Economic Analysis of Zero Liquid Discharge System Implementation

Zero Liquid Discharge (ZLD) systems are becoming increasingly popular as a viable alternative to wastewater disposal. The technology is being implemented across a variety of industries, ranging from food and beverage production to chemical and petrochemical manufacture.

ZLD systems rely on advanced treatment methods to clean and reuse essentially the entirety of the waste water delivered to a plant. This reduces the amount of new wastewater entering the environment, thereby increasing protection of water resources.

Cost of Wastewater Disposal

In many industries, wastewater is a significant waste product that must undergo a treatment process before it can be disposed of. This process can take place in a number of different ways, depending on the industry and its specific needs.

Often, the first step in treating wastewater is to remove large floating objects that can clog pipes and other equipment. This is done by screening the wastewater and removing any large grit particles that may be in it. After the grit is removed, the wastewater enters a sedimentation tank where solids such as cinders, sand and small stones settle to the bottom of the tank.

Next, the wastewater is treated using a variety of chemical and biological processes that may be necessary to meet strict effluent regulations. These processes may include coagulation, biochemical and physical processing. These processes can be used to reduce the concentrations of refractory organic pollutants and salts, which may prevent them from being discharged into waterways.

Once the wastewater is fully treated, it can be reclaimed and reused in a variety of ways. This is a common practice in industrial plants, but it also happens in many homes and businesses.

Another popular method of reclaiming wastewater is incineration. This is a cost-effective way to treat and dispose of liquid waste, but it can also be hazardous to the environment. Incineration releases toxic contaminants into the air, causing respiratory issues and reducing air quality.

Zero Liquid Discharge (ZLD) is an emerging technology that aims to minimize the volume of liquid waste generated while maximizing the amount of water recovered. This technology has gained increased interest worldwide in recent years.

The primary drivers for ZLD systems are growing concerns over water shortages and pollution of aquatic environments. These factors have led to a growing demand for ZLD systems in both the United States and Europe.

However, there are a number of challenges associated with ZLD that need to be addressed before it becomes a widespread solution. These challenges include fouling propensity, operational costs and energy input.

One of the biggest challenges of ZLD is minimizing the volume of liquid waste generated. This is a critical factor in the success of this system because it can help reduce waste disposal costs.

In some instances, this can be accomplished by recycling the water on-site, rather than disposing of it off-site. This can reduce the need for truck transportation and the related environmental risks that come with off-site disposal.

Other ways that wastewater can be recycled include through natural evaporation, such as in cooling tower blowdown ponds. This technique can be a cost-effective option, but it requires constant maintenance to ensure that the cooling tower ponds are clean.

Another technology that has shown promise in reducing the cost of ZLD is membrane-based technologies, such as reverse osmosis and flocculation. These technologies allow the water to be reclaimed and reused in beneficial applications such as irrigation and replenishing groundwater supplies. In addition, these technologies can be combined with traditional ZLD technologies to increase efficiency and lower capital and operating costs.

Cost of Wastewater Treatment

Zero Liquid Discharge (ZLD) is a wastewater management strategy that minimises liquid waste production, extends water supply, and recycles water into the facility. It is a solution that has become increasingly popular among industrial facilities and effluent regulators, due to its cost-effectiveness and environmental benefits.

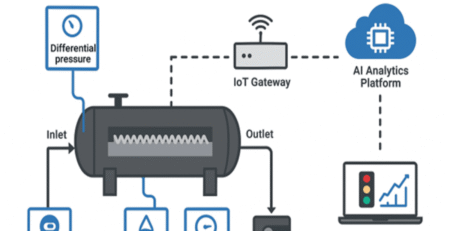

ZLD uses a sequence of advanced treatment processes to minimise the volume and concentration of wastewater, and increase the level of recovery. It utilises biological, membrane and thermal technologies for pretreatment, concentration and evaporation/crystallization.

The first stage of a ZLD system is pre-treatment, where the water is removed from the solids in the wastewater by a combination of biological and membrane technologies. This pretreatment can be performed in an on-site or off-site facility. The resulting clean water can be recycled back into the plant for other processes or to provide drinking water.

Next, the wastewater is sent to a thermal evaporator and crystallizer. These thermal evaporators remove the remaining liquid wastes, including brine, from the effluent. This process requires large amounts of energy to run, and it can be a significant source of operating costs in ZLD systems.

Once the evaporation/crystallization step is completed, the wastewater is sent to a final treatment facility that provides a solid waste product for disposal. This solid waste can then be disposed of in a landfill or used as fertilizer, or can be sent for further processing to produce another product like biogas.

Typically, the solid waste produced during this process will contain heavy metals and other chemicals. Therefore, proper disposal techniques are required. For this reason, it is essential to employ impervious liners and reliable monitoring systems.

The cost of a ZLD system will depend on what technology makes up the upstream treatment portion of the system, the flow rate at which it is operated and the specific contaminants in the wastewater. These factors will also affect the overall cost of the system.

Cost of Wastewater Recycling

In many regions where water supplies are at risk, zero liquid discharge (ZLD) is a viable option for wastewater management. This type of treatment combines multiple wastewater treatment technologies into one system that can be used to minimize or eliminate liquid effluent discharge and recycle all or almost all water resources.

ZLD systems use reverse osmosis, ultrafiltration, membrane filtration and evaporation processes to treat industrial wastewater in order to reduce the quantity of contaminated effluent discharged into aquatic ecosystems or groundwater. In addition to improving environmental performance and reducing regulatory risk profile, these technologies also can reduce the amount of trucking required for off-site waste disposal and decrease the greenhouse gas impact of wastewater transportation.

However, before a Zero Liquid Discharge System can be implemented at an industrial facility, there are several factors to consider. These factors include the location of the site and property line where wastewater is to be treated, the availability of land for a system footprint, the types of waste to be recovered and the operating costs of the facility.

As the ZLD process is based on thermal processes, these systems will incur capital and recurring energy costs. In addition, they can have unintended environmental consequences if not properly handled.

This is particularly true for evaporation ponds, which may leak or affect local wildlife and groundwater. Moreover, the solids produced by ZLD systems must be treated to meet stringent environmental regulations, which can add to the cost of implementation.

For this reason, it is important to evaluate the best technology for your ZLD process. This will help to determine whether this approach is a viable option at your facility.

Historically, ZLD systems were based on stand-alone thermal processes that required a high degree of energy and capital. These processes included a pretreatment step that reduced the scale potential of the wastewater, followed by a concentration process that used brine concentrators or brine crystallizers to convert it into a liquid and solid state. The condensed distillate water was then collected for reuse, whereas the produced solids were either stored in evaporation ponds or further processed for landfill disposal.

In recent years, increased awareness of water scarcity and pollution of aquatic environments has prompted the world to re-examine its water management strategies. This has resulted in a renewed interest in ZLD for industrial applications.

Some of the most common industrial sectors that have incorporated ZLD technology into their operations include power generation, textile manufacturing, chemical plants and bulk medicine manufacturing facilities. These companies are implementing ZLD as part of efforts to comply with increasingly stringent environmental standards and to avoid the discharge of polluted effluent into aquatic ecosystems or groundwater.

The ZLD process can also be effective at reclaiming valuable materials present in the wastewater, such as ammonium sulfate and gypsum. These resources can be sold as byproducts of the system, which can help offset the capital and operating costs associated with ZLD implementation.