Growing Demand of Desalination Plants in Guyana Market

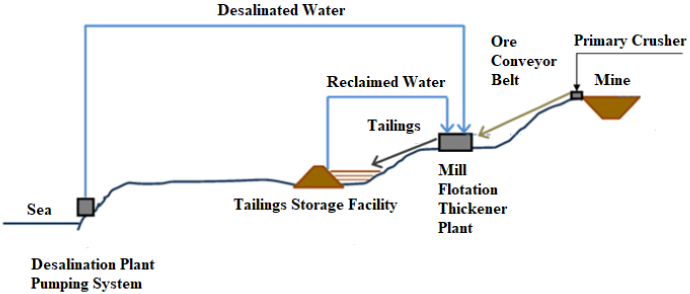

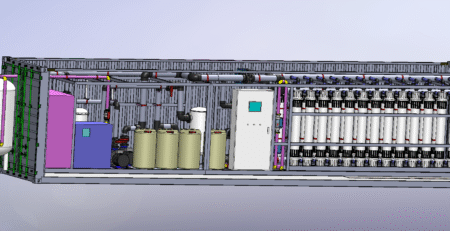

Water desalination plants play an important role in the water supply of developing countries. Water desalination plants help purify drinking water to make it drinkable and safe. Several methods are used for water desalination including reverse osmosis.

What is the Guyana Market Growth for Reverse Osmosis Plants?

The reverse osmosis membrane market in Guyana is expected to register an 8.9% revenue CAGR by 2023. This is attributed to the rising demand for clean drinking water. Increasing government initiatives, growing industrial activities, and rapid urbanization are also anticipated to drive the market during the forecast period.

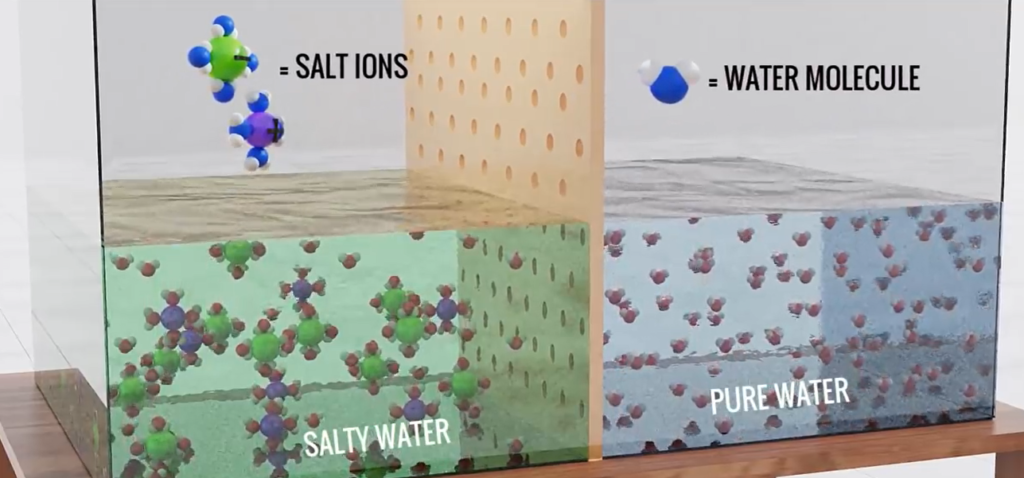

Reverse osmosis is a process of purifying seawater. It removes salt from the water and other dissolved substances. In the process, water is forced through a semi-permeable membrane, which is designed to stop particles and contaminants. However, some foulants can enter the semipermeable membrane. These include calcium carbonate, iron, manganese, and silica.

As the water passes through the membrane, it is collected on the other side of the membrane. Depending on the reverse osmosis system, it is discharged into a storage cistern or a drain. To increase efficiency, permeate pumps are used.

RO membranes are made of aromatic polyamides, cellulose acetate, or other materials. They are specifically designed for desalination of seawater.

RO membranes are manufactured in a variety of configurations, such as spiral wound, hollow fiber, plate and frame, and tubular. Among these, the spiral wound module is the most commonly used in the industry.

Thin-film composite membranes are another type of RO membrane, and are known for their high filtration rate. These membranes are also known to be flexible and formable, promoting high water recovery.

The demand for desalination of seawater is expected to grow in the developing countries including Guyana. In addition, the cost of desalination has decreased significantly thanks to technological advancements.

Why Use Ferralium in Desalination Plants?

When it comes to the water treatment industry, ferralium has a pretty good shot at being the go to material for a heat exchanger in your next desalination plant. It’s no secret that demand for freshwater is on the rise. As a result, the global desalination market is on a roll. In fact, the sector will see a compound annual growth rate of 7.7% over the next five years. This will translate to a significant investment of USD$27 billion over the same period.

For instance, there are about 500 desalination plants in the Guyana region alone. These plants pump in 7.1 million gallons of seawater per hour. Aside from that, the plant removes algae and other particles from the water. At the same time, the salty brine is pumped back into the gulf. Some managers believe the brine isn’t bad for the marine environment.

Ferralium 255 is a good choice for such applications. This chromium-heavy alloy is resistant to acids and withstands temperatures of up to 2100°F. With such a wide range, the grade has become the go-to option for liquid processing plants in arid climes. Compared to conventional stainless, the ferral 255 is a cost-effective metal. Compared to its austenitic counterparts, ferralium is about twice as resistive. While this alloy’s tensile strength is a modest 60ksi, its yield strength is more than 85ksi. The mechanical properties of ferralium make it ideal for use in marine environments. Despite its higher price, it is available in a variety of grades to suit your budgetary needs.

If you’re looking for the best stainless steel for your next desalination project, a ferralium based system is the way to go.

What is Shuaiba Desalination Plant?

The Shoaiba desalination plant was the largest of its kind in the world. With its two stages of construction, it has a combined capacity of 76800 tons per day.

For its time, it was an important milestone in the Kingdom’s quest to become self-sufficient in water. Its predecessor, the Shuqaiq plant, has a daily output of 400,000 cubic metres. A sister project, the Shuaiba 5 plant, is slated to produce 600,000 cubic metres a day. This is enough to double the current supply of desalinated water and reduce the country’s dependency on imported water.

Doosan Heavy Industries built the multi-stage flash distillation water desalination plant, along with the associated pipelines, pumping station, and storage tanks. The multi-stage design is a good idea, as it means less maintenance, less pollution and better efficiency.

It was also a good idea to use corrosion resistant alloys to construct the tower-like structure. In addition, the plant is powered by three turbines, which is a fairly standard CCGT (combined cycle gas turbine) arrangement.

Another major technological feat was the use of the patented Multi-Stage Flash Distillation (MSF) technology, a process used in the Middle East. While the process is relatively new, it is a clever and effective means of producing high quality water.

Finally, the plant has a power control system that is state of the art, a feat in itself, especially for a large installation like this one. There are a number of consortia that participated in the project, most notably the Saudi-Malaysian consortium led by Tenaga Nasional, which has a 60 percent stake.

One of the largest and most complex projects in the Kingdom, the Shuaiba desalination plant is finally up and running. During its first five years of production, it produced about 50 million cubic metres of water a year, a figure that has grown by nearly 40% since then.

Market for Water Desalination Equipment Globally

The water desalination equipment market is expected to grow at a CAGR of 9.0% in the next ten years. This growth is primarily driven by rapid industrialization, depleting freshwater sources and increased freshwater demand.

Asia Pacific region is expected to lead the global water desalination equipment market during the forecast period. Increasing consumption of clean water in emerging economies and intensified industrialization are expected to drive the market.

The municipal sector is expected to contribute the largest share in the water desalination equipment market. Rising urban population and expanding megacities are expected to put pressure on municipal water supply capacity. Therefore, increased investment in the municipal sector is projected to boost the market.

Industrial applications are also predicted to increase in the future. Industries such as oil and gas, pulp and paper, and food and beverages require large quantities of water for different processes. Thus, there is a need for efficient water treatment facilities.

China is a large market for water desalination equipment. Moreover, the country’s economy has experienced unprecedented growth in recent years.

The industrial segment is predicted to be the fastest growing segment over the forecast period. Rapid industrialization and increasing government expenditure in the developing nations are estimated to enhance the demand for this product.

In Conclusion

Water desalination equipment converts seawater into potable water. It uses electrical force to pass water through a membrane. Various types of water are purified by this process.

Technological advances in the desalination industry focus on increasing freshwater yield and reducing brine production. These technological innovations are predicted to boost technology acceptance in the sector. In addition, the market is projected to be boosted by the increasing population and increasing demand for clean water in developing countries.