Sludge Drying Equipment: An Innovative Solution to Manage Industrial Waste

Sludge, the semi-solid by product of wastewater treatment processes, is a significant challenge for industries worldwide. Disposing of this waste material has become an environmental and economic concern, especially in industries that generate massive volumes of sludge. Fortunately, sludge drying equipment has emerged as a promising solution to reduce the moisture content of sludge, making it easier to manage and dispose of. In this article, we will explore the advantages of sludge drying equipment and how it can benefit different industries.

What is sludge drying equipment?

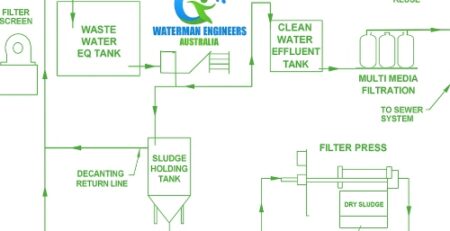

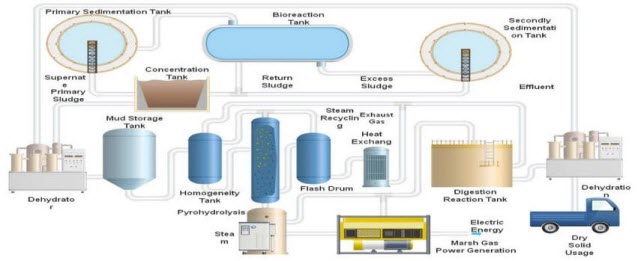

Sludge drying equipment is a system used to reduce the moisture content of sludge generated by industrial and municipal wastewater treatment processes.

It is necessary for industries to manage sludge because it is a by product of their manufacturing and production processes, and it can be harmful to the environment if not disposed of properly. Disposing of sludge in landfills or bodies of water can cause contamination, harm wildlife, and contribute to climate change. Proper management of sludge can also save costs associated with transportation, disposal, and potential fines for non-compliance with environmental regulations.

The need for sludge drying equipment

The need for sludge drying equipment is driven by several factors, including environmental concerns, economic considerations, and legal requirements.

Environmental concerns arise because sludge contains organic matter, pathogens, and other contaminants that can be harmful to the environment if not disposed of properly. Landfilling sludge can lead to groundwater contamination, and discharging it into waterways can cause eutrophication, the process of depleting oxygen levels in water, which can harm aquatic life.

Economic considerations come into play because sludge disposal can be costly, and businesses may face fines for non-compliance with environmental regulations. Sludge drying equipment can help reduce disposal costs by reducing the volume of sludge, making it easier and cheaper to transport and dispose of.

Legal requirements mandate that businesses dispose of sludge according to environmental regulations, which can include limits on the types and amounts of contaminants that can be discharged. Failure to comply with these regulations can result in fines and other penalties. Sludge drying equipment can help businesses meet these regulations by reducing the volume and moisture content of sludge, making it easier to handle and dispose of.

Types of sludge drying equipment

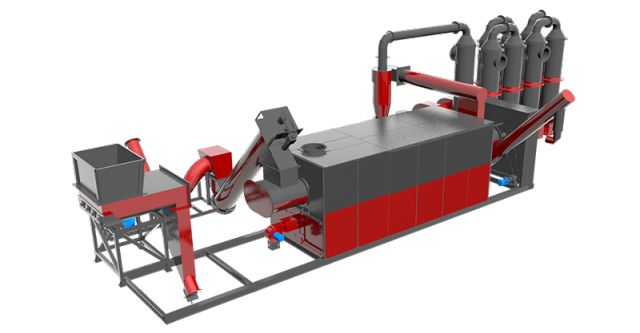

There are several types of sludge drying equipment available, each with its own advantages and disadvantages. The most common types of sludge dryers include:

- Direct sludge dryers: In this type of dryer, hot air is directly applied to the sludge to evaporate the moisture content. This can be achieved through various means, such as fluidized bed dryers, drum dryers, and belt dryers. Direct sludge dryers are efficient and have a relatively low operating cost, but they require a lot of energy to produce the hot air, and they can produce emissions.

- Indirect sludge dryers: Indirect dryers use a heat transfer medium, such as steam or hot oil, to transfer heat to the sludge. This is a gentler drying process that can result in higher-quality dried sludge. Indirect dryers are more expensive to operate than direct dryers but can be more energy-efficient in some cases.

- Solar sludge dryers: These dryers use the energy from the sun to dry the sludge. They are typically used in areas with a lot of sunshine and can be a cost-effective and environmentally-friendly way to dry sludge. However, they can be less effective in areas with low sunshine, and the drying process can be slow.

- Thermal sludge dryers: These dryers use a combination of direct and indirect heating to dry the sludge. They are typically used for high-volume sludge drying and can be very efficient. However, they are also very expensive to operate and require a lot of maintenance.

The type of sludge dryer used depends on several factors, such as the volume of sludge, the moisture content, and the available resources.

Advantages of sludge drying equipment

Sludge drying equipment offers several advantages over traditional methods of sludge disposal. These advantages include:

- Reduced sludge volume: Drying sludge reduces its volume, making it easier and cheaper to transport and dispose of. This can also reduce the environmental impact of sludge disposal by reducing the amount of space needed for landfilling.

- Efficient use of space: Sludge drying equipment can be designed to fit into small spaces, making it easier for businesses to manage their sludge on-site. This can save costs associated with transporting sludge to off-site facilities for disposal.

- Energy savings: Sludge drying equipment can be designed to use waste heat or other renewable energy sources, reducing energy costs and environmental impact. This can be a cost-effective way to dry sludge while also reducing greenhouse gas emissions.

- Reduced odour: Sludge drying equipment can reduce the odour associated with wet sludge, making it more pleasant to handle and transport. This can improve working conditions for employees and reduce complaints from neighbouring residents.

- Reduced transportation costs: Drying sludge reduces its weight and volume, making it cheaper and easier to transport. This can save businesses money on transportation costs and reduce their carbon footprint.

Overall, sludge drying equipment can be a cost-effective and environmentally-friendly way to manage sludge generated by industrial and municipal wastewater treatment processes. By reducing volume, improving handling, and using renewable energy sources, businesses can save money while also reducing their environmental impact.

Applications of sludge drying equipment

Sludge drying equipment has a wide range of applications in various industries. Some of the industries that commonly use sludge drying equipment include:

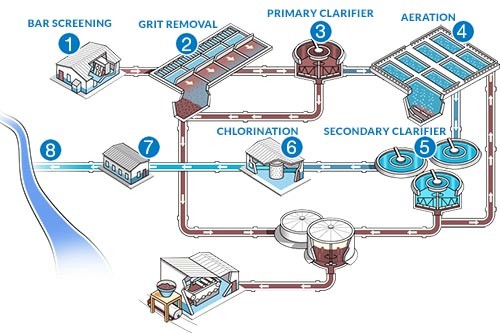

- Municipal wastewater treatment plants: Sludge drying equipment is commonly used in municipal wastewater treatment plants to dry the sludge generated during the treatment process. This makes it easier and more cost-effective to dispose of the sludge.

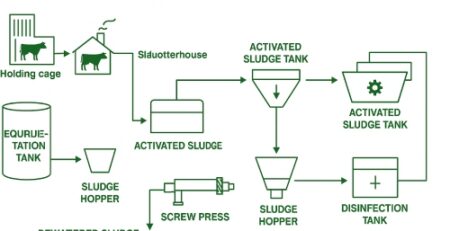

- Food processing industries: Food processing industries generate a large amount of sludge during their production process. Sludge drying equipment can be used to dry this sludge and convert it into a useful product, such as animal feed.

- Chemical and pharmaceutical industries: Chemical and pharmaceutical industries generate hazardous sludge that needs to be treated and disposed of safely. Sludge drying equipment can be used to dry this sludge and reduce its volume, making it easier and safer to transport and dispose of.

- Paper and pulp industries: Paper and pulp industries generate a large amount of sludge during their production process. Sludge drying equipment can be used to dry this sludge and convert it into a useful product, such as fuel.

- Mining and mineral processing industries: Mining and mineral processing industries generate a large amount of sludge during their production process. Sludge drying equipment can be used to dry this sludge and convert it into a useful product, such as fertilizer.

Overall, sludge drying equipment has a wide range of applications and can be used in any industry that generates sludge. By using sludge drying equipment, businesses can reduce their environmental impact and save money on sludge disposal costs.

Factors to consider when selecting sludge drying equipment

Selecting the right sludge drying equipment is critical for efficient and cost-effective sludge management. Here are some of the factors that should be considered when selecting sludge drying equipment:

- Sludge characteristics: The characteristics of the sludge being processed are important when selecting the right sludge drying equipment. Factors such as the moisture content, particle size, and chemical composition of the sludge should be considered when choosing a dryer.

- Type of dryer: There are several types of sludge dryers available, each with its own advantages and disadvantages. Direct dryers, indirect dryers, solar dryers, and thermal dryers are some of the most common types of dryers used in sludge drying. The type of dryer selected should be based on the specific needs and requirements of the business.

- Energy efficiency: Energy efficiency is an important factor to consider when selecting sludge drying equipment. The equipment should be designed to use energy as efficiently as possible to minimize operating costs.

- Maintenance requirements: Maintenance requirements are another important consideration when selecting sludge drying equipment. The equipment should be easy to maintain and repair to minimize downtime and maximize efficiency.

By considering these factors, businesses can select the most suitable sludge drying equipment for their specific needs and requirements. This can help to optimize sludge management and reduce operating costs over the long term.

How to optimize the performance of sludge drying equipment?

Optimizing the performance of sludge drying equipment is essential for ensuring efficient and effective sludge management. Here are some ways to optimize the performance of sludge drying equipment:

- Regular maintenance: Regular maintenance is crucial for ensuring that sludge drying equipment operates efficiently and effectively. This includes tasks such as cleaning, lubricating, and replacing worn parts. It is also important to inspect the equipment regularly to identify and address any potential issues before they become major problems.

- Proper operation and control: Proper operation and control of sludge drying equipment are essential for optimizing its performance. This includes setting and monitoring temperature, humidity, and air flow rates. Operators should also be trained in proper operation and maintenance techniques to ensure that the equipment is used correctly.

- Monitoring and troubleshooting: Monitoring the performance of sludge drying equipment is important for identifying and addressing issues quickly. This can include monitoring temperature and humidity levels, as well as the quality of the dried sludge. Troubleshooting techniques should also be employed to identify and resolve any problems that arise.

By following these tips, businesses can optimize the performance of their sludge drying equipment, resulting in more efficient and effective sludge management. This can help to reduce operating costs and minimize the environmental impact of sludge disposal.

Challenges and limitations of sludge drying equipment

While sludge drying equipment offers several advantages, there are also some challenges and limitations that need to be considered. Here are some of the most significant challenges and limitations of sludge drying equipment:

- Equipment cost: Sludge drying equipment can be expensive, and the initial investment cost can be a barrier for many businesses. Additionally, maintenance costs can add up over time, particularly if the equipment is not properly maintained.

- Energy consumption: Sludge drying equipment requires a significant amount of energy to operate, particularly if the sludge has a high moisture content. This can result in high operating costs, and the use of non-renewable energy sources can contribute to greenhouse gas emissions.

- High moisture content of some sludge types: Some types of sludge may have a high moisture content, which can make it difficult to dry using conventional methods. This can limit the effectiveness of sludge drying equipment, particularly if the equipment is not designed to handle high-moisture sludge.

- Technical expertise required: Sludge drying equipment requires a certain level of technical expertise to operate effectively. This includes knowledge of equipment operation, maintenance, and troubleshooting. Without this expertise, equipment performance may suffer, and equipment may not operate efficiently.

By understanding the challenges and limitations of sludge dewatering equipment, businesses can make informed decisions about whether this technology is right for their needs. While there are some limitations to sludge drying equipment, the benefits it offers can make it a valuable investment for many industries.

Conclusion

Sludge drying equipment has emerged as a viable solution for industries to manage their waste effectively. By reducing the moisture content of sludge, it becomes easier to handle and dispose of, reducing the environmental impact and saving on costs. However, selecting the right equipment and maintaining it properly is essential for achieving optimal results.

FAQs

Q: What is sludge drying equipment?

A: Sludge drying equipment is a system used to reduce the moisture content of sludge generated by industrial and municipal wastewater treatment processes.

Q: What are the benefits of using sludge drying equipment?

A: Sludge drying equipment reduces the volume of sludge, saves energy, reduces odor, and transportation costs, among other benefits.

Q: What are the different types of sludge drying equipment?

A: The different types of sludge drying equipment include direct sludge dryers, indirect sludge dryers, solar sludge dryers, and thermal sludge dryers.

Q: What are the factors to consider when selecting sludge drying equipment?

A: The factors to consider when selecting sludge drying equipment include sludge characteristics, dryer type, energy efficiency, and maintenance requirements.

Q: What are the limitations of sludge drying equipment?

A: The limitations of sludge drying equipment include high energy consumption, high equipment cost, and technical expertise required for optimal performance.