The Environmental Impact of Zero Liquid Discharge Systems

In oil & gas, chemical, petrochemical, mining and power industries, there is a need to manage large volumes of wastewater. Commonly, this waste is discharged to a surface water body, an evaporation pond or to a wastewater treatment plant.

Increasingly strict regulations on wastewater disposal and company mandated green initiatives have driven industrial users to explore the use of Zero Liquid Discharge Systems. While they have a high initial cost, this approach can help to conserve water resources while avoiding environmental pollution associated with wastewater discharge.

Water Reuse

Water reuse is an important component of a sustainable, efficient water management system. It helps close the loop between wastewater treatment and water supply, and offers significant environmental benefits by decreasing water diversion from or discharging to sensitive ecosystems and reducing pollution. It also has the potential to significantly expand supplies of freshwater in communities facing water shortages.

Reclaimed water can be used for agricultural and landscape irrigation, industrial processes, nonpotable urban applications (such as toilet flushing, street washing, and fire protection), groundwater recharge, recreation, and direct or undirected water supply. Depending on the application, reclaimed water may be treated to meet “fit-for-purpose” specifications that ensure public health, environmental protection, or specific end-user needs.

These systems are based on a series of advanced wastewater treatment technologies that remove biodegradable materials, nutrients, pathogens, and solids from wastewater before reusing it for a variety of purposes. Reclaimed water is regulated by local, state, and federal regulations.

In the United States, there are over 50 potable water reuse systems, mostly centered in coastal areas. These systems provide a cost-effective, reliable source of supplemental water for potable water demands.

However, reclaimed water can contain harmful organic micro-contaminants that may be ingested or absorbed by humans and animals in the process of use. This can cause adverse health effects and should be addressed when reclaimed water is used for potable purposes.

Zero Liquid Discharge Systems eliminate the discharge of liquid from wastewater by concentrating the dissolved salts and chemicals in a specialized process. By minimizing the volume of wastewater entering the main flow of water, ZLD reduces the energy required for treatment and minimizes greenhouse gas emissions.

Zero liquid discharge has become an increasingly common process for reclaimed water treatment, and the number of facilities that have ZLD systems continues to increase. Despite the numerous benefits of this technology, the process can be challenging due to its high capital expenditures and running costs, and its potential for releasing liquid waste into the environment.

Energy Reuse

Industrial processes, including power generation and oil and gas extraction, require water and raw materials. These processes also produce waste streams, which include wastewater and solvents. In many cases, these waste streams can contain valuable components that can be reused or recycled. However, most of these liquid wastes end up in landfills or in surface and ground waters, putting a strain on water resources and pollution levels.

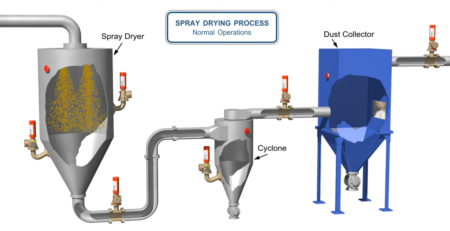

In these situations, zero liquid discharge (ZLD) technologies have emerged as an advanced water management strategy that minimizes the freshwater intake of the process and recovers valuable by-products from waste streams, reducing costs and complying with environmental regulations. These systems generally involve a series of pretreatment, membrane filtration, evaporation and crystallization stages to recover water and high-value solvents from the wastewater.

Typically, the dissolved salts in industrial wastewater are concentrated to their solubility limits through membrane filtration. The salts are then dehydrated to their solid form using an evaporation system, and these resulting dry products can be harvested for further treatment.

ZLD technologies often have a lower capital cost than other water reuse and recycling methods, and can be used for operations with high water demands or in locations where it is impractical to obtain sufficient source water. In addition, they offer the potential to minimize energy consumption in the process by recovering and reusing electricity or steam from the water that is recovered.

The benefits of Zero Liquid Discharge are particularly attractive for water-intensive industries, such as the oil and gas industry. These industries have increasingly stringent regulations regarding their waste disposal practices, making Zero Liquid Discharge an effective way to meet these requirements while minimizing environmental impact and cost.

It is also a good choice for operations that have poor source water quality or are in areas with limited water availability. In some cases, the resulting brine waste can be reclaimed to desalinate water for use in the production process.

There is a growing trend toward the use of energy recycling in various industries to improve the sustainability of these facilities. The re-use of energy can help decrease the demand on fossil fuels and increase the efficiency of the production process. Additionally, it can cut down on pollution and greenhouse gas emissions.

Landfill Disposal

The Environmental Impact of Zero Liquid Discharge Systems

Zero liquid discharge (ZLD) systems are an environmentally sound alternative to conventional wastewater treatment and disposal. They reduce water consumption and avoid pollution from wastewater discharge into surface waters. They also promote the development of a sustainable circular economy, making effective use of wastewater treatment and recycling while reducing the volume of liquid waste to be disposed of.

ZLD systems can be designed to meet the unique needs of each facility. They should be tailored to site specific conditions such as the waste water composition, various streams to be treated, operating costs, foot print availability and other factors.

Some of the benefits of ZLD include: Increasing the value of freshwater, minimizing the volume of wastewater that is disposed offsite, avoiding environmental damage from industrial processes, and lowering the expense of disposal. Moreover, industrial facilities are able to recover valuable materials that are dissolved in the waste water.

In addition to this, a ZLD system can help with water conservation by recycling wastewater on-site and avoiding the need for water intake. This helps alleviate issues of water scarcity and reliance on costly, long-distance imports.

Despite these benefits, there are some environmental concerns associated with ZLD systems. These include odors and the potential for leaching chemicals into groundwater. Therefore, impervious liners and reliable monitoring systems are necessary.

To minimize these risks, it is important to choose the right technology and ensure that the wastewater chemistry is well-designed for a ZLD system. For example, using a low operating temperature to process chloride brines can increase the recovery rate of feed brine without pretreatment and significantly reduce a facility’s overall footprint.

Another benefit of ZLD is that it can eliminate the need for sludge treatment, allowing facilities to recycle a high-quality water stream for reuse or landfill disposal. This can result in lower operating costs and higher ROI.

In the case of a distillery, Alfa Laval developed a customer-specific solution for treatment and evaporation to achieve zero liquid discharge at Fountain Quail. The solution helped the distillery save money on water, energy and treatment, while maximizing gas production. The company was able to recycle almost 100 percent of its waste water.

Greenhouse Gas Emissions

Zero liquid discharge (ZLD) is an industrial wastewater treatment strategy that minimizes liquid waste generation while extending water supply. It has attracted renewed interest worldwide in recent years. However, there are several challenges to overcome prior to wider application of ZLD.

The primary advantage of zero liquid discharge is that it eliminates the environmental pollution associated with liquid effluent discharge. It also maximizes the use of wastewater treatment, recycling and reuse processes. This is because most of the dissolved solids are converted into liquid concentrates that can be either disposed of as valuable byproducts or further processed to generate energy and valuable resources.

This approach can be applied to a variety of industrial applications. For example, it can be used for treating industrial brine wastewater to minimize the amount of dry sludge produced during the process.

Typically, ZLD systems are built around thermal processes that convert brines to liquid concentrates through various stages. These include a brine pretreatment step, a brine concentration unit and a brine crystallizer or evaporation pond.

These systems can reduce the amount of dry sludge by up to 70%, which can be a significant reduction in costs and environmental impact. Moreover, by recovering the salts and other byproducts of the processing process, ZLD systems can increase the value of raw materials.

A key element of the ZLD system is vacuum evaporation, which uses a powerful vapor pressure to evaporate the waste water. This is a highly efficient and versatile process that can concentrate up to 99% of the waste liquid.

Furthermore, evaporation can be used to separate a wide range of organic and inorganic components. It is a robust and reliable solution that can be applied to various streams of industrial waste.

In addition, a number of different membranes have been shown to be suitable for use in a variety of ZLD systems. For example, osmotically assisted reverse osmosis, low-salt rejection reverse osmosis and Janus membranes are all suitable for a wide variety of systems.

In addition to reducing the environmental impact, ZLD can save power costs and provide energy savings. It can also help companies meet new energy and wastewater discharge regulations. It can help reduce emissions of volatile organic compounds (VOCs) from power plants and chemical plants.