Rotary Drum Screens in Hydropower Plants

Rotary Drum Screens for hydropower plants, which are widely used for fish protection and debris/moss removal at turbine intakes.

⚙️ Rotary Drum Screens in Hydropower Plants

🔎 What is a Rotary Drum Screen?

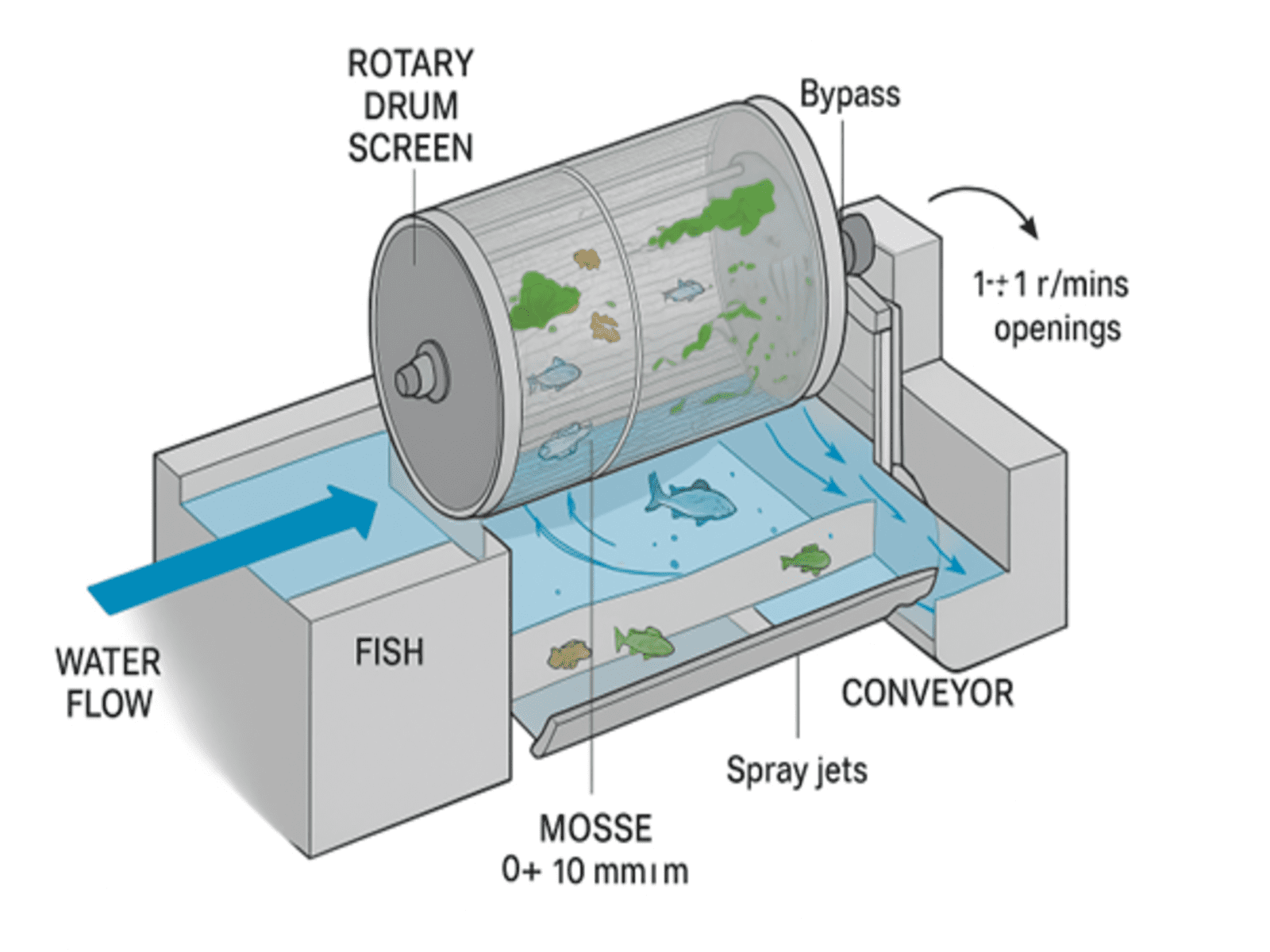

A rotary drum screen is a cylindrical drum with fine mesh or wedge-wire panels that rotates slowly in the water intake channel. Water passes through the screen into the intake → fish, moss, and debris are blocked and guided to a bypass → clean water enters the turbine.

Working Principle

- Water Flow

- Water enters the drum’s submerged portion.

- Screen mesh (slots 1–10 mm depending on target species) allows water through but blocks fish and debris.

- Fish Guidance

- Fish encounter the rotating drum surface.

- Flow and rotation guide them to a bypass channel alongside the drum.

- Self-Cleaning

- As the drum rotates upward, spray jets or brushes clean off trapped moss, algae, and debris.

- Waste is collected in troughs and conveyed away.

📏 Design Features

- Drum Size: Large diameter (2–6 m typical) and width up to several meters.

- Screen Material: Stainless steel wedge-wire or perforated mesh.

- Slot Size: Fine openings (1–2 mm for juveniles, 6–10 mm for larger fish).

- Rotation: Slow (1–5 rpm), powered by water current or motors.

- Bypass Location: Adjacent to drum for easy fish entry.

🐟 Role in Fish Protection

- Prevents fish from being drawn into turbines.

- Guides fish gently to bypass with low stress and high survival (>95%).

- Especially effective for juvenile salmonids, smolts, and eels, which follow surface flows.

🌱 Role in Moss & Debris Removal

- Removes floating moss, algae mats, and leaves before they clog penstocks.

- Continuous cleaning system reduces downtime and labor.

- Maintains hydraulic efficiency of intake flow.

✅ Advantages

- High fish protection efficiency (meets US NOAA / EU WFD standards).

- Automatic self-cleaning → low manual maintenance.

- Handles large debris + fine moss

- Long lifespan (stainless steel construction).

- Works in variable water levels and flows

⚠️ Limitations

- High capital cost compared to fixed bar screens.

- Needs reliable power or flow for drum rotation.

- Requires spray water system for cleaning.

- Performance depends on correct approach velocity design (≤ 0.3 m/s for juveniles).

🌍 Example Applications

- Columbia River (USA): Rotary drum screens protect juvenile salmon downstream of dams.

- UK Small Hydro Plants: Used for eel and trout protection at intakes.

- Norway & Germany: Installed for both fish safety and algae removal in alpine rivers.

✅ In summary:

Rotary drum screens are self-cleaning, rotating fish protection and debris removal systems at hydropower intakes. They ensure safe fish bypass, prevent turbine clogging from moss/algae, and maintain continuous operation with minimal manual cleaning.

Excellent request 👍 Let’s compare Rotary Drum Screens and Traveling Water Screens, since both are widely used in hydropower intakes for fish protection and debris/moss removal.

🔄 Comparison: Rotary Drum Screen vs. Traveling Water Screen

| Feature | Rotary Drum Screen | Traveling Water Screen |

| Basic Design | Large cylindrical drum (2–6 m dia.), rotates slowly in water. | Vertical conveyor-like screen with mesh panels attached to chains, moving upward and downward. |

| Screen Surface | Continuous curved drum surface. | Flat panels moving vertically. |

| Operation | Water flows through drum → fish/debris blocked → fish guided to bypass → debris washed off by spray jets. | Water flows through vertical screen panels → debris lifted out of water → high-pressure sprays remove debris at deck level. |

| Self-Cleaning | Automatic via drum rotation + spray jets. | Automatic via moving panels + spray wash at top. |

| Fish Protection | Very high survival (>95%). Fish gently guided to side bypass. Best for juvenile salmonids, eels. | Effective if approach velocity ≤0.3 m/s. Fish lifted away from intake but sometimes exposed to mechanical stress at spray wash. |

| Debris & Moss Handling | Excellent for moss, algae mats, floating debris. Drum keeps continuous removal. | Good for large debris (sticks, trash, leaves). Less effective for fine moss/algae unless frequent cleaning. |

| Bypass Integration | Direct lateral bypass channel adjacent to drum. | Fish bypass chute or sluice integrated near screen face. |

| Energy Use | Low (slow rotation, only spray pumps). | Moderate (continuous chain drive + spray pumps). |

| Maintenance | Simple, fewer moving parts. Long life (stainless steel drum). | More moving parts (chains, sprockets). Higher mechanical wear. |