Usefulness of IoT and AI in Ore Flow Monitoring & Theft Prevention in Mining Industry

🪨 Usefulness of IoT and AI in Ore Flow Monitoring & Theft Prevention in Mining Industry

Mining operations involve large-scale movement of ore from the mine face to crushers, concentrators, or stockpiles. The high value and volume of ore—especially in gold, copper, iron, and coal mines—make ore susceptible to leakage, diversion, and theft, especially during transit and processing.

IoT sensors provide real-time, granular data on material flow and asset location, while AI analytics provide pattern recognition, discrepancy detection, and predictive oversight that are beyond human capabilities.

✅ 1. Real-Time Ore Flow Visibility

IoT Contribution:

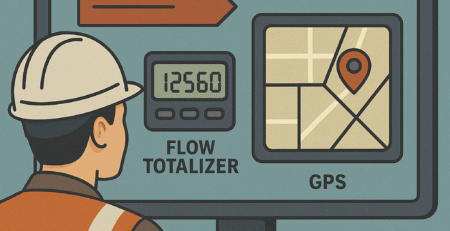

- Load cells on conveyors and belt scale integrators monitor ore mass flow in tonnes/hour.

- RFID tags, QR codes, or GPS trackers on trucks and containers log movement and weight at each checkpoint.

- Weighbridges transmit entry/exit data over MQTT/HTTP.

- Cameras (IP/thermal) verify loading and offloading events.

Usefulness:

- Provides live tracking of ore volumes from pit to plant.

- Detects bottlenecks, underloading, or overloading events.

- Eliminates the need for manual reporting, reducing data tampering.

✅ 2. Theft and Diversion Detection

IoT Contribution:

- Geo-fencing is implemented via GPS devices on ore trucks; alerts are generated if vehicles leave defined routes.

- Tamper-proof smart seals with BLE/NFC ensure containers are not opened mid-route.

- Cameras and RFID readers verify driver, truck, and load identity at each stage.

AI Contribution:

- AI-powered anomaly detection models (e.g., Isolation Forest, autoencoders) compare:

- Scheduled vs. actual route

- Declared vs. actual ore weight

- Loading vs. delivery timestamps

- Computer vision (CV) systems monitor live video feeds for:

- Unauthorized dumping or removal

- Human behavior at loading zones

Usefulness:

- Automated theft alerts triggered in case of:

- Weight mismatch

- Route deviation

- Unscheduled stops

- Prevents collusion or fraud involving truck drivers, loaders, or security personnel.

- Enhances auditability and chain of custody.

✅ 3. Ore Accounting and Reconciliation Accuracy

AI Contribution:

- AI models correlate data from weighbridges, sensors, GPS, and mill input using data fusion techniques.

- Discrepancies in:

- Excavated vs. transported ore

- Transported vs. processed ore

- Machine learning regression models predict expected flow rates actual readings to flag inconsistencies.

Usefulness:

- Enhances material balance accuracy between mine face, ROM pad, and mill feed.

- Reduces ore misclassification or blending errors.

- Improves financial reconciliation and reporting of ore grades and volumes.

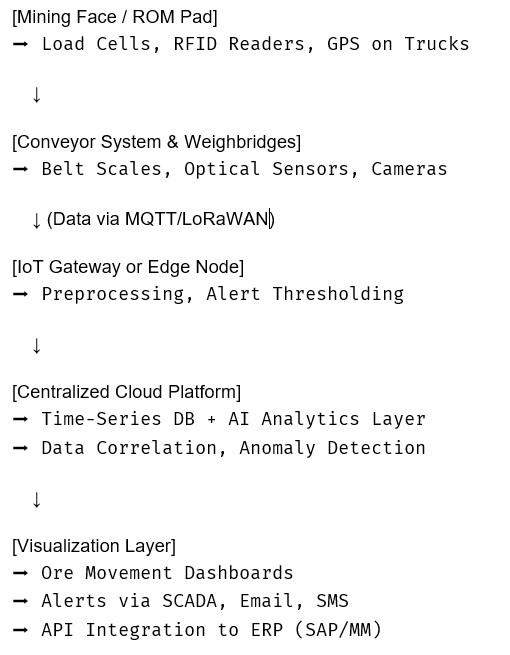

✅ 4. Integration into Centralized Ore Tracking Platform

IoT + AI Architecture:

✅ 5. Digital Chain-of-Custody & Anti-Theft Security Layer

AI + IoT Applications:

- Computer Vision + AI matches truck number plate + load face + material type.

- Blockchain integration for immutable tracking of ore movements across multiple stakeholders.

- AI Risk Scoring: Assigns each vehicle/operator a real-time “trust” score based on deviation history and anomalies.

Usefulness:

- Establishes a digital twin of ore movement in the mining supply chain.

- Prevents revenue loss due to material leakage, ghost trips, or pilferage.

- Provides audit trail for regulatory authorities, buyers, and internal finance teams.

📈 Operational and Financial Benefits

| Benefit Category | Before IoT/AI | After IoT + AI Integration |

| Material Loss & Theft | High (1–5% of output) | Near Zero (detectable in real-time) |

| Ore Reconciliation Accuracy | ~85–90% | >98% |

| Manual Checks | High labor, low accuracy | Minimal labor, high accuracy |

| Route Compliance | Limited GPS logs | Real-time deviation alerts |

| Chain of Custody | Paper-based | Secure, digital, traceable |

| Production Variance | High due to estimation errors | Reduced due to actual real-time data |

| Fraud Detection | Reactive | Proactive and automated |

📊 Example KPIs Improved

- Ore loss reduction: 2–4% of total ore handled

- Asset theft detection time: From days → to minutes

- Accuracy in transported ore weight: Increased from 88% → >99%

- Operational cost saving: ~15–20% reduction in ore handling costs

- Audit compliance score: Improved due to traceability and real-time data logs

🧠 Advanced AI Models in Use

| Use Case | AI Model Type |

| Theft detection | Isolation Forest, One-Class SVM |

| Route anomaly | GPS trajectory classification (KNN, HMM) |

| Flow prediction | LSTM (time-series), Regression Trees |

| Image-based event detection | YOLOv8, EfficientNet, OpenCV |

| Load misrepresentation detection | Classification models + CV |

| Operator trust scoring | Reinforcement learning, clustering |

✅ Final Summary

IoT & AI enable mining companies to:

- Achieve full visibility and control over ore movement

- Detect and prevent pilferage, underloading, and ghost trips

- Automate material accounting and regulatory compliance

- Enhance financial accuracy by closing gaps in ore reconciliation

- Reduce dependency on manual supervision and security teams