Usefulness of IoT and AI in Equipment Health Monitoring for Mining Companies

🛠️ Usefulness of IoT and AI in Equipment Health Monitoring for Mining Companies

Mining operations rely heavily on the continuous operation of high-value assets—such as haul trucks, hydraulic excavators, drills, crushers, conveyors, pumps, and fans—operating in harsh, remote, and hazardous environments. Any unplanned downtime can result in significant production losses, safety risks, and maintenance costs.

The integration of IoT sensors and AI-driven analytics revolutionizes how mining companies manage equipment health. It shifts maintenance strategies from reactive to predictive and prescriptive, thereby enhancing asset reliability, availability, and lifecycle.

✅ 1. Real-Time Condition Monitoring

IoT Contribution:

- Equipment is fitted with smart sensors (vibration, temperature, pressure, acoustic emission, RPM, torque, fluid level, oil quality).

- These sensors continuously collect data on:

- Bearing wear

- Hydraulic pressure fluctuation

- Motor winding temperature

- Lubrication degradation

- Fuel consumption

- Data is transmitted via wired (Ethernet, Modbus) or wireless (LoRaWAN, NB-IoT, LTE/5G) networks to local edge devices or cloud platforms.

Usefulness:

- Enables 24/7 visibility into the operating condition of all critical and non-critical assets.

- Early detection of mechanical anomalies that could lead to failures.

- Remote monitoring of hard-to-access or hazardous equipment zones (e.g., underground ventilation fans, slurry pumps).

✅ 2. Predictive Maintenance with AI

AI Contribution:

- Historical and real-time data is fed into Machine Learning models such as:

- Random Forest, XGBoost (for failure classification)

- LSTM, Prophet (for time-series predictions)

- Autoencoders (for anomaly detection)

- AI models learn patterns of normal vs. abnormal behavior to forecast potential failures before they occur.

Usefulness:

- Transitions from run-to-failure or calendar-based maintenance to data-driven predictive maintenance.

- Reduction in Mean Time to Repair (MTTR) and Mean Time Between Failures (MTBF).

- Minimizes spare parts overstocking by forecasting exact component wear.

- Optimizes maintenance crew scheduling—only when needed.

✅ 3. Root Cause Analysis and Decision Support

AI Contribution:

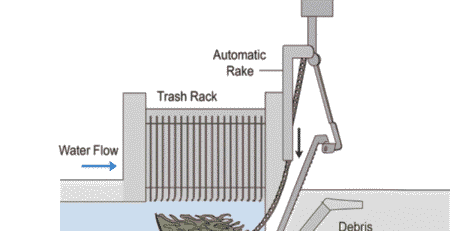

- AI-driven diagnostics systems analyze root causes based on sensor correlation:

- eg., increased vibration + rising temperature = bearing misalignment

- Pressure drop + flow rate anomaly = impeller clog or pump cavitation

- Natural Language Processing (NLP) can ingest maintenance logs and identify recurring failure modes.

Usefulness:

- Empowers operators and maintenance engineers with actionable insights, not just raw data.

- Reduces human error in identifying the root cause.

- Enhances knowledge retention and predictive knowledge base over time.

✅ 4. Equipment Lifecycle Management

Combined IoT + AI Contribution:

- Historical performance and failure records for each asset are digitized to create digital twins.

- AI predicts remaining useful life (RUL) of components such as:

- Engine blocks

- Hydraulic hoses

- Conveyor rollers

- Gearboxes

Usefulness:

- Enables total cost of ownership (TCO)

- Assists in equipment replacement decision-making.

- Helps optimize warranty claims and insurance compliance.

✅ 5. Safety & Environmental Compliance

IoT + AI Contribution:

- Condition monitoring helps prevent catastrophic failures such as:

- Brake failure on downhill trucks

- Overheated hydraulic systems causing fire

- Structural failure of cranes or drills

- AI models can trigger automatic shutdowns or alarms when operating parameters cross safe limits.

Usefulness:

- Reduces personnel exposure to dangerous equipment breakdowns.

- Ensures compliance with MSHA/OSHA safety standards.

- Reduces environmental risks from oil leaks or hazardous failures.

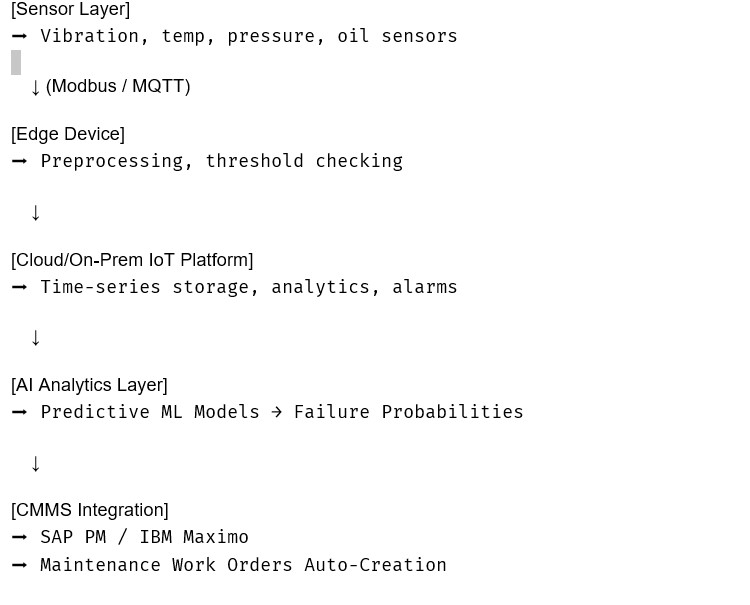

✅ 6. Integration with Maintenance Management Systems (CMMS)

System Architecture Example:

Usefulness:

- Real-time sync with maintenance and spare parts workflows.

- Reduced manual data entry and paper-based inspections.

- Enabling fully digital asset maintenance ecosystems.

📊 Measurable Benefits

| Metric | Before IoT/AI | After IoT/AI |

| Unplanned Downtime | 20–25% of total downtime | Reduced to < 5% |

| Mean Time Between Failures (MTBF) | 200 hours | > 400 hours |

| Maintenance Costs | 100% reactive | 30–50% reduction via predictive |

| Equipment Availability | ~85% | > 95% |

| Inventory Overstocking | 30–40% | Reduced to 10–15% |

| Safety Incidents (due to equipment failure) | Medium-High | Significantly reduced |

🔄 Summary

IoT + AI in Equipment Health Monitoring enables:

- Proactive maintenance rather than reactive firefighting

- Lower cost of ownership and increased asset life

- Real-time operational visibility across distributed sites

- Safer, smarter, and sustainable operations

Mining companies that adopt these technologies see enhanced productivity, asset performance, and compliance—transforming maintenance from a cost center to a strategic enabler.