All About Reverse Osmosis Plant

What is Reverse Osmosis Plant?

A reverse osmosis plant is a water treatment plant that uses pressure to force water through a semi-permeable membrane. The result is clean, high-purity drinking water. This process is used in a wide variety of industries, from the dairy industry to the wine industry.

Most reverse osmosis plants require pre-treatment before the membranes can do their job. These pre-filters can be carbon filters or sediment filters. Carbon filters remove chlorine and larger particles while sediment filters trap large particles and prevent them from passing through the system.

The membranes used in a reverse osmosis plant are available in different sizes. They range from two inches to eight inches in diameter.

Reverse osmosis is a pressure-driven filtration process that makes water drinkable by removing dissolved ions. It also separates out salts, dissolved inorganic solids, and other particles.

To begin the process, the feed water is treated with carbon filters or sediment filters to remove chlorine and large particles. Once the feed water is ready, it is pumped through the membranes.

Each membrane is placed in a housing that is connected to drain lines and check valves. The filtered water is then stored in a storage tank underneath the sink.

The process is finished with an ultraviolet treatment system that kills germs and odours. After this, the remaining contaminants are swept away by the flow of the water.

Reverse osmosis can remove up to 99% of dissolved solids from the water source. However, the process can only produce a small amount of fresh water. So, the desalination plant has to find ways to conserve energy and reduce waste.

How Does Reverse Osmosis Work?

Reverse Osmosis is a process that can make tap water taste better and remove a variety of contaminants. However, it is not without its drawbacks.

A reverse osmosis system is not self-sustaining. It needs maintenance, as well as pre-treatment of the water.

One of the benefits of reverse osmosis is the removal of dissolved salts and other particles that can cause harm to the human body. The membrane used in this type of filtration is a thin film composite material, which has a rejection rate of up to 97 percent.

To use this method of filtration, you need to have a high-pressure system. This is needed to get enough pressure to move the solution across the membrane. If the water is not strong enough, you may have to install a booster pump.

In a two-stage system, the water passes through a sediment filter and a carbon filter. The carbon filter will remove chlorine from the water.

Depending on the quality of the water, you may need to change the carbon filter twice a year. You may also need to replace the sediment filter every 6 months.

In a multi-stage reverse osmosis system, you can reduce a number of volatile organic compounds, such as chloramines. Additionally, you can lower the concentration of some taste-producing chemicals.

A reverse osmosis device is most effective when used to treat drinking water. However, it can be used to recycle water and produce energy.

A reverse osmosis water treatment plan can provide clean, great-tasting water for your home.

Reverse Osmosis Plants in Australia

It is estimated that Western Australia is the first state in the world to use desalination as a major public water source. The project is expected to provide up to 17 percent of the city’s water needs.

With a drier climate, the water supply in Perth has deteriorated significantly. Salt levels have also increased due to vegetation loss. This has led to the need for a more efficient water treatment system.

The Waterman Engineers Australia has developed Reverse Osmosis plants that allow poor quality water to be transformed into safe drinking water. They can be used to treat water from most city supplies.

Currently, Western Australia has three reverse osmosis plant facilities. One is at a seawater intake, another is at a product water facility, and one is a small domestic plant.

In addition to treating water from oceans, desalination can be used to treat brackish groundwater. As a result, the Saltwater Reverse Osmosis Plant has reduced energy costs by half.

Key Sensors and Alarm in RO Plant Monitoring

There are several challenges in RO plant monitoring. For instance, the membrane can get oxidized or damaged due to the use of oxidizers like chlorine. Hence, regular maintenance of the RO membrane can prolong its life and productivity.

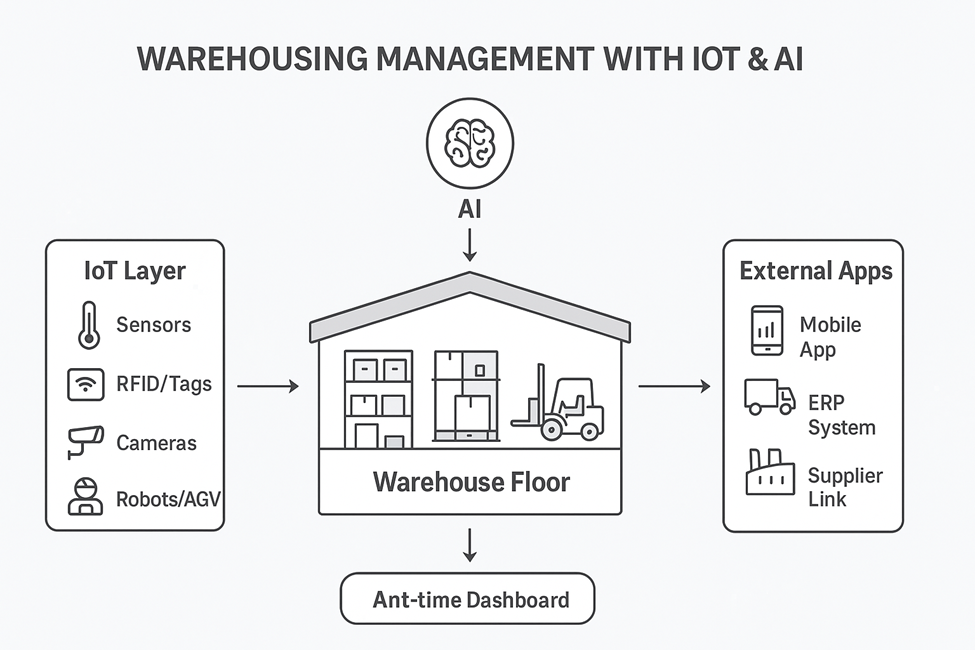

A RO plant status monitoring unit has been developed to monitor different plant parameters. It includes commercial sensors and a smartphone-based app interface to transfer the data to the cloud. This system is a cost-effective solution that can be operated by an unskilled individual.

The embedded RO plant status monitoring unit acquires real-time data from various commercial sensors. Real-time information about the RO plant can be used for rapid maintenance action.

The Life Cycle of a Seawater Reverse Osmosis Desalination Plant

A seawater reverse osmosis desalination plant is a technological advance that has led to the production of potable water. It is a process which removes many different types of ions from seawater. In general, the production of this type of water is energy intensive.

Seawater reverse osmosis technology has become very popular in recent years. However, it still needs to be improved to be more environmentally friendly.

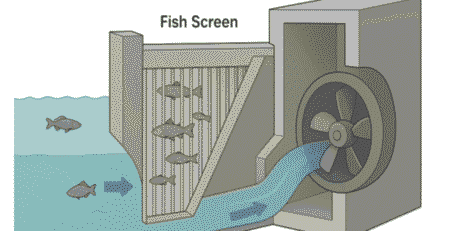

For this reason, the study examined the life cycle of two different SWRO processes. The first stage, pretreatment, included low-pressure ultrafiltration, granular media filtration, sedimentation and flocculation.

The next stage, the RO membrane, involved pressurization of seawater against a semi-permeable membrane. This phase produces the cleanest water. After the RO process, the permeate stream goes through conditioning chemicals.

The post-treatment stage is where the highest relative contributions to impact categories are seen. The most significant impacts are the effects on the environment.

These include global warming, terrestrial ecotoxicity and fossil resource scarcity. Overall, the process resulted in minimal concentrations of sludge.

The use of membrane technology in the operation of the facility has proved effective. However, further development is needed to recover osmotic energy.

The design of the brine outfall also ensures that the flow is dispersed safely into the sea. In addition, fault detection and isolation systems are essential for safe operation.

In Conclusion

Reverse osmosis is frequently used to transfer fluids and purify feed water. Due to the declining condition of groundwater and freshwater supplies, a rising number of saltwater desalination facilities are using these pumps.

Reverse osmosis systems are used in industrial operations to reduce environmental harm and expenses associated with handling wastewater. Reverse osmosis plants are crucial in the removal of pollutants and toxins from the vast amounts of water that industrial operations use and discharge at high rates of flow.

Many manufacturers, including those in the beverage and food manufacturing, big filtration systems, and household filters, benefit from reverse osmosis plants.