Smart Metering System for Gas Supply Companies, IOT, ARTIFICIAL INTELLIGENCE application — Detailed Technical & Operational Overview

Smart Metering System for Gas Supply Companies, IOT, ARTIFICIAL INTELLIGENCE application — Detailed Technical & Operational Overview

1. Introduction

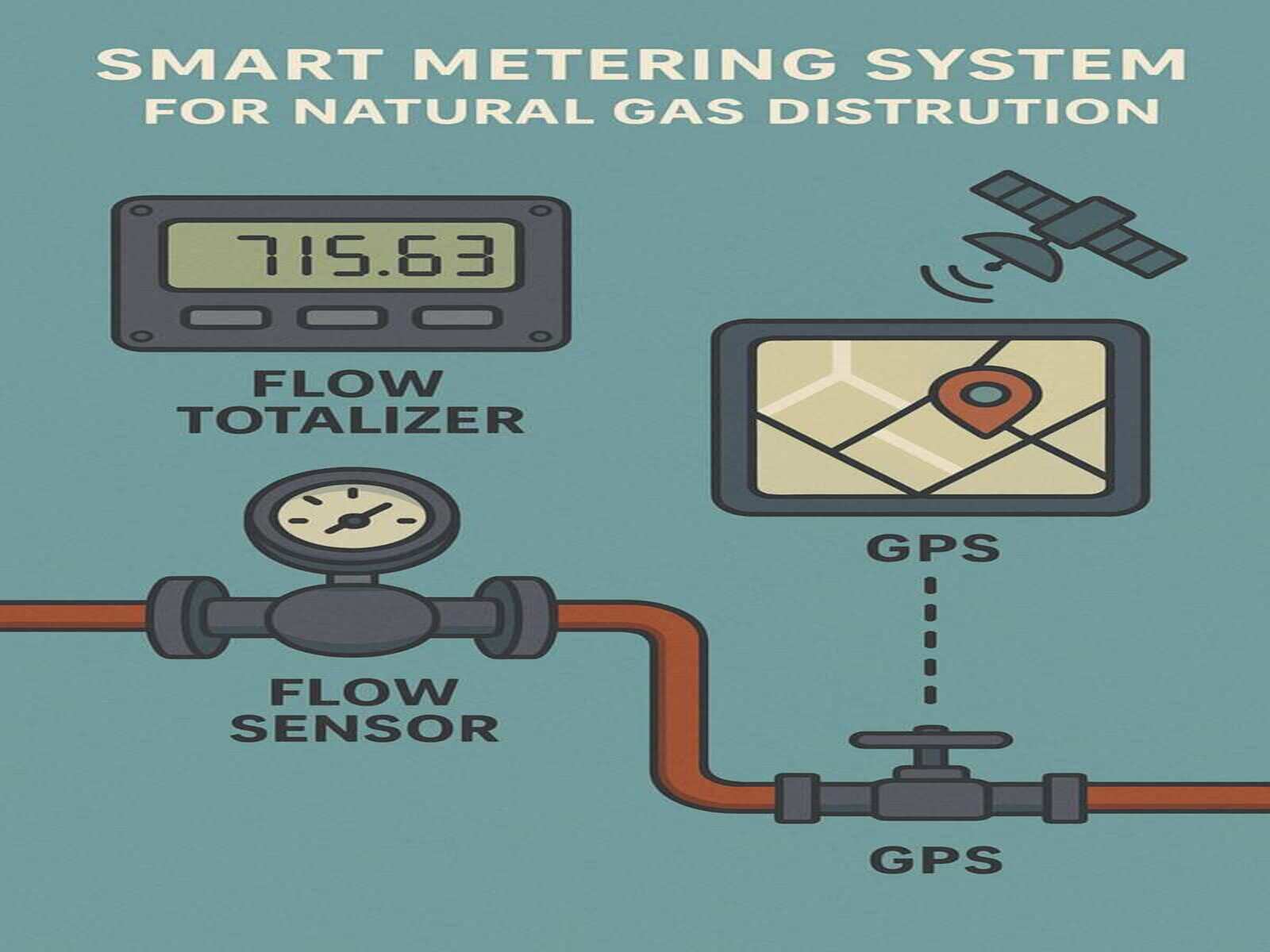

Smart metering for gas supply involves the use of advanced metering infrastructure (AMI) integrating smart gas meters, sensor networks, communication technologies, and data analytics platforms to measure, monitor, and manage natural gas or other gaseous fuels distributed through pipelines to residential, commercial, and industrial consumers.

These systems enable accurate real-time measurement, remote data acquisition, automated billing, and proactive detection of anomalies such as leaks and theft, improving operational efficiency and safety.

2. Core Components of a Smart Gas Metering System

2.1 Smart Gas Meter Hardware

- Meter Types:

- Ultrasonic Meters: Measure gas flow by transmitting ultrasonic waves; high accuracy and no moving parts.

- Turbine Meters: Measure velocity of gas flow with a rotating turbine.

- Coriolis Meters: Measure mass flow directly; useful in custody transfer.

- Thermal Mass Meters: Measure flow based on heat transfer principles, used for low flow rates.

- Pressure & Temperature Sensors:

- Gas volume varies with pressure and temperature, so these sensors enable compensation of readings to standard reference conditions (e.g., 15°C, 1 atm).

- Sensors typically include piezoelectric pressure transducers and RTDs (Resistance Temperature Detectors).

- Density Measurement (optional):

- Some advanced systems include density measurement for gas composition and quality monitoring.

2.2 Communication Devices

- Communication Modules: Enable data transmission to the central management system.

- NB-IoT: Narrowband IoT for low-power, wide-area cellular communication.

- LoRaWAN: Long-range, low-power wireless technology ideal for rural or remote areas.

- 4G LTE/5G: For high-throughput and low-latency requirements.

- Zigbee/Bluetooth: For local data collection within buildings or complexes.

- Satellite Communication: Used for extremely remote or offshore locations.

- IoT Gateway / Edge Devices:

- Aggregate data from meters and preprocess or filter locally.

- Perform local anomaly detection and reduce network traffic.

- Can be installed at pressure regulation stations or gas depots.

2.3 Control and Actuation

- Smart Valve Actuators:

- Remotely controllable valves allow operators to shut off gas flow in case of detected leaks, unauthorized flow, or maintenance.

- Actuators can be electric, pneumatic, or hydraulic depending on system design.

2.4 Power Supply

- Power options:

- Battery-powered for meters in remote locations, with low-power design to maximize battery life (5-10 years).

- Mains power or solar panels in fixed locations.

- Energy harvesting techniques (e.g., flow-driven turbine generators).

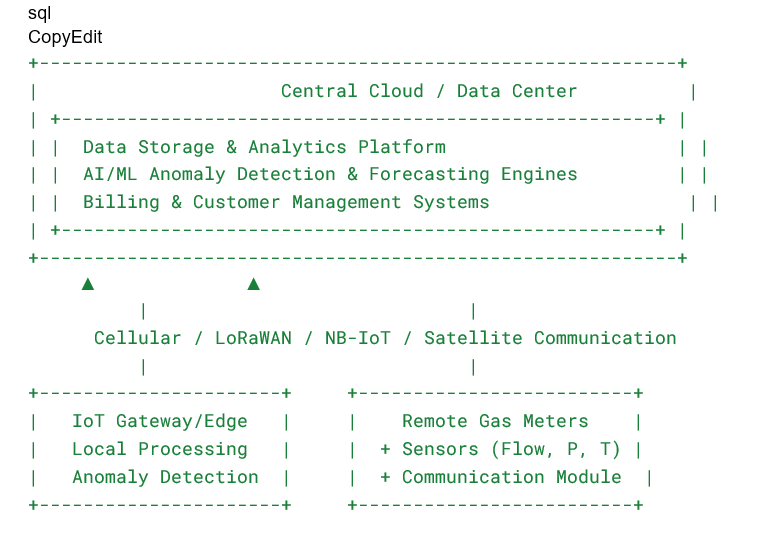

3. System Architecture

4. Data Acquisition and Processing Flow

- Gas flow, pressure, and temperature data continuously collected by smart meters.

- Data pre-processed locally at IoT gateway/edge device to filter noise and detect local anomalies.

- Data transmitted securely and periodically to cloud-based platforms.

- AI/ML models analyze incoming data streams to:

- Detect abnormal flow patterns, possible leaks, or theft.

- Predict meter faults or maintenance needs.

- Forecast demand for supply optimization.

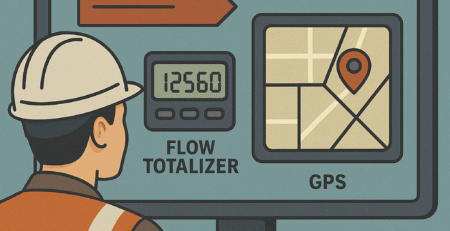

- Authorized personnel access dashboards with real-time visualization and alerting.

- Automated billing and regulatory compliance reports generated based on verified consumption data.

5. AI & Machine Learning Applications

5.1 Leak Detection

- AI models analyze flow rate fluctuations, pressure drops, and temperature changes that deviate from expected patterns.

- Correlate sensor data with external factors (weather, consumption trends) to reduce false positives.

- Early alerts allow quick isolation using remotely actuated valves to prevent catastrophic leaks.

5.2 Theft and Tampering Prevention

- Detect meter bypassing by comparing expected usage with historical customer patterns.

- Monitor reverse flow events (indicating meter manipulation).

- Analyze flow spikes or sudden drops inconsistent with known customer behavior.

- Alert security teams instantly for suspicious activity.

5.3 Predictive Maintenance

- AI identifies meters exhibiting signs of calibration drift or impending failure.

- Maintenance can be scheduled proactively to avoid service interruptions or inaccurate billing.

5.4 Demand Forecasting & Load Balancing

- Predict consumption trends per region or customer segment.

- Optimize gas purchase and supply schedules.

- Reduce costs and ensure supply reliability.

6. Security Features

- Data Encryption: TLS/SSL encryption ensures data in transit is secure.

- Authentication & Authorization: Role-based access control restricts meter and network management.

- Anti-Tamper Sensors: Physical intrusion detection (magnetic field detection, vibration sensors).

- Firmware Update Security: Secure over-the-air (OTA) updates prevent malware injection.

- Blockchain (optional): Immutable records of custody transfer and transactions for audit.

7. Integration with Business and Operational Systems

| System | Purpose & Benefits |

| Billing & ERP | Automated invoicing with real consumption data |

| SCADA/Distribution Control Systems | Real-time network monitoring and emergency response |

| Customer Information Systems (CIS) | Enhance customer service with consumption data |

| Geographic Information Systems (GIS) | Map-based visualization for pipelines and meters |

| Regulatory Reporting Platforms | Compliance with safety and environmental regulations |

8. Deployment Use Cases

| Use Case | Description |

| Residential Smart Metering | Individual gas meters connected wirelessly to gateway for urban and suburban areas. Enables detailed consumption profiles. |

| Industrial & Commercial Customers | High-volume customers get high-precision meters with continuous monitoring and control. |

| Pipeline Monitoring & Custody Transfer | Smart meters at critical pipeline points measure volume with custody transfer-grade accuracy. Real-time remote monitoring reduces pilferage and errors. |

| Cross-border Gas Supply | Standardized smart metering with secure data logging supports regulatory compliance and transparent transactions. |

9. Benefits and Impact

| Benefit | Explanation |

| Improved Accuracy | Eliminates manual meter reading errors and estimates. |

| Reduced Operational Costs | Minimizes field visits and manual data collection. |

| Enhanced Safety | Early leak detection reduces risk of explosions or poisoning. |

| Reduced Theft & Losses | Real-time monitoring prevents revenue loss. |

| Customer Engagement | Consumers receive consumption data and alerts via apps. |

| Regulatory Compliance | Meets government mandates on metering and emissions. |

10. Challenges & Mitigations

| Challenge | Mitigation |

| Power Constraints in Remote Areas | Use long-life batteries and energy harvesting tech. |

| Harsh Environmental Conditions | Deploy ruggedized meters with ATEX/IECEx certifications. |

| Network Connectivity Issues | Use multi-network failover (NB-IoT, LoRaWAN, Satellite). |

| Data Privacy Concerns | Employ end-to-end encryption and strict data policies. |

| Complex Calibration Needs | Use remote diagnostics and automated calibration reminders. |

11. Future Trends

- Integration with Smart Grids: Gas consumption data combined with electricity for holistic energy management.

- Blockchain-based Transactions: For secure, transparent custody transfers.

- AI-powered Virtual Sensors: To reduce hardware costs by inferring parameters.

- Edge AI: More processing locally to reduce latency and bandwidth use.

- Customer-facing Apps: For real-time usage monitoring, leak alerts, and billing insights.