Optimizing the Operation of Seawater Desalination Plants

Seawater desalination plants extract salt and other minerals from seawater, making it potable for human consumption. The process is highly beneficial for arid areas and island nations with limited water sources. Seawater desalination facilities necessitate consistent upkeep and operation to guarantee the production of superior potable water and optimal performance.

Understanding Seawater Desalination Plants

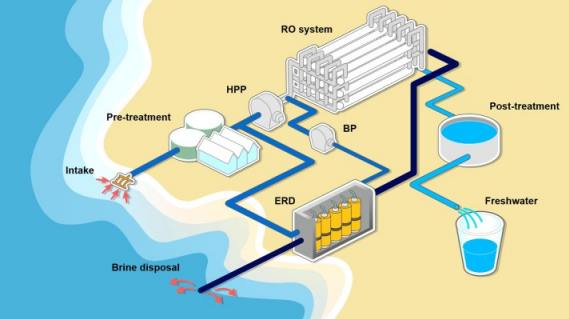

Seawater desalination plants can operate in different ways. The prevailing techniques employed are reverse osmosis and thermal desalination. Reverse osmosis coerces seawater to permeate a semi-permeable membrane that selectively permits water molecules to traverse through while capturing salt and other undesirables. Thermal desalination, conversely, capitalizes on heat to vaporize seawater, forsaking salt and other impurities in its wake.

Operation Optimization of Seawater Desalination Plants

Optimizing the operation of a seawater desalination plant can improve its efficiency and reduce operating costs. Here are some ways to optimize the operation of a desalination plant:

Monitoring and Control Systems

Monitoring and control systems are essential to ensure that the plant operates efficiently. The systems can detect abnormalities and alert operators to take corrective action. The following are some critical monitoring and control systems:

Flow meters: These devices measure the flow rate of water and alert operators to any changes in flow.

Pressure gauges: These gauges monitor the pressure in the system and alert operators to any fluctuations.

pH meters: These meters measure the acidity of water and alert operators to any changes.

Turbidity sensors: These sensors measure the level of turbidity in water and alert operators to any changes.

Cleaning and Maintenance Procedures

Desalination plants require regular cleaning and maintenance to remove scale and other deposits that can reduce the efficiency of the system. The following are some critical cleaning and maintenance procedures:

Chemical cleaning: Chemicals such as acids and bases can remove scale and other deposits from the system.

Mechanical cleaning: Mechanical methods such as high-pressure water jets can remove deposits from the system.

Backwashing: Backwashing can remove particles from the membranes and prevent clogging.

Membrane replacement: Membranes can become damaged or clogged over time and may require replacement.

Energy Efficiency Measures

Desalination plants necessitate an immense magnitude of energy to function, accentuating the gravity of energy-efficient tactics in diminishing operational expenditures and environmental footprints. The following are some ways to improve energy efficiency:

Recovery systems: Recovery systems can recycle wastewater and reduce the amount of energy needed to produce fresh water.

Variable frequency drives: Variable frequency drives can adjust the speed of motors to match the demand for water and reduce energy consumption.

Energy recovery devices: Energy recovery contrivances facilitate the reclamation of energy from the briny stream and harness it to fuel the desalination course.

Chemical Treatment

Chemical handling is indispensable in preserving the caliber of the water that a desalination plant dispenses. The following are some critical chemical treatments:

Antiscalants: Antiscalants prevent the formation of scale on the membranes and reduce the need for cleaning.

Disinfectants: To exterminate microbes such as bacteria and viruses that are present in the water, disinfectants like chlorine or ozone are implemented.

Maintenance Optimization of Seawater Desalination Plants

Optimizing the maintenance of a desalination plant can prevent equipment failure, reduce downtime, and increase the lifespan of the system. The following are some ways to optimize maintenance:

Preventive Maintenance

Preventive maintenance involves scheduled maintenance to prevent equipment failure. The following are some critical preventive maintenance procedures:

Lubrication: Lubrication can prevent wear and tear on moving parts and reduce friction.

Inspection: Regular inspection can detect potential problems before they become severe.

Calibration: Calibration of monitoring and control systems can ensure accurate readings.

Corrective Maintenance

Corrective maintenance involves repairing equipment after a failure has occurred. The following are some critical corrective maintenance procedures:

Troubleshooting: Troubleshooting can identify the cause of the problem and determine the necessary repair.

Repair or replacement: Repair or replacement of damaged equipment can restore the system to its optimal condition.

Predictive Maintenance

Predictive maintenance involves using data analysis to predict when equipment is likely to fail. The following are some critical predictive maintenance procedures:

Condition monitoring: Condition monitoring can detect changes in equipment performance that may indicate a potential problem.

Predictive analytics: Predictive analytics can analyze data to predict when equipment is likely to fail.

Importance of Optimization of Seawater Desalination Plants

The optimization of seawater desalination plants’ operation and upkeep is imperative to guarantee the cost-efficient and optimal production of high-grade potable water. Optimization accords the advantages of trimming operating overheads, forestalling equipment breakdowns, and augmenting the longevity of the system.

Seawater desalination is a crucial procedure for numerous countries around the globe, with optimization of the operation and upkeep of desalination plants being a vital cog in facilitating their proficient operation and production of high-standard potable water. By implementing monitoring and control systems, cleaning and maintenance procedures, energy efficiency measures, and chemical treatment, desalination plants can operate efficiently and cost-effectively.