Mining Dam, Mining Pit Wastewater Recycling Plant

Introduction

In order to extract valuable minerals and resources, mining is considered a crucial activity; nonetheless, mining causes a plethora of water-related environmental problems. Because mine pits and dams are often filled with water, the water within could include a variety of contaminants, including heavy metals, suspended particles, and other compounds. It is crucial to prioritize wastewater recycling in order to maintain sustainable operations, as this contributes significantly to the environmental impact of mining.

The Need for Wastewater Recycling in Mining

Mineral processing, dust suppression, and slurry transportation are just a few of the many uses for water in the mining industry. These processes consume vast amounts of water, as the name implies, and the result is polluted wastewater. This wastewater has the potential to contaminate adjacent bodies of water and the soil if not treated properly, causing permanent harm to the ecosystem.

This effluent is essentially from mining dams and pits, but there are many benefits to recycling it instead. Reduced freshwater usage, less wastewater entering treatment plants (if any), and easier recovery of precious minerals like metals are all results of this. Furthermore, recycling can lessen the likelihood of dam collapses and the catastrophic effects they have on downstream communities and ecosystems.

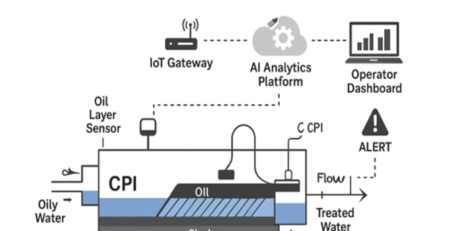

Technologies for Mining Dam, Mining Pit Wastewater Recycling

Reusing wastewater from mining dams and pits is possible thanks to a number of methods. The technologies in question can be broadly categorised into three areas: the physical, the chemical, and the biological.

1. Physical Processes

- Sedimentation:

During this procedure, any particles in the water that aren’t already suspended in the water settle to the bottom of the container or pond. It is typically used before to any other treatment procedures.

- Filtration:

Particulate removal from wastewaters is achieved using a variety of processes, including sand filtration and membrane filtration. However, membrane filtration techniques are handy point-of-use ways to get rid of those pesky tiny particles and dissolved solids.

- Evaporation:

It is possible to concentrate wastewater in regions with abundant sunshine by using evaporation ponds; the solids remaining after the water evaporates are either further treated or disposed of in landfills.

2. Chemical Processes

- Coagulation and Flocculation:

This method involves treating wastewater with chemicals, usually alum or ferric chloride, to aggregate small particles into bigger flocs that can be filtered or sedimented away.

- Chemical Precipitation:

Used to extract contaminants from water by combining them with chemicals to create insoluble precipitates, such as metals and other impurities.

- Ion Exchange:

The technique relies on the substitution of ions in a resin for those in the wastewater. Heavy metals and other specific contaminants would be the ones to which it would be most effective.

3. Biological Processes

- Constructed Wetlands:

These systems take advantage of the healing mechanisms already present in microbes and plants. A wide variety of pollutants, including fertilisers and heavy metals, can be removed by wetlands.

- Bioreactors:

Artificial devices that purify water by utilising live organisms to break down organic contaminants and eliminate metals. Bioreactors are adaptable in their use of wastewater recycling because they may be modified to target different contaminants.

Waterman Engineers Australia

Treatment issues in wastewater recycling and heavy metal removal are important topics of study in the pursuit of environmentally friendly mining activities. Businesses like Waterman Engineers Australia are at the forefront of developing ground-breaking answers to challenges of this complexity. When it comes to recycling wastewater from mining dams and pits and removing heavy metals from this effluent, Waterman Engineers Australia is the go-to expert.

The mining sectors confront significant challenges, and Waterman Engineers Australia has developed solutions that incorporate cutting-edge technologies such as biosorption, membrane filtration, and chemical precipitation. To aid mining companies in reducing environmental footprints while preserving operational efficiency, their strategy takes into account both the resource recovery issue and the need for adequate wastewater treatment.

The mining sectors confront significant challenges, and Waterman Engineers Australia has developed solutions that incorporate cutting-edge technologies such as biosorption, membrane filtration, and chemical precipitation. To aid mining companies in reducing environmental footprints while preserving operational efficiency, their strategy takes into account both the resource recovery issue and the need for adequate wastewater treatment.

Waterman Engineers Australia may work with mining industries to provide services beginning with evaluation and design and continuing through implementation and ongoing support. They are the go-to partner for mining companies when it comes to responsible resource management and environmental protection because of their dedication to sustainability and innovation.

When it comes to the dynamic mining industry’s increasing embrace of sustainability, specialised firms like Waterman Engineers Australia will be pivotal. With their expertise in wastewater recycling and heavy metal removal, mining operations are prepared to tackle the obstacles posed by regulatory and environmental regulations that aim to make the business more sustainable.

FAQs

- What is mining dam and mining pit wastewater?

Contaminated wastewater from mining operations is known as mining dam wastewater or mining pit wastewater. Typically, it contains contaminants including heavy metals, compounds released during mineral processing, and suspended solids. Adequate recycling is necessary for the efficient management of this water due to its effects on the ecosystem and the saved freshwater. - Why is recycling mining wastewater important?

There would be less of a need for potable water, less wastewater to treat, and more resource recovery if mining effluent could be recycled. It ensures that mining operations use water sustainably and prevents degradation of the environment. - What technologies are used for recycling mining wastewater?

Chemical processes like coagulation and precipitation, physical processes like sedimentation and filtration, and biological processes like built wetlands and bioreactors are all utilised in mining wastewater recycling. The wastewater’s unique composition and treatment goals will dictate the best course of action. - How are heavy metals removed from mining wastewater?

Heavy metal removal techniques span the physical (adsorption, membrane filtration, etc.), chemical (precipitation, ion exchange, etc.), and biological (biosorption, phytoremediation, etc.) realms. The kind and amount of metals in the effluent will determine the procedure to be followed. - What are the environmental impacts of untreated mining wastewater?

Mining wastewater degrades land and aquatic life, contaminates surface and groundwater, and harms the ecosystem if not handled. As with other contaminants, heavy metals have a cumulative impact on ecosystems and human health as they make their way up the food chain. - What services does Waterman Engineers Australia offer for mining dam and mining pit wastewater recycling?

Waterman Engineers Australia provides a comprehensive service for recycling wastewater from mining dams and pits, beginning with conceptualization and ending with detailed design. They apply cutting-edge treatment technologies, such as chemical precipitation systems and membrane filtration, and also build wetland systems to manage and recycle wastewater effectively. - How does Waterman Engineers Australia handle heavy metal removal from mining wastewater?

Adsorption, chemical precipitation, and biosorption are some of the heavy metal removal procedures used by Waterman Engineers Australia. By utilising their expertise, heavy metals can be properly eliminated, ensuring compliance with regulations and environmental protection. - What makes Waterman Engineers Australia a reliable partner for mining wastewater management?

The wastewater management team at Waterman Engineers Australia has a stellar reputation. Mining firms may rely on them as a reliable partner for wastewater treatment process improvement because of their personalised solutions, innovative technologies, and dedication to sustainability. - Can Waterman Engineers Australia provide customized solutions for specific mining operations?

Waterman Engineers Australia does, in fact, provide individualised services to meet the specific requirements of the mining industry. Careful evaluations are carried out so that treatment systems may be developed and put into place to meet the unique demands of wastewater composition and environmental regulations. - How can mining companies get in touch with Waterman Engineers Australia for their services?

If your mining company is interested in learning more about the services offered by Waterman Engineers Australia, you can do so by visiting their website. To further discuss their needs and schedule a consultation, they may also reach out to the company directly using the given contact information.