RADIATOR FIN FAN COOLER MANUFACTURER

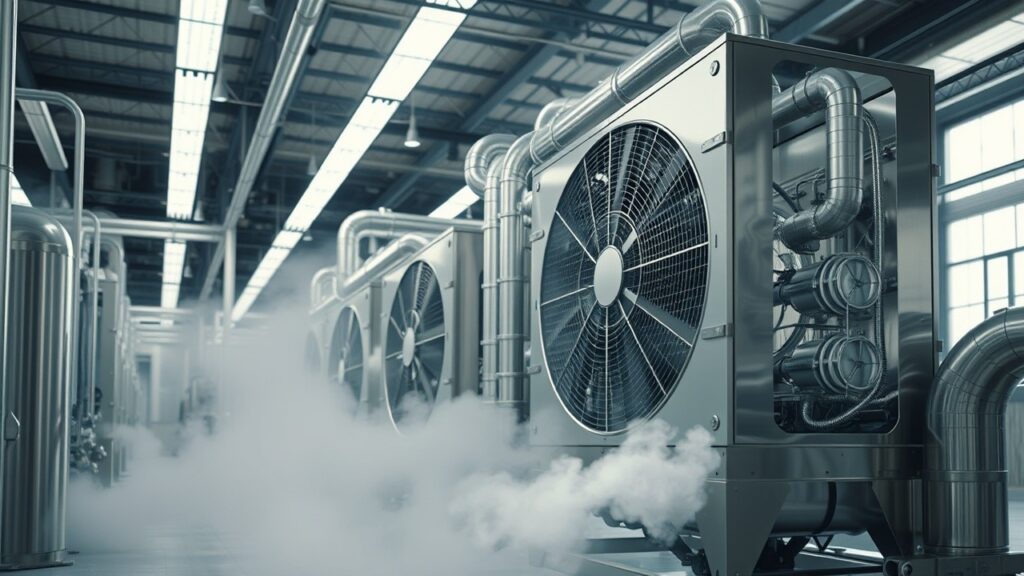

Heat in all industrial operations is highly important for ensuring that all equipment operates within its optimum working conditions and maintains the safety of operation. The Radiator Fin Fan Cooler, one of the most resourceful and widely applied heat exchangers in industry, is very efficient at cooling fluids and keeping machinery within safe temperature ranges. Waterman Engineers Australia is the engineering company recognized to give great technical facilities, and it offers services related to design, installation, and servicing on radiator fin fan coolers involved in various industrial sectors. The article elaborates on the intricacies involving various components, instruments, mechanisms, and working concepts of the radiator fin fan cooler, hence explaining its great importance in diversified applications.

Components and Design Structure

The Radiator Fin Fan Cooler consists of many key parts that comprise an overall system designed to optimize cooling. Every component is designed for strength and efficiency so the system can withstand the harshness of heavy-industry applications.

a.Radiator Core

It is the main core of the cooler and comprises several tubes and fins. In turn, the hot fluid flows through the tubes, but the fins enhance greater heat dissipation by increasing the exposed surface area to air. Typical materials for the core are aluminum, copper, or their alloys—high thermal conductivity and resistance to corrosive actions.

b.Fins

Thin metal sheets joined to the tubes, fins increase contact area between the fluid and air for maximum heat transfer. Depending on their application, fin density and geometry can be tuned to suit specific needs of the heat transfer. Waterman Engineers Australia deploys the latest materials and techniques in precision engineering in designing the fins, which undergo rigorous testing to withstand difficult environments for maximum cooling.

c.Fans

The fans force the air across the radiator core, thus speeding up the heat transfer process. Usually, they are electric motor operated and installed in strategic locations that ensure the distribution of airflow is uniform. The fans applied by Waterman Engineers Australia to the Radiator Fin Fan Coolers are energy-efficient and lightweight. They apply across industries to various operational needs.

d.Headers and Tanks

Headers distribute the fluid evenly along the tubes, and the tanks collect it at the far end of the processes. All these parts can withstand high-pressure fluids and are produced using materials that ensure minimal leakages and corrosion.

e.Frame and Supports

The radiating system is mounted on a sturdy frame that resists mechanical stresses from fan vibration and fluid pressure. Waterman Engineers Australia fabricates strong, robust frames according to spatial constraints and operational needs of specific installations.

Instrumentation and Control

Precise control and monitoring are essential for maintaining the efficiency of the Radiator Fin Fan Cooler and preventing overheating. The system instrumentation has proven to be a crucial feature in automating temperature regulation, optimizing performance, and ensuring safe operation.

i.Temperature Sensors

These sensors monitor the fluid entering and exiting the radiator core. From this data, operators can change fan speed or fluid flow to maximize cooling. High-accuracy sensors provided by Waterman Engineers Australia are specifically designed for such extreme conditions to provide accurate readings in such conditions.

ii.Pressure Gauges

Pressure gauges are installed in order to monitor fluid pressure within the system. Any rise in pressure indicates blockages and possible mechanical malfunction, which might lead to system failure. Waterman Engineers Australia incorporates high-quality pressure gauges with real-time pressure readings, where measures to correct the problem can be taken immediately.

iii.Flow Meters

It is important for the system to monitor fluid flow in order to maintain a consistent cooling potential. To maintain appropriate flow rates throughout the process, flow meters are incorporated into the system. In addition, adjustments allow matching of heat load fluctuations without efficiency being compromised.

iv.Fan Speed Controllers

Then, the fan speed regulators control the running of the fan with regards to temperature and pressure information. The component reduces energy consumption because it adjusts the fan speed depending on cooling demand and prolongs the life span of the equipment. In addition, its controllers, Waterman Engineers Australia, apply more advanced electronics in the whole operation to enable control by the operators.

Process Mechanism and Working Principle

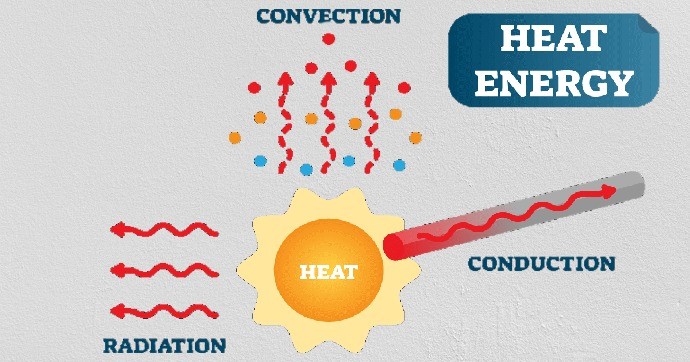

The mechanism of the Radiator Fin Fan Cooler is quite simple but the most efficient one as it deals with conduction, convection, and forced air cooling.

a.Heat Transfer Through Conduction and Convection

In the radiators, hot fluid flowing through the radiator tubes transfers heat to the tube walls as the fluid flows through. That heat is conducted along the fins attached to the tube. Since the fins have a larger surface area, the heat is dispersed via convection by transferring it to the surrounding air. Waterman Engineers Australia optimizes this by engineering its radiator tubes and fins with ideal material properties and thickness for constituting speedy and effective heat transfer.

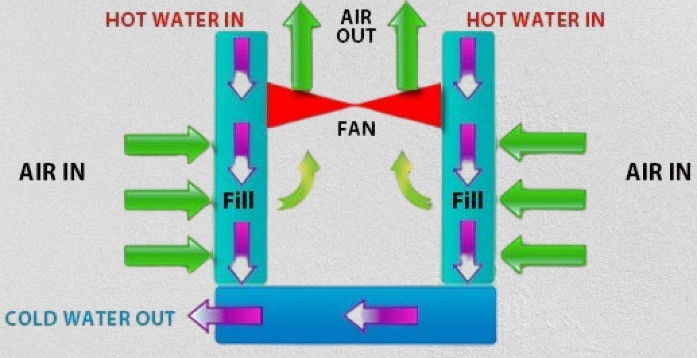

b.Forced Air Cooling

For the fans that are placed beside or at the rear of the core, it implies constant airflow across the fins. When the flow accelerates, the rate of heat transfer increases to enable the liquid to cool much better. As a result of the increased system capacity to accommodate all heat load variations, regulation of fan speeds promotes overall energy efficiency. Waterman Engineers Australia makes use of high-performance fans with variable speed to control the cooling process with least energy waste in consumptions.

c.Temperature Regulation and Energy Efficiency

The cooler has temperature sensors and controllers that measure temperatures and adjust fan speeds as needed. This way, the system will use the least amount of energy required in its operation, saving clients’ money and minimizing their contribution to environmental degradation. State-of-the-art control systems used by Waterman Engineers Australia ensure optimal temperatures are achieved while maximizing energy efficiency-a strategy that benefits not only the clients but also helps in sustainable practices.

Without a doubt, it’s just about being a reliable, energy-saving heat exchanger that can deal with heavy thermal loads in any industry, from petrochemicals to power generation. Waterman Engineers Australia has established its position as a trustworthy provider for industrial cooling solutions guaranteeing safety, efficiency, and durability in operation with its customized coolers catering to client-specific requirements.

Advanced Process Mechanisms and Adaptability

In the ever-evolving industrial cooling landscape, Radiator Fin Fan Coolers emerge as one of the most versatile mechanisms with robust performance over a wide swath of applications. Although Part 1 has established a foundational component and operational principle, Part 2 veers into advanced process mechanisms, varied configurations, and customizable features that render Radiator Fin Fan Coolers pretty versatile. The company excels in giving customised cooling solutions-to the most stringent needs of their client, ranging from demanding high-heat environments to industries with stringent cooling standards.

Advanced Cooling Mechanisms for Optimal Performance

It uses a combination of sophisticated cooling technologies to deal with challenging thermal loads. Such flexibility ensures that it finds wide application in industries in which temperature fluctuations could seriously affect the production processes and, hence, equipment efficiency as well as safety.

i.Cross-Flow and Counter-Flow Configurations

These radiators are available in either cross-flow or counter-flow configurations, each with its purpose in the cooling application.

ii.Cross-Flow

In this design, air flows perpendicular to hot fluid in the tubes. Crossflow coolers offer stable performance at a moderate level of cooling conditions and are easier to maintain since their structure is based on plain arrangements.

iii.Counter-Flow

Here, airflow is indeed opposite to fluid. Such a configuration is very effective for maximum heat transfer and thereby builds up a steeper temperature gradient along the cooler. Waterman Engineers Australia provides both configurations with specific recommendations based on operational requirements, ambient temperatures, and desired cooling efficiency.

iv.Two-Phase Cooling with Vapor Condensation

In some industrial processes, radiator fin fan coolers can be used to cool fluids that are in two phases, consisting of both vapor and liquid. These systems recover and recycle the fluid efficiently in a closed-loop cycle by cooling the vaporized component until it condenses back into the liquid phase. Fluid recovery and recycling are important in the chemical processing or gas-refining industry because maintaining fluid integrity is critical. Waterman Engineers Australia has integrated this sophisticated cooling technology into their designs for industries that need to have extraordinary control of phase transition.

v.Variable Fan Control for Energy Management

Fan power and its speed determine efficiency, amounting to energy consumption and operating costs, in a Radiator Fin Fan Cooler. Variable frequency drives allow operators to vary fan speed according to real-time cooling demand thereby avoiding excess energy usage. The VFD reduces the fan speed when demand is low, and it does this without forfeiting some capacity in cooling. This advanced control mechanism forms an integral part of the custom-built Radiator Fin Fan Coolers provided by Waterman Engineers Australia. These have ensured clients can minimize energy costs and increase equipment life.

vi.Environmental Adaptation for Ambient Cooling

As outdoor coolers, the interference from atmospheric conditions such as wind, rain, and dust negatively impacts their performance. Therefore, Waterman Engineers Australia has fitted their coolers with weather-resistant coatings, protective louvers, and filtration systems that prevent debris. These modifications enable coolers to be operated effectively in different weather conditions and harsh industrial settings, thus reemphasizing their reliability and durability.

Customizable Features for Industry-Specific Requirements

Each industrial industry has its own cooling requirements, most commonly determined by temperature, fluid type, and operational environment. The Radiator Fin Fan Coolers are highly adaptable to meet these particular demands, and Waterman Engineers Australia has many years of experience in designing the aforementioned systems for a vast range of applications.

- Material Selection for Corrosive Environments

Stainless Steel, titanium or other corrosion-resistant alloys would prevent degradation in the system for processes dealing with corrosive fluids or saline environments. Radiator Fin Fan Coolers from Waterman Engineers Australia are available with specific materials that will ensure durability even under the most hostile chemical or marine conditions.

- Compact, Modular Designs for Space Optimization

Some industries, such as offshore oil and gas or urban manufacturing facilities, are space-constrained. Waterman Engineers Australia has designed compact, modular coolers that do fit in restricted areas without sacrificing cooling capability. Modular configurations also make maintenance easy and provide for expansion when cooling requirements increase-what exactly makes these coolers the best for growing industrial configurations.

- Explosion-Proof and Fire-Resistant Models

In industries with flammable or hazardous materials, such as in the petrochemical and mining sectors, safety is paramount. Radiator Fin Fan Coolers can be designed with explosion-proof motors, fire-resistant coatings, and furthermore safety features to comply with regulatory requirements to work safely in high-risk areas. The Waterman Engineers Australia safety-enhanced models are developed to the highest safety standards. These serve to reduce operational risks to ensure maximum personnel safety.

- Noise Reduction Solutions for Urban or Enclosed Installations

Noise pollution is considered a serious issue in densely populated or confined industrial spaces. Radiator Fin Fan Coolers can be provided with sound-absorbing materials and low noise designed fan configuration to minimize the operational noise. Waterman Engineers Australia’s expertise in noise control ensures that their coolers not only meet regulatory standards but also upgrade environmental comfort in noise-sensitive areas.

Enhanced Applications in Diverse Industries

Due to their flexibility and durability, the applications of the Range of the Radiator Fin Fan Coolers extend across varied industries having specific cooling requirements. The Waterman Engineers Australia company customizes these systems for the respective sectors’ needs, ensuring every installation will provide peak performance and efficiency.

Oil and Gas: In oil refineries and gas processing plants, thermal management of the heat generated through drilling and processing operations is critical. Radiator fin fan coolers effectively manage hydrocarbon fluid temperatures, thus ensuring optimal process systems and less energy expenditure. Such coolers are typically required during remote offshore rigs, where a proper cooling solution is very much essential, and Waterman Engineers Australia stands as one providing maximum operational stability in this aspect.

- Power Generation

Radiator fin fan coolers play significant roles in ensuring equipment efficiency in power plants since steam turbines and generators are always in need of coolant. These coolers handle fluids at high temperatures with the ability to modulate the thermal load managed, through various steps of energy production. Customized cooling solutions for reliable high-power plant operations by minimizing environmental footprints engineered by Waterman engineers Australia.

- Chemical and Petrochemical Processing

Chemical processing entails reactions that involve maximum heat release. Therefore, their control must be effectively done so as not to damage equipment or contaminate a product. Radiator Fin Fan Coolers ensure stable cooling of chemical reactors, condensers, and storage tanks so that products are never compromised, and safety is maintained during operations. Waterman Engineers Australia has solutions specifically designed to address special challenges in the treatment of chemical cooling, such as corrosion resistance and high-temperature tolerance.

- Mining and Heavy Equipment

Mining liberates a lot of heat from heavy machinery to work under the earth. A majority of cooling is achieved in the hydraulic fluids, lubricants, and the engine system for a smooth operation of critical mining equipment. Waterman Engineers Australia supplies robust cooling systems proven at site in the most severe conditions encountered in mining, allowing the maximization of performance by minimum down time.

Enhanced Applications in Diverse Industries

Due to their flexibility and durability, the applications of the Range of the Radiator Fin Fan Coolers extend across varied industries having specific cooling requirements. The Waterman Engineers Australia company customizes these systems for the respective sectors’ needs, ensuring every installation will provide peak performance and efficiency.

Oil and Gas: In oil refineries and gas processing plants, thermal management of the heat generated through drilling and processing operations is critical. Radiator fin fan coolers effectively manage hydrocarbon fluid temperatures, thus ensuring optimal process systems and less energy expenditure. Such coolers are typically required during remote offshore rigs, where a proper cooling solution is very much essential, and Waterman Engineers Australia stands as one providing maximum operational stability in this aspect.

- Power Generation

Radiator fin fan coolers play significant roles in ensuring equipment efficiency in power plants since steam turbines and generators are always in need of coolant. These coolers handle fluids at high temperatures with the ability to modulate the thermal load managed, through various steps of energy production. Customized cooling solutions for reliable high-power plant operations by minimizing environmental footprints engineered by Waterman engineers Australia.

- Chemical and Petrochemical Processing

Chemical processing entails reactions that involve maximum heat release. Therefore, their control must be effectively done so as not to damage equipment or contaminate a product. Radiator Fin Fan Coolers ensure stable cooling of chemical reactors, condensers, and storage tanks so that products are never compromised, and safety is maintained during operations. Waterman Engineers Australia has solutions specifically designed to address special challenges in the treatment of chemical cooling, such as corrosion resistance and high-temperature tolerance.

- Mining and Heavy Equipment

Mining liberates a lot of heat from heavy machinery to work under the earth. A majority of cooling is achieved in the hydraulic fluids, lubricants, and the engine system for a smooth operation of critical mining equipment. Waterman Engineers Australia supplies robust cooling systems proven at site in the most severe conditions encountered in mining, allowing the maximization of performance by minimum down time.

Waterman Engineers Australia’s Expertise

The Radiator Fin Fan Cooler is an asset integral within industrial cooling management. It is responsible for efficient and reliable temperature control of critical machinery and processes. Its several operational benefits make it a preferred solution for industries requiring consistent cooling under adverse conditions. This final part will consider the benefits of Radiator Fin Fan Coolers and how Waterman Engineers Australia ensures best-in-class installation, maintenance, and service support for such systems.

Key Operational Benefits

- Energy Efficiency and Cost Savings

It optimizes the cooling system while ensuring low-energy expenditure. It has variable-speed fans to allow for controlled airflow in line with cooling demands. This decreases electricity charges and energy consumption. It is not only saving in operational expenses, but it responds to industrial attempts at reducing carbon emissions too. Waterman Engineers Australia specializes in designing high-efficiency cooling solutions that help ensure their clients reach sustainability goals and keep costs low.

- Reduced Water Usage

Among their many advantages, Radiator Fin Fan Coolers rely more than Water-cooled systems on ambient air. This means considerably reduced if not minimal usage of water. This is very handy in places where water resources are scarce or expensive. In water-scarce countries like Australia and Middle Eastern countries, where the heavy investment in oil and gas sectors requires strict environmental compliance, the system also wins the competition. Waterman Engineers Australia can provide environment-friendly air-cooled solutions.

- Enhanced Durability and Low Maintenance

The Radiator Fin Fan Coolers are designed to resist very adverse conditions. These are tough and maintenance friendly. Their structured design with quality parts minimizes wear and tear in harsh environments of extreme temperature, dust, or corrosive material. The modular design facilitates easy access to parts and, therefore, renders any service much easier. Waterman Engineers Australia uses quality materials and construction practices to make the cooling systems known to resist time and low maintenance aspects as well.

- Flexibility and Scalability

A Radiator Fin Fan Cooler can be scaled to match the evolution of the industrial need. Their modular structure can have more cooling capacity added to as required, thereby making them a good fit for growing operations or facilities with changing thermal loads. Waterman Engineers Australia specializes in designing scalable cooling solutions that can adapt to its clients’ expansions in operation, supporting smooth transitions as cooling demands grow.

- Reliability in Remote and High-Risk Locations

Because of their nature, Radiator Fin Fan Coolers are suited for working industries that are far-flung or distant from dwellings and towns, such as mining and offshore drilling. Low water dependency coupled with rugged design makes this cooling solution practical for areas lacking resources and more so in unfriendly conditions. Waterman engineers of Australia, in terms of expertise, ensure that these coolers perform reliably for safe operation by minimizing the incidences of the costly apparatus failures in isolated applications.

Waterman Engineers Australia’s Full-Service Solutions

Waterman Engineers Australia is marked with elaborate methods for designing, installing, and servicing Radiator Fin Fan Coolers. It includes an initial consultation and goes on through maintaining consistent actions that produce the best result for client changes in industrial cooling needs. Here’s how Waterman Engineers Australia’s services put together an unbeatable value in the installation of Radiator Fin Fan Coolers:

- Customized Design and Engineering

Every industry has exclusive cooling applications, and Waterman Engineers Australia is thus at the forefront of designing customized solutions for them. The company conducts comprehensive analyses of the diverse operational needs, environmental conditions, as well as budget constraints of every client to design the most effective cooling systems. In this way, Waterman Engineers Australia goes for customized solutions in the fan sizes, fin density, and cooling configuration to ensure efficient application-specific solutions that go beyond the industry’s standards.

- Installation and Commissioning Expertise

Gaining maximum efficiency and longevity of Radiator Fin Fan Coolers is possible if installed properly. Waterman Engineers Australia is confident that all components are set up to give the best possible performance with accurate installation in every part. The commissioning carried out by the manufacturer involves intensive testing with fine-tuning to ensure from day one that the cooler performs as desired. This precision in setup minimizes possible early wear or operational concerns, thereby boosting the duration of the system significantly.

- Comprehensive Maintenance Programs

For optimal performance and efficiency, Waterman Engineers Australia offers tailored maintenance packages that include regular checks of Radiator Fin Fan Coolers, their performance assessments, and prevention measures. Routine maintenance assures early detection of an impending problem to avoid the breakdown and costly expenses while incorporating an increased service life into the cooling system. Preventive care will help avoid downtime so clients can maintain uninterrupted activities.

- Training and Technical Support

Long-term reliability will depend on the understanding of how to operate and maintain cooling systems. In depth, Waterman Engineers Australia also provides training for client personnel. It includes basic operation, advanced troubleshooting, so that their clients can get appropriate assistance at any time. This attitude towards assistance takes care of clients’ confidence in managing and maintaining Radiator Fin Fan Coolers effectively.

- Upgrades and Modernization

With advancing technology, even the top-notch cooling systems have to be upgraded after a period of time. Waterman Engineers Australia offers radiator fin fan up-grades to use the latest innovation in fan technology, instrumentation, and energy management. All these will be an improvement toward enhanced performance, increased energy efficiency, and extended life of operating systems, thereby reaping the benefits of new technologies without having to replace the system outright.

Applications in Industry and Beyond

RADIATOR FIN FAN COOLERS Examples of the applications involving various sectors can be seen below. WATERMAN ENGINEERS AUSTRALIA has some experience in executing these cooling solutions in various industries, which have ensured smooth operations across borders and under pressure. Please find examples from some of these important applications:

- Data Centers

With a boom in digital infrastructure, cooling solutions for data centers have never been as important. Fin fan coolers through radiators are engineered to be an energy-saving alternative to traditional air conditioning while efficiently managing server temperatures without adding any energy expenditure. Data Centre Coolers from Waterman Engineers Australia are engineered with the goal of maximizing round-the-clock performance.

- HVAC and Refrigeration

Coolers are extensively used as part of the radiators fin fan coolers in HVAC systems to attain the right temperature for commercial and industrial environments. It is best suited for applications that need constant cooling without excessive utilization of water in refrigeration systems for food processing, pharmaceutical companies, among others.

- Automotive and Manufacturing

RADIATOR FIN FAN COOLERS are critical for the automotive and manufacturing industries, where they cool hydraulic fluids, lubricants, and other critical fluids. These coolers keep industrial machinery running at consistent temperatures, which helps extend the lifespan of equipment. Waterman Engineers Australia is pleased to offer customized designs tailored to the unique needs of automotive and heavy manufacturing facilities in order to ensure that these coolers provide reliable cooling in demanding production environments.

Conclusion

The Radiator Fin Fan Cooler is the core of modern industrial cooling. Its reliability, efficiency, and adaptability to different challenging applications make it the best choice for many applications. With comprehensive engineering, installation, and maintenance services, Waterman Engineers Australia has taken the lead in providing quality Radiator Fin Fan Coolers. Their client-centric approach, technical expertise, and commitment to innovation ensure that every cooling system they install delivers exceptional performance and longevity.

Solutions focused on the maximization of efficiency in operation come as support for sustainability practices from Waterman Engineers Australia. A business world geared towards huge industries that are highly focused on energy and environmental stewardship will now realize their ideals while having their production assets secured.

FAQs related to Containerized Sea Water Desalination Plant

- What is a Radiator Fin Fan Cooler?

A radiator fin fan cooler is an industrial cooling system utilizing ambient air to dissipate heat from fluids such as oil, water, or coolant. It employs the use of finned tubes to enhance the process of transferring heat. Fans are utilized in forcing air through the radiator. Fans push the system for maintaining the suitable temperature in industrial equipment.

- How does a Radiator Fin Fan Cooler work?

It works by pulling the fluid that has become heated through finned tubes in which heat is absorbed from the fins and dissipated through the airflow. Ambient air blown out by fans carries the heat out, coolifying the fluid efficiently.

- What are the main components of a Radiator Fin Fan Cooler?

The key parts consist of finned tubes, fans, motorized drives, headers and casings of the cooler. Finned tubes provide a larger surface area for heat transfer, and the air flow produced by fans facilitates better cooling.

- What industries benefit most from Radiator Fin Fan Coolers?

These coolers serve industries with very high needs for heat generation-from oil and gas, to power generation, data centers, HVAC, automotive, and manufacturing. Here, Waterman Engineers Australia offers various custom solutions for these very sectors.

- Why are Radiator Fin Fan Coolers more efficient than traditional water-cooled systems?

Unlike water-cooled systems, radiator fin-fan coolers work purely on ambient air only. Consequently, the use of water is completely ruled out and this in turn saves the environment, has low maintenance, and is highly suited to use in water-scarce areas.

- How does Waterman Engineers Australia enhance the efficiency of Radiator Fin Fan Coolers?

Waterman Engineers Australia tailors design and engineering of Radiator Fin Fan Coolers by maximizing fan speeds, spacings of fins, and material for solutions best suited to clients’ particular operating conditions, leading to improved cooling performance as well as decreased energy consumption.

- What type of maintenance is required for Radiator Fin Fan Coolers?

Basic maintenance calls for periodic inspections, cleaning of finned tubes, and checking for wear on fans and motorized parts. Waterman Engineers Australia provides a complete maintenance package where coolers run at peak performance.

- Are Radiator Fin Fan Coolers suitable for harsh environments?

Yes, they are designed to sustain intense temperatures, dust, and corrosive conditions. Waterman Engineers Australia uses strong material and engineering practices to deliver a robust system which is quite reliable and suitable for challenging industrial areas.

- What types of fluids can be cooled with Radiator Fin Fan Coolers?

These coolers can fit in with different liquids applied in industries, more so in water, oil, and one kind of coolant. Their applications are most seen cooling hydraulic fluids, lubricants, and transformer oils.

- What is the advantage of using air-cooled systems over liquid-cooled ones?

For instance, air-cooled systems are designed with Radiator Fin Fan Coolers; this lowers running costs because it does not require constant supply and consumption of water and treatment. For Waterman Engineers Australia clients, it is a significant necessity to conserve water resources and subsequently reduce footprints on the environment.

- What role does Waterman Engineers Australia play in the installation of Radiator Fin Fan Coolers?

Waterman Engineers Australia offers end-to-end installations, making sure each component is installed correctly for maximum efficiency. Their commissioning process includes performance testing and fine-tuning to ensure optimal operation from the start.

- Can Radiator Fin Fan Coolers be customized for specific industrial needs?

Absolutely. The Waterman Engineers Australia customizes each cooler on operational requirements, such as temperature ranges, fluid type, and ambient conditions. All this customization improves the cooling efficiency and lifespan of the system.

- What is the expected lifespan of a Radiator Fin Fan Cooler?

As long as they are well maintained, coolers can be used for over 10–15 years. Waterman Engineers Australia designs it so that the cooling system is long-lasting and efficient.

- Are there any regulatory compliance considerations for using Radiator Fin Fan Coolers?

Yes, many industries have environmental and safety regulations, especially about water usage and emissions. The Radiator Fin Fan Coolers are built to be water-efficient and environmentally friendly, complying with the governing regulations. Waterman Engineers Australia produces systems meeting the industry standards and environmental regulations.

- What support services does Waterman Engineers Australia provide for Radiator Fin Fan Coolers?

Waterman Engineers Australia is offering all the support services in the full range comprising design consultation, installation, preventive maintenance, training, and technical support. Being focused on client satisfaction, Waterman Engineers Australia ensures the smooth, no-break working of cooling systems.