Compressible Media Filter (CMF)

A compressible Media Filter (CMF) is a type of filter that is widely used to filter water for drinking, swimming pool water filtration, aquaculture, stormwater management, and, most crucially, gas and oil operations. This platform became well-known for its design and tools, which included a sand bed, crushed granite, anthracite, shredded tyres, foam, and a variety of other filtration materials to assist users in any field of water filtration. This media filter is unique in that it incorporates a significant amount of geo-textile fabric.

This platform’s most notable feature is media compression, which modifies the filter’s pore size in response to process changes. This high-rate, modular, and compact filter is suitable for a variety of wastewater and water filtration applications. It is considered the best-suited media filter with synthetic fibre spheres because of its high-rated solid removal effectiveness. To handle loading rates of 30-40 GPM/ft2, 20% of the floor space is required. This filtration system can handle contaminated stormwater, clean water, river water, and provide tertiary treatment, among other things.

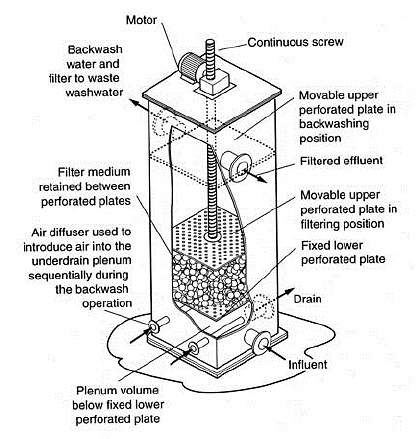

How it works:

The basic idea of this system is simple: it uses a ‘header’ to deliver water to the top of the container, which also helps to evenly distribute the water. Fine sand is on the top of the filter media, which becomes coarser sand gradually and gravel is on the bottom, which is usually in larger sizes. The top sand is used to physically remove particles from water, while other layers support a more suitable layer above it to ensure systematic drainage. After the particles are caught in the medium, the pressure across the sand bed increases, and the backwash facility removes solids trapped in the sand. Because the flow is in the opposite direction during backwash, it is particularly effective. The layers re-differentiate due to density before regular filtration may resume.

Features:

The Compressible Media Filter (CMF) is an advantageous and feature-rich filtration method that benefits users in a variety of ways. The following are only a few of the hundreds of features available:

- Ten times loading rate and works better than any other conventional filters and it uses compressible media to downflow gravity to achieve maximum results

- The finer layer of sand is an excellent compressible media that is lighter than sand

- The vital thing to notice is that there is no need for mechanical compression or moving parts for changing purposes of the process

- The life of media is between seven to ten years, which is also very useful and works efficiently throughout its useful life

- Water loss is roughly 3%, which is a significant feature that was even mentioned by the creators and description authors.

- The usage is simple, and users can have complete control over their filter media and get results according to their needs

- Backwash facility extends media life, and consumption of energy is also very low, which helps to achieve maximum recovery

- The backwash sequence reduces the footprint and maintenance compared to sand filters

- Small filtration facilities can employ this technique since it is less expensive to replace than other media filters and materials, and it does not require any mechanical compression mechanisms.

Benefits:

Users want to know about the advantages of utilizing any system before using it, thus the advantages of this media filter are also vital to discuss. Some of the benefits are as follows:

- The low waste volume is a very important benefit to enjoy because users can get rid of extra work of waste management

- Energy consumption is also very low to save extra electricity and other filtration expenses

- This method produces excellent output quality.

- The compact footprint benefit helps users in a variety of filtration processes

- The overall cost of a Compressible Media Filter (CMF) is much low than any other media filter

- The most important benefit is its easy maintenance which helps workers to save time and energy

Application of Compressible Media Filter (CMF):

Unlike other filtration plants and media, it has unique and effective uses in several fields of water filtration. Some of them are described below:

Drinking water:

Among all the filters, the sand filter is the most important and commonly used. There are two types of sand filters. Both a slow sand and a rapid sand filter are available. These filters are used by users based on their needs. There is also silica sand in this media filter. Other filter media elements used in Compressible Media Filter (CMF) to purify drinking water for domestic use include ilmenite, activated carbon, manganese sand, recycled glass, anthracite coal, and many others.

Stormwater:

These compressed media filters are used to remove contaminants, sediments, phosphorus, and other impurities that cause hard water in a variety of applications. In rivers, streams, and lakes, sand is the most important and effective media filter element. Other things that can assist protect water quality include wood chips and biological filters.

Wastewater:

These media filters are also used to filter wastewater from companies, cities, and households because this water is extremely toxic to humans and aquatic organisms. Septic tank effluents are cleaned from water with the help of these media filters, which can handle a lot of water pressure and produce very consistent results. Peat, natural stone fibre, and sand are common ingredients.

Oil and Gas industry:

These filters are used in numerous departments and for diverse purposes in the oil and gas sector. In businesses, sand solids are used to remove fine sediments and effluent from oil refineries. Media filters can also be used to purify produced water and wastewater. The principal materials utilized in multi-media filters are gravel, garnet, and sand. Nutshell filters, which are also good alternatives to sand filters, are used in the tertiary oil removal process for wastewater and generated water treatment. In the biological treatment of wastewater and suspended solids, media filters are particularly effective.

Compressible Media Filter Frequently Asked Questions

1) What should be the required characteristics of common filter media?

Strength, stability, resilience to wear and stretch, absorption, permeability, and cost are the characteristics of a filter medium that matter most. Because they are inexpensive to repair and have a short lifespan, disposable oil and air filters make up for it.

2) How many layers of filter media are there?

What’s the process of a multimedia filter? Anthracite coal, sand, and garnet are the three media layers that generally make up a multi-media filter. At the bottom is a supporting (non-filtering) layer of gravel. Because of the variations in size and density, these are the preferred media.

3) What types of media may be used for filtration?

Types of Filter Media

- Cellulose Filter Media. Cellulose is a widely used media type for industrial applications because it is fairly cheap to produce.

- Glass Media and Water Removal Elements.

- Wire Mesh

- Coalesce

- Resin

4) What is filtration in oil and gas?

Filtration is the process of removing impurities from a liquid to make it safe for eating by humans in any form. Mechanical, cartridge, magnetic, sedimentation, centrifugal, and high-efficiency oil filters are the various types.

5) What is the importance of filter media?

To preserve the purity of the water in streams, rivers, and lakes, media filters are utilized. They may be successful in eliminating phosphorus and suspended particles from runoff. The most typical type of filter material is sand. Other filters, commonly referred to as “organic filters,” can make use of leaf mould or wood chips.