Using IoT and Artificial Intelligence to Detect, Manage, and Control H₂S in Crude Oil and Gas Exploration

Using IoT and Artificial Intelligence to Detect, Manage, and Control H₂S in Crude Oil and Gas Exploration

⚠️ 1. Understanding H₂S and Its Dangers

Hydrogen Sulfide (H₂S) is a highly toxic, corrosive, and flammable gas often found in crude oil and natural gas reservoirs. It is considered a sour gas and poses multiple risks:

| Risk Type | Impact |

| Health Hazard | H₂S is lethal even at low concentrations (as low as 100 ppm). |

| Corrosion | It reacts with water to form sulfuric acid, causing internal corrosion in pipes and equipment. |

| Operational Downtime | Requires shutdown and evacuation if levels exceed safety thresholds. |

| Environmental and Regulatory Risk | Releases are strictly regulated and monitored. |

🛑 2. Traditional Challenges in H₂S Management

| Challenge | Description |

| Delayed Detection | Manual gas testing leads to slow responses. |

| Non-continuous Monitoring | Spot testing cannot identify transient spikes or leaks. |

| Remote Locations | Many oilfields and wells are unmanned or offshore. |

| Corrosion Prediction | Hard to link H₂S levels with real-time corrosion rates. |

| Complex Fluid Composition | Coexistence with CO₂, water, and other compounds complicates detection and control. |

🛰️ 3. Role of IoT in H₂S Detection and Monitoring

🧪 3.1. Smart Sensors for Real-Time Monitoring

IoT-based H₂S sensors provide continuous, remote monitoring at key points in the production chain.

| Sensor Type | Application |

| Electrochemical H₂S Sensors | Accurate and sensitive to H₂S in ppm/ppb levels. Installed in wellheads, separators, pipelines. |

| Infrared (IR) Gas Detectors | Used in harsh environments, detects H₂S gas clouds. |

| Tunable Diode Laser Absorption Spectroscopy (TDLAS) | Measures H₂S in gas pipelines with high precision. |

| Corrosion Probes (ER & LPR) | Monitor metal loss rate due to H₂S corrosion. |

| Multigas Monitors | Combine H₂S, CO₂, CH₄, and O₂ detection. Ideal for unmanned platforms. |

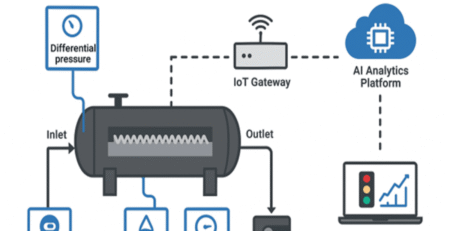

🔗 3.2. Data Collection and Transmission

IoT devices communicate wirelessly via:

- 4G/5G cellular, LoRaWAN, NB-IoT, or satellite

- Send data to edge gateways or cloud platforms

- Support real-time alerts, trending, and historical logging

🧠 4. Artificial Intelligence in H₂S Management and Control

AI turns raw IoT sensor data into actionable intelligence for predictive and autonomous control.

📈 4.1. Predictive H₂S Mapping

- AI models analyze historical H₂S readings, geology, flowrates, and composition.

- Generate real-time H₂S dispersion models and hotspot prediction across the field.

- Helps optimize:

- Drilling direction (to avoid high-H₂S zones)

- Casing and metallurgy choices

- Safety planning

⚙️ 4.2. Real-Time Anomaly Detection

- Detects abnormal H₂S spikes due to:

- Casing breach

- Reservoir fluid changes

- Leaks or equipment failure

- Alerts triggered for evacuation or shutdown procedures

🧪 4.3. Corrosion and Asset Integrity Management

AI models correlate:

- H₂S levels

- Water cut

- Flow velocity

- pH

- Metal loss rates (from sensors)

To predict future corrosion, allowing proactive maintenance and pipe replacement schedules.

⚗️ 4.4. Dynamic Chemical Dosing

AI can control scavenger dosing systems based on live H₂S data:

- Injects triazine, MEA, or other scavengers proportionally

- Minimizes chemical wastage

- Adjusts dosing to flow rate and temperature in real-time

📊 4.5. Safety & Regulatory Compliance

- AI ensures H₂S levels are always below regulatory thresholds.

- Automates report generation for OSHA, EPA, or local oilfield regulations.

- Integrates with emergency shutdown (ESD) systems.

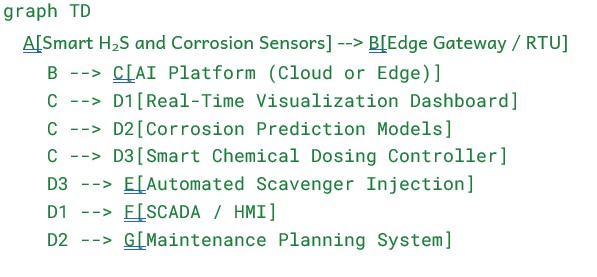

🧰 5. System Architecture

mermaid

CopyEdit

6. Field Application Examples

🛢️ Example 1: Unmanned Onshore Sour Gas Well

- TDLAS gas analyzers monitor H₂S at the wellhead.

- AI predicts H₂S spikes due to formation water intrusion.

- Chemical injection pumps are auto-adjusted based on flow conditions.

- Alerts sent to control room and mobile devices in case of abnormal H₂S levels.

⚓ Example 2: Offshore Platform with Gas-Lift Wells

- IR-based area monitors ensure atmospheric H₂S detection for safety.

- AI distinguishes false positives due to wind or heat distortion.

- System controls both scavenger and corrosion inhibitor dosing via smart algorithms.

✅ 7. Benefits of IoT and AI in H₂S Management

| Benefit | Description |

| 🎯 Accurate Detection | Real-time, continuous H₂S sensing across the facility |

| 🧠 Smart Prediction | AI predicts H₂S levels and corrosion risk ahead of time |

| 🔐 Improved Safety | Early detection allows timely evacuation and system shutdown |

| 💰 Cost Efficiency | Reduces chemical overdosing, unplanned downtime, and maintenance costs |

| 📡 Remote Autonomy | Ideal for unmanned or offshore installations |

| 📄 Regulatory Compliance | AI automates reporting and ensures adherence to safety limits |

🔮 8. Future Developments

- Digital Twin for H₂S Exposure Modeling

Simulates H₂S behavior across facility layout and time series. - AI Co-Pilots for Field Engineers

Wearable AR with live H₂S predictions, safety zones, and sensor overlays. - Robotic Inspection Drones

Equipped with H₂S sensors for pipeline and tank inspections. - Blockchain-Backed Compliance Reporting

Immutable H₂S exposure logs for audits and certifications.

🏁 Conclusion

In sour crude oil and gas exploration, managing H₂S is non-negotiable due to the health, safety, and environmental risks. The integration of IoT and AI transforms traditional reactive approaches into smart, proactive systems that:

- Continuously monitor H₂S

- Accurately predict risks

- Intelligently respond through chemical dosing or safety protocols

- Operate autonomously in unmanned environments

“With IoT as the sensory system and AI as the decision-maker, oil and gas fields can manage H₂S smarter, safer, and faster than ever before.”