Importance of Machine Learning for Desalination Plants in Artificial Intelligence Usage

Importance of Machine Learning for Desalination Plants in Artificial Intelligence Usage

Desalination plants play a critical role in ensuring water security by converting saline water into freshwater. However, these systems are energy-intensive and complex to operate efficiently. Machine Learning (ML), a subset of Artificial Intelligence, offers robust solutions to optimize processes, reduce costs, enhance reliability, and maintain water quality. By learning patterns from data and making predictions or decisions without explicit programming, ML enables a transition from reactive to proactive, data-driven operations.

1. Predictive Maintenance and Fault Detection

Challenges:

– Unexpected equipment failure

– High repair and downtime costs

– Inefficient maintenance schedules

ML Solutions:

– Supervised learning to classify and predict failure modes

– Anomaly detection in sensor data

– Predicting Remaining Useful Life (RUL) for components like membranes and pumps

Benefits:

– Fewer unplanned outages

– Optimized maintenance intervals

– Reduced spare part costs and downtime

2. Energy Optimization

Challenges:

– High energy consumption (up to 50% of total OPEX)

– Variable energy efficiency due to input conditions

ML Solutions:

– Predicting optimal pump speeds and pressures

– Adjusting operations to minimize energy per unit of water produced

– Real-time optimization based on historical and current data

Benefits:

– 10–20% reduction in energy use

– Enhanced energy planning and integration with renewables

– Lower operational costs and emissions

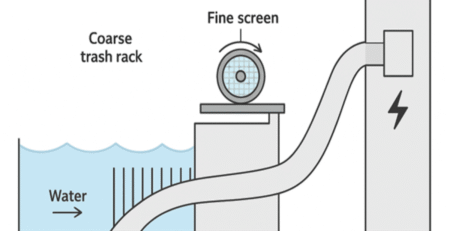

3. Membrane Fouling Prediction and Management

Challenges:

– Decreased performance due to fouling and scaling

– High cleaning and replacement frequency

ML Solutions:

– Classification of fouling types

– Predictive models for fouling events based on pressure drop, conductivity, and flow data

– Optimized cleaning schedules

Benefits:

– Extended membrane life

– Reduced chemical use

– Improved process continuity

4. Water Quality Prediction and Assurance

Challenges:

– Variability in feedwater and risk of non-compliance

– Delays in lab testing

ML Solutions:

– Time-series models to forecast feedwater quality changes

– Predicting treated water parameters (e.g., TDS, pH)

– Real-time alerts for potential quality breaches

Benefits:

– Consistent water output quality

– Automated quality assurance

– Faster decision-making

5. Dynamic Process Control and Optimization

Challenges:

– Fixed control logic cannot adapt to real-time changes

– Difficulty managing complex multivariate systems

ML Solutions:

– Reinforcement learning for adaptive control strategies

– Model Predictive Control (MPC) for multi-variable systems

– Self-learning control loops

Benefits:

– Better recovery rates

– Greater stability

– Reduction in manual tuning and interventions

6. Forecasting and Strategic Planning

Challenges:

– Inaccurate water demand forecasts

– Poor planning of maintenance and upgrades

ML Solutions:

– Demand forecasting using historical and environmental data

– Brine and chemical usage predictions

– Lifecycle planning for assets

Benefits:

– Better resource allocation

– Improved infrastructure planning

– Lower operational risk

7. Integration with Digital Twins and IoT

Challenges:

– Lack of system-wide visibility

– Difficulty validating operational decisions

ML Solutions:

– Powering digital twins with ML models

– Continuous simulation and optimization

– Automated learning from IoT sensor data

Benefits:

– Risk-free experimentation

– Holistic process optimization

– Real-time decision support

8. Environmental Impact Reduction

Challenges:

– Environmental concerns about brine discharge

– Carbon emissions from high energy use

ML Solutions:

– Predicting brine impact and salinity patterns

– CO₂ emissions estimation models

– Optimization for minimal environmental load

Benefits:

– Better environmental compliance

– Sustainability performance tracking

– Improved stakeholder confidence

Conclusion

Machine Learning is becoming an essential tool for modern desalination plants, enabling them to transition from traditional reactive models to intelligent, predictive systems. From optimizing energy use and membrane performance to ensuring water quality and environmental compliance, ML empowers plant operators with actionable insights and automation capabilities. Embracing machine learning is key to making desalination sustainable, resilient, and economically viable for future water needs.