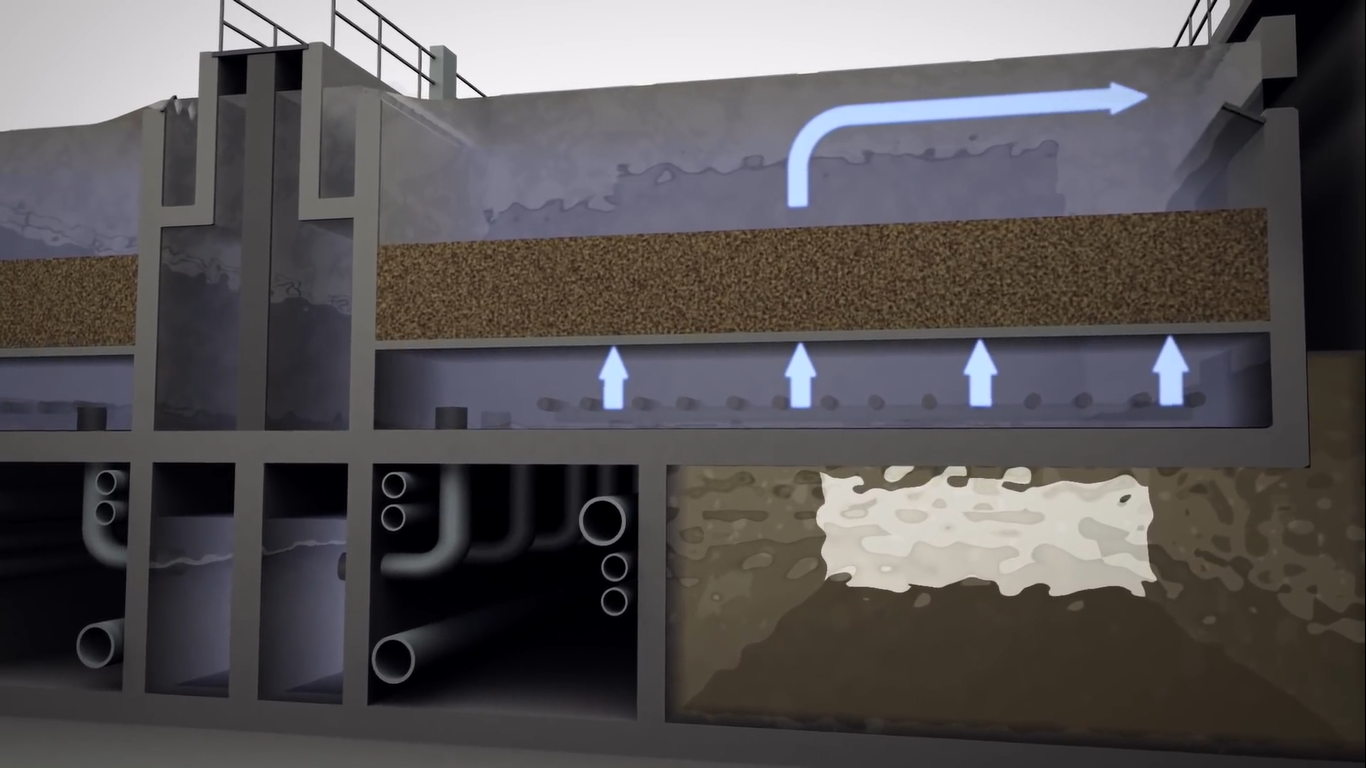

Once it passes through a screen to filter out sticks and rags. Sewage entering a wastewater treatment plants first step or primary treatment is the simple process of slowing the wastewater down to allow time for suspended solids to settle out.

How do you create such conditions from a constant stream of wastewater, you can’t tell people to stop flushing or showering to slow down the flow velocity and volumetric flow are related by a single parameter the cross-sectional area, if you increase this area without changing the flow, the velocity goes down. As a result, basins used for sedimentation are essentially just enormous expansion fittings on the end of the pipe, dramatically increasing the area of flow so the velocity falls to nearly zero. But just because the sewage stream is now still in serene doesn’t mean impurities and contaminants instantly fall to the bottom.

How do you create such conditions from a constant stream of wastewater, you can’t tell people to stop flushing or showering to slow down the flow velocity and volumetric flow are related by a single parameter the cross-sectional area, if you increase this area without changing the flow, the velocity goes down. As a result, basins used for sedimentation are essentially just enormous expansion fittings on the end of the pipe, dramatically increasing the area of flow so the velocity falls to nearly zero. But just because the sewage stream is now still in serene doesn’t mean impurities and contaminants instantly fall to the bottom.

How much time is an important question if you’re an engineer because it affects the overall size of the basin and thus it affects the cost particles falling out of suspension quickly reach a terminal velocity just like a skydiver falling from a plane that maximum speed is largely a function of each particle size. I think it’s intuitive that larger particles fall through a liquid faster than smaller ones compare me dropping a pebble to a handful of sand. The Pebble reaches the bottom in an instant while the smaller particles of sand settle out more slowly.

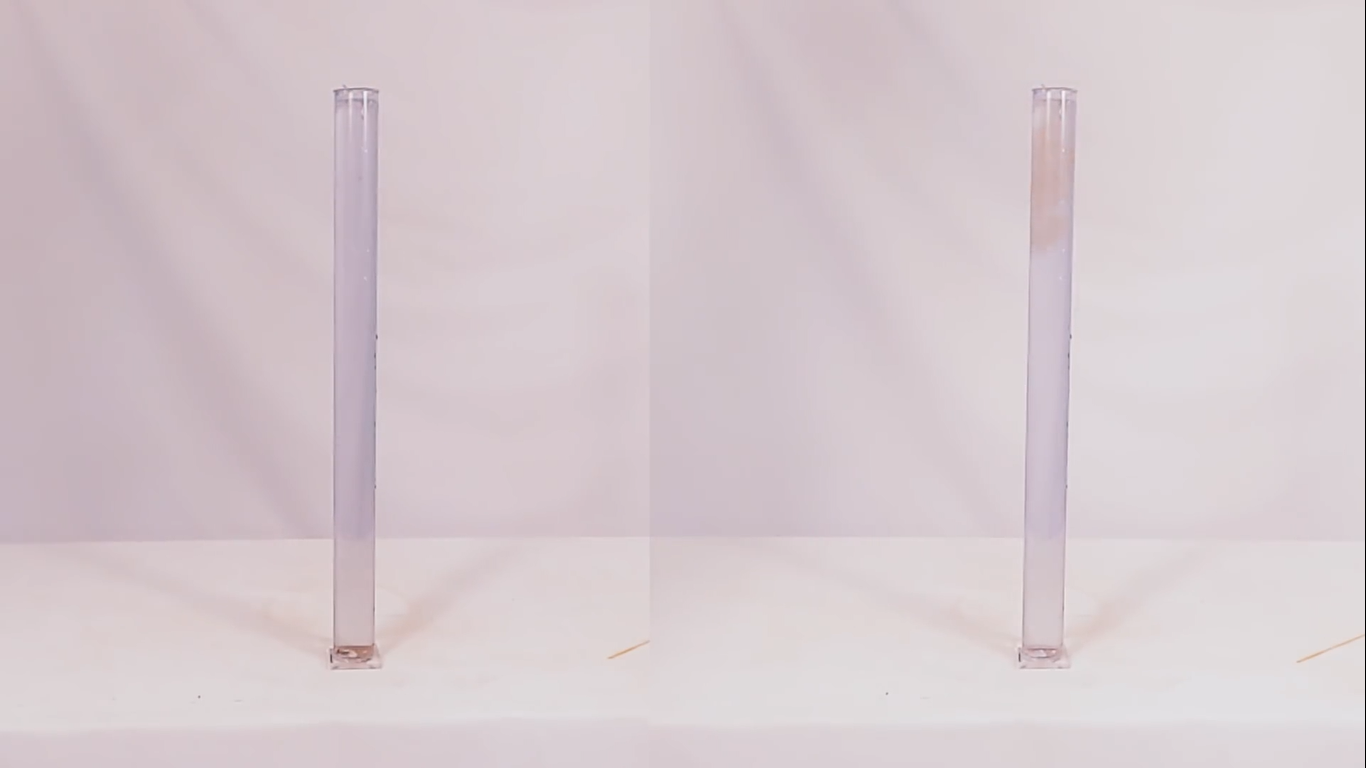

Wastewater contains a distribution of particles from very small to quite large and ideally, we want to get rid of them all. As an example, I have two colours of sand here I sifted the white sand through a fine mesh discarding the smaller particles and keeping the large ones I sifted the black sand through the same mesh this time keeping the fine particles and discarding the ones retained by the sieve. After that I combined both sins to create a grey mixture and we put it into a column of water. This length of pipe is full of clean water and I’m turning it over, so the mixture is at the top watch what happens is the sand settles to the bottom of the pipe.

Wastewater contains a distribution of particles from very small to quite large and ideally, we want to get rid of them all. As an example, I have two colours of sand here I sifted the white sand through a fine mesh discarding the smaller particles and keeping the large ones I sifted the black sand through the same mesh this time keeping the fine particles and discarding the ones retained by the sieve. After that I combined both sins to create a grey mixture and we put it into a column of water. This length of pipe is full of clean water and I’m turning it over, so the mixture is at the top watch what happens is the sand settles to the bottom of the pipe.

You can see that on the whole the white sand reaches the bottom faster while the black sand takes longer to settle. The two fractions that were previously blended together separate themselves again just from falling through a column of water. Of course, physicists to view sophisticated fluid dynamics with partial differential equations to work out the ideal settling velocity of any size of spherical particle in a perfectly We still call them with water based on streamlines viscosity, gravity and drag forces. But we civil engineers usually just drop them in water and time how quickly they fall.

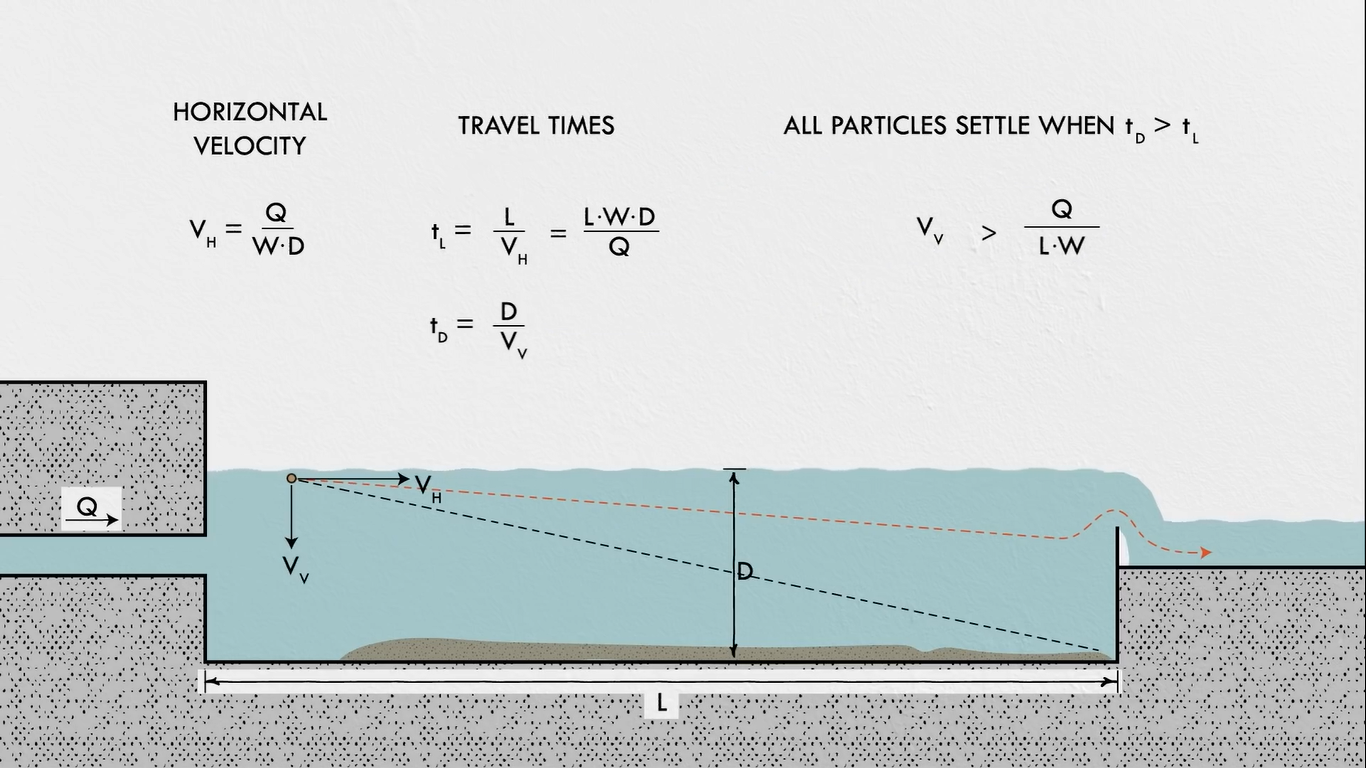

After all, there’s hardly anything ideal about a wastewater treatment plant. As water moves through a sedimentation basin, then individual particles fall downward out of suspension, they take paths like the one shown here, based on this diagram, you would assume that depth of the basin would be a key factor in whether or not a particle reaches the bottom or passes through to the other side. Let me show you why settling basins defy your intuitions with just a tiny bit of algebra, you’ve got a particle coming in on the left side of the basin, it has a vertical velocity that’s how fast it settles and the horizontal velocity. That’s how fast the water is moving through the basin. If the time it takes to fall, the distance D to the bottom is shorter than the time it takes to travel the length L of the basin, the particle will be removed from the flow.

otherwise, it will stay in suspension past the settling basin that’s what we don’t want. As I mentioned, the speed of the water is the flow rate divided by the cross-sectional flow area. That’s the basis width times its depth. Since both the time it takes for a particle to travel the length of the basin and the time it takes to settle to its bottom are a function of the basin’s depth, the term cancels out and you’re left only with the basin’s length times width.

otherwise, it will stay in suspension past the settling basin that’s what we don’t want. As I mentioned, the speed of the water is the flow rate divided by the cross-sectional flow area. That’s the basis width times its depth. Since both the time it takes for a particle to travel the length of the basin and the time it takes to settle to its bottom are a function of the basin’s depth, the term cancels out and you’re left only with the basin’s length times width.

In other words, its surface area that’s how we measure the efficiency of a sedimentation basin. Divide the flow rate coming in by the surface area and you get a speed that we call the overflow or surface loading rate. All the particles that settle faster than the overflow rate will be retained by the sedimentation basin. Regardless of its depth settlement is a cheap and efficient way to remove a large percentage of contaminants from wastewater, but it can’t remove them all.

Settlement Basins

There are a lot more steps that follow in a typical wastewater treatment plan. But in addition to being the first step of the process, settlement is also usually the last one as well. Those circular ponds are clarifiers used to settle and collect the colonies of bacteria used in the secondary treatment process. clarifiers are just settlement basins with mechanisms to automatically collect the solids as they fall to the bottom.

The water from the secondary treatment process called mixed liquor flows up through the centre of the clarifier and slowly makes its way to the outer perimeter dropping particles that form a layer of sludge at the bottom. The clarified water passes over a weir so that only a thin layer farthest from the sludge can exit the basin. A scraper pushes the sludge down the sloped bottom of the clarifier into a hopper where it can be collected for disposal.

Settlement isn’t only used for wastewater treatment; many cities use rivers and lakes as sources of fresh drinking water and these surface sources are more vulnerable to contamination than groundwater. So, they go through a water purification plant before being distributed to customers.

Settlement isn’t only used for wastewater treatment; many cities use rivers and lakes as sources of fresh drinking water and these surface sources are more vulnerable to contamination than groundwater. So, they go through a water purification plant before being distributed to customers.

Raw surface water contains suspended particles of various materials that give water a murky appearance called turbidity and can harbour dangerous micro-organisms. The first step in most drinking water treatment plans is to remove these suspended particles from the water. But unlike the larger solids in wastewater, suspended particles creating turbidity and surface water don’t readily settle out. Because of this. Most treatment plants use chemistry to speed up the process.

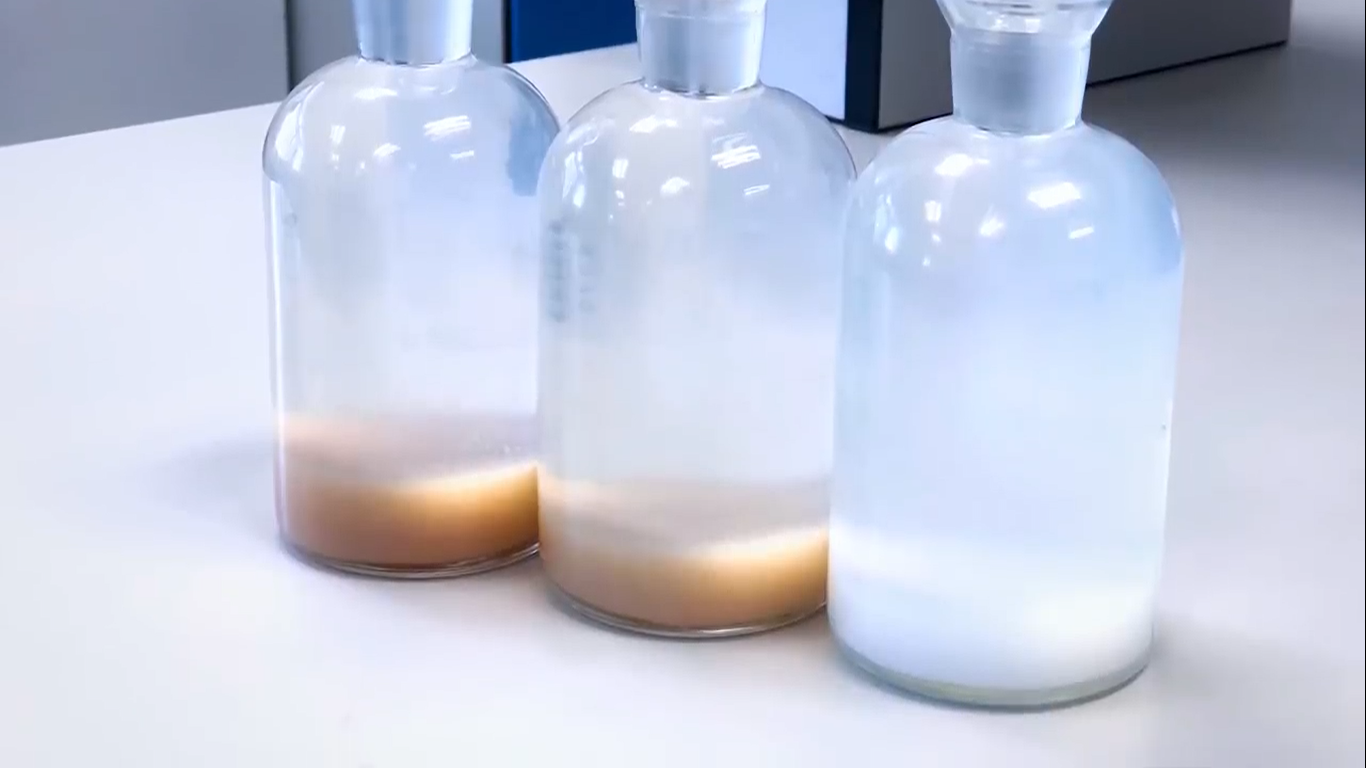

I have two bottles full of water that I vigorously mixed with dirt from my backyard one will serve as the control and the other as a demonstration. The reason these tiny soil particles remain suspended without settling is that they carry an electrical charge. Therefore, each particle repels its neighbours fighting the force of gravity and preventing them from getting too close to one another chemical coagulants neutralise the electric charges, so fine particles no longer repel one another additional chemicals called flocculants bond the particles together into clumps called flocks.

As the flocks of suspended particles grow, they eventually become heavy enough to settle out, leaving clarified water at the top of the bottle. treatment plants usually do this in two steps, a clarifier the sludge at the bottom would be pumped to a digester or some other solids handling process and the clear water would move on to filtration and disinfection before being pumped into the distribution system of the city. Our ability to clean both drinking water and wastewater at the scale of an entire city is one of the most important developments in public health.

As the flocks of suspended particles grow, they eventually become heavy enough to settle out, leaving clarified water at the top of the bottle. treatment plants usually do this in two steps, a clarifier the sludge at the bottom would be pumped to a digester or some other solids handling process and the clear water would move on to filtration and disinfection before being pumped into the distribution system of the city. Our ability to clean both drinking water and wastewater at the scale of an entire city is one of the most important developments in public health.

Sedimentation is used not only in water treatment plants but also ahead of pumping stations to protect the pumps and pipes against damage with canals to keep them from silting in fish hatcheries, mining, farming, and a whole host of other processes that create or rely on dirty water. The science of sedimentation and settlement is something that impacts Our lives in a significant way.

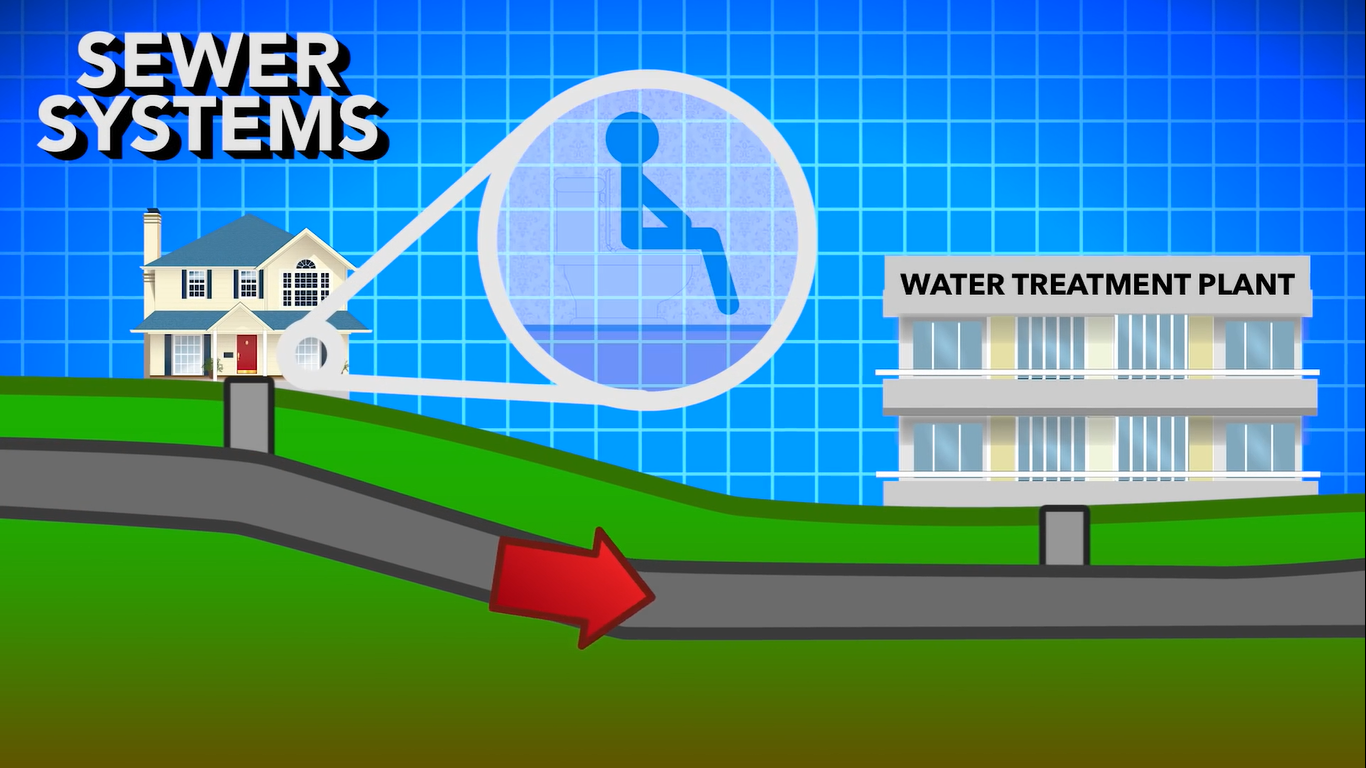

How Do Sewer Systems Work

It is the fundamental idea of physics on Earth. It is precisely 9.80665 m/s2 at sea level and has an impact on almost everything in the cosmos. Additionally, it’s how waste is transported from your toilet to the wastewater treatment facility. The miracles of contemporary infrastructure are sewer systems. Cities used to have open sewers where trash would run through unlined canals on the streets. Today, when society is much more civilised, waste is transported underground in substantial pipelines.

Modern plumbing requires sewer systems. Every time you use a sink, a toilet, or a shower. You produce liquid waste with various chemical compositions that needs to be processed and delivered. Simply flush it down the toilet to a septic tank.

We must manage our trash because it stinks in modern cities, but these tanks need upkeep and come with a variety of other problems when incorporated. It has hazardous substances that could harm the environment as well as deadly microorganisms. You are surely aware that wastewater treatment plants handle the treatment of sewage.

We must manage our trash because it stinks in modern cities, but these tanks need upkeep and come with a variety of other problems when incorporated. It has hazardous substances that could harm the environment as well as deadly microorganisms. You are surely aware that wastewater treatment plants handle the treatment of sewage.

Sewer System

In densely populated places, urban wastewater systems are required so you don’t have to deal with your neighbours. Sewer systems are totally gravity fed in ideal settings, which means that the pipes slope downward from the toilet source to the wastewater treatment facility. In an ideal sewer system, pipes from each home or building flow into a sewer main that typically runs alongside or underneath a road. Wastewater has a lot of solids in it, making it harder to pump. Wastewater also has a lot of bacteria and chemicals, and when we push it through turbulent environments like pumps, it can create dangerous and deadly gases like hydrogen sulphide.

A major area’s sewer main typically has a diameter of three to five feet, while the pipes coming from each house typically have a diameter of six to twelve inches. Every sewer main contains periodic vertical pipes that finish in manholes; these access points are spaced in accordance with local codes and are necessary in the event that a problem should occur in the sewer main, for example, if your toddler has a bad habit of flushing toys. Sewer mains will gradually flow into ever larger pipes as they amass more and more sewage until they eventually reach a wastewater treatment plant if they do this frequently enough and the toys manage to get into the main.

A major area’s sewer main typically has a diameter of three to five feet, while the pipes coming from each house typically have a diameter of six to twelve inches. Every sewer main contains periodic vertical pipes that finish in manholes; these access points are spaced in accordance with local codes and are necessary in the event that a problem should occur in the sewer main, for example, if your toddler has a bad habit of flushing toys. Sewer mains will gradually flow into ever larger pipes as they amass more and more sewage until they eventually reach a wastewater treatment plant if they do this frequently enough and the toys manage to get into the main.

These facilities are typically located in low-lying areas to make it easier for engineers to develop sewer lines. All this talk about gravity-fed sewer systems is the best-case scenario, but what happens if your home is located below the wastewater treatment facility’s elevation or if the sewage must cross a hill? The waste needs to be pressurised. This is accomplished by pumping sewage up hills using grinder pumps or lift stations.

These facilities collect sewage from lower elevations and use pumps to raise it to the necessary level so that it can continue to flow by gravity. These pumps are especially made to handle the substantial amounts of solid waste, such as flushable wipes and toilet paper. Due to their nature, these pumping locations are often at very low elevations and will probably have a small facility to house the machinery.

Additionally, these facilities are frequently located far from populated areas because of their unpleasant propensity to explode or, at the very least, to produce dangerously high levels of hydrogen sulphide because of turbulent sewage. At its core, sewer networks are made up of a few sloped piped drains that transport waste from homes to treatment facilities. Although there are occasionally pumps, gravity is the main force at action.

Additionally, these facilities are frequently located far from populated areas because of their unpleasant propensity to explode or, at the very least, to produce dangerously high levels of hydrogen sulphide because of turbulent sewage. At its core, sewer networks are made up of a few sloped piped drains that transport waste from homes to treatment facilities. Although there are occasionally pumps, gravity is the main force at action.

What Sewage Treatment and Brewing Have in Common

You probably don’t think about cellular biology when you consider civil engineers, even though we’re made of cells just like everyone else. We’re associated more with steel, concrete, and earthwork. But the engineers who designed wastewater treatment plants, and the operators who run them must know a lot about microbes. The worst part about sewage isn’t the solids they can be easily removed in settling basins. It’s not even the pathogens, dangerous organisms that can make us sick. Those can be eliminated using disinfection processes like UV light or chlorine.

The worst part about sewage is the nutrients it contains. I’m talking about organic material nitrogen, phosphorus, and other compounds. You can’t just release this stuff into a creek river or ocean because the microbes already in the destination water like bacteria and algae will respond by increasing their population beyond what the ecosystem would ever see under natural conditions. As they do they use up all the oxygen dissolved in the water, ruining the habitat, and killing fish and other wildlife. nutrient pollution is one of the most severe and challenging environmental issues worldwide.

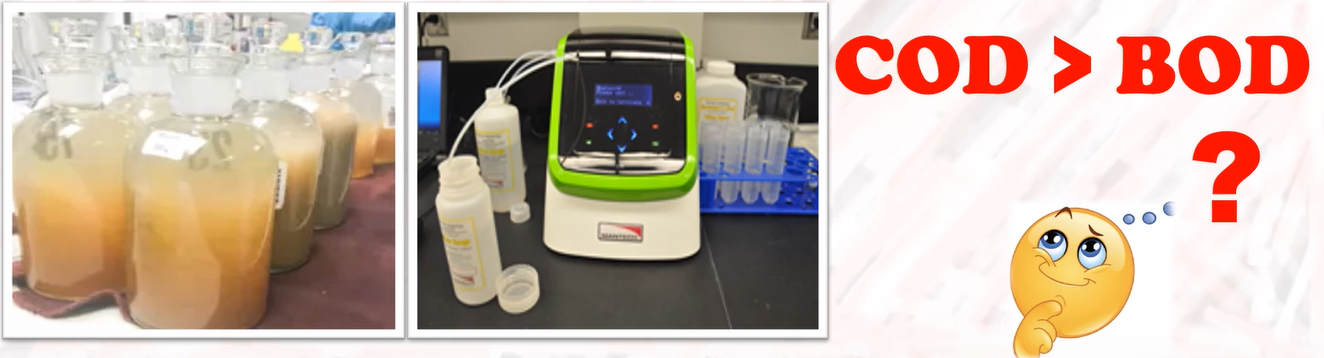

So, one of the most critical jobs wastewater plants do is clean nutrients out of the water before it can be discharged. But because they’re dissolved into solution at the molecular scale, nutrients are much harder to separate from sewage than other contaminants like domestic wastewater. Making a fermented beverage starts with a liquid full of dissolved nutrients that we want to convert into something better. In this case, the nutrients are sugars that we’re trying to convert into alcohol, I should point out that making cider is technically not brewing since there’s no heat used to extract the sugars.

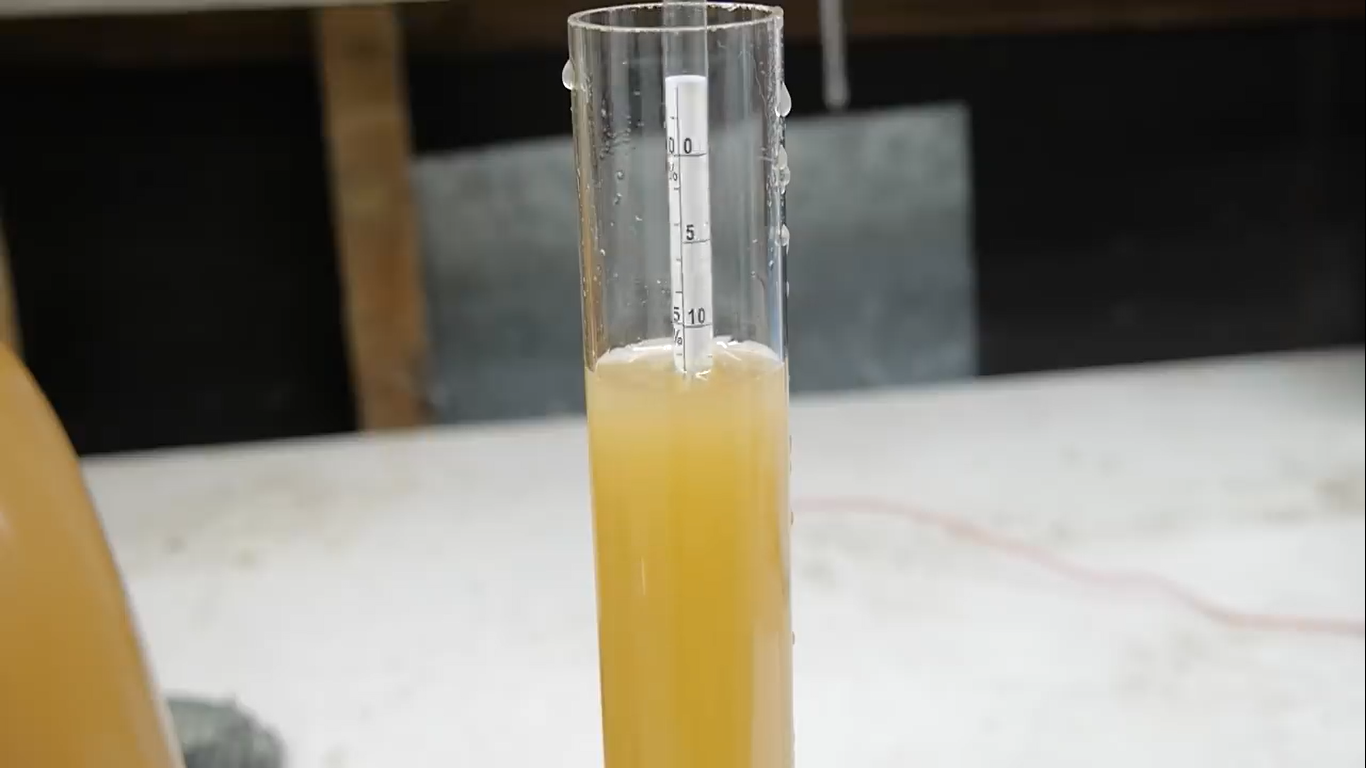

But the fermentation processes we’re talking about is the same no matter whether you’re making beer, wine or even distilled spirits. It all starts out with some kind of sugary liquid. The way we measure the nutrient concentration and brewing is pretty simple. Dissolve sugars increase the density or specific gravity of the liquid. This class tool is called a hydrometer and it floats up right when suspended in a liquid just like a ship sits a little higher in seawater than it does in freshwater a hydrometer floats to a different height depending on the density of the fluid. The more sugar the higher the hydrometer rises.

On the other hand, characterising the strength of sewage is equally as important but a little more complicated. For one not all nutrients change the density of a fluid equally, but more importantly, there are a lot more of them than just show and they can all exist at different strengths. So rather than try and separate all the complexity, we usually just measure what matters most. How much dissolved oxygen would organisms steal from the water to break down the nutrients within a sewage sample. The technical term for this is biochemical, oxygen demand, or BOD.

On the other hand, characterising the strength of sewage is equally as important but a little more complicated. For one not all nutrients change the density of a fluid equally, but more importantly, there are a lot more of them than just show and they can all exist at different strengths. So rather than try and separate all the complexity, we usually just measure what matters most. How much dissolved oxygen would organisms steal from the water to break down the nutrients within a sewage sample. The technical term for this is biochemical, oxygen demand, or BOD.

In general terms, treatment plant operators measure the amount of oxygen dissolved in a sewage sample before setting it aside for a five-day period. During that time critters in the sample will eat up some of the nutrients robbing the dissolved oxygen as they do. The difference in oxygen before and after the five days is the BOD. Once you know your initial concentration of nutrients, whether sugars or other stuff, you can work on a way to get them out of there.

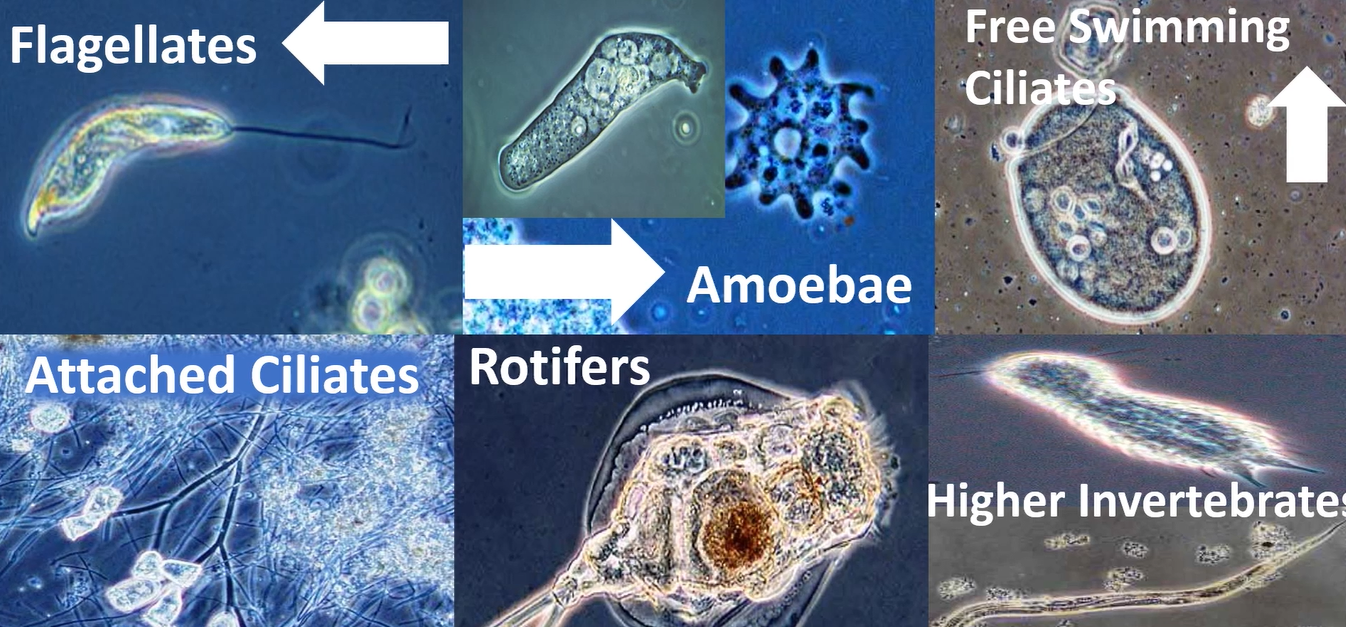

In both sewage and brewing we expropriate tiny biological buddies for this purpose. In other words, we use them to our advantage. Wastewater treatment plants rely primarily on bacteria with some protozoa as well.

In both sewage and brewing we expropriate tiny biological buddies for this purpose. In other words, we use them to our advantage. Wastewater treatment plants rely primarily on bacteria with some protozoa as well.

There is a myriad of secondary treatment processes used around the world, but one is more common than all the rest, and it has the best name to activated sludge.

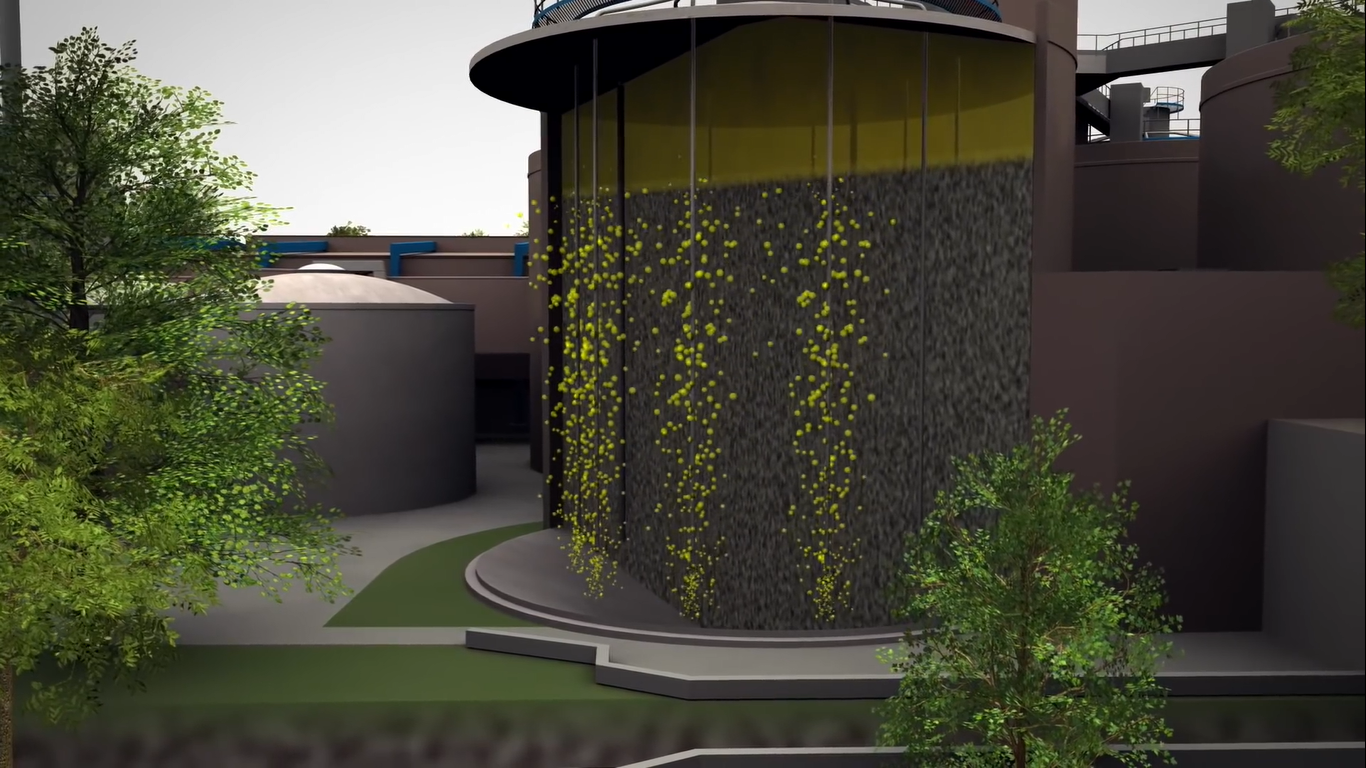

After the primary treatment of removing solids from the flow wastewater passes into large basins where enormous colonies of microorganisms are allowed to thrive. At the bottom of the basins are diffusers that bubble prodigious quantities of air up through the sewage dissolving as much oxygen as possible into the liquid and maximising the microorganism’s capacity to consume organic material.

After the primary treatment of removing solids from the flow wastewater passes into large basins where enormous colonies of microorganisms are allowed to thrive. At the bottom of the basins are diffusers that bubble prodigious quantities of air up through the sewage dissolving as much oxygen as possible into the liquid and maximising the microorganism’s capacity to consume organic material.

This combination of wastewater and biological mass is known as mixed liquor. But that’s just a coincidence in this case. Either way, you don’t want to be drinking too much.

Fermentation of an alcoholic beverage. The process where sugars are converted to ethanol works a little bit differently. First, the microorganisms doing the work in fermentation are yeast. These are single celled organisms from the fungus kingdom in some way similar but in many ways quite unlike the bacteria and protozoa in a wastewater treatment plant.

In fact, brewers work hard to keep equipment clean and sanitised so that bacteria can’t colonise the brew the foam you see in the carbo it before I filled it with apple juice is a no rinse sanitizer meant to kill unwanted microorganisms before pitching the one on ones in the yeast themselves will even take advantage of the antimicrobial effects of the very ethanol they produce.

Another difference between the processes is air except at the very beginning when the yeast is first expanding their population fermentation is an anaerobic process. That means it happens in the absence of oxygen, a wastewater treatment plant adds a year to speed up the process. However, yeast exposed to oxygen stop producing alcohol, so the vessel is usually sealed to minimise the chances of that the bubbles you see are carbon dioxide that the yeast creates in addition to the ethanol, an airlock device lets the carbon dioxide vent so it can’t build up pressure without letting airborne contaminants inside.

As the sugars are converted and CO2 gas leaves the vessel the density of the liquid drops and that change can be measured using hydrometer. My cider started at a specific gravity of 1.06 and fermented down to 1.0, meaning it has an alcohol content of around 8% by volume. However, just like the outflow from an activated sludge basin, it’s not quite ready to drink.

As the sugars are converted and CO2 gas leaves the vessel the density of the liquid drops and that change can be measured using hydrometer. My cider started at a specific gravity of 1.06 and fermented down to 1.0, meaning it has an alcohol content of around 8% by volume. However, just like the outflow from an activated sludge basin, it’s not quite ready to drink.

Once the microorganisms have done their job and the liquid is nearly free of nutrients or sugars, you need to get them out in both brewing and wastewater treatment that usually happens through settling but the basics are pretty simple. Most solid particles including microorganisms are denser than water and thus will sink but they sink slowly so you have to keep the liquid still for this type of separation to work well.

Wastewater treatment plants use settling tanks called clarifiers that send the mixed liquor slowly from the centre outward so that it drops the sludge of microorganisms to the bottom as it does leave clear effluent to pass over a weir around the perimeter to leave the tank. Similarly, you can see a nice layer of mostly dead yeast on the bottom of my fermentation vessel typically called the leaves or Trump homebrewers use a process called racking which is just syphoning the liquid from the fermentation vessel while leaving the solids behind.

Wastewater treatment plants use settling tanks called clarifiers that send the mixed liquor slowly from the centre outward so that it drops the sludge of microorganisms to the bottom as it does leave clear effluent to pass over a weir around the perimeter to leave the tank. Similarly, you can see a nice layer of mostly dead yeast on the bottom of my fermentation vessel typically called the leaves or Trump homebrewers use a process called racking which is just syphoning the liquid from the fermentation vessel while leaving the solids behind.

In both cases, these microorganisms are not all dead. That’s where the activated in activated sludge comes from a rotating arm and the clarifier pushes the sludge to a centre hopper. From there it’s collected and returned to the aeration chamber to see the next colony that will treat new wastewater entering the tanks.

Of course, not all that sludge is needed so the rest must be discarded creating a whole separate waste disposal challenge. Similarly, the yeast at the bottom of my fermenter is not all dead and can be reused and another batch. commercial breweries and home brewers alike often use yeast repeatedly. However, they mutate quickly because of their short lifetime so the flavour can do leftover time

However, there are some final tests that may be wanted or needed in both cases. It doesn’t make it taste any different, but it does look a lot nicer. Like the finishing steps of homebrewing. Many wastewater plants use tertiary treatment processes to target other pollutants the bugs couldn’t get. Depending on where the effluent is going. standards might require more purification, then primary and secondary treatment can achieve on their own. In fact, wastewater treatment plants have been experiencing a relatively dramatic shift over the past few decades as they treat sewage less like a waste product and more like an asset.

After all, raw sewage is 99.9% water and water are a valuable resource to cities and places with water scarcity. It can be cost effective to treat municipal wastewater beyond what would typically be required so that it can be reused instead of discarded. A few places across the world have potable reuse, also known as toilet, to tap or sewage is clean drinking water quality standards and reintroduced to the distribution system. However, most recycled water isn’t meant for human consumption. Plenty of uses don’t require potable water including industrial processes and the irrigation of golf courses, athletic fields, and parks.

After all, raw sewage is 99.9% water and water are a valuable resource to cities and places with water scarcity. It can be cost effective to treat municipal wastewater beyond what would typically be required so that it can be reused instead of discarded. A few places across the world have potable reuse, also known as toilet, to tap or sewage is clean drinking water quality standards and reintroduced to the distribution system. However, most recycled water isn’t meant for human consumption. Plenty of uses don’t require potable water including industrial processes and the irrigation of golf courses, athletic fields, and parks.

As a result of pumping effluent to customers who can utilise it rather than releasing it into a stream or river, many wastewater treatment facilities are now referred to as water reclamation facilities, thereby lessening demands on the potable water supply. Purple pipes are used in several nations to designate non-potable water delivery systems, assisting in the prevention of cross connections. You may occasionally encounter warnings like this one to keep people healthy.

How We Track COVID-19 (And Other Weird Stuff) In Sewage

How We Track COVID-19 (And Other Weird Stuff) In Sewage

When the COVID 19 pandemic was just getting started in early 2020, every major city state health department and federal agency involved built out data dashboards you could access online to check case counts and trends. Public health officials could constantly be heard asking everyone to flatten the curve, that curve being a graph of infection rates over time.

By and large our measure the pandemic came through individual case count confirmed with laboratory testing and reported to a data Clearinghouse like the local public health department, there was a lot of confusion about testing positivity rates, how that information applied to the greater population, and how could be used to implement measures to slow the spread of disease.

The limitations of individual testing data, including test shortages, reporting delays and unequal access to health care made public health decisions extremely challenging. Much of the controversy surrounding mask mandates and stay at home orders was provoked by the disconnect between what we could reliably measure and the reality of the pandemic on the ground public health officials were constantly on the lookout for more indicators that could help inform decisions and manage the spread of disease.

One of these measures didn’t really show up in the online data dashboards, but it was and continues to be used as a broad measure of infection rates and cities. It’s a topic that combines public health, epidemiology and infrastructure that didn’t get much coverage in the news and they’re both some interesting privacy implications, and some really fascinating applications on the horizon. we’re talking about wastewater surveillance for public health.

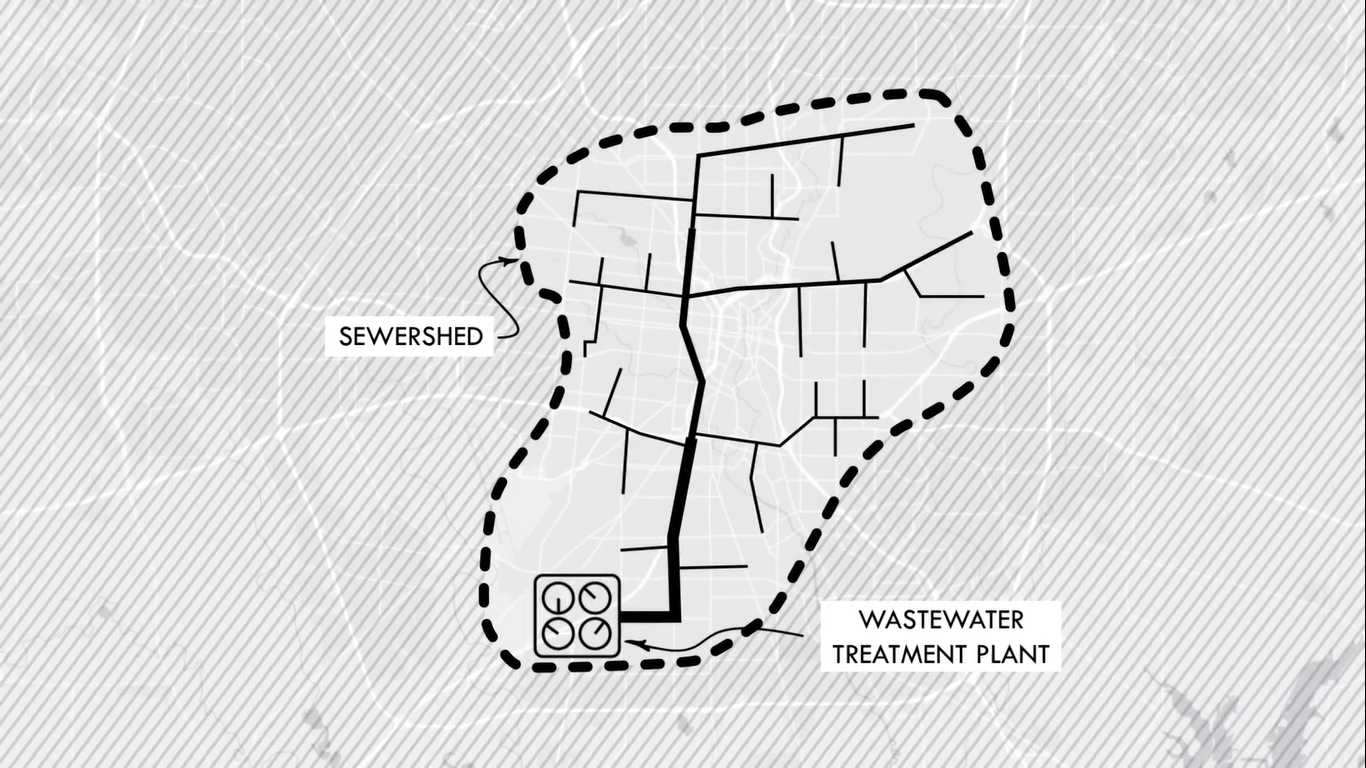

Wastewater flows in sewers primarily via gravity combining and concentrating as it continues to a treatment plant where a number of processes are used to rid it of concomitant contaminants so it can be reused or discharged back into the environment. Just like a watershed is an area of land that drains to a specific part of a river or stream.

Wastewater flows in sewers primarily via gravity combining and concentrating as it continues to a treatment plant where a number of processes are used to rid it of concomitant contaminants so it can be reused or discharged back into the environment. Just like a watershed is an area of land that drains to a specific part of a river or stream.

A sewer shed isn’t an outhouse but an area of a city that drains to a specific wastewater treatment plant. The largest sewer sheds can include hundreds of 1000s, or even millions of people all whose waste flows to a single facility designed to clean it up.

Wastewater treatment plants regularly collect samples of incoming sewage to characterise various constituents and their strengths. After all, you must know what’s in the wastewater to track whether or not it’s been sufficiently removed at the other end of the plant. In the early days of sewage treatment sampling consisted only of measuring the basic contaminants such as nutrients and suspended solids.

Wastewater treatment plants regularly collect samples of incoming sewage to characterise various constituents and their strengths. After all, you must know what’s in the wastewater to track whether or not it’s been sufficiently removed at the other end of the plant. In the early days of sewage treatment sampling consisted only of measuring the basic contaminants such as nutrients and suspended solids.

Contaminants of Emerging Concern

But as our testing capabilities increased, it slowly became easier and less expensive to measure other impurities, sometimes known as contaminants of emerging concern. These included pharmaceuticals, pesticides, personal care products, and even illicit drugs. It didn’t take too long to realise that tracking these contaminants was not only a tool for wastewater treatment, but also a source of information about the community within the sewer shed, the gathering of which is a notoriously difficult challenge in the field of public health, rather than coordinating expensive and arduous survey campaigns where many people aren’t always truthful anyway, or going through the hoops of privacy laws to gather information from health care providers, we can just take a sample of sludge from the bottom of a clarifier send it off to a lab and roughly characterise in hours or days, the dietary habits, pharmaceutical use, and even cocaine consumption of a specific population of people.

If you’re a public health researcher or public official, that is a remarkable capability. To quote one of the research papers I read wastewater is a treasure trove of biological and chemical information. Think about all the stuff that gets washed down the drain, and all the things you consume that might create unique metabolites that find their way out the other side of your excretory system. Other wastewater surveillance is a relatively new field of study. We’re already able to measure licit and illicit drugs, cleaning, and personal care products and even markers of stress, mental health, and diet. That’s a lot of useful information that can be used to monitor public health, but one wastewater constituent took centre stage starting in early 2020.

Of course, for decades, we’ve tracked pathogens and wastewater to make sure they aren’t released into the environment and treatment plan effluent, but the COVID-19 pandemic created a vacuum of information on virus concentrations that had never been experienced before.

We realised early in the pandemic that the SARS-CoV-2 virus is shed in the faeces of most infected people. Even before widespread tests for the virus were available. Many public health agencies were sampling the wastewater in their communities to track the changes in infection rates over time.

Realising the importance of coordinating all these separate efforts, many countries created national tracking systems to standardise the collection and reporting of virus concentrations and sewage. In the US the CDC launched the National wastewater surveillance system in September of 2020.

Realising the importance of coordinating all these separate efforts, many countries created national tracking systems to standardise the collection and reporting of virus concentrations and sewage. In the US the CDC launched the National wastewater surveillance system in September of 2020.

Individual communities can collect and test wastewater for SARS-CoV-2 and then submit the data to the CDC for a process called normalisation virus concentrations go up and down with infections, but they also go up and down with dilution from non-sewage flows and changes in population. For example, in sewer sheds with large event venues or seasonal tourism normalisation helps correct for these factors so that comparisons of virus load between and among communities is more meaningful.

Benefits from Tracking COVID-19

There are some serious benefits from tracking COVID-19 infections using wastewater surveillance. It’s a nonintrusive way to monitor health that’s relatively impartial to differences in access to health care, or even whether infections are symptomatic or not. Next, it is orders of magnitude less expensive than testing individuals nearly 80% of US households are served by a municipal wastewater collection system. So, you can get a much more comprehensive picture of a population for just the cost of a laboratory test.

It can also provide an earlier indicator of changes in community wide infection rates. Individual tests can have delays and myths asymptomatic infections and hospitalisation counts come well after the onset of infection. So, wastewater Surveillance can provide the first clue of a COVID-19 spike sometimes by several days.

Finally, now the vaccination programmes are widespread and there is significantly less testing being carried out wastewater surveillance is a great tool to keep an eye out for a resurgence in COVID 19 infections, and it can even be used to monitor for new variants. Of course, wastewater surveillance has some limitations to the biggest one being accuracy, the science is still relatively new and there are lots of confounding variables to keep in mind.

In addition to changes in dilution from other wastewater flows, and sewer shed population mentioned before, the quantity of viruses shed vary significantly between individuals, and even over the course of any one infection. Wastewater surveillance just isn’t accurate enough to provide a count of infected individuals within a population. So, it’s mostly useful in tracking whether infections are increasing or decreasing, and by what magnitude.

There are also some ethical considerations to keep in mind that term surveillance should at least prick up your ears a little bit. Monitoring the constituents in wastewater at the treatment plant averages the conditions for a large population. But what if samples were taken from a lift station that serves a single apartment complex school or office building? What if a sample was taken from a manhole on the street right outside your house? Could the police department use the data to deploy more officers to neighbourhoods where illicit drugs are found in the sewage? Could a city or utility provider sell wastewater data to private companies for use in research or advertising? That’s a lot of hypotheticals.

But I wouldn’t be surprised to see a black mirror episode where some tech company provides free trash and sewer service just to collect and sell the data from each household. If you wanted to open a new coffee shop, how much would you pay to learn which parts of town have the highest concentrations of caffeine and the sewage? Maybe it would be called brown mirror.

But I wouldn’t be surprised to see a black mirror episode where some tech company provides free trash and sewer service just to collect and sell the data from each household. If you wanted to open a new coffee shop, how much would you pay to learn which parts of town have the highest concentrations of caffeine and the sewage? Maybe it would be called brown mirror.

The truth is that public health professionals have put a tremendous amount of thought into the ethics and privacy concerns of wastewater surveillance. But as with any new field of science, there’s still a lot of questions to be answered.

The truth is that public health professionals have put a tremendous amount of thought into the ethics and privacy concerns of wastewater surveillance. But as with any new field of science, there’s still a lot of questions to be answered.

One of those questions is what comes next in this burgeoning field of wastewater surveillance, where public health researchers have access to a literal stream of data. There are many measures of public health that can be valuable to policymakers and health officials, including stress levels, changes in mental health and the prevalence of antimicrobial resistant bacteria one of the greatest human health challenges of our time. Of course, all the work that went into standardising and building out capabilities of tracking infections will certainly give us a leg up on resurgences of COVID-19 or any future new virus heaven forbid.

We might soon see infection rates of the various diseases that spread through community populations to help individuals, planners and public officials make better informed decisions about our health.

We might soon see infection rates of the various diseases that spread through community populations to help individuals, planners and public officials make better informed decisions about our health.

Sewers were one of the earliest and most impactful advocates of public health in urban areas and it’s exciting that we’re still finding new ways to use them to that in wastewater surveillance requires a whole bunch of technical fields combining engineering public health and epidemiology. I think one of the easiest shortcuts to success is finding opportunities to mix and match areas of expertise like this.

How Sewers Work

In addition to being a contemporary comfort, sewage selection systems are one of the most important pillars of public health in urban areas. Humans are kind of gross; as a species, we consistently produce trash that, if not properly disposed of, poses a pestilential and plague hazard to city people. Sewers turn that metaphorical stream into a real one that moves underground, out of sight and presumably out of scent. The logistics of moving so much crap from point A to point B present many difficulties and the fact that we primarily do it mentally.

As simple as sticking a pipe in the ground and directing it toward the closest wastewater treatment facility. Like many other engineering tasks, designing sanitary sewage lines is more difficult than it first appears. Subsurface pipe installation is a disruptive and expensive process, made more difficult by the fact that the pipes are so closely connected to underground utilities and roads.

As simple as sticking a pipe in the ground and directing it toward the closest wastewater treatment facility. Like many other engineering tasks, designing sanitary sewage lines is more difficult than it first appears. Subsurface pipe installation is a disruptive and expensive process, made more difficult by the fact that the pipes are so closely connected to underground utilities and roads.

If we’re going to install or replace them, it will be worth the work and expense. Speaking of decades, sewers need to be planned not just for the current conditions but also for the growth and changes that will occur to the city over time. We need to make sure that these lines will be there and continue to function efficiently for many decades. Sewers must be sized appropriately because more people typically produce more wastewater.

If we’re going to install or replace them, it will be worth the work and expense. Speaking of decades, sewers need to be planned not just for the current conditions but also for the growth and changes that will occur to the city over time. We need to make sure that these lines will be there and continue to function efficiently for many decades. Sewers must be sized appropriately because more people typically produce more wastewater.

The upsizing in that instance was forced. Last but not least, these lines transport some terrible material that we do not want to leak into the ground or, God forbid, into the water supply, whose lines are nearly always close.

All of this is to imply that the risks are great for the engineers, designers, and builders who construct our sewers. Understanding the expected amount is one of the first steps in building a sewage collecting system. There are several published studies and standards for calculating average and peak wastewater flows based on population and land use.

However, counting the flushes alone does not provide the full picture. Although the majority of sanitary systems are isolated from storm drains, which remove rainwater and snowmelt, precipitation can still enter the sewage system. For one simple reason, the inflow and infiltration I refer to in the businesses i&i are the enemies of utility providers. Rainfall entering sewers through open manholes, gaps in pipes, and other openings can exceed the system’s capacity during storms.

When compared to a major downpour, the famous super flush that occurs during the Super Bowl halftime is often a drop in the bucket. Overflows caused by i&i might expose people to raw sewage and cause environmental issues. Therefore, utilities work to minimise this i&i as much as they can through system upkeep, and sewer engineers work to consider it when determining the system capacity.

When compared to a major downpour, the famous super flush that occurs during the Super Bowl halftime is often a drop in the bucket. Overflows caused by i&i might expose people to raw sewage and cause environmental issues. Therefore, utilities work to minimise this i&i as much as they can through system upkeep, and sewer engineers work to consider it when determining the system capacity.

You must design pipes to manage the anticipated amount of sewage once you know it. It’s a common misconception that a civil engineer just considers friction and gravity. You can hazard a guess as to which of those causes faeces to roll downhill. It is true that the majority of sewage collection systems depend on gravity to collect and move waste.

We don’t have to pay a gravity bill, so this is convenient. It is completely free. The fact that gravity only operates in one direction—down—comes with an asterisk, though, like most free things do. More than any other issue, this fact imposes limitations on the layout and building of contemporary sewer systems. We’ll look at the factors engineers take into account when developing these systems as I construct some demonstrations in the garage to show you how I’m pushing a slurry of sand and water through this clear pipe that serves as a sewer.

We don’t have to pay a gravity bill, so this is convenient. It is completely free. The fact that gravity only operates in one direction—down—comes with an asterisk, though, like most free things do. More than any other issue, this fact imposes limitations on the layout and building of contemporary sewer systems. We’ll look at the factors engineers take into account when developing these systems as I construct some demonstrations in the garage to show you how I’m pushing a slurry of sand and water through this clear pipe that serves as a sewer.

The flow of a sewer line needs to be managed in some way. It shouldn’t move too quickly so as to harm the pipe’s joints or walls. However, it can’t move too slowly, or you run the risk of solids settling out of suspension and gradually accumulating. To achieve this balance, gravity cannot be raised or lowered. Additionally, since individuals flush when they flush, we have no control over the flow of wastewater. The sewer pipe’s size and slope are the only factors that engineers can manage.

Examine what transpires when the slope is too steep. Solids are allowed to settle on the bottom because the water travels too slowly. The solids accumulate over time and lower the pipe’s capacity. Without enough slope, they might even fully jam pipelines, necessitating frequent and expensive maintenance from work crews. to maintain clean lines. Watch what happens if I change the line’s slope without adjusting the flow rate: the water will go at a faster rate.

Examine what transpires when the slope is too steep. Solids are allowed to settle on the bottom because the water travels too slowly. The solids accumulate over time and lower the pipe’s capacity. Without enough slope, they might even fully jam pipelines, necessitating frequent and expensive maintenance from work crews. to maintain clean lines. Watch what happens if I change the line’s slope without adjusting the flow rate: the water will go at a faster rate.

This enables the water to scour away the solids that have previously settled out while also allowing solids to remain in suspension. The self-cleaning velocity, which must be maintained at a minimum speed to ensure that the line remains clear, is explained in the demonstration. Although this can change, the majority of towns demand that a sewer pipe’s flow be at least three feet or one metre per second.

This enables the water to scour away the solids that have previously settled out while also allowing solids to remain in suspension. The self-cleaning velocity, which must be maintained at a minimum speed to ensure that the line remains clear, is explained in the demonstration. Although this can change, the majority of towns demand that a sewer pipe’s flow be at least three feet or one metre per second.

Sand has been used up to this point to represent the typical solids that might be present in a wastewater stream. We are, happily, only scraping the surface of synthetic human waste, which may interest you to know. There are numerous intriguing recipes published in the academic literature for safe and realistic standards for excrement, which are frequently required by laboratories conducting research on urban sanitation, wastewater treatment, and even life support systems in space. The slope of a sewer pipe must take into account the slope of the ground above it in addition to the necessary range of flow velocities.

The sewer may come too close to the surface and lose its protection from the soil above if the slope is too shallow relative to the surrounding area. The sewer may eventually sink too far below the surface if the slope is excessively steep relative to the surrounding terrain. Although it is expensive, digging deep excavations to install sewer pipes is not impossible. To prevent the trench from collapsing above a particular depth, you must lay back the slopes of the trench.

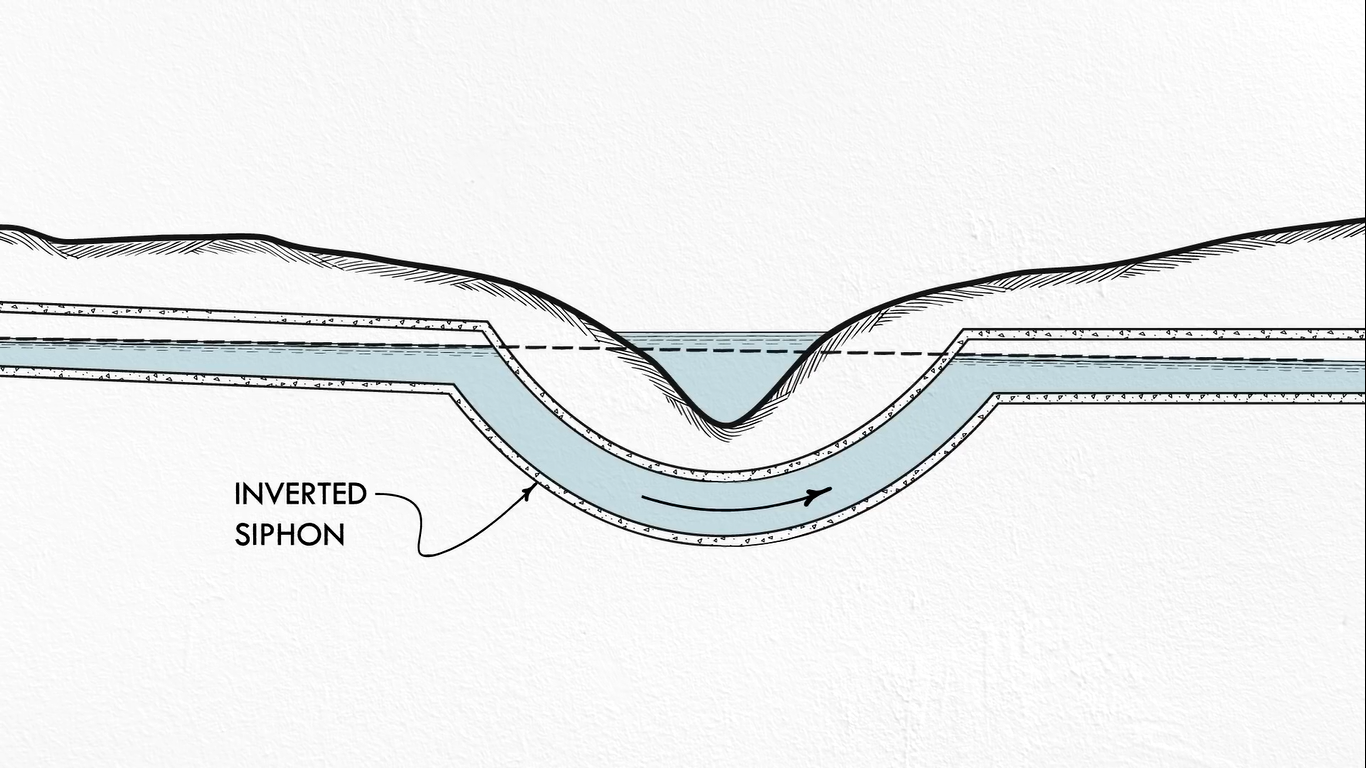

In places like cities where that’s impossible. Instead, temporary shoring must be installed to hold the walls open while construction is taking place. All of this is to indicate that by picking a slope for a sewer that is either too shallow or too steep, you are adding to the problems already there. Getting across a creek or river is another topographic difficulty faced by sewage engineers; typically, it is not financially advantageous to lower a complete sewer line or raise its slope to remain below a natural waterway.

In places like cities where that’s impossible. Instead, temporary shoring must be installed to hold the walls open while construction is taking place. All of this is to indicate that by picking a slope for a sewer that is either too shallow or too steep, you are adding to the problems already there. Getting across a creek or river is another topographic difficulty faced by sewage engineers; typically, it is not financially advantageous to lower a complete sewer line or raise its slope to remain below a natural waterway.

We can install a structure known as an inverted syphon in these circumstances. This enables a section of the line to descend beneath a depressed geographical feature, such as a river or creek, and then rise again on the opposite side. The pipe contains the flow below the surface, while the hydraulic grade line, an imaginary line that represents the fluid’s surface, rises above the ground’s surface. The issue with inverted syphons is that the flow velocity decreases as they fill up. Solids will so likely settle out more frequently. Something that is particularly difficult to do on a structure with constrained maintenance access.

It’s comparable to the pea or being stuck behind your sink where everything seems to get stuck. Observe how settling only takes place within the syphon, despite the pipe being the same size throughout. Inverted syphons frequently divide the flow into numerous smaller pipes to address this problem. The self-cleaning limit is maintained by doing this. Smaller pipes naturally have a lower capacity, which is one of the reasons syphons sometimes have two or three. You can see that even while some settling is taking place, it isn’t getting worse over time since the flow velocity in the smaller syphons is sufficient to keep the majority of the solids in suspension.

It’s comparable to the pea or being stuck behind your sink where everything seems to get stuck. Observe how settling only takes place within the syphon, despite the pipe being the same size throughout. Inverted syphons frequently divide the flow into numerous smaller pipes to address this problem. The self-cleaning limit is maintained by doing this. Smaller pipes naturally have a lower capacity, which is one of the reasons syphons sometimes have two or three. You can see that even while some settling is taking place, it isn’t getting worse over time since the flow velocity in the smaller syphons is sufficient to keep the majority of the solids in suspension.

Engineers encounter a variety of difficulties in addition to the volume and hydraulics of wastewater movement. Thankfully, there are no wastewater police watching what you flushed down the toilet because sewers are naturally anarchic places. However, this implies that sewers frequently find themselves transporting-or at least attempting to-substances and objects for which they were not intended. Since they congeal at room temperature, fat and oil have historically been the most heinous of these invaders.

For example, grease and fat combined with wet wipes and sewers to form disturbing but aptly termed fat, Burke’s filthy conglomerates, which, among other things, are not easily carried through sanitary sewage lines, has only made the problem worse as flushable wipes become more and more popular. This is a wet wipe that is designated as flushable, and this is how rapidly toilet paper decomposes when stirred in a mixer.

You can understand the issues this would create given that solid trash can normally be removed without flushing, but this is often done using trucks rather than pipes in most places across the world. Clearly, this problem is more intricate than my small test. The classification of white people has given rise to a complex debate that is beyond the scope of this article.

You can understand the issues this would create given that solid trash can normally be removed without flushing, but this is often done using trucks rather than pipes in most places across the world. Clearly, this problem is more intricate than my small test. The classification of white people has given rise to a complex debate that is beyond the scope of this article.

How does a Sewage Treatment Plant Work

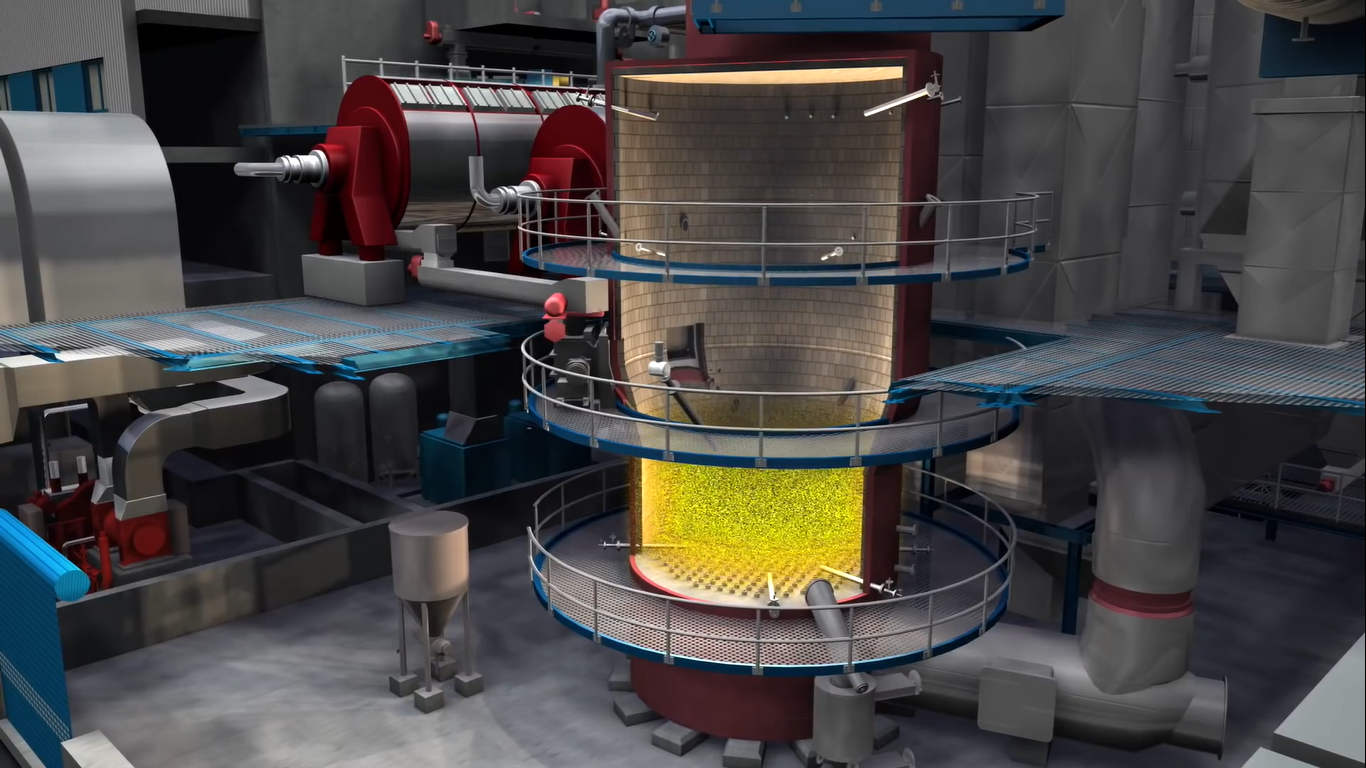

After heavy rainfalls, the flow in the plant rises to six cubic metres, or 35 filled bathtubs per second. This adds up to 70 to 80 million cubic metres of wastewater per year which nearly equals the load of a super tanker per day. The water is in the plant for around 19 hours where it undergoes various treatment stages.

- Mechanical treatment,

- Biological treatment,

- Sedimentation,

- Ozonation.

- Filtration