Future Prospects for Zero Liquid Discharge Systems in Water Resource Management

The global water crisis has revived interest in Zero Liquid Discharge (ZLD) systems. More stringent regulations, rising expenses for wastewater disposal, and increasing value of freshwater are driving ZLD implementation in both developed and developing countries.

However, a number of challenges remain for ZLD technology. These include energy efficiency, cost effectiveness, environmental impact, and sustainability.

Energy Efficiency

With a growing number of people and materials relying on water, there is an increasing need to improve the efficiency of waste water management. Zero liquid discharge (ZLD) systems are one of the many technologies available to help limit wastewater discharge while also improving sustainability and cost effectiveness.

ZLD is a complex and expensive technology that requires a lot of energy to process wastewater, but the benefits are significant. It can recover up to 90 percent of the water in industrial effluent for reuse, while saving costs related to water and energy consumption.

The main challenges to consider when implementing ZLD are energy usage, disposal and the environment. However, there are several ways to reduce the energy footprint of these technologies.

For instance, membrane systems can be used in combination with evaporation systems to increase water recovery and decrease the overall capital and operating costs associated with these systems. Additionally, advanced technology can be applied to remove the majority of dissolved salts from the waste stream and concentrate them for crystallization, reducing the required evaporation volume and energy output.

Moreover, the use of forced circulation evaporation (FCE) reduces energy demands by up to 50%, while still meeting high water recovery targets. These techniques are particularly effective for a wide range of industrial wastewaters.

While a number of industrial operations are transitioning to ZLD treatment programs, there are some challenges that plant leaders must overcome before making a decision. These include the need to develop a long-term strategy that addresses the potential for future expansions of production capacity and product lines, as well as any impact on waste water disposal and value-added potential.

In addition, it is important to determine the best type of treatment method for the incoming wastewater. A number of wastewaters have very specific chemistry, and therefore require a specific treatment technology. Similarly, some wastewaters have extremely high fouling propensity and require special filtration equipment for optimal performance.

The best wastewater treatment technique depends on the waste composition, the target application and the site location. It should be noted that the application of a ZLD system in an area that is subject to a drought can result in increased energy costs and reduced water recovery.

Cost Effectiveness

Zero Liquid Discharge (ZLD) is an innovative water management strategy that can help industrial operations meet water-shortage risks while meeting their environmental and operational stewardship goals. ZLD systems use a series of advanced treatment processes and technologies for increasing water recycling while minimizing wastewater volumes and improving contaminant recovery.

In ZLD systems, feed wastewater is typically treated using a series of membrane filtration and separation processes that reduce turbidity and sludge density index (SDI) to acceptable levels. After these steps, the feed is passed into a multi-stage membrane brine concentrator or electrodialysis (ED) to further concentrate the waste to a high salinity level and produce clean product water for reuse.

Membrane brine concentrators and ED are commonly used as the first step in ZLD systems, but other promising technologies (such as ED/EDR, FO and MD) with higher recoveries have also emerged. These technologies are able to increase the amount of waste water that can be processed and minimize the size of evaporator/crystallizer units required, thus reducing both capital and operating costs.

The next stage in ZLD systems is thermal evaporation or crystallization that turns the high-salinity brine into pure, solid dry water that can be stored and recycled for salt recovery purposes or landfill disposal. The evaporation process is generally more capital and operating cost intensive than membrane systems, with the evaporator/crystallizer unit being the most costly element.

Other components of a ZLD system may include a brine storage tank for the distillates that are produced, as well as a solids reclamation unit to recover valuable resources that can be sold or reused in other processes. These reusable materials may be further refined or disposed of as landfill waste or processed into valuable byproducts for additional reuse.

Achieving the highest possible water recycling and wastewater volume recovery in a ZLD system requires an optimized design that addresses site-specific operating, environmental and contaminant limitations. This design must be flexible enough to accommodate changes in the source waste stream and to handle changing demands of the system.

As the water supply in many areas continues to become more scarce, the need for more advanced and optimised solutions is ever more prominent. This is especially true for industrial wastewaters that are difficult to treat and produce challenging liquid waste streams.

Environmental Impact

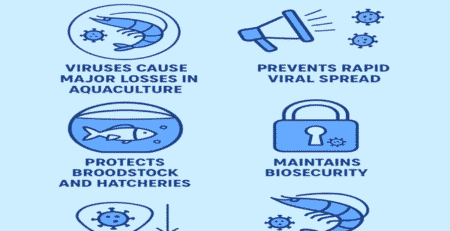

The environmental impact of wastewater discharge is often a matter of concern for local communities. It can lead to the degradation of water resources, increase water consumption, and pollute aquatic environments. However, Zero Liquid Discharge Systems are increasingly gaining widespread adoption across a variety of industries because they prevent the discharge of contaminated wastewater and promote water recycling.

Unlike other water treatment methods, Zero Liquid Discharge (ZLD) aims to completely eliminate all produced wastewater before sending it into surface waters or sewers. It is a multi-stage process that starts with pre-concentration of the waste using membranes such as reverse osmosis or brine concentrators. Then, evaporation and crystallization of the condensed distillate is used to produce clean water for reuse or salts can be recovered as valuable products.

ZLD is a powerful, cost-effective way to improve water resource management and minimize pollution. It can help to mitigate rising costs of water, reduce the amount of wastewater that is disposed into a sewer system, and protect public health and the environment.

It can also be a key factor in reducing the risk of contamination of surface waters and groundwater, particularly when it is not possible to transport the wastewater through a sewer system. It also contributes to less reliance on natural freshwater sources for industrial processes, as it allows for the use of reclaimed water to meet production demands.

Achieving Zero Liquid Discharge is a goal for many power plants, as it can help them meet their environmental stewardship goals and improve the perception of their operations in the community. In addition, stricter regulations for wastewater disposal have made it more attractive for power plants to adopt ZLD technology, especially in the U.S.

EPA recently revised the discharge standards for thermal power plants, which include new guidelines that require plants to eliminate liquid discharge from their treatment systems. This change will offer increased regulatory support for the installation of ZLD at power plants, especially for hazardous pollutants in wastewater from fly ash transport and bottom ash transport.

The treatment of wastewater is a complex and costly process that must be designed to maximize its water recycling potential. ZLD can help to address the challenge by recycling up to 80 percent of waste, while avoiding the release of untreated wastewater into the environment. It can also reduce the amount of wastewater that needs to be treated, which will save energy and costs. It can also be a key factor in helping to avoid water shortages, which is important for the future of industrial processes.

Sustainability

In many countries, there is a growing awareness of the need to reduce water pollution and conserve water resources. This is a trend that extends across industrial sectors and governmental bodies. However, it is not always possible to meet all requirements for water conservation, especially where wastewater disposal is a problem.

The use of Zero Liquid Discharge (ZLD) systems is a promising option for reducing the discharge of wastewaters and improving water sustainability. The technology aims to minimize liquid waste generation and extend water supply by utilizing wastewater treatment, recycling, and reuse.

As the world faces increasing demands for water, it is necessary to find more sustainable solutions that can help meet those needs. One such solution is ZLD, which combines various techniques and processes to effectively treat wastewater.

ZLD has been used in a wide range of industries, including power plants, oil & gas, chemical, petrochemical, mining, and other industries. It has proven to be effective in minimizing the volume of liquid waste produced while also extending water supply.

Although ZLD is a proven water resource management strategy, it does have some limitations and challenges. These limitations include high energy consumption and carbon dioxide emissions.

For this reason, ZLD is not necessarily the best choice for every application. Some plants have tight budgets and regulatory compliance, which make it unaffordable for them to install a ZLD system.

Nevertheless, some of these plants can still implement ZLD strategies that reduce the total wastewater volume and improve energy efficiency. Typically, these near-ZLD programs can recover between 70 and 90 percent of the total wastewater volume for reuse, depending on plant specifics and financial goals.

As the global economy grows and environmental issues become more prominent, it is likely that governments will impose stricter regulations for the discharge of wastewater. This will likely increase the demand for wastewater treatment and re-use technologies. Therefore, companies should consider using ZLD systems as a means to conserve and protect water resources.