Nutshell Filter Applications for Oil Removal in Crude Oil Exploration

Introduction

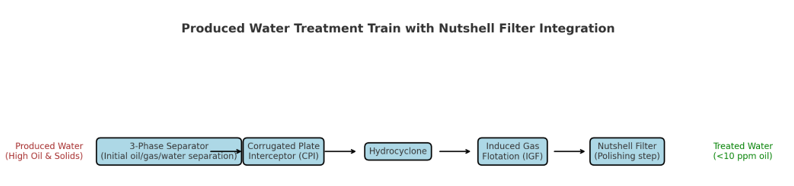

Crude oil exploration and production activities generate significant volumes of produced water, which is often contaminated with oil, grease, and suspended solids. Before this water can be discharged, reinjected, or reused, effective treatment is required to meet environmental regulations and protect reservoir and equipment integrity. One of the widely adopted technologies in upstream oil and gas operations for secondary treatment is the Nutshell Filter, a deep-bed media filter specifically designed to remove free and emulsified oil, as well as suspended solids, from produced water.

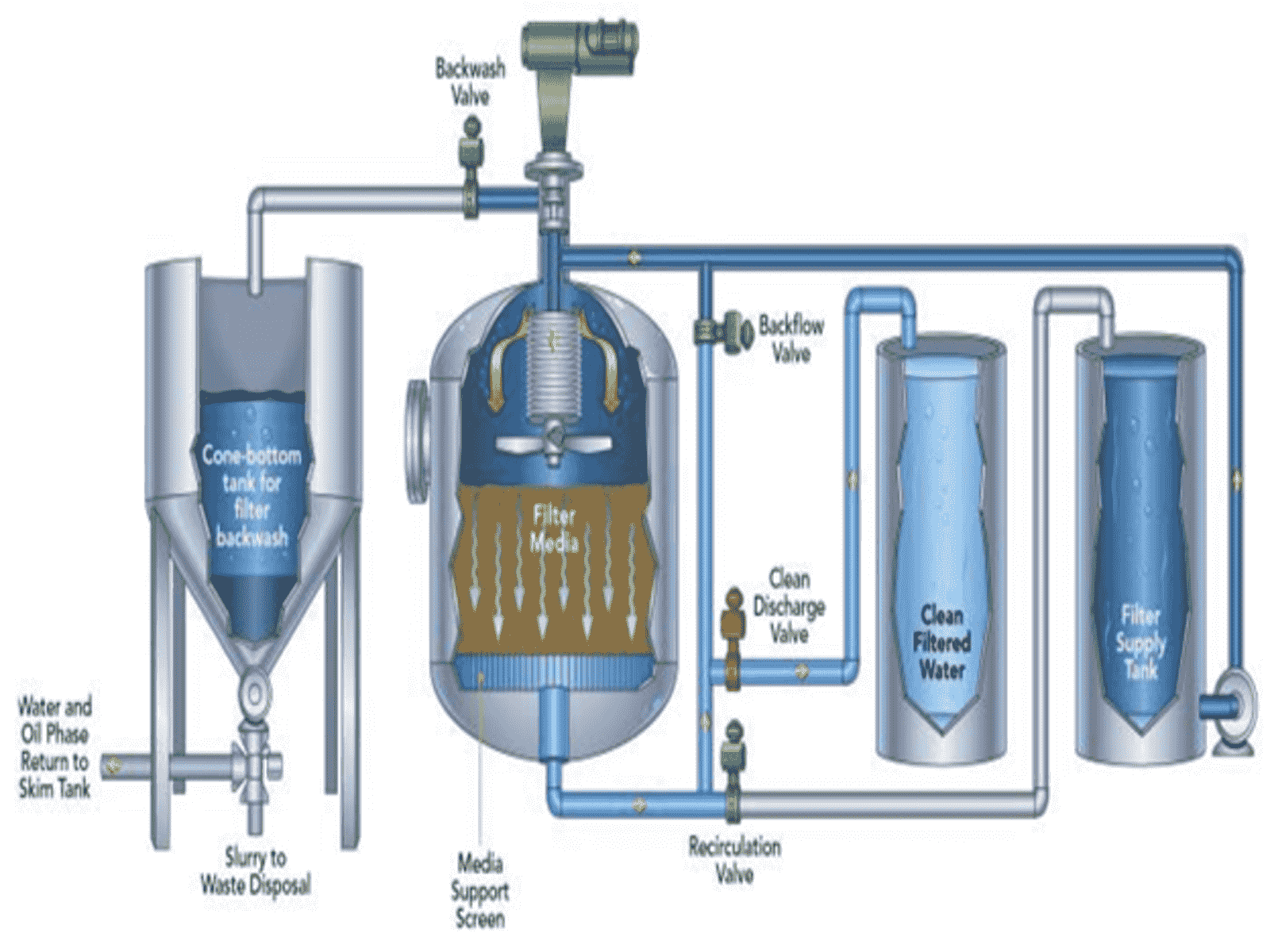

Principle of Operation

A nutshell filter uses crushed black walnut shells or other selected nutshell media as the filter bed. Walnut shells are naturally oleophilic (oil-attracting) and hydrophobic (water-repelling), making them ideal for adsorbing oil droplets from water.

- Filtration Stage

- Produced water passes downward (or upward in some designs) through the nutshell media.

- Oil droplets and suspended solids are trapped on the surface and within the interstices of the nutshell media.

- Backwash/Regeneration Stage

- Periodically, the filter undergoes backwashing using produced water, gas, or both.

- The abrasive nature of nutshells and agitation during backwash allow self-scouring, restoring the media without chemical cleaning.

Applications in Crude Oil Exploration

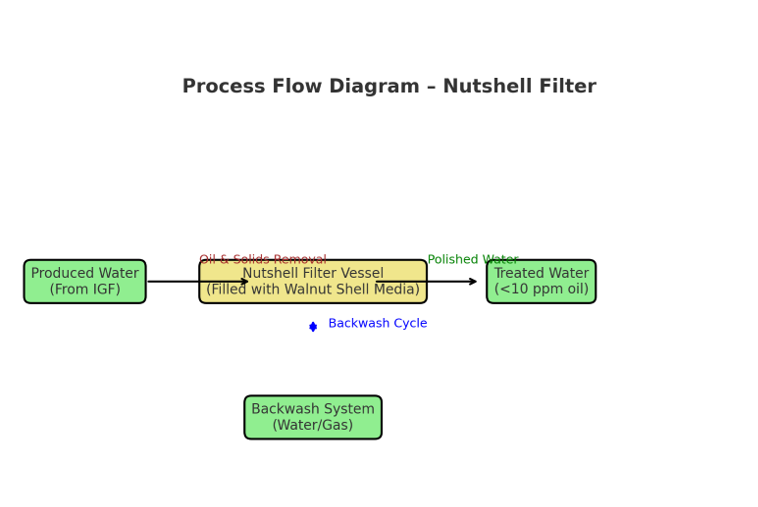

1. Produced Water Treatment

- Primary application is polishing produced water after induced gas flotation (IGF), corrugated plate interceptor (CPI), or hydrocyclone units.

- Removes residual oil droplets (typically reducing oil-in-water concentration from 50–100 ppm down to less than 10 ppm).

- Ensures water meets discharge standards or reinjection quality for reservoir pressure maintenance.

2. Enhanced Oil Recovery (EOR) Operations

- High-quality injection water is critical in waterflooding operations.

- Nutshell filters remove oil and solids that could plug reservoir pores, maintaining injection well productivity and extending reservoir life.

3. Equipment Protection

- Prevents fouling and scaling in downstream water handling equipment such as pumps, membranes (in advanced treatment systems), and reinjection wells.

- Enhances reliability and reduces maintenance costs of water treatment systems in remote oilfields.

4. Offshore Platforms

- Compact, robust, and environmentally friendly design makes nutshell filters suitable for offshore produced water treatment where space is limited.

- Helps operators meet stringent offshore discharge regulations (e.g., <30 ppm oil-in-water by international maritime standards).

5. Onshore Oilfields and Remote Exploration Sites

- Used as a polishing step where produced water volumes are high.

- Since walnut shells are natural and reusable, the system is low-maintenance and suitable for harsh environments with limited chemical supplies.

Advantages of Nutshell Filters

- High oil removal efficiency (removes oil droplets as small as 2–5 microns).

- Media longevity: Walnut shell media can last 10–15 years with proper maintenance.

- Self-cleaning: Backwash cycle cleans the filter without chemical regenerants.

- Environmentally friendly: No chemical consumption and minimal waste generation.

- Low operating cost compared to disposable cartridge filters or chemical treatment systems.

- Robust design suitable for fluctuating flow rates and oil loads in crude oil exploration.

Limitations

- Performance can be affected by high concentrations of fine solids (may require pre-treatment).

- Requires periodic backwash water supply and energy.

- Not suitable as a primary treatment unit — best applied after CPI, hydrocyclones, or IGF systems.

Conclusion

In crude oil exploration and production, nutshell filters provide a reliable, sustainable, and cost-effective solution for removing residual oil from produced water. Their natural affinity for oil, coupled with durability and ease of operation, makes them an essential part of modern produced water treatment trains — especially where compliance with stringent discharge or reinjection water quality standards is mandatory.

Comparison of Oil Removal Efficiency in Produced Water Treatment Units

| Treatment Stage | Oil Removal Efficiency (%) | Outlet Oil Concentration (ppm) | Oil Droplet Size Removed (µm) | Role in Treatment Train | Advantages | Limitations |

| Corrugated Plate Interceptor (CPI) | 50–70% | ~80–100 ppm | ≥60 µm | Primary treatment – separation of large oil droplets | – Simple gravity-based system – Low energy consumption – Robust and reliable | – Ineffective for fine/emulsified oil – Large footprint – Sensitive to flow surges |

| Hydrocyclone | 50–90% | ~30–50 ppm | ≥20 µm | Secondary treatment – removal of medium-sized droplets | – Compact design – No moving parts – Handles fluctuating loads | – Efficiency drops at low flow – Requires pressure drop to operate – Not effective for <20 µm droplets |

| Induced Gas Flotation (IGF) | 70–95% | ~20–30 ppm | ≥10–15 µm | Tertiary treatment – removal of fine and dispersed oil | – High efficiency for dispersed oil – Adjustable performance with gas flow – Compact compared to CPI | – Requires chemical additives (sometimes) – Mechanical parts need maintenance – Efficiency reduced with solids |

| Nutshell Filter | 90–99% | <10 ppm | ≥2–5 µm | Polishing – final stage before discharge/reinjection | – Removes very fine droplets – Long media life (10–15 years) – Self-cleaning via backwash – Environmentally friendly (no chemicals) | – Requires periodic backwash water – Sensitive to very high solids load – Higher CAPEX than CPI |

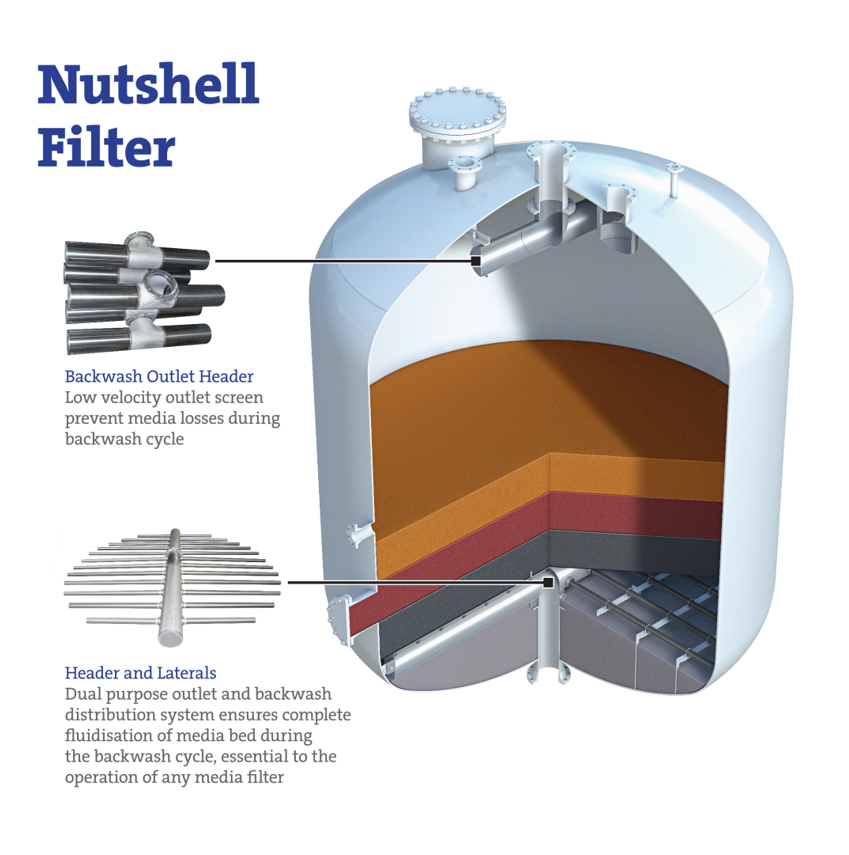

Main Components

- Produced Water Inlet (Side Nozzle – Upper Section)

- Brings produced water (after IGF or hydrocyclones) into the vessel.

- Flow directed downward through the nutshell media bed.

- Walnut Shell Media Bed (Filter Zone)

- Crushed black walnut shells fill the main chamber.

- Oil droplets (≥2–5 µm) and suspended solids are trapped on and between media.

- Treated Water Outlet (Side Nozzle – Mid/Lower Section)

- Clean water (<10 ppm oil) exits after passing through the bed.

- Suitable for reinjection or discharge as per environmental norms.

- Backwash System

- Backwash Inlet at vessel bottom (gas/water injection).

- Backwash Outlet at vessel top (dirty water & oil exit).

- Flow reversal agitates nutshell media, scouring oil/solids off.

- Media re-settles for reuse (no replacement or chemicals needed).

✅ This table shows progressive oil concentration reduction:

- CPI: from high ppm down to ~100 ppm

- Hydrocyclone: down to 30–50 ppm

- IGF: down to 20–30 ppm

- Nutshell Filter: final polishing to <10 ppm

This progression explains why nutshell filters are always used downstream of CPI, hydrocyclone, and IGF units.