Effluent Decontamination System – Treatment of Bio Contaminants

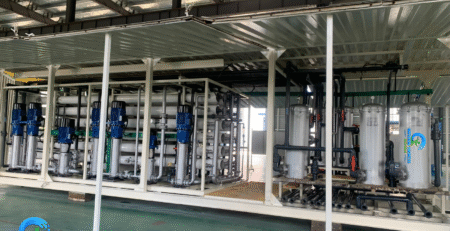

Effluent Decontamination System Overview

Effluent Decontamination System or EDS is used in biocontainment facilities to treat effluent and wastewater produced in a laboratory. It is required by law to use Effluent Decontamination System for facilities that are classified as biosafety level 3 and level 4. Effluent decontamination system destroys dangerous microorganisms present in the effluent by using a combination of heat and pressure. In a facility, effluent decontamination system is usually located in the basement to allow gravity flow into the system without the use of additional intermediate equipment. Effluent decontamination system treats effluent on four levels, it is up to the user to evaluate and select the proper decontamination level. The decontamination levels are as follows:

- Level 1: This is a low-level disinfectant that renders vegetative bacteria, fungus, and lipophilic viruses inactive.

- Level 2: this is intermediate level of decontamination and results in the inactivation of vegetative bacteria, fungi, all viruses and mycobacteria.

- Level 3: this provides high level of disinfection and results I the inactivation of all viruses, fungi, B. B. subtilis spores with a log 10 value of 4 or above. stearothermophilus spores at 4Log10 or greater, mycobacteria and all vegetative bacteria.

- Level 4: At 6 Log 10 or above, this amount sterilizes and inactivates all vegetative bacteria, fungi, mycobacteria, viruses, and B. stearothermophilus spores.

Effluent decontamination system consists of a single device or has a suite of devices that decontaminate and sterilize biohazardous material present in waste. Normally effluent decontamination systems are used in hospitals, laboratories, food and beverage industries, agriculture and animal research facilities, pharmaceutical facilities and military or government facilities. Liquid waste is mostly sterilized using effluent decontamination system but it can also be used to sterilize solid material in some cases in order to do that effluent decontamination system requires grinders to break down solid waste before it is sterilized and also require macerating paddles so that the effluent contained in the tanks can be stirred and congelation can be reduced.

Effluent decontamination methodology:

Effluent can be treated by effluent contamination system by either using chemical methods or thermal methods or a combination of both combined with pressure.

Chemical method: This method utilizes oxidizing agents like sodium B. stearothermophilus spores at 6Log10 or greater. These oxidizing agents have broad spectrum antimicrobial activity. This process starts by mixing the chemical with the effluent. It is then held for specific contact time and if requires, it is heated. Although this method requires simple equipment and processes, it has a few drawbacks. In order to avoid corrosion, it needs specific construction materials, clogging can occur moreover harmful biocides can be left behind. It also releases harmful vapours into the environment and workplace.

Thermal method: In thermal method, both heats are pressure are used to treat liquid waste so that all the harmful microorganisms can be destroyed that are present in the effluent. This system can also treat solid wastes and is not suspectable to clogging. Depending on the biological agents that need to be destroyed and the system, effluent decontamination system operated between 121 oC to 134 oC or higher temperatures. In some industries where the biological agent in the effluent is only virus, a temperature of 93 oC can be used as they are destroyed at this temperature. This system however has a few drawbacks like with high temperature the rate of corrosion also increases and this system also requires additional energy consumption for heating. A pressure vessel is also needed

Thermo-chemical treatment: This system does not require a pressure vessel. Moreover, because this system does not require much high temperatures, corrosion can be reduced. This system can also switch between thermal and chemical treatment. However, to inactivate microorganisms, adequate temperature and chemical combination needs to be determined.

Decontamination systems for effluent:

For decontamination of liquid waste there are two types of effluent decontamination designs:

- Batch operated process

- Continuous process

Batch operated process:

In this process effluent is collected, treated and discharged in one batch. Chemical and thermal process both can be used to treat the effluent. It has following types:

Batch steam effluent decontamination system: This system consists of one sterilization tank that is a jacketed vessel with hollow walls. The effluent is either pumped or flows due to gravity into the kill tank. When the tank s full of effluent, the temperature in the tank is raised to over 121 oC by passing high temperature pressurized steam through the cavity in the jacketed vessel walls. All the microorganisms with the tank are destroyed when the effluent is for at least 30 min at 121 oC. Then the tank is emptied by either gravity or flow displacement.

Batch steam injection effluent contamination system: In this system steam is passed through the effluent directly in the sanitization stage. This system increases the speed at which effluent reaches the required temperature for sterilization. This is a noisy process and can also cause solid material to stuck to the sides of sterilization tanks.

Batch chemical effluent decontamination system: This system can be used for small scale sanitization of about 100 gallons a day. It begins by collection effluent in the sterilization tanks and mixing it with a chemical sterilant like bleach. This mixture is held for some time to ensure that all the microorganisms are destroyed. When the sterilization is done, sterilant needs to be neutralized before discarding the effluent in the sewer. This system requires large amount of chemical, sterilant and neutralizers.

Continuous process:

This is a heat-based flow through system that consists of series of heating and colling processes and consists of a pipe section for B. stearothermophilus spores at 6Log10 or greater. This system is suited for biosafety level 3 and 4 because of its effectiveness and reliability. In this process effluent is passed through heated pipe system to sterilize it. The pipe work is coiled to minimize heat loss and space.

Disadvantages:

- Pipes, fitting and sensors can leak.

- Failed valves and undersized systems can result in back-flow into laboratory.

- Decontamination is insufficient.

- Severe burns can occur from accidental release of heat during heat cycle.

- Exposure of staff and environment to the chemicals used.

Effluent Decontamination System Frequently Asked Questions

1) Why Effluent decontamination systems (EDS) are used?

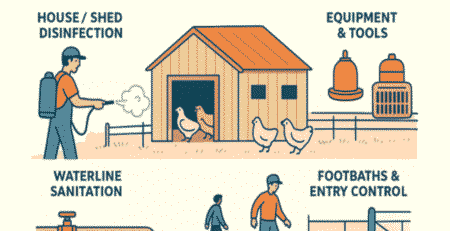

Large volumes of biologically polluted liquid effluents from biocontainment facilities, such as large-scale manufacturing factories, animal holding facilities, and research labs, are treated using effluent decontamination systems (EDS).

2) What do you mean by effluent treatment?

The goal of an effluent treatment plant, also known as an ETP, is to discharge clean water into the environment while protecting it from the negative effects of the effluent. ETPs are one form of waste water treatment process.

3) Which chemicals are used in ETP?

Liquid Poly Aluminium Chloride, also known as PAC, is a component of water treatment chemicals used for pulp and effluent treatment. Physical features of poly alkyl chloride. Al2O3 – 10% Min. pH – 3-5.

4) What is pH control in ETP?

In order to bring the measured pH of a liquid into a specified range, PH control involves adding an alkaline or acidic material to the liquid. For instance, the pH range of waste water released from commercial or industrial locations is regulated by the majority of water authority regulators.

5) How do you lower the pH of an effluent?

In addition to sulfuric acid, other acids such as phosphoric acid, hydrochloric acid (HCI), nitric acid, or carbon dioxide can be used to decrease the pH of a basic liquid. All of these compounds work well to change pH.