Zero Liquid Discharge System – ZLD Thermal Systems

A zero liquid discharge system or ZLD System, is an innovative wastewater management approach that assures that almost no industrial effluent is discharged further into the environment. The goal of ZLD water treatment plants is just to minimize the cost of wastewater while producing safe water that can be reused for other purposes, for instance, agriculture to save and benefit the environment. ZLD system purifies and recycles nearly all the wastewater generated using modern wastewater management techniques and desalination treatment processes. ZLD has been considered an essential method for long-term wastewater reuse. Over the globe, nearly 100 to 200 million dollars has already been devoted to the improvement of ZLD technologies with a dramatic increase in industrialized countries including the United States, China, and Europe, and also developing countries like India.

PURPOSE OF THE INNOVATION

As one of the best ZLD suppliers, it is a dire need to develop systems like Zero Liquid Discharge System due to rapid industrialization and urbanization that are tapping rising demands on freshwater supplies around the globe. It is considered as one of the world’s most significant problems, compromising the quality of the water, water security, economic expansion, and ecosystems. As a result of the increased demand for fresh water in industries, huge quantities of wastewater is being produced. When wastewater is dumped into bodies of water without even being properly treated, this can lead to serious contaminants, which negatively impact marine ecosystems and human health. Hence it was a need of the hour. This wastewater recovery system minimizes the incidence of contamination of water from untreated wastewater while simultaneously increasing water efficiency.

MAJOR ZLD SYSTEMS

Some major zero liquid discharge systems are discussed below:

ZLD Thermal Systems

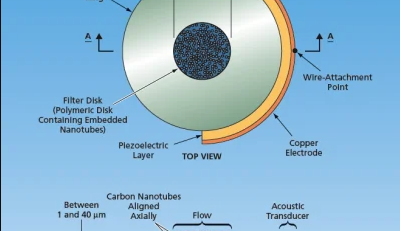

In the ZLD system, pre-treatment of wastewater, management inside a brine crystallizer as well as brine concentrator, evaporation, and solids recovering are the main components. To reduce the maximum extent possible of water, wastewater undertakes pre-treatment operations like filtering, de-aeration, anti-scaling, and pH modification. Following that, a brine concentrator and a brine crystallizer are used to concentrate the water in zero discharge systems. Distillates are used again as safe water, whereas solids either are collected as economic residues or disposed of in evaporation ponds upon further treatment.

Thermal ZLD Systems with RO Integrated

RO, a pressure-compelled desalination technique, is integrated with thermal ZLD systems inside this system to reduce the amount of brine sludge reaching the brine crystallizer and concentrator, cutting energy usage. RO uses about 2 kW/m3 of product water with 50 percent recovering in saltwater desalination which is substantially lesser energy than brine crystallizers and concentrators. If RO-fed waste has a reduced salinity often up to 70,000 mg/L then this sort of system is cost beneficial, whereas the advent of freshly developed filters signals further potential to use RO in treating wastewater. Hence RO concentrates wastewater before this enters thermal operations, lowering capital and operating expenses.

ZLD Systems with MD Integration

ZLD or Zero Liquid Discharge Systems incorporation with MD is a valuable addition to this system. MD typically uses hydrophobic micro-porous membranes composed of polyvinylidene fluoride, polypropylene, or polytetrafluoroethylene. Poor mass transfer resistance, excellent chemical resistance, low thermal conductance to reduce heat loss, and good thermal resilience at high temperatures are all features of these materials. It’s a rapidly evolving technique that can use waste heat to concentrate saline wastewater to approach saturation. In most ZLD systems, a brine concentrator is used to concentrate wastewater to near saturation utilizing thermal energy or electrical energy. These brine concentrators are far more costly, and they can extract 60–90% of the water in the brine. MD can use reduced thermal energy to treat high salinity feed waterways that must not be desalinated through RO. Furthermore, as compared to other techniques, it is a cost-effective and environmentally benign procedure, particularly as low-grade energy is accessible. It can also work at low temperatures as well as pressures and has a minimal fouling proclivity.

ZLD Systems with FO Integration

ZLD integration with FO is also an effective technique as water molecules pass across a semipermeable membrane due because of an osmotic difference in FO. This membrane allows clean water molecules to flow through while rejecting saline or solute molecules. The pull solutions, that have a Bonaventure chemical potential as well as lower osmolality, are being used in the FO process to lure water from saltwater, which has a greater water chemical reactivity and lesser osmotic pressure. An energy-efficient separating technology is then used to recover clean water from the dilute solution. Water molecules are transferred from the feeding to a draw solution above a semipermeable membrane in the first phase of desalination, and then freshwater is isolated from the diluted solution enabling draw-solution recovery and recycling in the second phase. The brine generated by these operations is sent to a crystallizer or perhaps an evaporation pond for more concentrating and recovering freshwater as well as other salt residues.

ZLD Systems with ED Integration

ZLD integration with ED has been used to desalinate both surface and groundwater with great effectiveness. It could also be used to pre-treat as well as pre-concentrate brine before it is sent to the evaporation crystallizer for ZLD systems. Ion exchange membranes are typically employed in this approach to remove soluble contaminants from water, with electric potential as the main driver. Such membranes enable selective counter ion transfer but inhibit co-ion transfer. Cations migrate forward towards a negative electrode via a cation exchange membrane, whereas anions migrate oppositely via an anion-exchange membrane surface. Salt-depleted dilutes and concentrates brine flows are formed on this basis. Electrodialysis reversal removes whatever scalability or contaminants of membranes by changing the polarity of such electrodes, requiring less processing than RO. Furthermore, since neutral silica also isn’t collected in the brine stream, these approaches have quite a lesser tendency towards scaling, even with silica-enriched feeding waters. By spending 7 to 15 kW/m3 in the feed solution, ED and EDR are able of concentration feed fluids to salinity levels beyond 100,000 mg/L, comparable to RO. The cost estimate for desalination by ED is greater than the corresponding dilute salinities. As ED/EDR is combined with RO using ZLD systems, the salinity limitation of RO is increased while energy consumption is reduced when compared to saline concentrator processes.