Benefits and Regulatory Frameworks for ZLD Systems in Thailand’s Industrial Sector

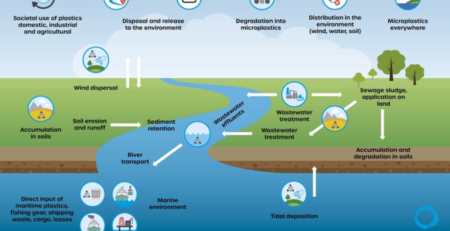

Zero liquid discharge (ZLD) aims to minimize the generation of waste while recovering resources such as fresh water and valuable salts. This industrial strategy has been gaining increased popularity worldwide in recent years.

ZLD systems are used in resource-intense industries where water resources are scarce or strict environmental regulations are enforced. These include coal-to-chemical plants and oil refineries.

Regulatory Frameworks for ZLD Systems in Thailand

The regulatory frameworks for ZLD systems in Thailand have been established to promote sustainable industrial development and reduce environmental impacts. These frameworks aim to ensure that industries adopt sustainable practices in their operations and promote the reuse of treated wastewater.

The DIW (Department of Industrial Works) has established a standard for wastewater discharge, which requires industries to reduce the discharge of pollutants into the environment. Under this standard, industries are required to treat their wastewater to a certain level before discharging it into the environment.

The DIW has also established regulations for ZLD systems, which require industries to implement these systems to treat their wastewater effectively. These regulations require industries to use ZLD systems to reduce the discharge of wastewater into the environment and promote the reuse of treated wastewater.

The Growing Importance of Zero Liquid Discharge Systems in the Thailand Industry

Zero Liquid Discharge (ZLD) systems have become increasingly important in Thailand’s industrial sector due to their ability to effectively manage and reduce water consumption and waste. ZLD systems are designed to eliminate wastewater discharge by treating and recycling all wastewater generated by industrial processes. This approach helps to conserve water resources and minimize pollution.

Thailand has been facing water scarcity issues due to a combination of factors, including increasing demand for water, population growth, climate change, and inadequate water management practices. As a result, the government has been implementing policies and regulations to promote sustainable water use and management.

In line with these efforts, many industries in Thailand are adopting ZLD systems to reduce their water footprint and comply with regulatory requirements. ZLD systems are particularly relevant for industries that generate large volumes of wastewater, such as chemical, textile, and food processing industries.

Moreover, ZLD systems can also have economic benefits for industries by reducing water consumption and costs associated with wastewater treatment and disposal. By recycling water, industries can also improve their overall operational efficiency and reduce their environmental impact.

ZLD systems are becoming increasingly important in Thailand’s industrial sector as they provide an effective solution to manage and reduce water consumption and waste. As water scarcity continues to be a challenge, industries that adopt ZLD systems can benefit from reduced costs and increased sustainability.

The Benefits and Growing Demand of Zero Liquid Discharge Systems in the Thailand Industry

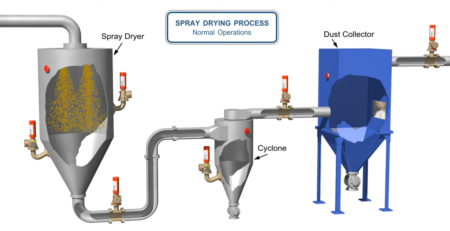

Zero Liquid Discharge (ZLD) systems are increasingly becoming popular in Thailand’s industrial sector due to the numerous benefits they offer. In simple terms, ZLD is a process that ensures no liquid waste is discharged into the environment. Instead, all the water from industrial processes is treated and reused or evaporated.

These systems are an effective way to reduce the impact of industrial wastewater on water bodies, and they are becoming more popular as a result of rising concerns over the environment’s water availability. They also help companies save on disposal costs and eliminate the need to waste valuable resources by recycling the water used in their operations.

Several factors determine the optimum design for a ZLD system. These include the type and composition of wastewater, different streams that need to be treated, site-specific operating costs and available footprint.

The cost of penalties and noncompliance is another factor that can discourage companies from using ZLD systems. However, these costs can be mitigated by the savings that are incurred in the long run when compared with conventional wastewater treatment methods.

The global zero liquid discharge systems market is expected to grow at a rapid pace over the next few years. The main drivers for this market include rising concern for water conservation and the emergence of stringent regulatory requirements. This is especially true in the Asia Pacific where increasing population and rising industrialization are creating a demand for freshwater.

The growing demand for ZLD systems in Thailand can be attributed to the increasing awareness of the benefits of sustainable practices and environmental protection. Additionally, the Thai government has set targets for reducing industrial wastewater discharge, which has led to more industries adopting ZLD systems.

Zero Liquid Discharge systems are an innovative solution for industrial wastewater treatment, which is gaining popularity in Thailand. These systems have numerous benefits for industries, including reduced environmental impacts, cost savings, and compliance with regulations. However, there are challenges in implementing these systems, including high capital costs, technical expertise.