Detection and Control of BTEX in Gas Exploration Using IoT and Artificial Intelligence: A Detailed Overview

Detection and Control of BTEX in Gas Exploration Using IoT and Artificial Intelligence: A Detailed Overview

1. Introduction to BTEX and Its Relevance in Gas Exploration

BTEX—Benzene, Toluene, Ethylbenzene, and Xylene—are volatile organic compounds (VOCs) commonly found in petroleum and natural gas operations. These compounds are hazardous to human health and the environment:

- Benzene is a known carcinogen.

- Toluene, Ethylbenzene, and Xylene affect the nervous system and can cause long-term environmental damage.

During gas exploration, BTEX compounds may be released due to leaks, equipment malfunctions, or evaporation from storage tanks and pipelines. Because many gas exploration sites are remote and often unmanned, early detection and control of BTEX emissions are challenging yet essential.

2. Challenges in BTEX Monitoring During Gas Exploration

- Remote and Unmanned Sites: Difficult access limits manual inspections.

- Low Concentration Levels: BTEX emissions can be at very low concentrations (ppb to ppm range) but still hazardous.

- Environmental Factors: Temperature, humidity, wind, and pressure affect gas dispersion.

- Multiple Emission Sources: Storage tanks, valves, pipelines, and processing equipment all potentially emit BTEX.

- Regulatory Compliance: Strict environmental regulations require continuous monitoring and reporting.

3. IoT Technology for BTEX Detection

3.1 Sensor Technologies

The core enabler for BTEX detection is a network of IoT-enabled sensors that provide continuous, real-time data:

- Photoionization Detectors (PID):

- Sensitive to a wide spectrum of VOCs including BTEX.

- Detect concentrations as low as parts-per-billion (ppb).

- Provide fast response times.

- Miniaturized Gas Chromatography (GC) Sensors:

- Provide detailed chemical analysis distinguishing between Benzene, Toluene, Ethylbenzene, and Xylene.

- More accurate but higher cost and power consumption.

- Metal Oxide Semiconductor (MOS) Sensors and Electrochemical Sensors:

- Cost-effective options for ambient air BTEX monitoring.

- Useful for broad screening but may require frequent calibration.

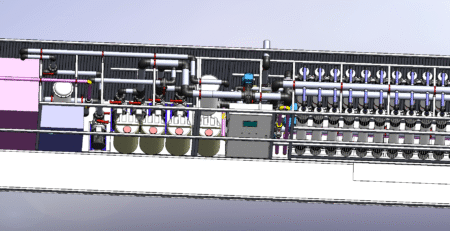

3.2 Deployment Strategy

- Strategic Sensor Placement:

- Near high-risk points: valves, storage tanks, flanges, compressors.

- Perimeter monitoring for ambient air quality.

- At varying heights to account for gas density and dispersion patterns.

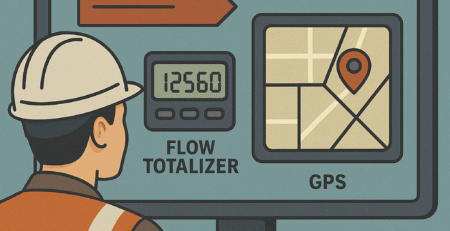

- Networking and Data Transmission:

- Wireless connectivity options include LoRaWAN, NB-IoT, 4G/5G cellular, satellite.

- Redundant communication paths ensure continuous data flow.

- Power Solutions:

- Solar-powered or battery-operated sensors for remote deployment.

4. Artificial Intelligence in BTEX Detection and Control

AI technologies transform raw IoT sensor data into actionable intelligence.

4.1 Data Preprocessing and Fusion

- Sensor data is cleaned, calibrated, and combined using sensor fusion techniques to improve reliability and reduce noise or false positives.

- Environmental data (wind, humidity, temperature) is integrated to contextualize BTEX readings.

4.2 Anomaly and Pattern Detection

- Machine Learning Models (e.g., Random Forests, Neural Networks) learn typical BTEX emission patterns under normal operations.

- Sudden deviations or spikes trigger anomaly detection alerts.

- Models differentiate between transient fluctuations and genuine emission events.

4.3 Source Localization

- Using multiple spatially distributed sensors and environmental data, AI algorithms triangulate the most probable source of BTEX leaks.

- This reduces time to locate and address issues.

4.4 Predictive Analytics

- AI predicts possible future BTEX emission scenarios based on historical data and ongoing operational parameters.

- This enables preventive maintenance and operational adjustments to minimize emissions.

4.5 Automated Control Systems

- AI integrates with plant control systems to automatically trigger mitigation actions such as:

- Activating vapor recovery units (VRUs) to capture VOCs.

- Adjusting process parameters to reduce emissions.

- Initiating emergency shutdowns or isolations if leak severity increases.

- Remote operators receive real-time alerts and detailed diagnostics via dashboards and mobile apps.

🧰 5. Example System Architecture

mermaid

CopyEdit

6. Case Study Example: BTEX Monitoring at an Unmanned Gas Well

- Setup: Distributed PID and GC sensors installed at critical locations.

- Operation: Sensors transmit data every few minutes to a cloud AI platform.

- Detection: AI identifies rising Benzene concentration beyond permissible limits.

- Localization: Combining sensor data with wind direction, AI pinpoints a leaking valve as the source.

- Control: System activates a VRU and remotely commands valve shutdown.

- Outcome: Emission quickly contained, preventing regulatory violations and health risks.

7. Benefits of Using IoT and AI for BTEX Management

| Benefit | Explanation |

| Continuous Real-Time Monitoring | Immediate detection of BTEX emissions without manual intervention |

| Improved Detection Accuracy | AI reduces false alarms through data fusion and contextual analysis |

| Rapid Response and Mitigation | Automated controls minimize exposure and environmental impact |

| Cost Efficiency | Reduced need for frequent manual inspections and emergency repairs |

| Enhanced Safety | Protects workers and communities from hazardous exposures |

| Regulatory Compliance | Automated reporting simplifies adherence to environmental laws |

| Scalable and Flexible Systems | Easily expandable sensor networks adaptable to changing site needs |

8. Challenges and Considerations

- Sensor Calibration and Maintenance: Regular calibration is essential for accurate BTEX detection.

- Power Management: Ensuring reliable power in remote locations.

- Data Security: Protecting sensitive operational data from cyber threats.

- Integration Complexity: Seamless integration between IoT devices, AI platforms, and control systems requires robust engineering.

9. Future Trends

- Edge AI Processing: Deploying AI models directly on edge devices for faster decision-making and reduced communication load.

- Advanced Sensor Materials: Developing more selective, sensitive, and durable sensors for BTEX detection.

- Digital Twins: Using AI-driven virtual replicas of gas exploration sites for scenario testing and predictive maintenance.

- Blockchain for Data Integrity: Ensuring tamper-proof emission reporting.

10. Conclusion

The combination of IoT sensors and Artificial Intelligence offers a comprehensive, intelligent approach to detecting and controlling BTEX emissions in gas exploration activities. This integration enables:

- Enhanced environmental and worker safety

- Regulatory compliance with automated reporting

- Proactive operational control to reduce emissions

- Cost-effective and scalable monitoring solutions for even remote unmanned gas wells

Adopting these technologies is critical for sustainable and responsible gas exploration operations.