Water Filter Screens in Hydroelectric Power Stations

🔹 Water Filter Screens in Hydroelectric Power Stations

Hydroelectric power stations draw huge volumes of water from rivers, reservoirs, or dams. Along with water, debris like logs, leaves, fish, aquatic vegetation, silt, and garbage can enter the intake system.

If unchecked, this debris can:

- Damage turbine blades and pumps

- Reduce efficiency of the turbines

- Cause blockages in penstocks

- Increase maintenance downtime

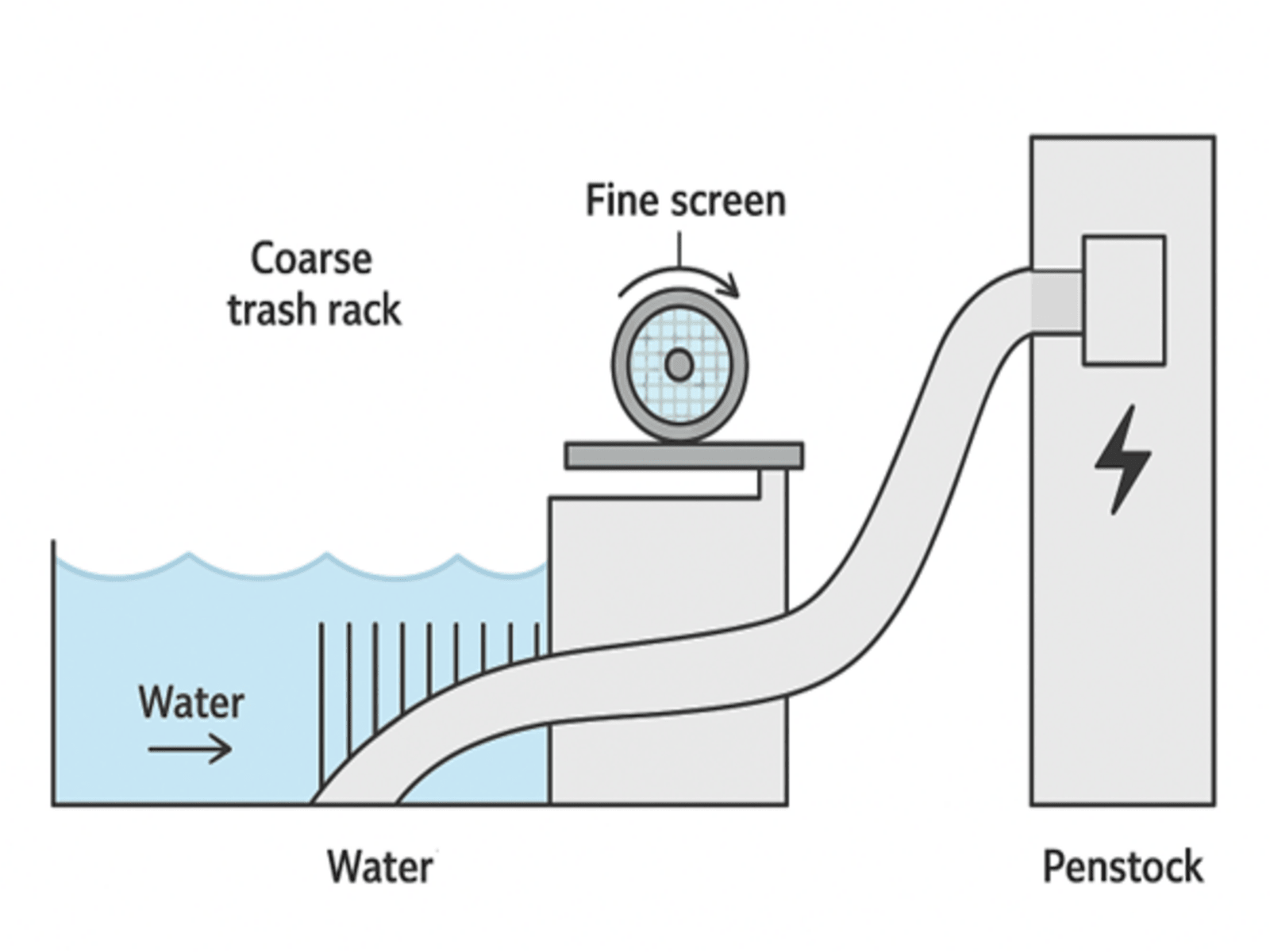

To prevent these issues, water filter screens are installed at intake points to filter out debris before water enters the penstock.

🔹 Types of Filter Screens in Hydropower

- Coarse Screens (Trash Racks)

- Installed at dam or intake points.

- Made of heavy-duty steel bars.

- Spacing: 10–150 mm depending on debris load.

- Stops large objects (logs, branches, plastics).

- Fine Screens / Traveling Screens

- Mechanized, rotating belt or drum type.

- Spacing: 3–20 mm.

- Removes smaller debris, weeds, fish.

- Often self-cleaning with raking mechanisms.

- Micro / Drum Screens

- Cylindrical mesh or perforated drum.

- Fine openings (0.2–3 mm).

- Used for very clean intakes where silt, algae, or small organisms must be controlled.

- Automatic Self-Cleaning Screens

- Work on suction or backwash principle.

- Common in modern hydropower plants.

- Reduce manpower and prevent clogging.

🔹 Key Design Considerations

- Hydraulic Load Capacity → Must match flow rate (m³/s).

- Bar Spacing / Mesh Size → Balances debris removal vs. head loss.

- Head Loss → Too fine a screen increases resistance, reducing efficiency.

- Structural Strength → Must withstand high water pressure and debris impact.

- Self-Cleaning System → Rakes, brushes, water jets to prevent clogging.

- Fish-Friendly Design → Gentle screens or bypass channels to protect aquatic life.

- Automation & IoT Integration → Sensors for debris load, motorized rakes, predictive maintenance.

🔹 Applications in Hydroelectric Plants

- Intake Protection → Ensures clean flow into penstocks.

- Turbine Protection → Prevents erosion, pitting, cavitation from debris.

- Cooling Water System → Filters water used in cooling generators, bearings.

- Environmental Compliance → Screens with fish diversion systems to protect biodiversity.

🔹 Modern Developments

- IoT + AI in Screen Monitoring

- Sensors detect differential pressure across screen (clogging indicator).

- AI algorithms predict cleaning cycles to minimize downtime.

- Remote monitoring for unmanned hydro stations.

- Energy Efficient Raking Systems

- Hydraulically driven rakes synchronized with water debris load.

- Save power and reduce operational cost.

- Fish-Friendly Screens

- Inclined screens with bypass channels.

- Allow safe fish passage while keeping turbines clean.

🔹 Example: Typical Screening Layout in Hydropower

- Coarse Trash Rack at reservoir intake → Removes big debris.

- Automatic Fine Screen before penstock → Removes smaller debris.

- Secondary Fine Screen for cooling water pumps.

- Sedimentation / Desilting Basin (optional) → Controls silt before turbines.

✅ In summary: Water filter screens in hydroelectric power plants are multi-stage protective barriers that safeguard turbines, optimize efficiency, and ensure compliance with environmental regulations.