Market Potential for Suriname’s Desalination Plants

The Suriname market is an attractive location for the manufacture of desalination plants. However, there are some challenges that the companies operating in this country must face. They include cavitation corrosion, cost reduction, and the prospect of growth.

How is the Market of Reverse Osmosis Rising in Suriname?

Reverse osmosis desalination plants in Suriname are a part of the growing global demand for clean drinking water. The market is estimated to reach USD 7.09 Billion by 2030.

Various industries rely on reverse osmosis systems to produce purified water for different uses. It is often used for agriculture, pharmaceuticals, and electronics.

The operating costs of reverse osmosis plants are significant. These costs include electricity, labor, and replacement of membrane elements. However, technological advancements have decreased these costs.

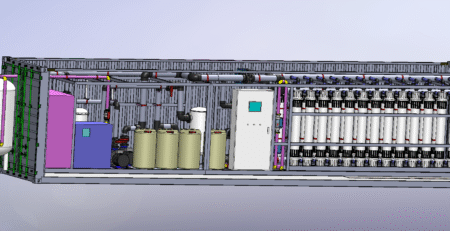

A successful reverse osmosis system requires a well-constructed and durable casing. Ideally, the reverse osmosis system should be fitted with a powder coated carbon steel frame, which is resistant to the elements. High-grade pumps are necessary to maintain the rejection rate of the reverse osmosis system.

What is the Working of a Reverse Osmosis Desalination Plant?

In the reverse osmosis process, a pump pushes a water solution through a semi-permeable membrane. A small percentage of the salt passes through the membrane, while the majority of the salt is rejected.

Seawater is abundant and can be easily accessed. But this resource can contain high concentrations of contaminants. Therefore, it is important to use a membrane to ensure that only the purest, freshest water is produced.

Reverse osmosis membranes are made of thin film polymer composites. Thin-film composite membranes are known to have a high filtration rate and are known to reject unwanted materials. They also exhibit excellent membrane formability characteristics.

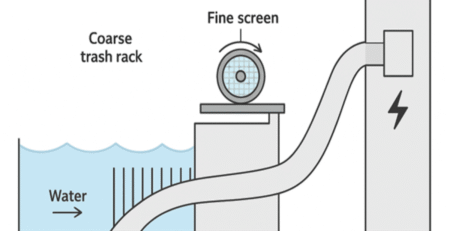

Membranes are usually accompanied by a cartridge filter to remove particles that are larger than five microns. Typically, a spun polypropylene filter is used.

Reverse osmosis systems can include hundreds of eight-inch membranes. Each system can have a capacity of 750 000 litres per day. Depending on the size of the task, a system can be customized to accommodate a variety of needs.

Nano Filtration in Desalination Plants

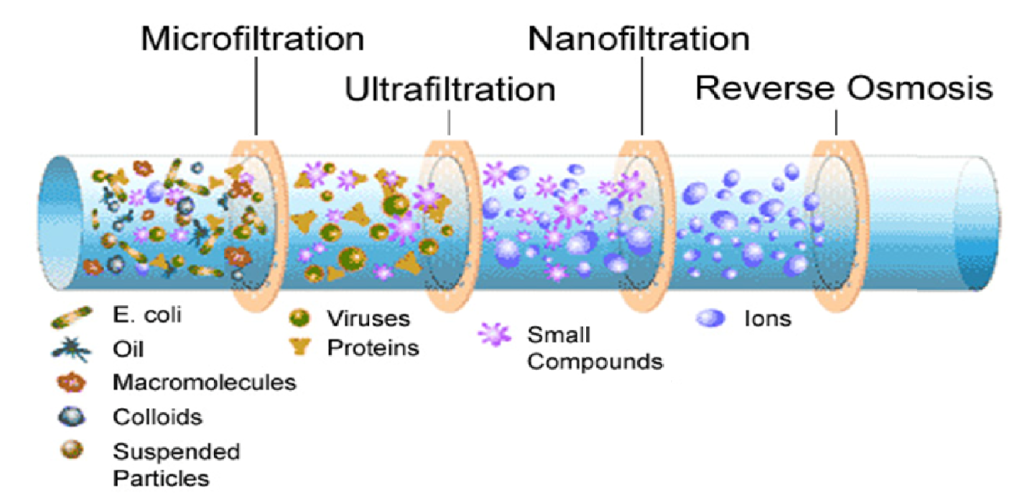

Nano filtration in desalination plants is a process that uses membranes to produce ultra-pure water. This technology has emerged as an effective way to achieve this goal. It is a type of osmosis in which dissolved solutes are separated from treated water by the use of a low pressure, highly efficient membrane.

There are several processes used to remove salts from water. These include reverse osmosis, pre-treatment, and membrane filtration. The membrane pore size is divided into two categories: microfiltration and ultrafiltration.

Reverse osmosis removes the majority of solutes. Pre-treatment helps to lower the MFI (mean filtration intensity).

A membrane’s pressure gradient is defined as the mean inflow pressure minus the filtrate pressure. The pressure gradient ensures that the filter can remain stable for a long time. When a filter clogs, the pressure gradient must increase to keep the filter functioning. Eventually, the clogged filter needs a cleaning process to restore performance.

One of the most important functions of a nanofiltration membrane is its ability to prevent the passage of unwanted organic compounds. Most of the organic fouling is due to bacteria. In order to control the number of bacteria, the feed water is usually pre-treated.

The membrane is also able to separate trace amounts of dissolved solutes. Unlike traditional reverse osmosis, nanofiltration does not require high pressures.

The use of these technologies in water treatment systems is expected to grow in the future. The rising number of investments in the industry are leading to the installation of new equipment. Furthermore, the growing living standards are increasing demand for municipal water services.

The growth of the nano filtration in desalination plants market is expected to be driven by the global scarcity of clean water. However, the use of this technology is limited by the lack of funding in developing countries.

How to Prevent Cavitation Corrosion in Desalination Plants?

The rising standards of living have led to a critical demand for potable water. As a result, the industry has been constantly refining their processes and saving energy. In recent years, desalination experts have become increasingly active in this field.

The first step in preventing cavitation corrosion is to maintain the smooth flow of fluids. Proper pump design reduces the chance of cavitation by minimizing the velocity of the input fluid.

The second step in preventing cavitation is to minimize the pressure gradients. This can be achieved through the use of a suitable surface coating or cladding. It is also important to design out cavitation by avoiding pressure drops below the vapor pressure.

Cavitation corrosion is most commonly associated with abrupt pressure changes. However, it can occur with low pressure as well.

Cavitation damage is caused by the formation of gas bubbles on the metal surfaces. These bubbles collapse when the gas vapor pressure inside the bubble exceeds the external pressure.

This can erode the protective oxide film. Moreover, it can accelerate the erosion-corrosion process. Similarly, the speed of the input fluid can also increase the rate of accelerated corrosion.

Among the materials that have good resistance to cavitation corrosion are stainless steels, nickel alloys, and titanium alloys. However, there are several factors to consider before choosing an alloy.

The material hardness, the oxidising potential, and the aggressive species in the environment can play a major role in determining the performance of the material. Increasing the material hardness can help delay the formation of cavitation bubbles.

In addition, the inclusion of nickel can enhance the corrosion resistance of copper and improve its durability. Moreover, adding Cr can also increase the resistance to crevice corrosion.

Cost Reduction in Desalination Plants

While a plethora of desalination plants dot the landscapes of the planet, they are a pricey proposition. The cost of converting seawater into drinking water is often in the millions of dollars. Fortunately, technology improvements in recent years have lowered the cost of bringing freshwater to market.

Some countries have benefited from less costly infrastructure to meet their domestic water demands. Depending on where you live, you may have a choice between freshwater and seawater. To make things even more interesting, the cost of shipping seawater can be prohibitively expensive. Nonetheless, desalination has helped many Caribbean islands provide the drinking water their residents deserve.

The cost of operating a distillation plant is a bit more than the water flowing out of the tap, but the quality of the end product can’t be beat. Desalination has been used in the Caribbean, the Middle East, and North Africa, among other regions. Today, there are over 19,000 desalination plants in operation around the world, with many more planned. These projects are expected to increase in size as the global population grows.

Aside from consuming a lot of energy, distillation technology is also a labour intensive endeavour. For this reason, it makes sense that the largest cost-savings are achieved by focusing on the most efficient methods of getting your hands on the cleanest and tastiest waters. In some cases, the best solution is a combination of reverse osmosis and flash distillation. Both of these processes are proven to extract the requisite salt from the sea.

Nevertheless, the real cost reduction lies in maximizing the performance of your current technology while at the same time keeping it up to date. To do this, consider replacing your old technology with a more scalable, modern system.

Growth Prospects of Desalination Plants in Suriname

Desalination plants are used in a variety of industries in Suriname. This includes municipal water, agriculture and mining. The demand for water is growing, and climate change is causing more frequent droughts. In order to meet this need, countries are taking action to adapt desalination processes.

As a result, the number of desalination projects has increased. Some were already under construction, while others were under development. The total number of desalination plants are continuously increasing in Suriname market.

Desalination plants have become a necessity for cities around the world including Suriname. With rising living standards, more people are requiring municipal water services.

Another option for a continuous desalination process is to use storage systems. However, these are expensive to build, so desalination plants must be located in an area where water is abundant. Also, it is estimated that 40% of the energy requirement for desalination can be eliminated by using evaporation reduction methods.

Other factors to consider are local regulations and environmental impacts. Most desalination plants are powered by a combination of solar, wind and photovoltaics.

If a plant is designed properly, it can deliver clean, fresh water for a large population. However, the process can have a negative impact on the environment, and it must meet the goal of sustainable development.

In Conclusion

Although there are some concerns about the effects of desalination, the technology has a lot of potential in many areas, including the environment, social and economic. For example, it is possible to recycle the water after the process. It also has the potential to avoid saltwater pollution.

In addition, the process could prevent the occurrence of sea level rise. A significant study showed that geothermal-based desalination plants are very promising.