ETP Plants – Characteristics of Textile Sludge and Its Treatment

Did you know? 800,000 tonnes of textile waste have been discarded by Australians every year? A rate of 15 tonnes every 10 minutes.

Textile industries are regarded as large industrial consumers of water in addition to the major producers of wastewaters. Although the main purpose of tightening environmental standards is to treat wastewater before discharging it safely. But generally, various pollutants are concentrated during different wastewater treatment process steps (WTP) into the sludge (consisting of between one to two percent weight of dry solids).

A semi-solid part obtained after the treatment of effluent in the effluent treatment plant (ETP) is known as sludge. It is an inevitable by-product of textile WTP. Sludge from Effluent Recycling Systems usually constitutes clusters of inorganic and organic complexes with high concentrations of chemicals, heavy metals obtained from dyestuff, bleaching, and other process residues. The low efficiency of spillage of chemicals and chemical operations causes a significant pollution hazard. Some generalized physiochemical characteristics of textile sludge are shown in table 1.

Table 1: Typical physico-chemical characterization of textile sludge

|

Parameter |

Value |

| pH (1:5 suspension) | 6.46 |

| Electrical conductivity (250C) | 11.93 mS |

| Dry density | 1200-1500 kg/m3 |

| Specific gravity | 1.2-1.5 |

However, solid sludge from wastewater treatment plants is usually discarded into the environment without any further modification thus disregarding environmental regulations. Handling and processing of sludge are becoming a major hazard for companies that are operating their WTP regularly.

Moreover, the classification of sludge is based on its composition and origin. Basically, there are three categories of sludge.

Category A: Municipal Sludge including comparable sludge

Category B: Industrial sludge, it includes sludge from the central effluent treatment plant (CETP) too

Category C: Sludge from industry including sludge from CETP that belongs to the category of hazardous waste.

The textile industries produce Category C sludge, which falls in the most hazardous category. Although, sludge belonging to Category A and B don’t pose any hazardous consequences. However, category A and B sludge when mixed with category C then it will become Category C as well.

In order to facilitate and simplify this sludge classification, thresholds for heavy metal concentrations were proposed by US EPA as shown in table 2 given below:

Table 2: Threshold of heavy metals concentrations in sludges

| Parameter | Unit (DM) | Category A | Category B# | Category C |

| Cd | mg/kg | ≤10 | 11-85 | >85 |

| As | mg/kg | ≤40 | 41-75 | >75 |

| Cu | mg/kg | ≤800 | 801-4300 | >4300 |

| Cr | mg/kg | ≤600** | <600 | >600 |

| Ni | mg/kg | ≤200 | 201-420 | >420 |

| Pb | mg/kg | ≤840** | <840 | >840 |

| Hg | mg/kg | ≤8 | 9-57 | >57 |

| Zn | mg/kg | ≤2500 | 2501-7500 | >7500 |

Furthermore, there is a need for the safe disposal of this large volume of textile sludge in an environmentally friendly manner. In developed countries, reducing the volume and weight of the sludge along with avoiding its potential health hazards depends upon the handling and disposal of this sludge. Moreover, in developing countries like India, Pakistan, Bangladesh, Indonesia, Iran, Iraq, etc common disposal techniques like composting, landfilling, and incineration are commonly used. Generally, for carrying out proper incineration there is a need for a furnace, fuels, additional support systems, trained personnel and follow up of some precautions against safety and fire hazards while emissions of flue gas and ashes mark a significant threat to the environment, Likewise, the fluctuating quantity of textile sludge, high number of heavy metals and volatile organic matter makes composting and landfilling a less desirable option.

Normally the treatment of textile sludge is a difficult task and requires sophisticated technologies and specialized methods but now. We are one of the most trusted manufacturers for ETP plants or Effluent recycling plants, employing the most advance and best technologies. We as textile effluent treatment systems manufacturers aim to remove critical substances, especially sludge till the last stage of getting quality treated water effectively and efficiently with great efficiency at our treatment plants.

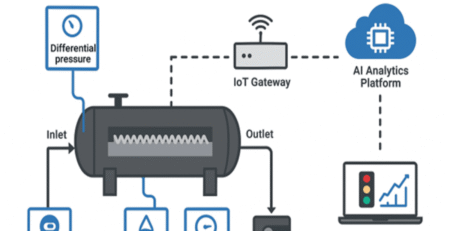

Generally, physical, chemical, and biological are three methods for treating textile sludge. Physical treatment involves floatation, sedimentation, stripping, filtering, adsorption, ion exchange, and many other processes for the removal of non-dissolved and dissolved substances without usually changing their chemical structures. Additionally, chemical treatment involves chemical oxidation or chemical reduction, and chemical precipitation while biological sludge treatment processes involve living organisms utilizing organic and sometimes inorganic substances for food.

Commonly, for treating water containing colloids and dissolved solids, the most versatile biological oxidation method can be employed, also called the “activated sludge process”. During this process, agitation and aeration of wastewater are carried out in the reaction tank in which microbial flocs get suspended. Moreover, biological degradation takes place by aerobic bacteria flora into the water, carbon dioxide, and heat and consumes organic matter for bacteria. The bacteria grow and get suspended in the form of floc which is also known as Activated sludge. After that, the separation of the sludge from the effluent takes place by settling and discharging it. Also, for the provision of an effective microbial population and in order to utilize bacteria alive present in the sludge, a part of the sludge is recycled to the oxidation tank. In the sludge digester, the surplus sludge is digested in addition to primary sludge obtained from primary sedimentation. Then this sludge is dried in the filter press.

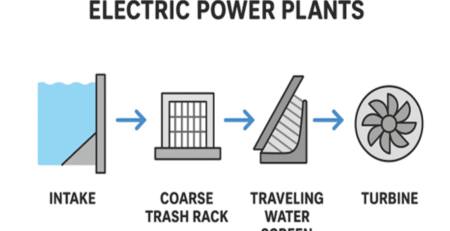

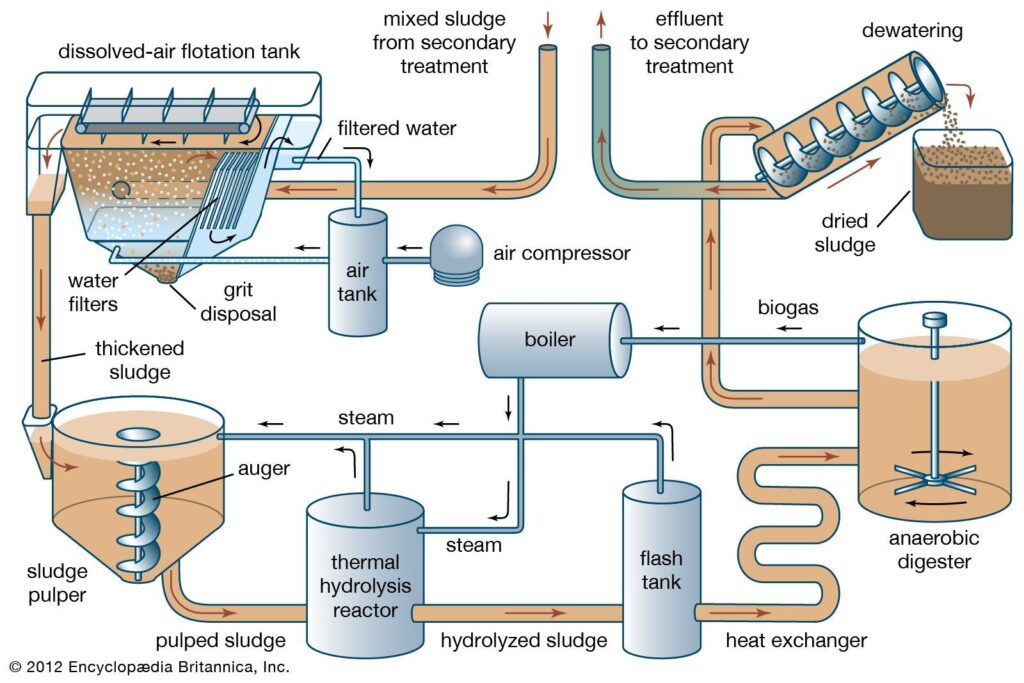

In all treatment methods of Effluent treatment plants, the generation of sludge takes place. Through dissolved air floatation tank, mixed sludge received from secondary wastewater treatment is passed in which solids arise to the surface and are skimmed off. After that, the pulping of sludge takes place with the help of steam and after that, it passes to thermal hydrolysis in which large molecules like lipids and proteins are broken down under pressure and heat. After that passage of hydrolyzed sludge takes place through a flash tank where an instant drop in pressure causes the bursting of the cell and then to anaerobic digestion, where the conversion of bacteria converts dissolved organic matter to biogas. Then passing of digested sludges passes through a dewatering step; the dried solids are disposed of and are sent back to the secondary treatment.

Figure 1:Textile sludge treatment and disposal

An important question arises in our minds how this sludge will be managed?

There are many options available for the management of textile sludge. It can be utilized for the preparation of brick, it can be mixed with cement, can be incinerated for the production of electricity. Moreover, it can be used for sanitary landfilling. Also, it can be used for the generation of biogas and can be used for composting too. As compared to traditional methods, the composting of textile sludge is a more efficient and effective method compared to any other traditional methods for disposal. However, composting is known to be aerobic biological degradation and stabilization of organic substrates under certain conditions that allow the development of thermophilic temperatures as a product of biologically produced heat, for obtaining a stable final product that is free of plant seeds and pathogens and its application can provide benefits to land. In addition to this the process of composting commits to reducing the production of waste products.

ETP Plants Frequently Asked Questions

1) What are the characteristics of sludge?

Sludge is a foul, semisolid by-product of wastewater treatment’s solid-liquid separation operations that resembles thick, squishy mud. Its composition is typically quite erratic, and it is frequently unmanageable.

2) What is sludge ETP?

SLUDGE. Industrial waste water is treated in an ETP (Effluent Treatment Plant) so that it can be recycled or safely dumped into the environment. Untreated industrial waste water is a factor.

3) What are the stages of sludge treatment?

4-Step Wastewater Sludge Treatment Process

- Sludge Thickening

- Sludge Digestion

- Dewatering

- Disposal

4) What is ETP effluent treatment plant?

Most businesses in a variety of industries utilize effluent treatment plants (ETPs) to purify water and remove any toxic and non-toxic materials or chemicals from it so that it can be reused or released in the environment with less environmental harm.

5) Why is sludge treatment important?

Sludge treatment’s main goals are to minimize volume and stabilize organic components prior to final disposal. Stabilized sludge can be handled without endangering one’s health or producing an unpleasant odour. Having less sludge results in lower pumping and storage costs.

6) What is ETP in textile dyeing?

Effluent Treatment Plant or ETP. The dyeing house’s effluent treatment facility is utilized to remove the colour and chemicals that are present in the water. Throughout the many stages of production, dye house water contains a number of compounds.

7) Which chemical is used in ETP plant?

Liquid Poly Aluminium Chloride, also known as PAC, is a component of water treatment chemicals used for pulp and effluent treatment. Physical features of polyalkyl chloride. Al2O3 – 10% Min. pH – 3-5.