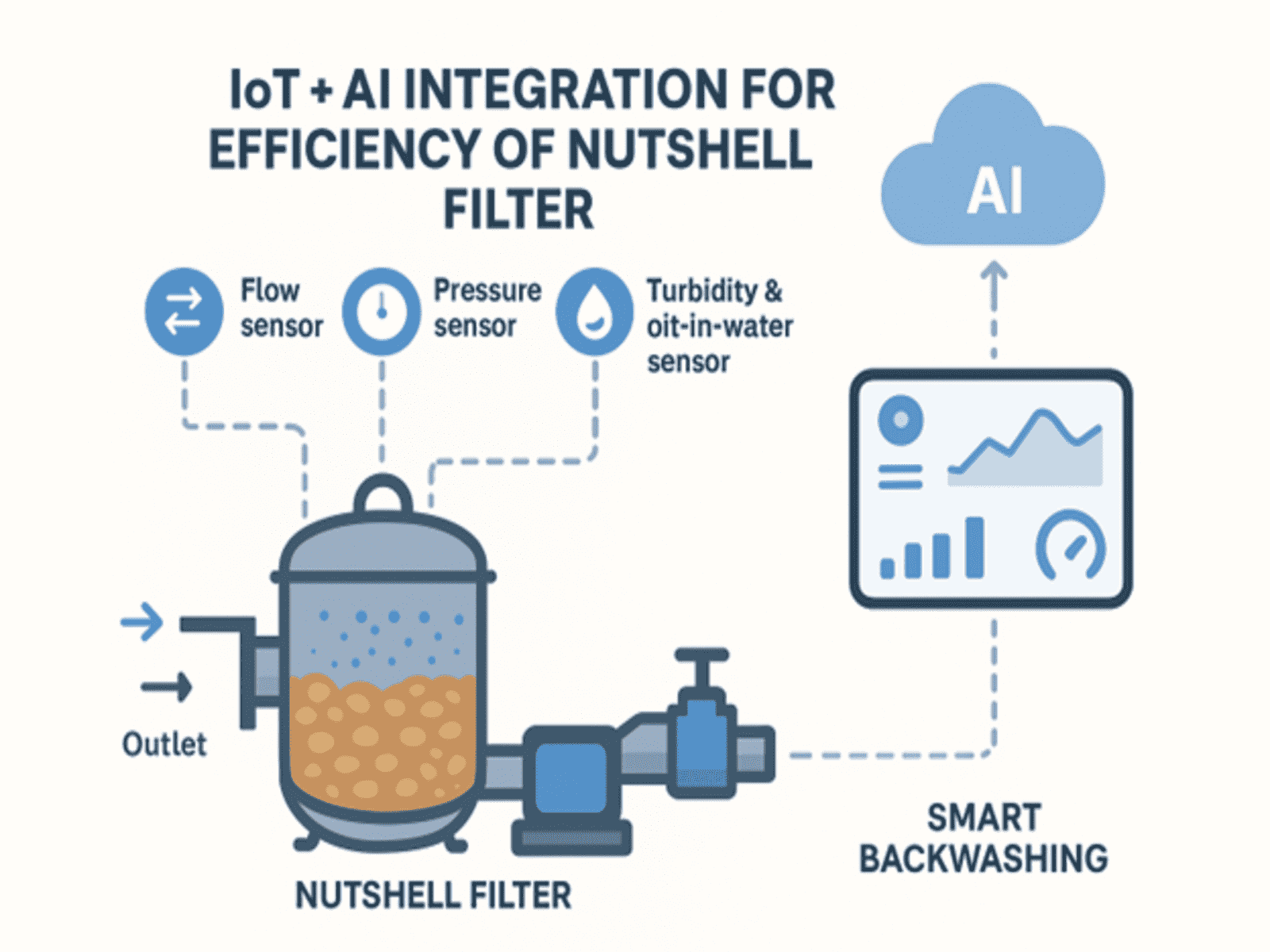

IoT and Artificial Intelligence Integration for Efficiency of Nutshell Filters

1. Introduction

Nutshell filters are widely used in industrial water treatment and oil & gas operations to remove suspended solids and oil from produced water and wastewater streams. Their performance depends on parameters such as flow rate, differential pressure, media bed condition, and backwashing cycles. Traditional operation often relies on manual monitoring and fixed-time backwashing, which may lead to energy waste, reduced efficiency, and increased downtime.

Integrating Internet of Things (IoT) and Artificial Intelligence (AI) into nutshell filter systems provides real-time monitoring, predictive control, and automated optimization. This improves operational efficiency, reduces maintenance costs, and ensures consistent effluent quality.

2. Role of IoT in Nutshell Filters

IoT enables the collection of real-time process data from the filter system. Key instrumentation includes:

- Flow Sensors – Measure inlet and outlet water flow.

- Pressure Sensors – Monitor differential pressure across the filter media.

- Turbidity & Oil-in-Water Sensors – Track effluent quality continuously.

- Level Sensors – Detect water levels in filter vessels.

- Motor & Actuator Monitoring – Track backwash pump performance and valve positions.

- Cloud Connectivity – Transmit operational data to centralized dashboards for remote monitoring.

With IoT, operators gain visibility into filter performance anytime, anywhere, and can detect anomalies before they escalate.

3. Role of Artificial Intelligence (AI)

AI enhances the efficiency of nutshell filters by analyzing historical and real-time data. Major applications include:

- Predictive Backwashing

- AI models predict the optimal time for backwash based on turbidity trends, pressure differential, and flow history.

- Prevents premature or delayed backwashing, saving water and energy.

- Anomaly Detection

- Machine learning algorithms identify abnormal behavior, such as media fouling, pump failure, or valve malfunction.

- Early detection reduces unplanned downtime.

- Process Optimization

- AI adjusts operational parameters (flow rate, backwash intensity, cycle duration) dynamically to maximize filtration efficiency.

- Reduces energy and chemical consumption.

- Predictive Maintenance

- AI forecasts wear and tear of filter internals (media degradation, pump efficiency loss).

- Enables condition-based maintenance rather than fixed schedules.

4. Benefits of IoT + AI Integration

- Improved Filtration Efficiency – Maintains consistent water quality.

- Reduced Operating Costs – Optimized backwash reduces water, energy, and chemical usage.

- Increased Equipment Life – Smart monitoring prevents overloading and excessive wear.

- Remote Operations – Centralized monitoring suits remote oilfields and offshore platforms.

- Regulatory Compliance – Continuous quality monitoring ensures discharge standards are met.

5. Example Workflow

- IoT sensors continuously collect data on pressure differential, turbidity, and flow.

- Data is sent to a cloud platform where AI algorithms analyze performance.

- AI predicts when backwash is needed and sends automatic commands to actuators.

- Operators receive alerts on dashboards and mobile apps for remote decision-making.

- Predictive maintenance alerts are generated before failures occur.

6. Future Outlook

As IoT and AI technologies mature, nutshell filters will evolve into self-learning, autonomous filtration systems. Integration with digital twins of treatment plants could enable real-time simulation and scenario analysis, further optimizing operations at scale.

✨ In short: IoT provides the real-time eyes and ears of the nutshell filter, while AI acts as the brain, optimizing every cycle for maximum efficiency.