Comparison of Different Types of Tailings Storage Facilities for Wastewater Recovery

Comparison of Different Types of Tailings Storage Facilities for Wastewater Recovery

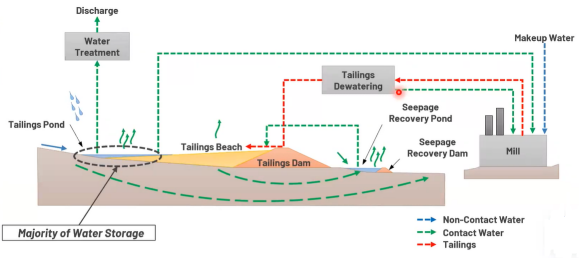

Tailings storage facilities can be a complicated project to design and construct. They are prone to water induced failures such as liquefaction, internal and external erosion, seepage and overtopping.

Water management in conventional tailings impoundments involves the interception, collection and treatment of ponded water. It also requires the adherence to regulatory licenses and tailings guideline documents.

Dry Stacking Tailings Storage Facility

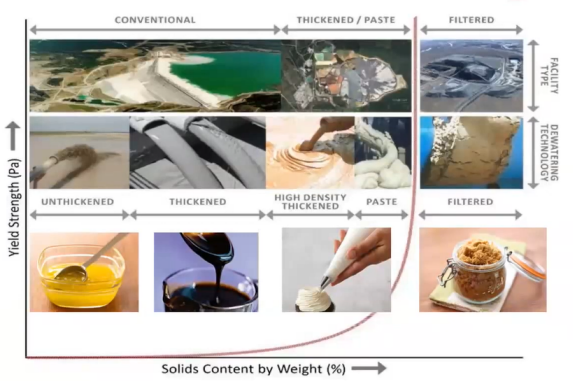

Dry stacking tailings storage facilities are a newer alternative to conventional tailings storage. These facilities use a combination of thickening, filtering, and drying to produce a dry tailings material. The dry tailings material is then stored in a facility, while the water is treated and reused in the mining process.

One of the advantages of dry stacking tailings storage facilities is that they can significantly reduce the amount of water required in the mining process. Additionally, dry stacking tailings storage facilities can reduce the environmental footprint of mining operations.

Filtered Tailings Storage Facility

Filtered tailings storage facilities are an alternative to conventional tailings storage. These facilities use filters to separate the water from the tailing material. The filtered tailings material is then deposited in a storage facility, while the water is treated and reused in the mining process.

One of the advantages of filtered tailings storage facilities is that they can reduce the risk of dam failure. This is because the filtered tailings material is typically denser and more stable than conventional tailings material. Additionally, filtered tailings storage facilities can reduce the environmental footprint of mining operations.

Paste Tailings Storage Facility

Paste tailings storage facilities are another alternative to conventional tailings storage. These facilities use a mixture of tailings material and water to create a paste-like material. The paste is then deposited in a storage facility, while the water is treated and reused in the mining process.

One of the advantages of paste tailings storage facilities is that they can reduce the amount of water required in the mining process. Additionally, paste tailings storage facilities can reduce the risk of dam failure, as the paste-like material is typically more stable than conventional tailings material.

Conventional Tailings Storage Facility

Conventional tailings storage facilities are the most commonly used type of tailings storage. These facilities consist of a dam, which is constructed by depositing the tailings material in layers. The dam is designed to hold back the tailings material and prevent it from entering the surrounding environment. The water in the tailings can be treated and reused in the mining process.

One of the benefits afforded by the traditional containment means of tailings is that the construction process is relatively uncomplicated and cost-effective. Nevertheless, there are certain downsides that must be considered. As an example, such systems are vulnerable to breaches in the dam structure, which may result in severe ecological devastation and the loss of human life.