How IoT and Artificial Intelligence, Prevent Theft, Robbery, and Leaks in Crude Oil Pipeline Supply Systems

How IoT and Artificial Intelligence, Prevent Theft, Robbery, and Leaks in Crude Oil Pipeline Supply Systems

1. Introduction

Crude oil pipeline networks are vital infrastructure, transporting millions of barrels of oil daily across vast distances. However, they face significant risks such as:

- Oil theft (illegal tapping, bunkering)

- Robbery (siphoning from terminals or tankers)

- Leaks (from corrosion, mechanical failure, sabotage)

Traditionally managed via manual patrols and SCADA systems, modern pipeline operators now rely heavily on IoT and AI-based technologies to ensure real-time threat detection, prevent losses, and improve response time.

2. Nature of Threats

| Threat Type | Description |

| Theft | Illegal tapping of pipelines using concealed valves or hoses |

| Robbery | Direct siphoning from tanks, terminals, or transport vehicles |

| Leaks | Due to corrosion, aging, sabotage, or operational errors |

| Tampering | Intentional alteration of sensor data or mechanical damage to avoid detection |

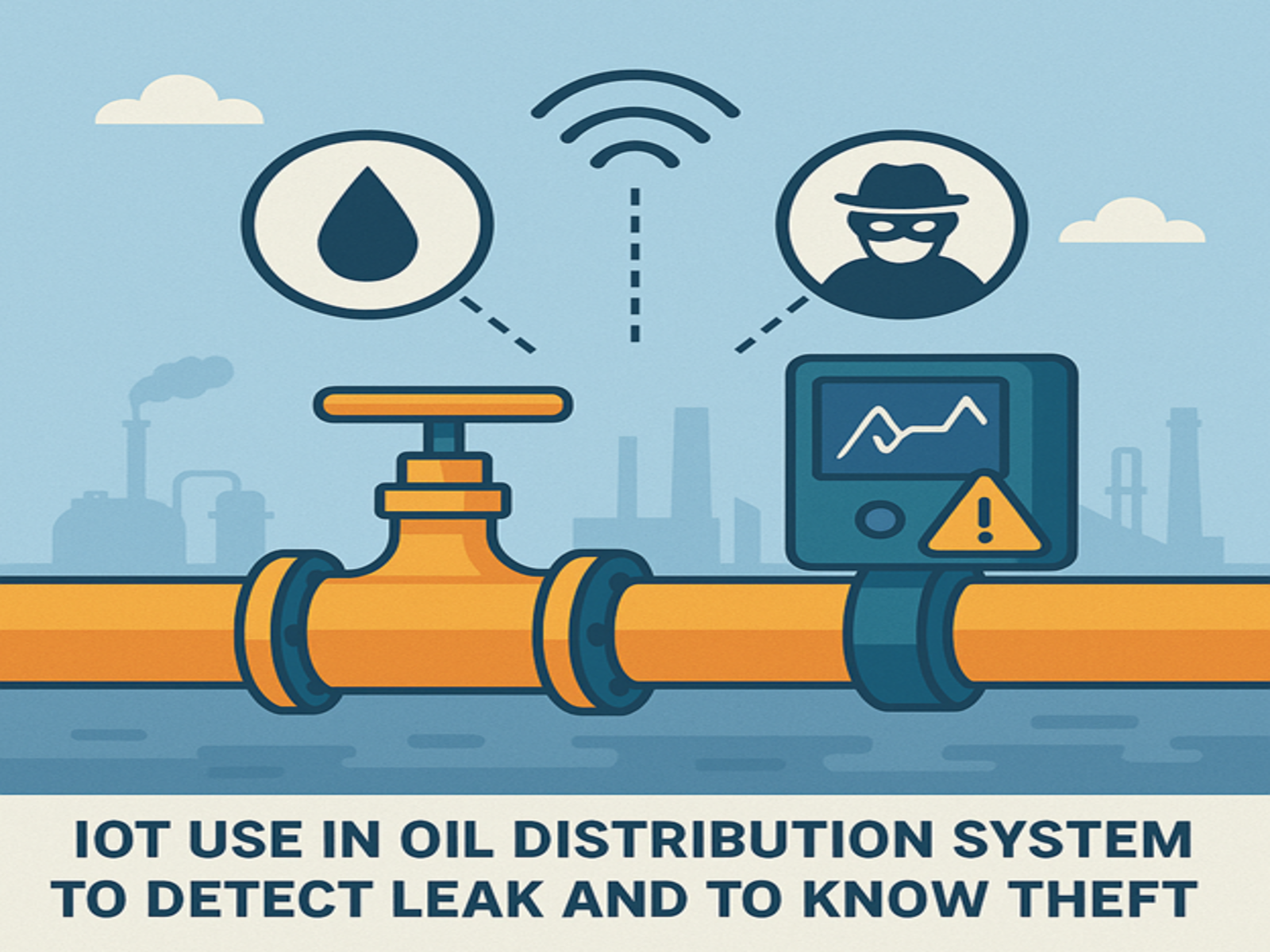

3. Role of IoT in Threat Prevention

IoT involves embedding smart, connected sensors and devices across the pipeline and distribution system. These sensors collect and transmit real-time data to a central control system for analysis and decision-making.

3.1. Sensor Types and Functions

| Sensor Type | Function |

| Pressure sensors | Detect sudden drops from illegal tapping or leaks |

| Flow meters | Detect inconsistencies between inlet and outlet volumes |

| Acoustic/vibration sensors | Detect sound/vibration signatures from mechanical tampering or tapping |

| Temperature sensors | Monitor crude temperature variations due to leaks or sabotage |

| Gas/hydrocarbon detectors | Detect presence of escaped crude or vapors (VOC, H₂S, CH₄) |

| Motion sensors & thermal cameras | Detect unauthorized movement along the Right of Way (ROW) |

| GPS trackers | Monitor vehicle/tanker movement for diversion or theft |

| Strain gauges/fiber optics | Detect structural stress or bending of underground pipes |

| Tamper detection sensors | Alert when enclosures or valves are forced open |

4. Role of AI in Threat Detection and Prevention

AI enables systems to:

- Interpret sensor data in real time

- Detect anomalies

- Predict failure or attack patterns

- Automate responses

4.1 AI Capabilities

A. Anomaly Detection

- AI continuously compares real-time data with historical baselines.

- Flags:

- Sudden flow drops

- Pressure surges

- Unusual sound patterns

- Suspicious vehicle or human activity near pipeline

B. Predictive Maintenance

- AI uses machine learning models trained on:

- Vibration patterns

- Corrosion rates

- Temperature cycles

- Equipment runtime data

- This predicts the most likely failure points before leaks occur.

C. Intrusion Detection (AI Vision & ML)

- AI analyzes camera feeds and drone footage to:

- Identify unauthorized individuals or equipment

- Recognize facial patterns or license plates

- Detect anomalies in heat signatures using thermal imaging

D. Behavioral Pattern Analysis

- Tracks movement of field personnel and equipment using IoT tags.

- Detects deviations from authorized paths, time windows, or activities.

5. Integrated Theft and Leak Prevention System Architecture

5.1 Functional Layers

| Layer | Description |

| Sensing Layer | Embedded smart sensors along the pipeline and terminals |

| Communication Layer | Wireless (LoRaWAN, NB-IoT), fiber optics, or satellite data transmission |

| Edge Computing Layer | Local decision-making, filtering, and response (e.g., shut-off valve actuation) |

| AI Platform Layer | Cloud-based analytics for anomaly detection, predictions, and reporting |

| Application Layer | User dashboards, alerts, maps, and automated maintenance scheduling |

5.2 Response Workflow (Example: Theft Detection)

- Pressure drop is detected between segment A and B

- Acoustic sensor confirms foreign mechanical noise

- Thermal camera spots activity at GPS-tagged ROW point

- AI dashboard flags a theft attempt and sends:

- SMS/email alerts to security

- Live drone feed to control center

- Smart valve shuts pipeline section

- Event logged to blockchain for tamper-proof evidence

6. IoT/AI Use Cases

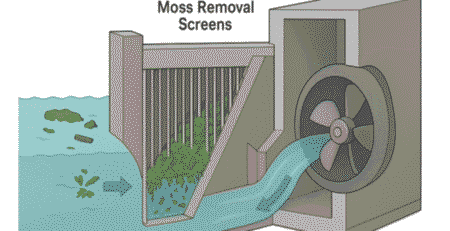

6.1 Leak Prevention in Corrosion-Prone Zones

- IoT corrosion probes monitor internal wall thickness.

- AI models predict corrosion trends based on chemical composition and pressure.

- High-risk segments are proactively scheduled for repair.

6.2 Smart Surveillance with Drones

- Drones fly daily routes over vulnerable areas.

- AI analyzes drone video feeds to:

- Detect illegal activities

- Track excavation or tampering

- Trigger alarms automatically

6.3 Theft at Distribution Terminals

- IoT-connected tank gauges compare dispatched and received volumes.

- AI reconciles data from:

- SCADA systems

- Gate access logs

- Vehicle GPS records

- Discrepancies flagged as theft attempts.

7. Blockchain for Data Integrity

To prevent tampering of logs or theft reports:

- All sensor data is timestamped and logged to a blockchain ledger.

- Each transaction (valve open, pressure drop, camera alert) is immutable.

- Ensures traceability and audit compliance for:

- Insurance claims

- Environmental penalties

- Legal investigations

8. Benefits Summary

| Benefit | Description |

| 24/7 Automated Monitoring | Constant sensor vigilance without human fatigue |

| Real-time Alerts | Instant notifications reduce damage and response time |

| Predictive Capabilities | Prevent failures before they occur |

| Physical Security | Detect unauthorized personnel, equipment, or activity |

| Data Integrity | Blockchain prevents data manipulation or hiding |

| Centralized Control | Remote visibility and command from centralized dashboards |

| Regulatory Compliance | Easy reporting and auditing for safety/environmental agencies |

9. Challenges and Solutions

| Challenge | Solution |

| Remote Area Connectivity | Use LoRaWAN, NB-IoT, or satellite links |

| Powering Devices in Isolation | Solar + battery-powered sensor nodes |

| Cybersecurity | Encryption, firewalls, AI-based intrusion detection |

| Data Overload | Edge computing filters unnecessary data locally |

| Integration with Legacy SCADA | IoT-SCADA bridges and OPC-UA protocol adapters |

10. Conclusion

IoT and AI offer unprecedented capabilities to monitor, analyze, and secure oil pipeline infrastructure. By enabling real-time detection of theft, leakage, and tampering, they reduce losses, prevent environmental disasters, and improve system reliability. As pipeline systems grow more complex and risks increase, integrating these technologies is no longer optional—it is essential for resilient and sustainable oil distribution systems.

📎 Optional Add-ons

- Process Flow Diagram: Showing sensor placement, data flow, AI response.

- Dashboard UI Mockups: For monitoring, alerts, drone feeds.

- Case Studies: Nigeria, India, and the US have reported dramatic theft reduction using these systems.