Debris Removal Screens in Hydroelectric Power Stations NECESSITY

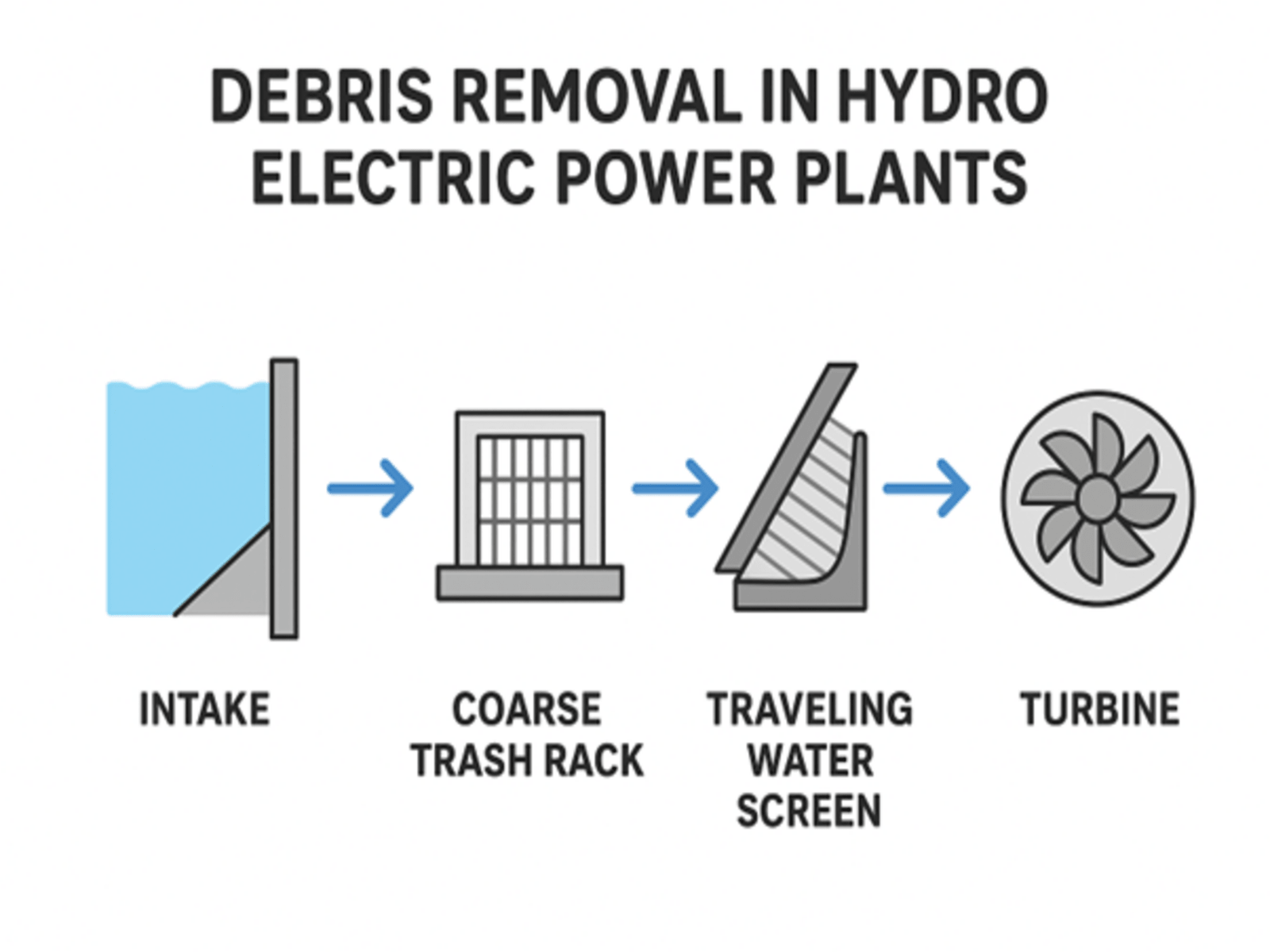

Debris removal screens are critical components in hydroelectric power stations, as they protect turbines and other equipment from damage and ensure uninterrupted operation. Water entering a hydroelectric intake often carries large quantities of debris, such as logs, branches, leaves, plastics, sediments, and even aquatic life. If this material reaches the turbines, it can cause mechanical wear, cavitation, clogging, and efficiency loss.

Detailed explanation of their applications and significance:

🔹 Debris Removal Screens in Hydroelectric Power Stations NECESSITY

1. Protecting Turbines

- Turbines are precision-engineered machines that must operate with clear water flow.

- Debris screens prevent wood, rocks, and plastics from entering turbine blades, avoiding damage and costly shutdowns.

2. Maintaining Hydraulic Efficiency

- Clean screens ensure that water flow into the turbines is uninterrupted and uniform.

- Reduces turbulence and cavitation, improving overall power generation efficiency.

3. Extending Equipment Life

- By keeping debris away from turbine blades, bearings, and wicket gates, screens help extend the life of mechanical equipment.

- Reduces wear and tear, lowering maintenance and replacement costs.

4. Preventing Blockages in Penstocks

- Penstocks (pipes that carry water to turbines) can become blocked by debris if not filtered at the intake.

- Screens eliminate the risk of flow obstruction and emergency shutdowns.

5. Reducing Downtime

- Automatic debris removal screens (self-cleaning or trash rakes) prevent manual cleaning, reducing plant downtime.

- Ensures continuous power generation even in flood seasons when debris load is high.

6. Environmental Protection

- Fish-friendly debris screens prevent aquatic life from entering turbines, improving compliance with environmental regulations.

- Helps maintain river biodiversity while enabling power production.

🔹 Types of Debris Removal Screens Used

- Coarse Trash Racks – Capture large logs, rocks, and heavy debris.

- Fine Trash Racks – Remove smaller sticks, plastics, and organic matter.

- Traveling Water Screens – Moving screens that continuously remove and carry debris to disposal chutes.

- Automatic Trash Rakes – Mechanized rakes that lift and dispose of debris collected on racks.

- Fish Exclusion Screens – Special fine-mesh screens that block fish and guide them to bypass channels.

🔹 Benefits in Hydroelectric Plants

- Prevents turbine trips and shutdowns.

- Increases plant reliability and efficiency.

- Minimizes manual labor and operational hazards.

- Meets environmental and regulatory requirements.

- Provides long-term cost savings on maintenance.

✅ In summary:

Debris removal screens are essential to ensure safe, reliable, and efficient operation of hydroelectric power plants. They act as the first line of defense at water intakes, protecting turbines and penstocks from damage while supporting environmental stewardship.

Comparison table of different debris removal screen types used in hydroelectric power stations:

📊 Comparison of Debris Removal Screens in Hydroelectric Power Stations

| Screen Type | Debris Size Handled | Mechanism | Advantages | Limitations | Typical Applications |

| Coarse Trash Rack | Large logs, branches, rocks (>50 mm) | Fixed bar racks at intake | – Simple design – Low cost – Protects from large debris | – Requires manual cleaning or trash rake – Can clog easily during floods | Initial intake barrier before fine screens |

| Fine Trash Rack | Small sticks, plastics, leaves (10–50 mm) | Fixed finer-spaced racks | – Prevents smaller debris from entering turbines – Protects wicket gates and penstocks | – More prone to clogging – Higher head loss | Secondary filtering stage, placed after coarse racks |

| Traveling Water Screen | Fine debris, fish, plastics (2–10 mm) | Continuous chain of mesh panels | – Continuous cleaning – Removes debris automatically – Can be fish-friendly | – High initial cost – Requires power & maintenance | Medium-to-large hydro plants, high debris load |

| Automatic Trash Rake | Large & medium debris (>25 mm) | Motorized rake removes debris from racks | – Reduces manual cleaning – Handles heavy loads – Reliable during floods | – Higher capital cost – Requires automation system | Large hydro plants, seasonal rivers with high debris |

| Rotating Drum Screen | Small debris, sediment (1–10 mm) | Rotating drum with mesh screen | – Very fine filtration – Continuous cleaning via rotation – Good for sediment & fish exclusion | – Higher maintenance – Limited flow capacity | Fish protection, fine debris removal in small-to-medium hydro |

| Fish Exclusion Screen | Aquatic organisms & fish | Fine mesh (≤2–5 mm), angled flow | – Protects fish & biodiversity – Regulatory compliance – Directs fish to bypass | – Can clog easily – Requires frequent cleaning | Plants with strict environmental compliance requirements |

🔹 Key Insights

- Coarse & fine trash racks = basic protection, essential in all plants.

- Automatic trash rakes = best for reducing labor and handling heavy debris loads.

- Traveling water screens & drum screens = advanced systems for continuous operation and fish protection.

- Fish exclusion screens = increasingly required for eco-friendly hydro projects.

✅ This table can serve as a procurement & design guideline when selecting the right debris screen system for a hydroelectric power plant, depending on water conditions, debris load, and environmental requirements.