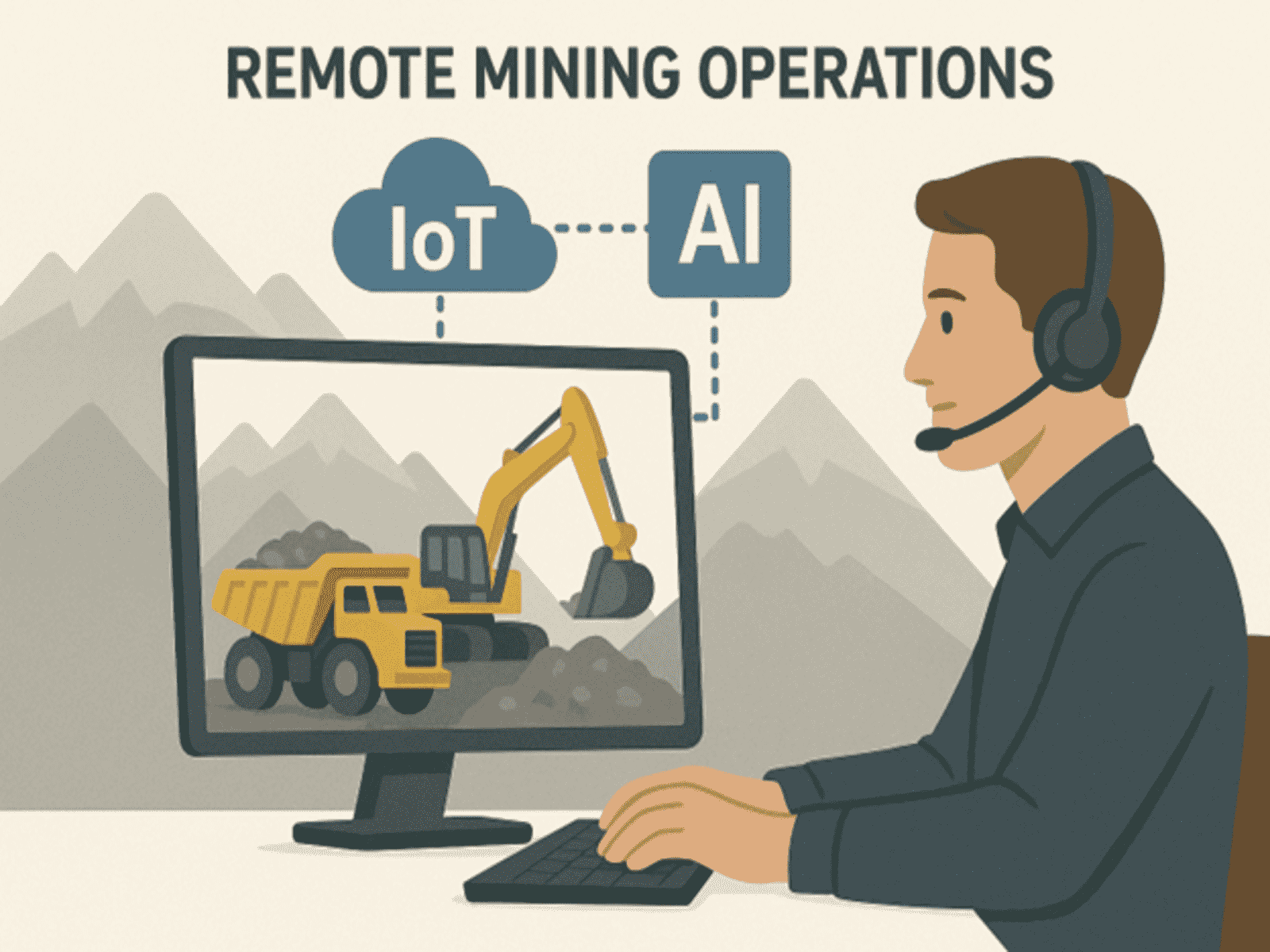

Use of IoT & AI in Remote Operation and Automation in the Mining Industry

How IoT (Internet of Things) and Artificial Intelligence (AI) are used for Remote Operation and Automation in the Mining Industry, including systems architecture, technologies involved, and benefits:

⚙️ 1. Introduction

Modern mining operations—especially in deep, remote, hazardous, or highly mechanized environments—are increasingly adopting remote operation centers (ROCs) powered by IoT and AI to:

- Improve safety

- Reduce human error

- Operate 24/7

- Increase precision and efficiency

- Reduce costs of onsite manpower

📡 2. IoT Components Enabling Remote Operations

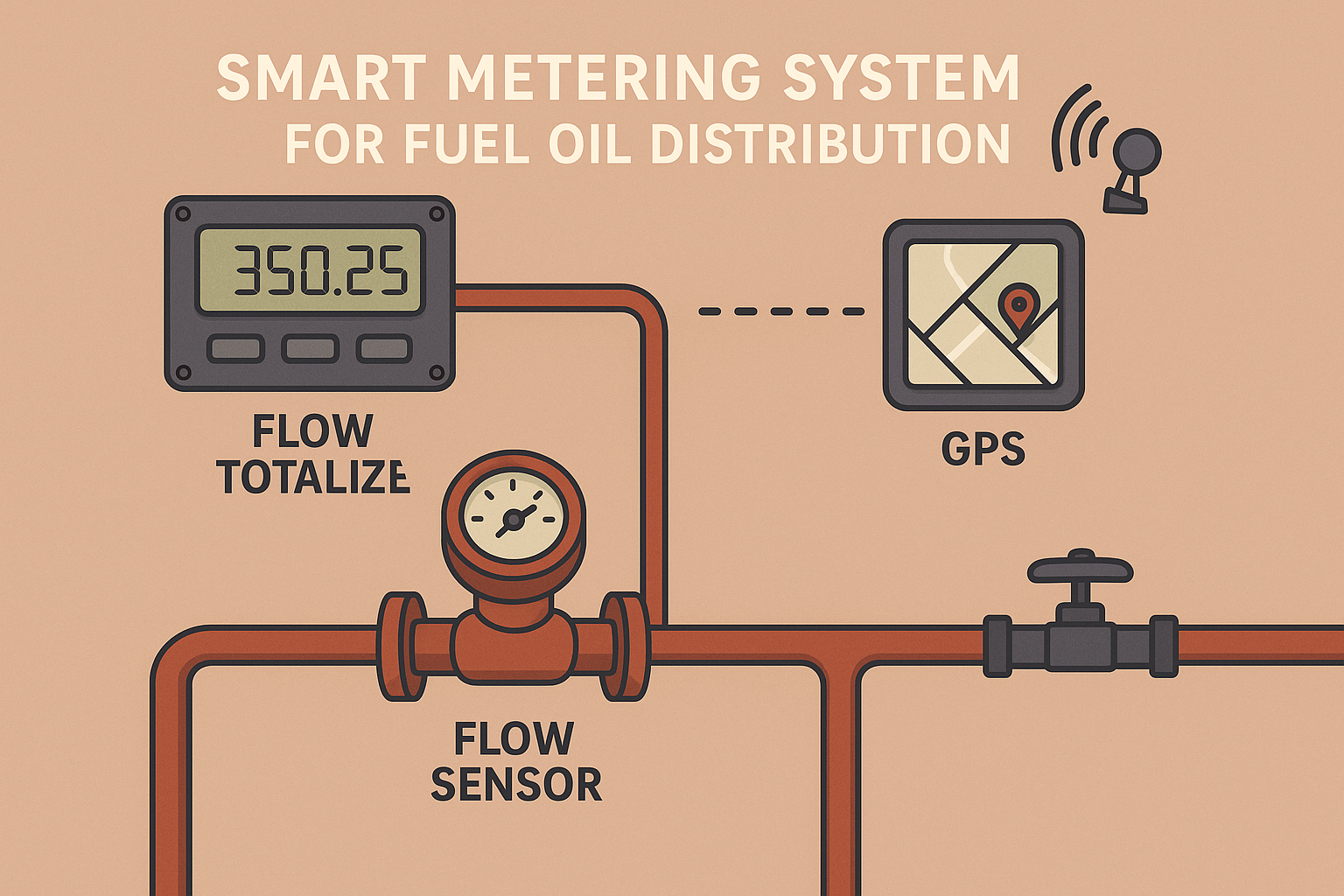

A. Sensors and Actuators

- Mounted on mining equipment (drills, excavators, haul trucks, crushers, conveyors, etc.)

- Collect real-time data: engine load, fuel consumption, RPM, vibration, hydraulic pressure, temperature, alignment, payload

B. Positioning and Tracking

- GPS/GNSS systems for equipment localization

- IMUs (Inertial Measurement Units) for orientation and movement tracking

C. Industrial IoT Gateways

- Aggregates sensor data

- Performs initial filtering and preprocessing

- Connects to cloud or local edge servers via Ethernet, 4G/5G, LoRaWAN, or private LTE

D. CCTV & Machine Vision

- Real-time video from crushers, loading zones, and conveyors

- AI-powered vision used for anomaly detection, worker safety, and equipment control

E. Connectivity Infrastructure

- Mesh networks, fiber optics, 5G, VSAT, microwave backhaul, or private LTE for data transmission

🤖 3. AI Applications for Remote Operation & Automation

A. Autonomous Haulage Systems (AHS)

- AI-driven algorithms navigate and control driverless haul trucks

- Path planning, collision avoidance, payload optimization

- Example: Komatsu FrontRunner, CAT MineStar Command

B. Drill Automation

- AI optimizes drill depth, feed rate, and bit pressure based on rock hardness data

- Reduces over-drilling and bit wear

- Autonomous drilling rigs can operate unmanned with remote supervision

C. Autonomous Load-Haul-Dump (LHD) Vehicles

- LHDs navigate underground autonomously using LiDAR and SLAM (Simultaneous Localization and Mapping)

D. AI-Based SCADA Integration

- Remote SCADA/HMI with AI models to:

- Adjust conveyor speeds

- Auto-start/stop pumps, crushers, mills

- Switch power loads or ventilation based on real-time demand

E. Predictive Control with Digital Twins

- Digital replicas of assets and process lines simulate various scenarios

- AI models suggest operational adjustments in real-time

F. AI-Based Scheduling

- AI creates shift-free task schedules for autonomous equipment

- Real-time adjustment based on breakdowns, terrain, or productivity needs

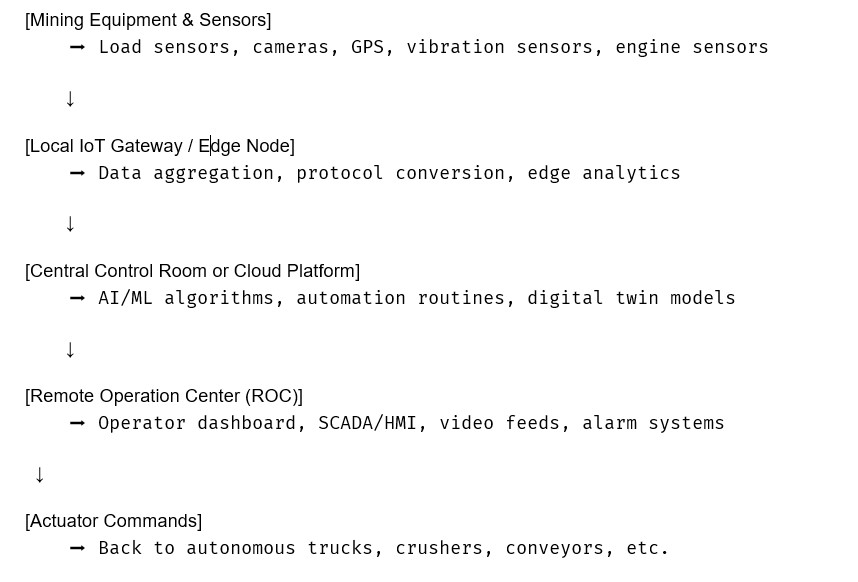

🧩 4. System Architecture for Remote Automation

🧪 5. Key Use Cases

✅ 1. Autonomous Truck Operations

- No drivers needed on-site

- AI handles route optimization, haul cycles, and obstacle detection

- Human operator intervenes only in complex scenarios remotely

✅ 2. Remote Drilling Control

- Drill parameters controlled from ROCs

- Multiple rigs can be operated by a single technician

- Reduces human exposure in explosive-prone or deep-pit zones

✅ 3. Remote Crusher and Conveyor Control

- Based on belt load sensors, ore moisture, and particle size from vision systems

- AI adjusts crusher gap or conveyor speed autonomously

✅ 4. Remote Blasting Planning

- AI uses geospatial and rock density data to suggest blast patterns

- Integrated with drone-based mapping and vibration monitoring

✅ 5. Process Plant Automation

- Remote control of leaching, flotation, and thickening tanks via AI-based control loops

- Automated chemical dosing based on pH, turbidity, and ORP readings

📊 6. Benefits

| Benefit | Description |

| 🧍♂️ Fewer People Onsite | Improves safety and reduces cost of remote manpower deployment |

| 🕹️ 24/7 Operation | Autonomous and remote systems can operate continuously |

| 📉 Downtime Reduction | AI identifies faults early, adjusts operations before failure |

| ⚡ Energy Efficiency | AI optimizes equipment runtime and energy consumption |

| 🎯 Precision and Repeatability | Improves quality and consistency of drilling, hauling, processing |

| 🌍 Multi-site Operation | Central ROCs can operate multiple mines from hundreds of kilometers away |

🛠️ 7. Technologies Commonly Used

| Technology | Application |

| LiDAR/SLAM | Autonomous vehicle navigation in underground mines |

| Edge Computing | Real-time decisions with low latency onsite |

| AI/ML | Optimization, scheduling, predictive maintenance |

| IoT Sensors | Real-time telemetry from equipment |

| Private 5G / LTE | High-bandwidth low-latency communication in remote areas |

| Computer Vision | Load detection, personnel tracking, hazard monitoring |

🧭 8. Example – Remote Operation Center Layout

- Large wall displays for real-time telemetry

- Workstations for:

- Autonomous truck fleet monitoring

- Crusher & conveyor control

- AI anomaly alerts

- Drill rig supervision

- Video surveillance feeds from multiple mine zones

- AI dashboard showing equipment KPIs, safety metrics, energy usage

🔒 9. Security & Reliability

- Encrypted communication (TLS/SSL, VPN)

- Multi-factor authentication for remote access

- Redundant communication links (fiber + satellite)

- Fail-safe mode to allow manual override if automation fails