VACUUM MULTI EFFECT DISTILLATION DESALINATION

Introduction:

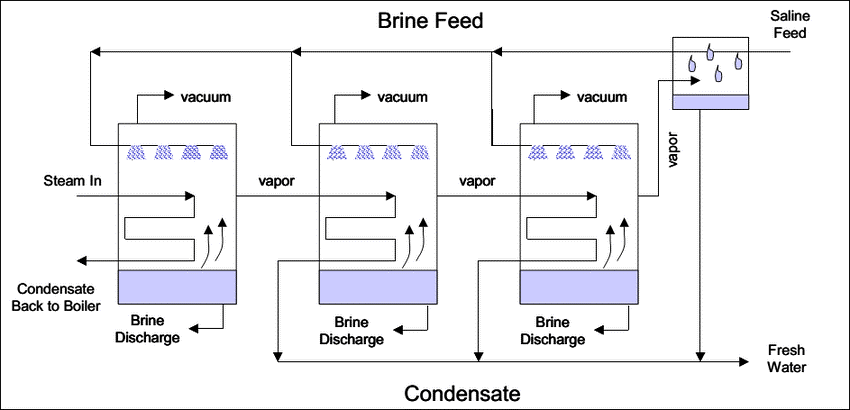

A Multi-Effect Distillation Vacuum (MEDV) system is a process that combines multi-effect distillation (MED) with vacuum distillation to efficiently purify high saline water or seawater using waste heat. The process can be extended to include multiple stages and a vacuum chamber or vacuum system for further water purification.

Introduction to Desalination and MEDV Technology

Access to freshwater is a critical resource for sustaining life, agriculture, and industrial processes. However, as global populations increase and water resources become scarcer due to factors like climate change and pollution, the need for efficient and sustainable desalination technologies has grown significantly. Desalination is the process of removing salts and impurities from seawater or brackish water to produce freshwater suitable for various applications. One of the innovative desalination methods is the Multi-Effect Distillation Vacuum (MEDV) system.

The MEDV system is an advanced water purification technology that combines multi-effect distillation (MED) with vacuum distillation to efficiently produce freshwater from saline water sources while minimizing energy consumption and waste generation. This comprehensive guide will take you through the entire MEDV process, from its fundamental principles to its real-world applications and benefits.

1: Understanding Desalination Technologies

- Overview of Desalination

Desalination is the process of removing salts and impurities from water to make it suitable for drinking, irrigation, industrial processes, and other applications. Various desalination methods are employed worldwide, including reverse osmosis (RO), distillation, electrodialysis, and forward osmosis. Each method has its advantages and limitations, and the choice of technology depends on factors such as feedwater quality, energy availability, and cost-effectiveness. - Distillation-Based Desalination

Distillation-based desalination methods rely on the principles of evaporation and condensation. These methods include multi-effect distillation (MED), multi-stage flash (MSF) distillation, and MEDV. Distillation-based desalination processes are particularly well-suited for treating saline water sources, such as seawater, and are known for their ability to produce high-quality freshwater.

2: The Basics of Multi-Effect Distillation (MED)

- Introduction to MED

Multi-Effect Distillation (MED) is a thermal desalination process that uses multiple stages or “effects” to efficiently remove salt and impurities from saline water. It operates under reduced pressure conditions, which allows water to boil at lower temperatures, thereby saving energy. In a typical MED system, each effect is a separate chamber or unit where water is evaporated and condensed. The heat required for evaporation is supplied by a heat source, often waste heat from industrial processes or power generation. - How MED Works

The fundamental operation of MED involves the following steps:- Evaporation

Saline water is heated, and the water vaporizes, leaving behind the salt and impurities. - Condensation

The water vapor is then condensed back into liquid form - Collection

The resulting purified water is collected and further processed.

- Evaporation

- Advantages of MED

MED offers several advantages, including:-

- Energy Efficiency: MED utilizes waste heat effectively, making it energy efficient.

- High Purity: It produces high-quality freshwater with low salinity levels

- Scalability: MED systems can be scaled up or down to meet varying water demands.

- Suitable for High Salinity: MED is effective for treating highly saline water sources, such as seawater.

-

- The Role of Vacuum Technology in MEDThe integration of vacuum technology with Multi-Effect Distillation (MED) represents a key strategy for optimizing saline water desalination and purification processes. By reducing boiling points, enhancing energy efficiency, and facilitating cascading effects, the vacuum system maximizes production yields while simultaneously reducing energy consumption costs. These benefits make the combination of vacuum technology and MED a compelling choice for addressing water scarcity and ensuring access to high-quality freshwater resources.The broader implications extend beyond cost savings and energy efficiency. Vacuum-enhanced MED systems contribute to sustainable water management practices, making saline water desalination an environmentally responsible solution. As advancements continue to refine vacuum technology and MED processes, the synergy between the two holds promises for meeting the growing global demand for freshwater while minimizing the environmental footprint of desalination operations.

- Lowers boiling points, enhancing energy efficiency

- Optimizes heat transfer and waste heat utilization

- Reduces energy consumption costs

- Ensures high-purity distilled water.

- Provides operational flexibility and scalability.

- Enhances system reliability and performance.

By harnessing the advantages of vacuum technology, MED systems are poised to play a pivotal role in addressing water scarcity challenges and promoting sustainable water resource management worldwide.

3. Working mechanism of Multi-Effect Distillation Vacuum (MEDV) system.

-

- 3.1 Operating Principles

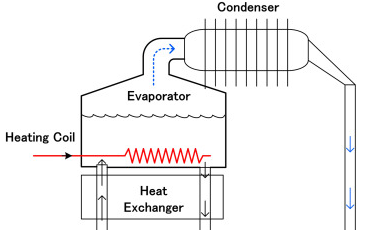

The operation of an MEDV system involves the following key principles:- Heat Transfer: Heat is transferred to the saline water, causing it to evaporate.

- Evaporation: Water vapor is generated in the low-pressure environment of each effect.

- Multi-Effect Operation: The vapor from one effect is used as a heat source for the next effect, cascading the heat and increasing energy efficiency

- Vacuum Control: Vacuum systems maintain the required low pressure, enabling water to boil at reduced temperatures

- Condensation: Water vapor is condensed back into liquid form, yielding purified freshwater.

- 3.1 Operating Principles

Below is an elaboration of how the MEDV system can work:

-

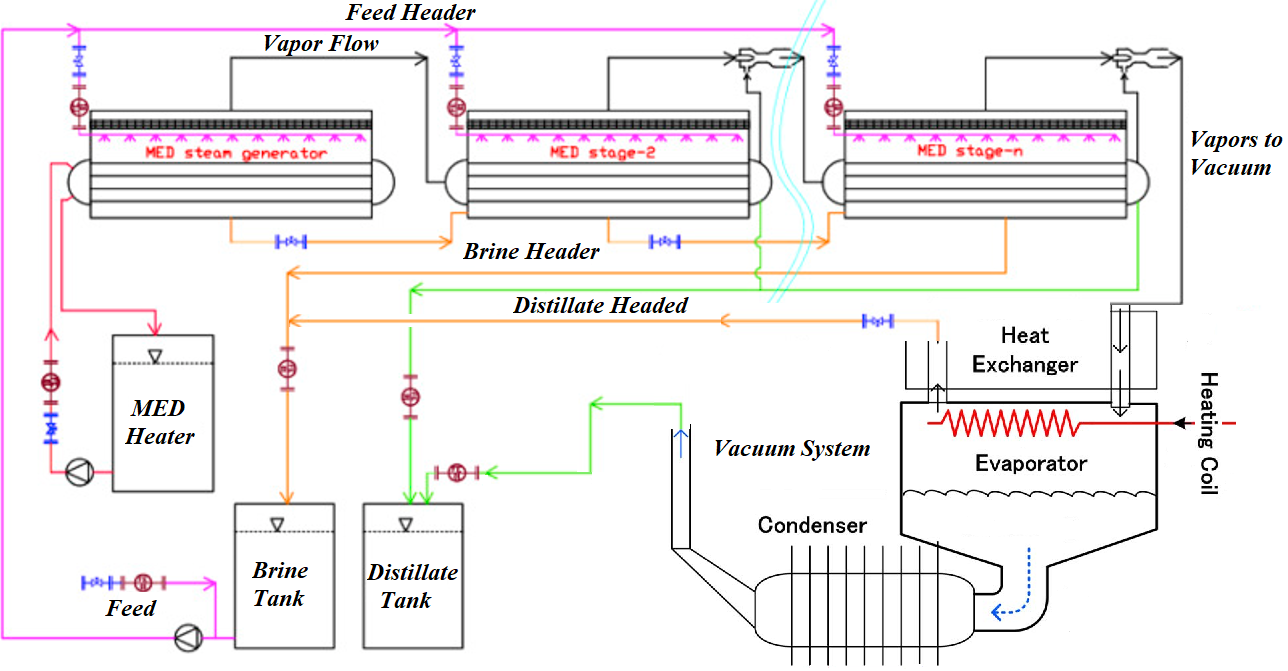

- 3.2 Multi-Effect Distillation (MED):

In the initial stages of the process, seawater or high saline water is heated using waste heat sources, typically at temperatures around 55°C or higher. This waste heat can come from various industrial processes or power generation.- The heated seawater is introduced into a series of distillation chambers, typically referred to as “effects.”

- In each effect, the seawater is evaporated at a lower temperature due to the vacuum conditions within the chamber. The reduced pressure allows water to boil at lower temperatures, saving energy.

- As the water vaporizes, it leaves behind the salt and impurities, resulting in distilled water vapor.

- The distilled water vapor is then condensed and collected as purified water.

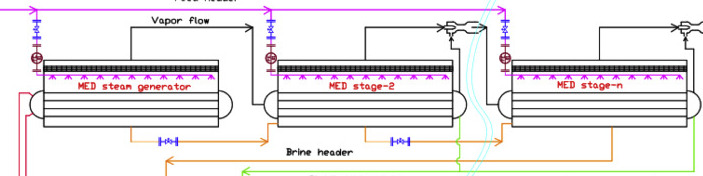

- 3.3 Multiple Effects:

To improve the efficiency of the process, multiple effects are used in series.-

- In a multi-effect system, the heat from the previous effect is used to heat the seawater in the next effect.

- Each effect operates at a lower pressure and higher temperature than the previous one, utilizing the waste heat efficiently.

- This cascading effect helps in maximizing the water production and energy efficiency.

-

- 3.4 Vacuum Chamber or Vacuum System:

After going through the multiple MED effects, there may still be some impurities and residual salts in the water.-

- To achieve even higher purity levels, a vacuum chamber or vacuum system can be added at the end of the MED process.

- In this chamber, the pressure is further reduced to a near-vacuum level, and the water is exposed to even lower temperatures, typically close to its freezing point.

- This extreme vacuum and low temperature conditions promote the sublimation of any remaining impurities, leaving behind highly purified water vapor

- The purified water vapor is condensed and collected as ultra-pure water.

-

- 3.5 Ice Production (Optional):

In some applications, you may want to produce ice from the remaining brine. In this particular scenario, a portion of the distilled water (approximately 10 to 20%) converted into ice as a valuable byproduct.- If ice production is desired, the purified water vapor can be directed to a freezing chamber where it is allowed to freeze.

- The ice produced is pure, as impurities are left behind in the vapor phase.

- The ice can be collected and used for various purposes, such as cooling or freshwater storage.

By combining MED with vacuum distillation and, optionally, ice production, the MEDV system can achieve exceptionally high levels of water purity from seawater or very high saline water sources, making it suitable for various industrial, agricultural, or potable water applications where stringent water quality standards are required. The specific design and parameters of the system would depend on the desired water quality, capacity, available waste heat sources, and other site-specific factors.

- 3.6 Overview of how this process works.

In a Multi-Effect Distillation (MED) system with vacuum, the process involves the desalination of saline water, typically seawater, to produce distilled water (pure water). Additionally, in this particular scenario, a portion of the distilled water (approximately 10 to 20%) will be converted into ice as a valuable byproduct. Here’s an overview of how this process works:- 3.6.1 Evaporation and Condensation:

In the MED system, saline water is heated in the first effect, where it evaporates under vacuum conditions. The reduced pressure in the effect lowers the boiling point of water, allowing the evaporation to occur at a lower temperature. This results in the separation of freshwater vapor from the salt and impurities in the feedwater.

- 3.6.1 Evaporation and Condensation:

- 3.2 Multi-Effect Distillation (MED):

-

-

- 3.6.2 Multiple Effects:

The vapor generated in the first effect is then used to heat the subsequent effect, creating a cascading effect that increases the overall energy efficiency of the system. As the vapor condenses in each effect, purified freshwater is collected.

- 3.6.2 Multiple Effects:

-

-

- 3.6.3 Ice Production:

To produce ice as a byproduct, a portion of the purified freshwater (typically 10 to 20%) is directed into an ice-making chamber. This chamber is set at temperatures below freezing point, causing the freshwater to freeze and form ice. The ice produced in this manner is of high purity because the freezing process separates impurities and salts from the water. - 3.6.4 Collection and Storage:

The ice produced is collected and stored in a suitable container or storage facility. It can be used for various applications, such as cooling, refrigeration, or even sale. - 3.6.5 Remaining Distilled Water:

The remaining portion of the purified freshwater, not converted into ice, continues through the MED system to the final effect. The collected water in this final effect is the highest quality distilled water, suitable for a wide range of applications, including drinking water, industrial processes, and more.

- 3.6.3 Ice Production:

- 3.7 Benefits of Ice Production as a Byproduct:

The production of ice as a byproduct offers several advantages:- Value-Added Product: Ice can be sold or used for various purposes, providing an additional source of revenue

- Efficient Resource Utilization: It maximizes the utilization of purified freshwater and waste heat from the MED system.

- Environmental Benefits: High-quality ice is produced from the vapor phase, reducing impurities and minimizing waste.

The precise design and operational parameters of the MED system, including the temperature and pressure levels in each effect, vacuum levels, and the exact volume of ice production, can be adjusted based on specific project requirements and goals. The percentages mentioned (10 to 20%) are typical ranges but can be customized as needed.

- 3.8 Benefits of Multi-Effect Operation

The multi-effect operation of MEDV offers several advantages:- Sequential use of heat energy: Heat is efficiently utilized across multiple effects.

- Energy savings: Lower boiling points reduce energy consumption.

- Scalability: Multiple effects can be added to accommodate increased freshwater demand

- Water quality: High-purity freshwater is produced through the cascading effects.

4. Specification and Parameters

Calculating the specific performance of a Multi-Effect Distillation (MED) system with a vacuum chamber or vacuum system for ice production and water purification involves several factors, including the seawater feed quality, operating temperatures, and the number of MED effects.

- Seawater feed: 5 m^3/hr (5,000 liters/hr) at 40,000 ppm TDS.

- Initial MED operation: We’ll consider a hypothetical scenario where there are 3 MED effects before the addition of the vacuum system for ice production.

- Waste heat source temperature: 55°C (default).

- BBT (bottom brine temperature): 1°C.

- TBT (top brine temperature): Variable, depending on the number of MED effects.

- Vacuum system operation: To produce pure ice.

- Pure water TDS: The goal is to produce purified water with low TDS.

- Crude distillate TDS: The TDS of the output brine from MED before further treatment.

4.1 Step 1: Multi-Effect Distillation (MED) Operation.

MED typically operates with multiple stages or effects. Each effect uses waste heat from the previous stage to evaporate water. Here, we’ll consider three effects:

Effect 1:

TBT1 (top brine temperature): 40°C (assumption).

Calculate the amount of pure water produced in Effect 1.

Calculate the TDS of the crude distillate.

Effect 2:

TBT2 (top brine temperature): 60°C (assumption, higher than TBT1).

Calculate the amount of pure water produced in Effect 2.

Calculate the TDS of the crude distillate.

Effect 3:

TBT3 (top brine temperature): 80°C (assumption, higher than TBT2).

Calculate the amount of pure water produced in Effect 3.

Calculate the TDS of the crude distillate.

4.2 Step 2: Vacuum Chamber (MEDV) for Ice Production

Use the vacuum chamber or vacuum system to produce pure ice from the remaining brine (saline water).

Please note that precise calculations would require detailed information on the heat transfer coefficients, equipment specifications, and more. The performance of the system can also

be affected by various factors like efficiency losses, fouling, and design considerations.

The goal is to maximize the production of pure water while minimizing energy consumption and maximizing ice production. It’s also important to consider the efficiency of the vacuum

system in ice production and the potential energy input required for this process.

4.3 Parameters in MEDV

Parameters in Multi-Effect Distillation Vacuum (MEDV) system for the desalination of seawater with a feed rate of 5 m^3/hr (5,000 liters/hr) can vary depending on system design, operating conditions, and the number of effects employed. Below a generalized description of these parameters, but please note that specific values will depend on the system configuration and local conditions.

4.3.1. Temperature in Each Effect or Section:

In a typical MEDV system, each effect or section operates at progressively lower temperatures. The specific temperatures can vary, but here is a general example:

- Effect 1 (Hottest Effect): This is where the feedwater is heated, often by waste heat from an industrial process. The temperature in this effect can be around 70-85°C.

- Effect 2: The vapor generated in Effect 1 is used to heat Effect 2. The temperature here can be lower, around 50-65°C.

- Effect 3: Effect 3 operates at an even lower temperature, around 35-50°C.

- Effect 4 (Coldest Effect): The last effect, which typically operates at the lowest temperature, can be as low as 20-35°C.

Note: Effects may increase on requirements.

These temperatures are approximate values and can vary depending on factors such as the number of effects, the design of heat exchangers, and the quality of waste heat available.

4.3.2. Pressure in Each Effect or Section:

Pressure levels in each effect decrease progressively in an MEDV system to match the decreasing boiling points of water:

- Effect 1: This is typically the highest-pressure effect, operating at or near atmospheric pressure (1 atm).

- Effect 2: The pressure in this effect is lower than in Effect 1 but higher than in subsequent effects.

- Effect 3: Lower pressure compared to Effect 2.

- Effect 4: The lowest pressure among all effects, creating the necessary vacuum for efficient operation.

4.3.3. Vacuum:

The vacuum created in the MEDV system is essential for lowering the boiling points of water in each effect. The vacuum level can vary, but it often ranges between 1-50 mbar (millibar), depending on the specific design and requirements of the system.

4.3.4. Yield:

Yield represents the amount of freshwater produced by the system compared to the feedwater. In a well-designed MEDV system, the yield can be relatively high, often exceeding 50-60% of the feedwater volume. Yield can be optimized by carefully controlling operating conditions, such as temperature, pressure, and vacuum.

4.3.5. Rejected Brine:

The rejected brine is the concentrated saline solution left behind after the distillation process. The exact volume of rejected brine depends on system efficiency and design. In MEDV systems, achieving zero liquid discharge (ZLD) is a goal, meaning that almost all of the feedwater is converted into freshwater, leaving a minimal volume of concentrated brine for disposal or further treatment. The brine volume can be less than 10% of the feedwater volume.

4.3.6. Ice Production from Waste:

The production of ice from waste brine is a valuable byproduct of MEDV systems. The quantity of ice produced can vary depending on system design and operating conditions. In some cases, it can be as much as 10-20% of the feedwater volume. The ice is typically of high purity and can be used in various applications, including cooling and refrigeration.

4.3.7. Heat Reuse in Different Effects:

Heat reuse is a critical aspect of MEDV systems to maximize energy efficiency. Each effect utilizes the heat energy from the previous effect, cascading it through the system. The heat reuse in different effects depends on the design and temperature differences between effects. As a rough estimate:

- Effect 1 provides the primary heat source for subsequent effects.

- Effect 2 uses the vapor from Effect 1 as its heat source.

- Effect 3 uses the vapor from Effect 2.

- Effect 4 uses the vapor from Effect 3.

The specific heat reuse values will depend on the temperature differences between effects and the efficiency of heat exchangers, but in well-designed systems, a significant portion of the heat is effectively reused, contributing to the overall energy efficiency of the MEDV process.

5: Multi-Effect Distillation Vacuum (MEDV) System Design

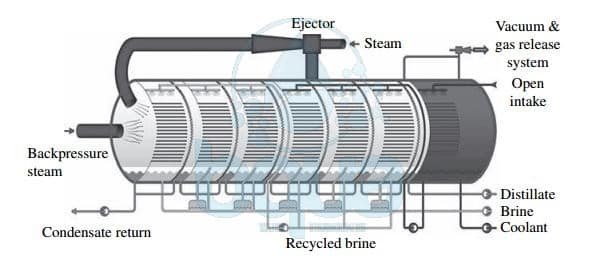

5.1 Components of an MEDV System

A typical MEDV system comprises several key components:

- Multi-Effect Distillation Units: These include multiple evaporation chambers or effects.

- Heat Sources: Waste heat from industrial processes, power generation, or solar collectors can provide the necessary energy for evaporation.

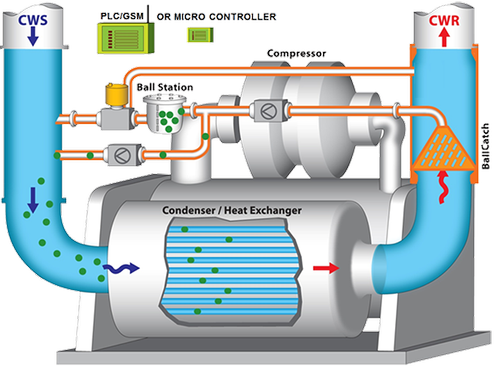

- Vacuum Systems: Vacuum pumps or systems create and maintain the required low-pressure conditions.

- Condensation Units: Equipment for condensing water vapor back into liquid form.

- Control Systems: Advanced control systems monitor and optimize the entire process.

- Feedwater Pre-treatment: Filtration and pre-treatment systems remove particulates and impurities from the feedwater.

5.2 Design Considerations

The design of an MEDV system is influenced by several factors:

- Feedwater Quality: The initial quality of the saline water source, whether seawater or brackish water, impacts system design.

- Heat Sources: The availability and temperature of waste heat sources determine the overall energy efficiency.

- Capacity: The required freshwater output dictates the number of effects and the overall system size.

- Geographic Location: Local climate conditions influence the choice of system components and operating parameters.

6: Distillate crude, High saline water disposal

In a Multi-Effect Distillation Vacuum (MEDV) system, one of the key goals is to minimize liquid discharge, especially the disposal of the concentrated brine (distillate crude) produced during the desalination process. Initially, you may need to dispose of the distillate crude, but the long-term objective is to achieve a Zero Liquid Discharge (ZLD) system.

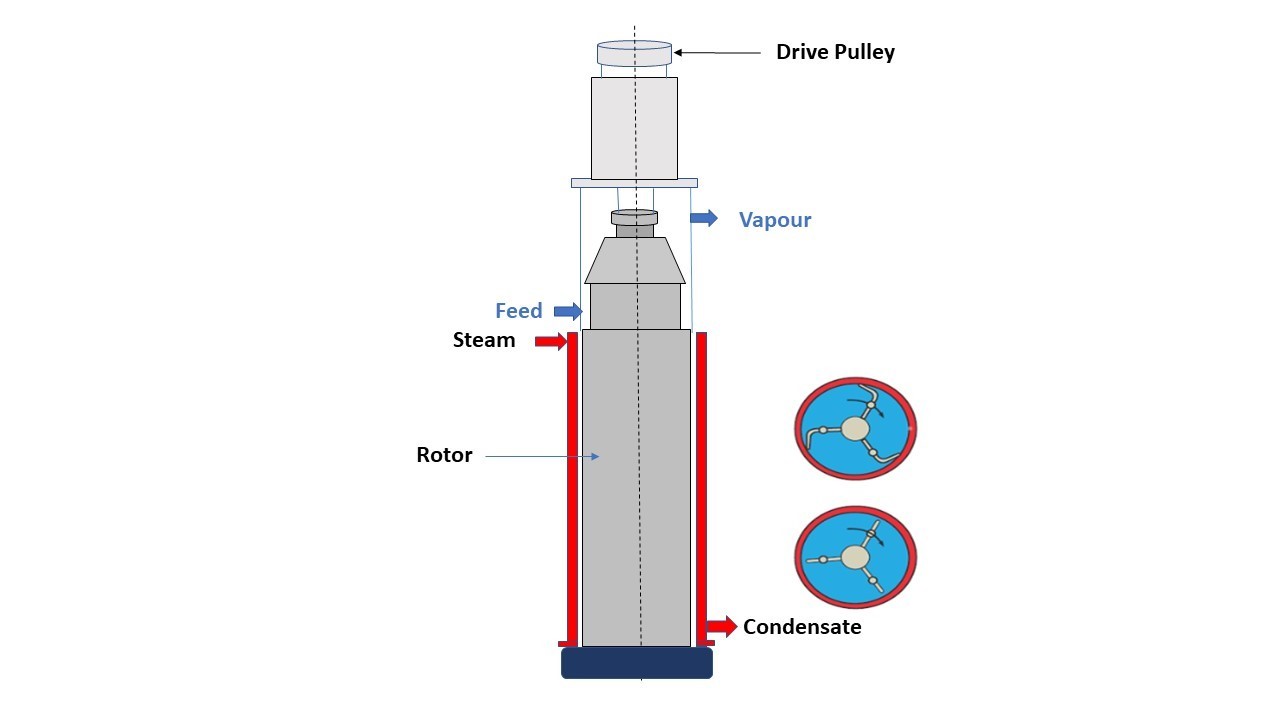

Here’s how you can work towards implementing a ZLD system with the help of ATFD (Agitated Thin Film Dryers) and/or Multi-Effect Evaporators:

6.1. Initial Disposal of Distillate Crude:

Initially, when you have no ZLD system in place, you may need to dispose of the distillate crude as per local regulations and environmental guidelines. The distillate crude is the concentrated brine left behind after the distillation process, which contains a high concentration of salts and impurities. Proper disposal methods must be followed to ensure minimal environmental impact.

6.2. Zero Liquid Discharge (ZLD) System Implementation:

To move towards a ZLD system and minimize liquid discharge, you can consider the following steps:

-

- Multi-Effect Evaporators:Multi-Effect Evaporators can be integrated into your desalination system to further concentrate the distillate crude. These evaporators work on the same principle as MED but are

specifically designed to reduce waste by evaporating and concentrating the remaining liquid. - Agitated Thin Film Dryers (ATFD):ATFD technology can be used as part of a ZLD system. ATFD is an effective way to further concentrate and dry the brine, reducing it to a solid or semi-solid state. It is particularly useful in industries where high levels of solid waste are generated.

- Multi-Effect Evaporators:Multi-Effect Evaporators can be integrated into your desalination system to further concentrate the distillate crude. These evaporators work on the same principle as MED but are

- Evaporation and Crystallization:In a ZLD system, the concentrated brine can undergo further processes like evaporation and crystallization to recover valuable salts or minerals. This not only reduces waste but can

also yield valuable byproducts. - Reuse and Recycling:Part of the ZLD strategy involves recycling and reusing treated water. The purified water can be reused within the facility or released into the environment, depending on the local

regulations. Reusing water minimizes the need for additional freshwater sources.

6.3. Environmental Compliance:

Throughout this process, it is crucial to remain in compliance with local environmental regulations and permits. The successful implementation of a ZLD system often requires close coordination with regulatory authorities to ensure that all discharge and waste management practices are in line with legal requirements.

6.4. Continuous Improvement:

ZLD systems should be designed for continuous improvement. Regular monitoring and optimization of the system can help reduce operating costs and environmental impact over time.

6.5. Benefits of a ZLD System:

Implementing a ZLD system offers several benefits:

- Environmental Responsibility: It minimizes the environmental impact of brine disposal.

- Resource Recovery: Valuable salts and minerals can be recovered from the concentrated brine.

- Sustainable Water Management: ZLD supports sustainable water management practices by minimizing waste and maximizing resource utilization.

The transition to a ZLD system may require capital investment and careful planning, but it ultimately aligns with sustainability goals and environmental responsibility, making it a crucial step in minimizing the environmental footprint of desalination operations.

7: Achieving Zero Liquid Discharge (ZLD) with MEDV

7.1 Zero Liquid Discharge (ZLD) Concept:

Zero Liquid Discharge (ZLD) is an environmentally responsible approach that aims to eliminate liquid waste discharge from industrial processes. MEDV systems can be designed to achieve ZLD by efficiently concentrating reject brine and converting it into valuable byproducts.

7.2 Concentration of Reject Brine

In ZLD-MEDV systems, the reject brine from the distillation process is further concentrated. This can be achieved through additional evaporation and crystallization stages, which increase the salinity of the brine.

7.3 Crystallization of Reject Brine

The highly concentrated brine can be processed to recover valuable salts or minerals through crystallization. Crystallization involves inducing the brine to form solid crystals, leaving behind purified water.

8: Ice Production as a Byproduct

8.1 Ice Production in MEDV

In some MEDV systems, ice production can be integrated as a valuable byproduct. The ultra-pure water vapor generated in the MED process can be directed to a freezing chamber or ice maker to produce high-quality ice.

8.2 Benefits of Ice Production

The production of ice as a byproduct offers several advantages:

- Value-added product: Pure ice can be used for cooling, refrigeration, or sale.

- Efficient resource utilization: The system maximizes the use of purified water vapor.

- Environmental benefits: High-quality ice is produced from the vapor phase, minimizing impurities.

9: Real-World Applications of MEDV Technology

9.1 Industrial and Municipal Water Supply

MEDV technology finds applications in providing freshwater for both industrial and municipal use. It is particularly valuable in arid regions, coastal cities, and remote locations where freshwater resources are limited.

9.2 Agriculture and Irrigation

Agriculture relies heavily on a consistent and reliable water supply. MEDV systems can support agricultural practices in regions with water scarcity, enabling sustainable food production.

9.3 Industrial Processes

Industries that require high-quality process water, such as the pharmaceutical, power generation, and electronics sectors, benefit from MEDV systems’ ability to provide purified water.

9.4 Sustainable Development

MEDV technology contributes to sustainable development goals by providing a reliable and energy-efficient source of freshwater while minimizing environmental impact.

10: Challenges and Considerations

10.1 Energy Efficiency Optimization

Efforts to enhance energy efficiency in MEDV systems include improving heat transfer efficiency, optimizing vacuum systems, and selecting suitable heat sources.

10.2 Maintenance and Reliability

Regular maintenance is essential to ensure the efficient and reliable operation of MEDV systems. Proper maintenance routines are critical for prolonging the lifespan of equipment.

10.3 Environmental Considerations

Environmental considerations include managing the disposal of brine concentrate and ensuring the responsible use of waste heat sources.

11. Conclusion

The Multi-Effect Distillation Vacuum (MEDV) system represents a powerful and sustainable solution to the growing challenges of water scarcity and the need for freshwater production from saline sources. Its efficient utilization of waste heat, cascading effects, and potential for zero liquid discharge make it a promising technology for a wide range of applications. As technological advancements continue to drive innovation in the field of desalination, MEDV systems are poised to play a pivotal role in securing reliable freshwater supplies for the future.

- Combines the principles of multi-effect distillation and vacuum distillation.

- Maximizes energy efficiency through the use of waste heat and reduced pressure.

- Produces high-purity freshwater suitable for various applications.

- Has the potential to achieve zero liquid discharge by concentrating reject brine and producing valuable byproducts.

- Offers the possibility of ice production as an additional byproduct.

- Finds applications in industrial, municipal, agricultural, and other sectors, contributing to sustainable development.

The successful implementation of MEDV technology requires careful planning, design, and ongoing maintenance. As the world faces increasing water challenges, the adoption of advanced desalination technologies like MEDV represents a critical step toward ensuring access to clean and sustainable freshwater resources for generations to come.

12: Outlook of MEDV with ICE Production

The production of ice in Multi-Effect Distillation Vacuum (MEDV) systems represents an innovative approach to maximize resource utilization and minimize environmental impact in desalination processes. This high-quality ice, rich in potential applications, is a valuable byproduct that finds use across diverse sectors, from food and healthcare to manufacturing and agriculture.

The precise design and operational parameters of the MED system, including the temperature and pressure levels in each effect, vacuum levels, and the exact volume of ice production, can be adjusted based on specific project requirements and goals. The percentages mentioned (10 to 20%) are typical ranges but can be customized as needed.

As the world addresses increasing water scarcity and environmental concerns, the sustainable practices associated with ice containing brine production make it a promising component of future water treatment and resource management strategies. The continued development of technology, combined with a focus on environmental responsibility and economic viability, ensures that the utilization of reject brine in ice production will play a vital role in meeting the world’s freshwater needs while mitigating waste and resource depletion.

13. General Steps for Implementing MEDV Technology:

- Feasibility StudyThe first step in implementing MEDV technology in any location involves a feasibility study. This study evaluates the local water source, its quality, and the demand for purified water. It also assesses the availability of waste heat sources, which are crucial for the energy-efficient operation of MEDV.

- Design and Engineering:After the feasibility study, detailed engineering and design work would take place. This includes designing the MEDV system, including the number of effects, heat exchangers, vacuum chambers, and associated equipment. The design would also factor in local conditions, such as climate and available space.

- Construction:Once the design is finalized, construction of the MEDV facility begins. This involves installing the various components, including heat exchangers, vacuum chambers, pumps, and controls.

- Integration of Waste Heat Sources:The success of MEDV technology relies on the efficient utilization of waste heat sources, which may come from industrial processes, power generation, or other sources. These waste heat sources need to be integrated into the system to maximize energy efficiency.

- Testing and Commissioning:After construction, the system undergoes rigorous testing and commissioning to ensure that it operates as designed. This includes checking the performance of each MED effect, vacuum chamber, and the entire system as a whole.

- Operation and Maintenance:Once the system is operational, it requires regular maintenance to ensure it continues to function efficiently. This includes monitoring water quality, inspecting equipment, and addressing any issues that may arise.

14. Potential Benefits of a Successful MEDV Implementation:

- High-Quality Water Production: MEDV technology can produce high-purity water, making it suitable for various applications, including drinking water, industrial processes, and agriculture.

- Zero Liquid Discharge (ZLD): By effectively concentrating and processing reject brine, MEDV systems can achieve zero liquid discharge, reducing environmental impact.

- Energy Efficiency: :The integration of waste heat sources makes MEDV technology energy-efficient and environmentally friendly.

- Byproduct Generation:The process can generate valuable byproducts, such as ice and recovered salts, which can be sold or used in other industries.

- Sustainable Water Supply:Implementing MEDV technology can help ensure a sustainable and reliable water supply, especially in areas with water scarcity or high salinity.

- Compliance with Regulations:The technology helps meet stringent water quality and environmental regulations.

It’s important to note that the success of such a project depends on various factors, including careful planning, efficient operation, and ongoing maintenance. Additionally, local regulations and environmental considerations should be taken into account during the implementation of MEDV technology.