Carbon Capture Storage Recovery Transportation Turnkey Projects CCS

Introduction

The 21st century has brought about a time of unimaginable technological progress and global connectivity, but it has also brought about a number of environmental problems, the most important of which is the rise in carbon emissions. As the world struggles to deal with the effects of climate change, it has become very important to understand and manage carbon well. This goes into the complicated web of problems that are caused by carbon and stresses how important it is to manage carbon to lessen the bad effects on our planet.

A. Overview of Carbon-related Challenges

While the industrial revolution sped up progress, it also caused a huge rise in carbon dioxide (CO2) emissions because people burned more fossil fuels for their daily activities. Putting carbon into the air over and over again has caused greenhouse gases to build up quickly, which has caused climate change and global warming. There are many different effects that happen, such as rising sea levels, extreme weather, changes in ecosystems, and threats to biodiversity.

Carbon problems affect more than just the environment; they also affect people’s health and the stability of the economy. When fossil fuels are burned, they release CO2 and other pollutants that hurt the air quality and make breathing problems worse. Also, depending on industries that use a lot of carbon poses a threat to stability because changes in energy prices and lack of resources can mess up markets and economies.

Because these problems are linked, the picture is complicated. To stop carbon emissions where they start and lessen their effects on many fronts, we need a complete plan.

B. Importance of Carbon Management

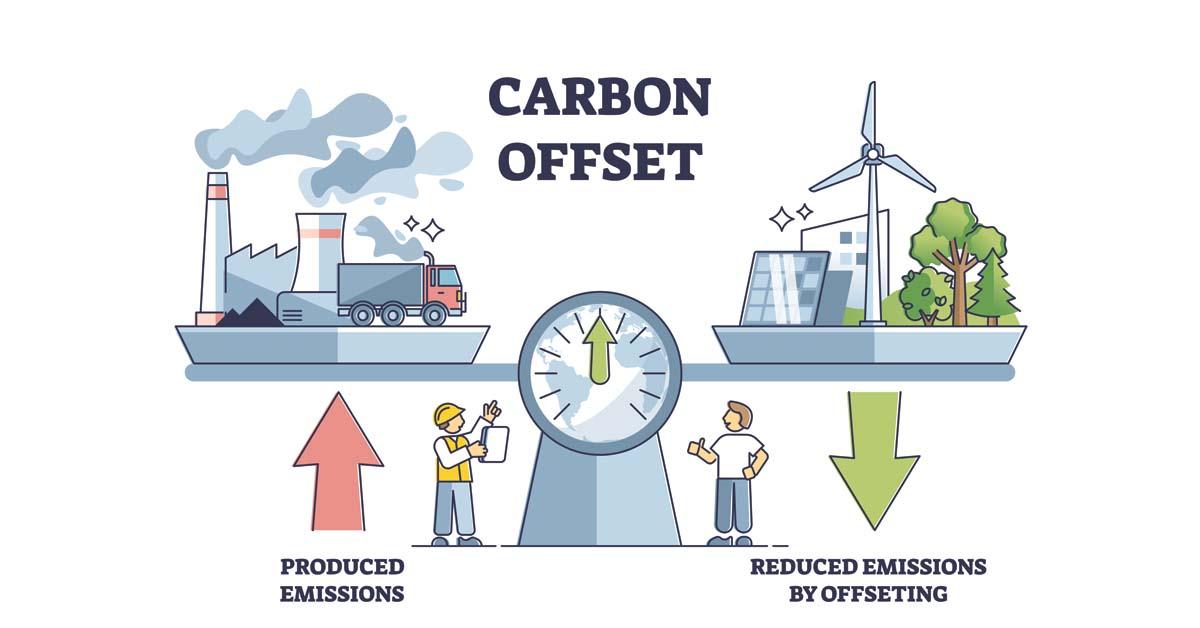

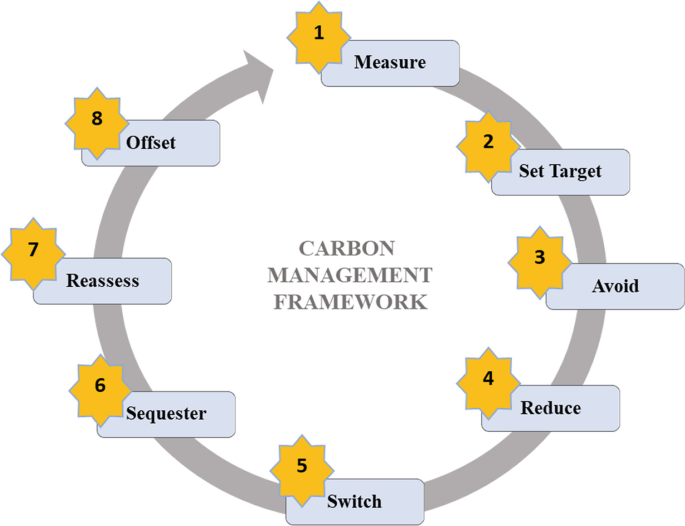

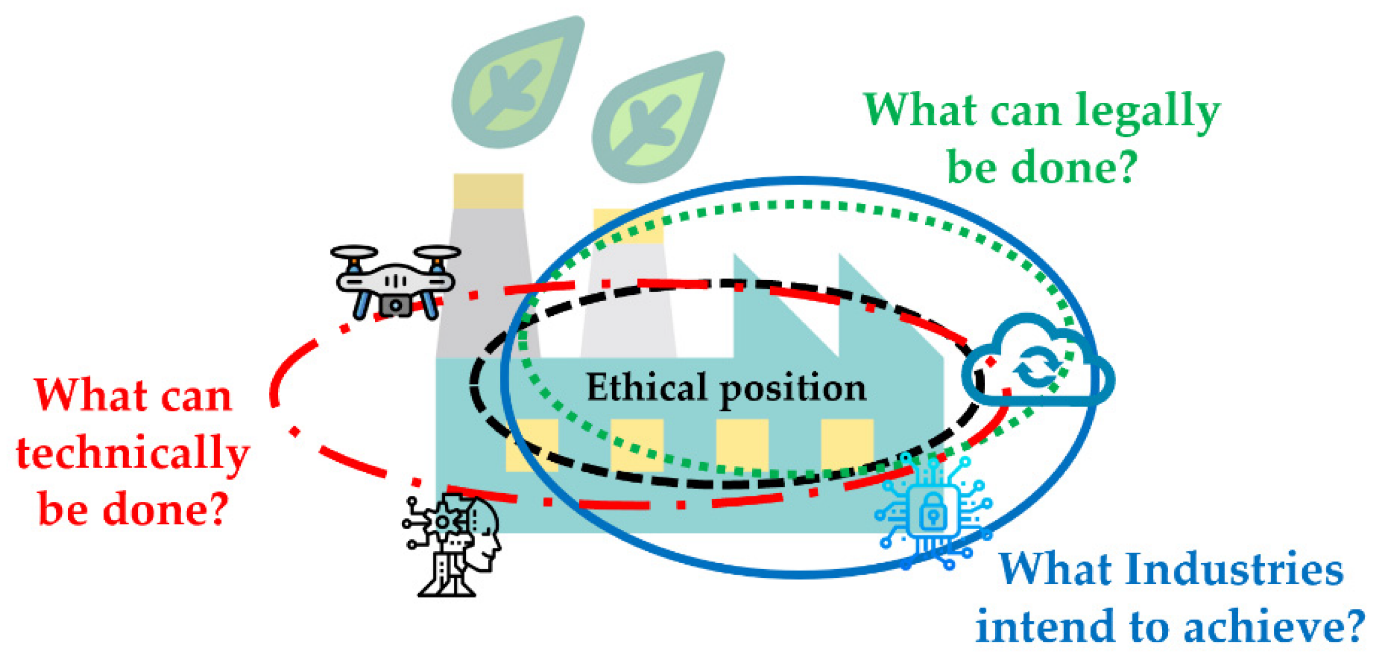

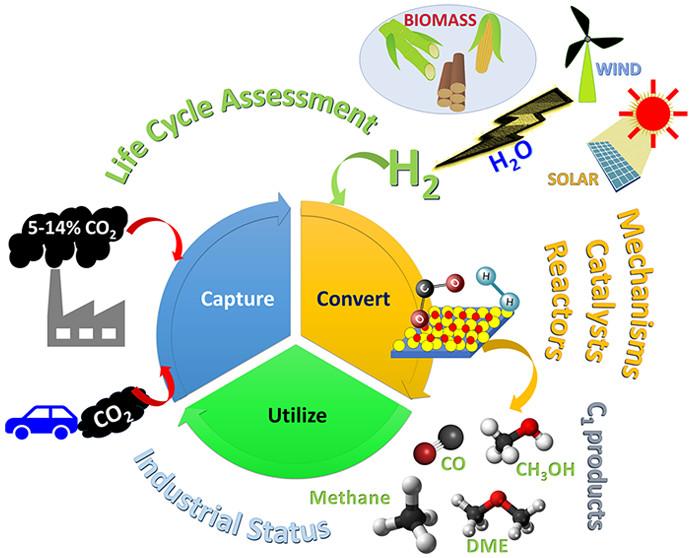

Carbon management basically means handling carbon emissions in a way that protects the environment and people’s health as much as possible. It includes a wide range of actions, technologies, and rules that are meant to lower, capture, store, and use carbon in a way that keeps the balance over time.

- Climate change mitigation is one of the main goals of carbon management. We can help keep the global temperature rise from getting too high by taking steps to lower carbon emissions. Using less energy, switching to renewable energy sources, and adopting technologies that don’t produce carbon are all important parts of this plan to reduce carbon emissions.

- Natural ecosystems must be protected in order for carbon management to work well. For instance, forests take in and store a lot of carbon dioxide, which is called a carbon sink. It is very important to protect these ecosystems so that the delicate balance that supports biodiversity and the planet’s health stays in place.

- Managing carbon has a positive effect on public health as well. Cutting down on fossil fuel use and air pollution leads to better air quality, which lowers the risk of respiratory diseases and improves health in general. Cleaner energy sources and sustainable transportation are very important in this case.

- Taking on carbon management makes room for new ideas and economic growth. As carbon capture technologies, renewable energy solutions, and environmentally friendly practises are developed and used more widely, they open up new business opportunities. There are incentives for governments, businesses, and entrepreneurs to invest in green technologies that are good for the environment and help the economy grow.

- For carbon management to work, people from all over the world need to work together. Countries need to set and reach goals for lowering carbon emissions, share technologies, and deal with the problems that climate change brings about as a whole. International partnerships and agreements are very important for bringing people together to fight problems related to carbon.

Waterman Engineers Australia company

Waterman Engineers Australia is a top company that is at the forefront of offering full carbon services. The company specializes in coming up with new engineering solutions and is committed to using a variety of fields to solve carbon-related problems. Carbon capture, storage, utilization, and purification are just some of the areas of carbon management that they are experts in.

Waterman Engineers Australia uses cutting-edge technologies to create custom solutions for clients in a wide range of industries. They are dedicated to sustainability and environmental care. From planning to carrying out, the recovery offers carbon services that include recovering carbon from industrial processes, creating carbon conversion technologies, and setting up CO2 recovery plants.

Waterman Engineers Australia is ready to handle the tricky world of carbon management thanks to its team of skilled engineers and environmental experts. Not only do their services help protect the environment, but they also help the economy by promoting carbon-neutral practices and following global standards.

As people around the world work to lessen the effects of climate change, Waterman Engineers Australia stands out as a key player. They provide important services that are in line with the global commitment to responsible and sustainable carbon management.

II. Carbon Capture

A. Definition and Concept

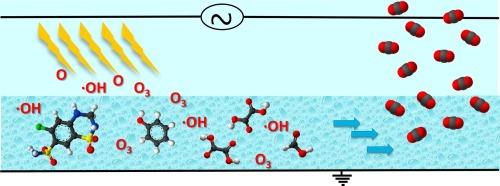

Carbon capture is an important part of efforts to stop climate change because it lowers the amount of carbon dioxide (CO2) that is released into the air, mostly from factories and power plants. The main idea is to capture CO2 emissions at their source, before they are released into the air. This stops them from adding to the greenhouse effect and climate change.

CO2 can be separated from the flue gas that is made when fossil fuels are burned. This is what carbon capture is all about. CO2 is not released into the air; instead, it is captured, moved, stored, or used. This process not only helps reduce the damage that carbon emissions due to the environment, but it also makes it easier to create cleaner energy sources and more environmentally friendly ways of doing business.

B. Technologies for Carbon Capture

-

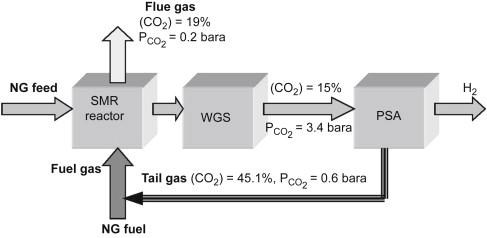

Pre-combustion Capture

Pre-combustion capture is the process of capturing carbon before fossil fuels are burned. Carbon-containing fuels, like coal or natural gas, are partially oxidized or reformed in this method to make a gas mixture mostly made up of hydrogen (H2) and carbon dioxide (CO2) (CO2).

Steam Methane Reforming (SMR)

CH4 + H2O → CO + 3H2

Water Gas Shift (WGS)

CO + H2O → CO2 + H2

Techniques for Separation: Next, the CO2 is taken out of the stream of hydrogen-rich gas using techniques such as pressure swing adsorption (PSA) or chemical absorption.

-

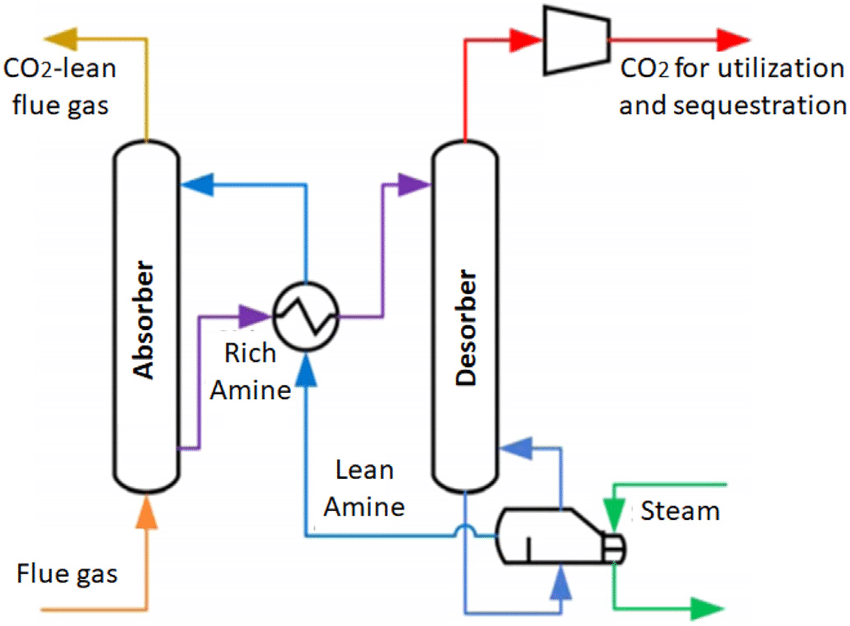

Post-combustion Capture

Post-combustion capture is the process of removing carbon from the air after fossil fuels have been burned. This is especially true for power plants and factories that are already up and running. The flue gas, which has CO2 and other pollutants in it, is cleaned up to separate the CO2.

Absorption using Amines.

CO2 + 2RNH2 → R2N-CO2H + RNH3

Desorption (Regeneration) of Amines

R2N-CO2H + RNH3 → CO2 + 2RNH2

The CO2 is separated using absorption methods, which usually involve amines. It is then desorbed so that it can be used or stored.

-

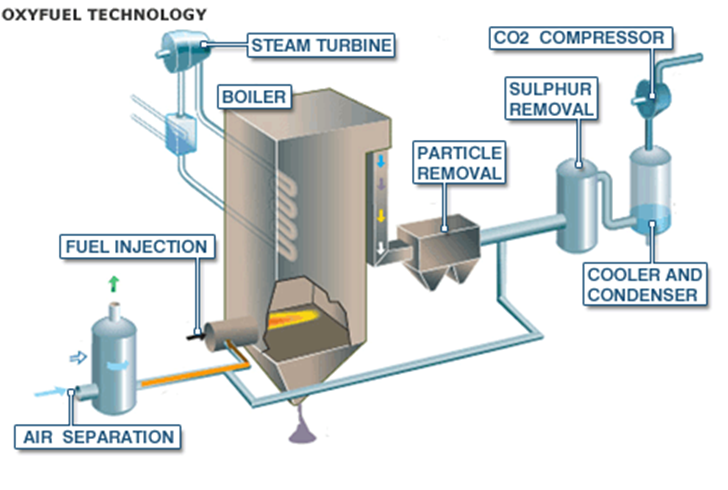

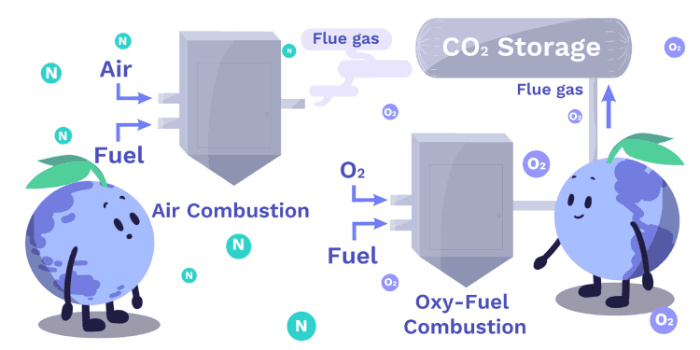

Oxy-fuel Combustion

Oxy-fuel combustion is the process of burning fossil fuels in a room filled with pure oxygen instead of air. This makes flue gas mostly made up of CO2 and water vapour, which makes the process of capturing it easier.

Combustion with Oxygen

CH4 + 2O2 → CO2 + 2H2O

Condensation separates the CO2 from the water vapour, making a stream of very pure CO2.

C. Current Developments in Carbon Capture

The field of carbon capture is always changing. New technologies are being researched and developed all the time to make them more efficient, cheaper, and easier to use on a larger scale. A number of important changes are occurring in the field of carbon capture, including:

Advancements in Materials for Absorption

The main goal of research is to make absorbent materials for post-combustion capture that work better and cost less. This includes looking into new solvents and solid adsorbents to make the processes of absorption and desorption better.

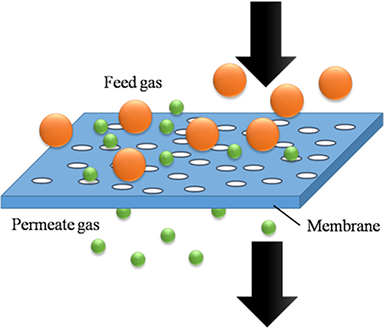

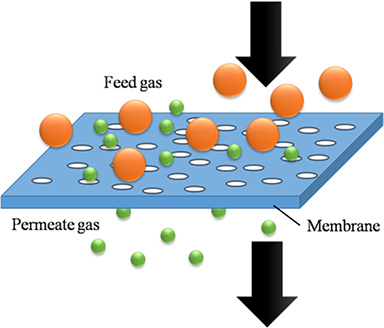

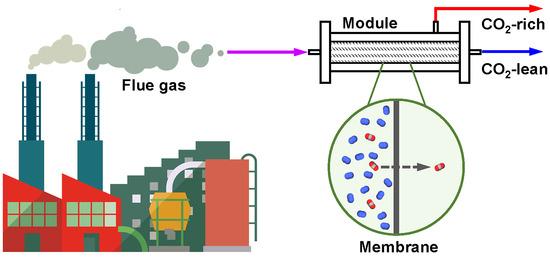

Membrane-based Technologies

Carbon capture technologies based on membranes are getting more attention because they could be useful before and after combustion. These membranes can selectively separate CO2 from other gases, which is a good improvement over the old ways of separating gases.

Integration with Renewable Energy

To make things work better, carbon capture technologies are being combined with renewable energy sources. For example, combining biomass energy generation with carbon capture can lead to a process with net-negative carbon emissions, which makes energy production more environmentally friendly overall.

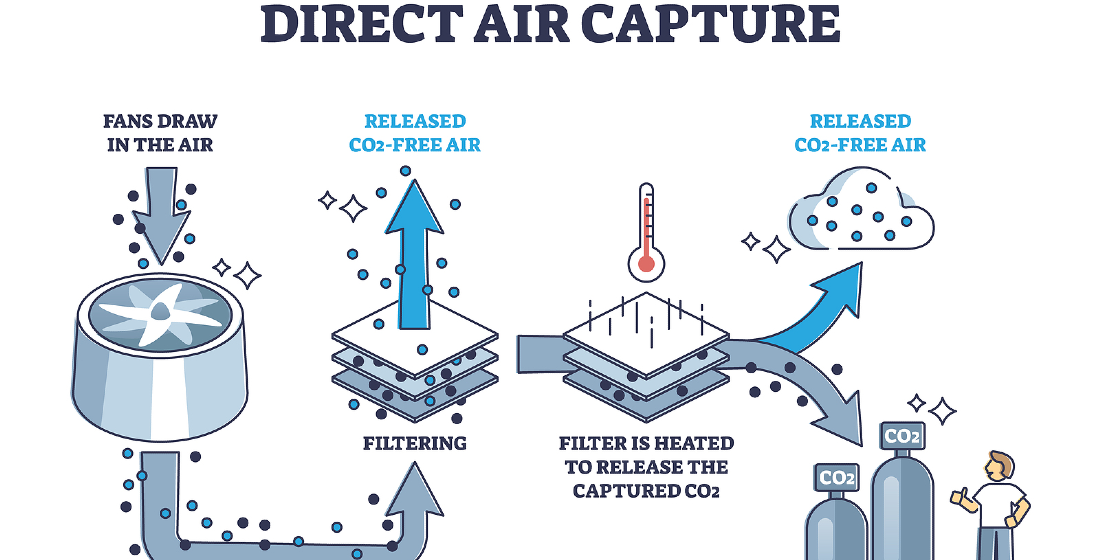

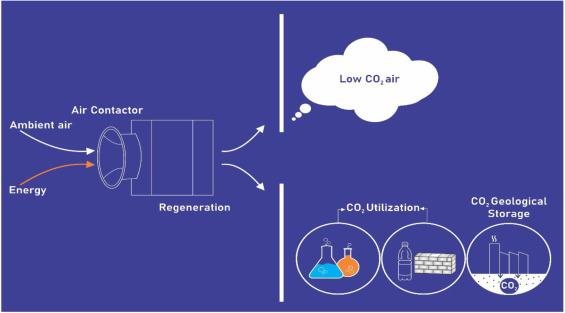

Direct Air Capture (DAC)

More and more people are using DAC technologies, which are made to take CO2 directly from the air. Chemical processes or materials that selectively remove CO2 from the air are used in these methods. This is a way to deal with emissions from sources that are spread out.

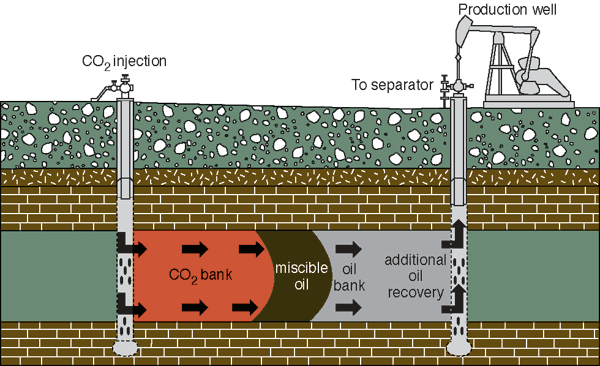

Enhanced Oil Recovery (EOR) with Carbon Capture

Some projects are looking into how to combine carbon capture with techniques for enhanced oil recovery. In these methods, CO2 is captured and then injected into oil reservoirs to help get more oil out of them while the carbon is stored underground.

Policy and Financial Incentives

More and more governments and international groups are realizing how important carbon capture is to meeting climate goals. Policies and financial incentives are being put in place to encourage the use of carbon capture technologies. This creates an environment that is good for research and development.

III. Carbon Storage

A. Introduction to Carbon Storage

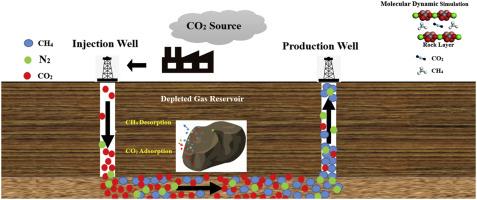

As the world struggles to deal with the growing problems caused by climate change, carbon storage has become an important way to lessen the bad effects of too much carbon dioxide (CO2) emissions. Carbon storage, which is also called carbon sequestration, is the process of capturing and safely storing CO2 emissions from power plants and factories so that they don’t get released into the air. This all-around approach is very important for lowering the amount of greenhouse gases in the air and stopping global warming.

The idea behind carbon storage is to keep CO2 safely stored for a long time in different geological and oceanic reservoirs, so it doesn’t add to the greenhouse effect. Even though advances in technology have made carbon storage more possible, it needs to be used with a deep understanding of the different ways it can be stored, how they affect the environment, and the problems that come with each.

B. Geological Storage

Geological storage is a popular way to store carbon, using formations deep underground to safely hold CO2. Geological storage has been looked into in a number of different ways, and each has its own pros and cons.

Depleted Oil and Gas Fields

Carbon storage could be done in oil and gas fields that have been used up. These fields often have the right geological features to safely store CO2 after they have been used to extract hydrocarbons.

CO2 Injection into Depleted Reservoirs

CO2 + H2O → H2CO3 (Carbonic Acid)

The injected CO2 can push out any remaining hydrocarbons, which can help get more oil or gas out of the ground while also storing carbon.

Depleted fields have been shown to be geologically stable, and they often already have infrastructure that can be used for monitoring and injecting fluids.

Deep Saline Aquifers

Deep saline aquifers, which are found deep underground, can store a lot of CO2. These formations are made up of porous rock that is full of salty water and can be used as safe storage areas.

Dissolution of CO2 in Saline Water

CO2 + H2O → H2CO3

When CO2 is pumped into saline aquifers, it mixes with the salty water and turns into carbonic acid. The CO2 that has been dissolved is then trapped inside the salty rock of the aquifer.

Deep saline aquifers can store a lot of water, and adding CO2 to them is thought to be a safe and reliable way to do it.

Coal Seams

Coal seams, which are usually used to get fossil fuels out of the ground, can also be used to store CO2. It is possible to inject CO2 into coal seams that can’t be mined. This helps recover coalbed methane and stores carbon at the same time.

Adsorption of CO2 onto Coal

CO2 + Coal → Adsorbed CO2

CO2 sticks to the coal surface, which lowers the pressure in the coal seam and makes it easier for methane to escape (coalbed methane recovery). Utilizing coal seams for carbon storage has two benefits: it improves gas recovery and stops CO2 from being released.

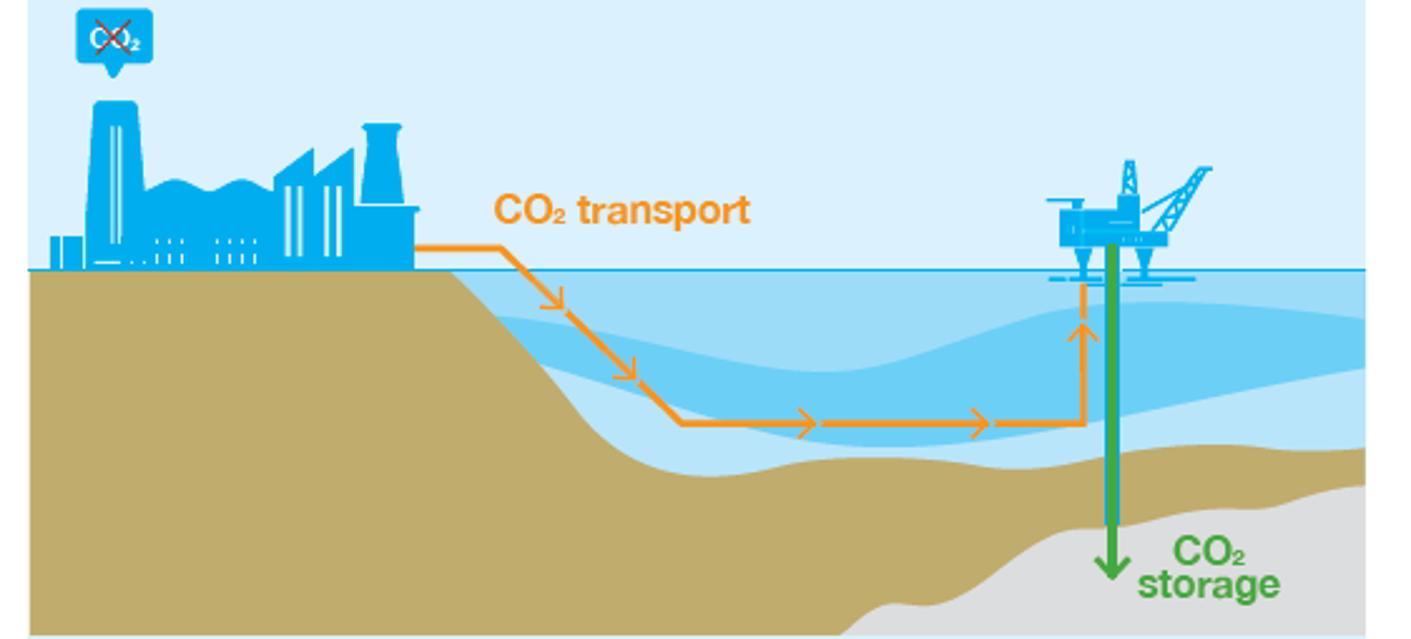

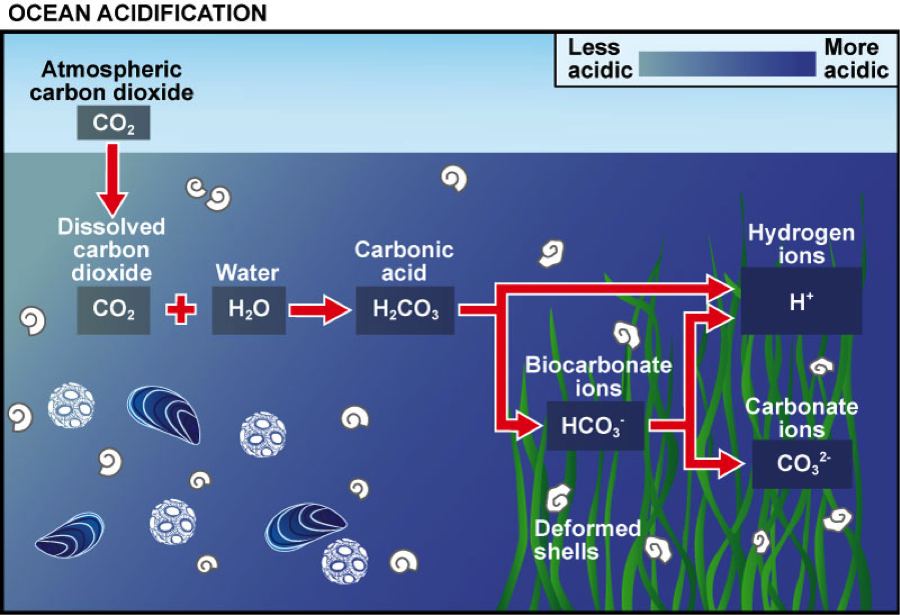

C. Ocean Storage

Putting CO2 directly into the deep ocean is what ocean storage is all about. This idea has caused a lot of debate because of worries about the environment and unknown long-term effects. This method could provide a huge amount of storage space, but it comes with a number of problems and moral concerns.

It is possible to bring CO2 from land and inject it into the deep ocean, where it will dissolve and stay in solution.

Dissolution of CO2 in Seawater

CO2 + H2O → H2CO3

When CO2 is injected into seawater, it breaks down and turns into carbonic acid. This method depends on how well the ocean can take in CO2 and spread it out over time.

There are problems with storing CO2 in the ocean because it could harm marine ecosystems, CO2 could leak out because of unplanned events, and changing natural processes is morally questionable.

D. Current Challenges and Future Prospects

Carbon storage has a lot of potential as a way to fight climate change, but it’s not easy to make it widely used. It is important to understand these problems in order to come up with good solutions and get the most out of carbon storage methods.

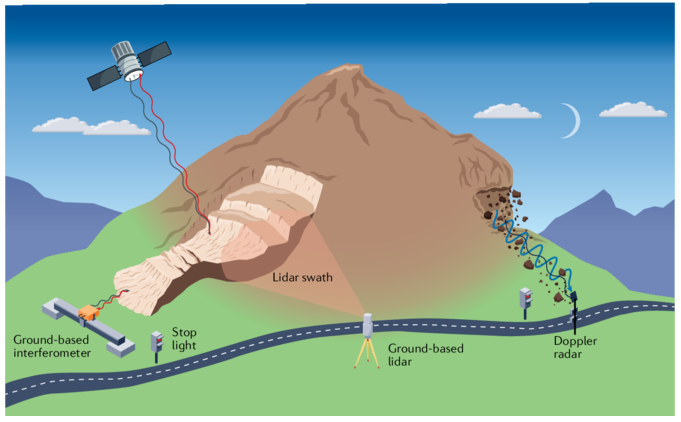

Monitoring and Verification

The safe containment of injected CO2 is the most important thing. Strong monitoring and verification methods are needed to find any possible leaks or unintended effects. Technologies like seismic monitoring, satellite imaging, and ground-based sensors are always getting better at making monitoring more accurate.

Storage Capacity and Site Selection

It’s not easy to find good storage areas that have enough space and are stable geologically. When choosing a site, it’s important to think about how close it is to emission sources, what the geology is like, and how it might affect the ecosystems nearby. Getting a full picture of the subsurface is important for getting the most storage space.

Economic Viability

The cost of technologies for capturing carbon, transporting it, injecting it, and keeping an eye on it all affects how economically viable carbon storage is. The goal of ongoing research is to lower these costs so that carbon storage is more competitive and financially viable, especially when compared to other ways to cut down on emissions.

Public Perception and Social Acceptance

How people feel about and accept carbon storage projects is very important to their success. Getting people to support carbon storage requires open communication and involvement from the community about its safety and benefits. It is very important to address concerns about safety and the environment.

Regulatory Frameworks and Legal Considerations

It is very important to set up clear legal and regulatory frameworks for carbon storage. International organizations and governments need to make broad rules about who is responsible, what their long-term responsibilities are, and how their actions might affect the environment. Harmonizing these rules around the world will make it easier for carbon storage projects to be built in different countries.

Ocean Storage Ethical Considerations

Even though ocean storage has a lot of potential, it raises ethical concerns about changing natural processes and the effects it might have on marine ecosystems. To find a balance between reducing climate change and protecting the environment, we need to think carefully about the moral issues and possible unintended effects of storing carbon in the ocean.

Future Prospects

Advancements in Storage Technologies

Advanced storage technologies that make carbon storage more efficient and safer are the focus of ongoing research. It is expected that advances in materials science, nanotechnology, and monitoring methods will help make storage methods better.

Integration with Carbon Removal Technologies

Using technologies that both store and remove carbon, like direct air capture and bioenergy with carbon capture and storage (BECCS), together is the best way to get rid of all emissions. Researchers are still looking into how different ways of removing and storing carbon can work together.

International Collaboration and Standardization

To take a global approach to stopping climate change, countries must work together and standardize the protocols they use to store carbon. Working together can make it easier to share information, best practices, and technologies, which can help carbon storage projects around the world be successful.

Policy Incentives and Carbon Markets

Carbon storage is becoming more and more important to governments and international groups working to protect the environment. Carbon pricing, policy incentives, and the growth of carbon markets can make it easier for people to invest in carbon storage projects, which can lead to new ideas and widespread use.

Waterman Engineers Australia’s services

When it comes to cutting-edge engineering services for carbon storage, Waterman Engineers Australia is the leader. The company uses its knowledge of environmentally friendly solutions to create complete plans for collecting, transporting, and safely storing carbon dioxide (CO2). As a company that cares about the environment, Waterman Engineers Australia provides custom services in the areas of geological storage and other cutting edge carbon storage technologies.

Their services include figuring out which geological formations are best for storing carbon. These could be depleted oil and gas fields, deep saline aquifers, or coal seams. The company is committed to keeping captured CO2 safe and secure for a long time, which helps the world’s efforts to slow down climate change.

The skilled workers at Waterman Engineers Australia can also use advanced monitoring and verification methods to make sure that carbon storage projects are honest. The company is very important to the success of carbon storage projects because it helps with problems like choosing the right site, making sure there is enough space, and following the rules.

With an emphasis on sustainability, innovation, and caring for the environment, Waterman Engineers Australia has become a major force in advancing carbon storage technologies, which will help make the future more sustainable and low carbon.

IV. Carbon Utilization

A. Introduction to Carbon Utilization

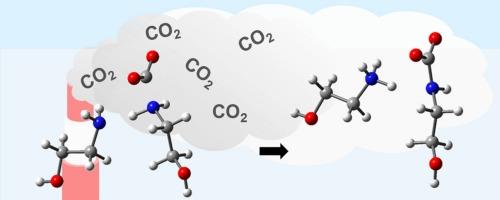

As people look for long-lasting ways to stop climate change, carbon utilization has become a major idea. It changes the focus from just lowering carbon emissions to actively reusing and harnessing carbon dioxide (CO2) for many useful purposes. Carbon utilization is the process of turning CO2 into useful products, which reduces its damage to the environment and increases economic value. This way of doing things fits with the circular economy, which stresses making good use of resources and lowering waste.

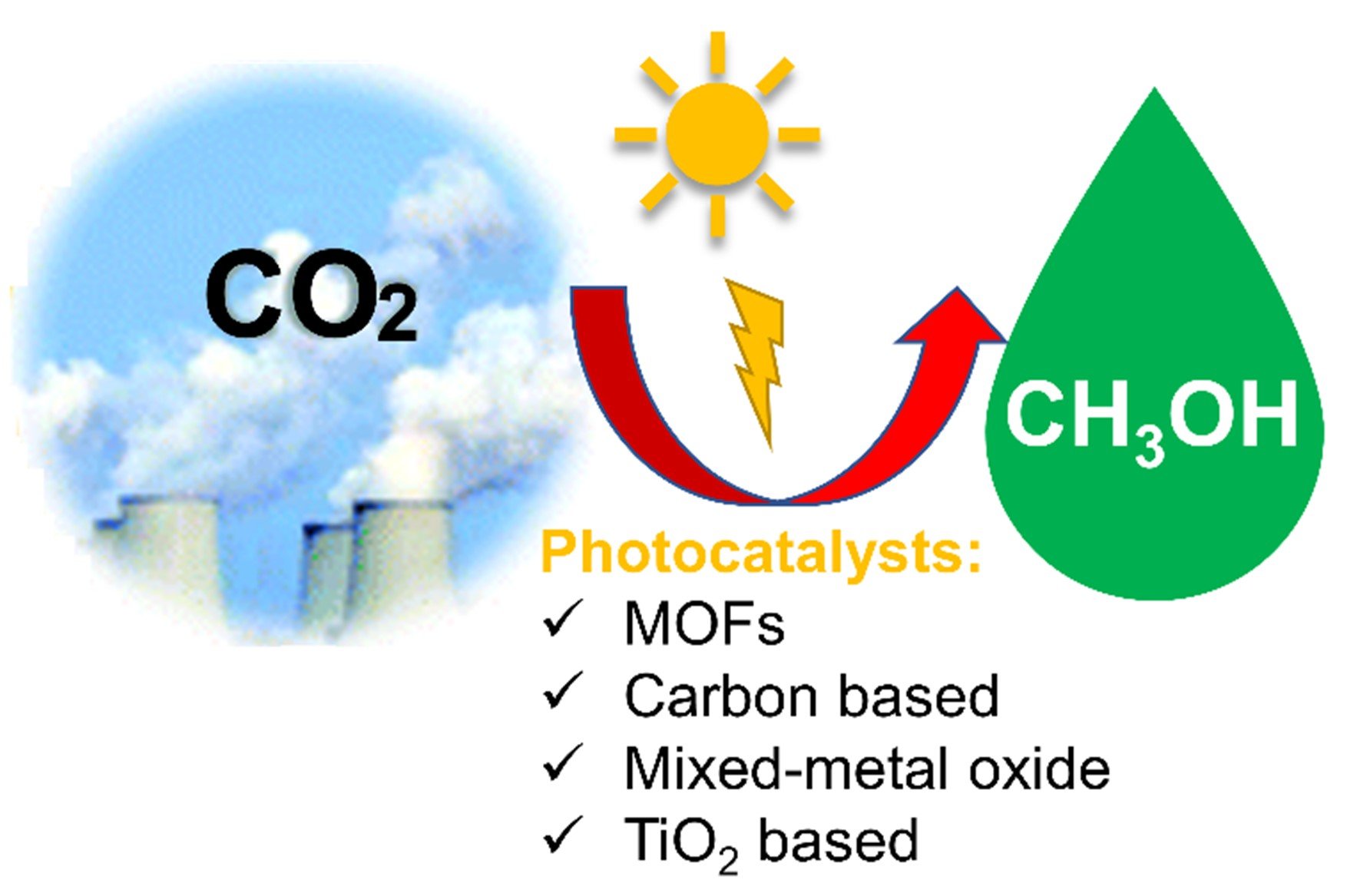

Recognizing CO2 not only as a pollutant but also as a possible raw material for making fuels, chemicals, and materials is at the heart of carbon utilization. The use of new technologies in carbon utilization helps lower greenhouse gas emissions and boosts economic growth at the same time. This article goes into detail about the different ways that carbon can be used. It talks about technologies like direct air capture and how they are used in fields like making carbon fiber, concrete, and chemicals.

B. Direct Air Capture

Direct Air Capture (DAC) is a new technological breakthrough in the field of using carbon. This method involves taking CO2 directly from the air, which is a way to deal with emissions from many different sources. This capture of CO2 can then be used for many different purposes or stored permanently, helping to lower the amount of carbon in the air.

Absorption of CO2

Chemical absorbents or sorbents that selectively pull CO2 out of the air are often used in DAC systems.

CO2 + Sorbent → Sorbent-CO2 Complex

Desorption (Regeneration)

The CO2 is then taken up by the sorbent and let go of through a process called desorption or regeneration.

Sorbent-CO2 Complex → CO2 + Sorbent.

Utilization or Storage:

The released CO2 can be used in different ways or stored underground, which helps use carbon or store it permanently.

Direct Air Capture looks like it could be a good way to deal with emissions from places where it might be hard to use traditional methods. Technology is changing quickly, and researchers are always looking for ways to make it more efficient and lower the costs that come with it.

C. Carbon Utilization in Industry

Carbon Fiber Production:

Carbon fiber is valued for being strong and light, and it is usually made from precursors that come from petrochemicals. Using CO2 as a raw material for carbon utilization is an alternative method.

Carbonization of Precursors:

Polymer Precursor + Heat → Carbon Fiber + CO2

During the carbonization process, CO2 is added to the structure of the carbon fiber. This makes the material sustainable and carbon negative.

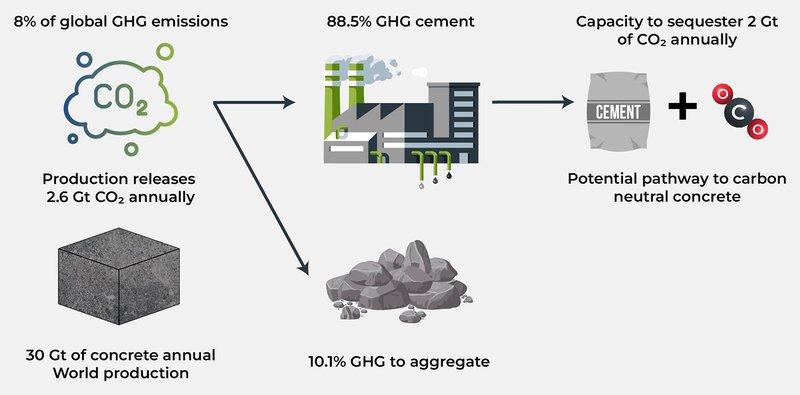

Concrete Production

There are a lot of CO2 emissions that happen when traditional concrete is made. By adding CO2 to the concrete, itself, carbon utilization changes this process.

Mineralization of CO2

CO2 + Calcium and Magnesium Ions → Carbonate Minerals

CO2 is turned into carbonate minerals, which are then mixed into the concrete matrix. This makes the concrete stronger and stores carbon.

Chemical Manufacturing

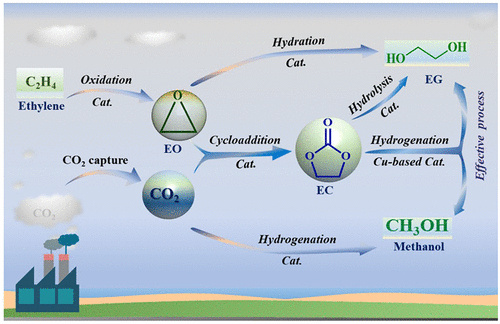

In chemical manufacturing, carbon utilization means using CO2 as a raw material to make different chemicals and fuels.

CO2 + H2 → Methanol

CO2 + Ethylene Oxide → Polycarbonates

CO2 reacts with hydrogen or other starting materials to make chemicals like methanol or polycarbonates. These chemicals help make useful materials.

D. Advantages and Challenges of Carbon Utilization

Climate Mitigation

Carbon utilization actively helps to protect the climate by turning CO2 emissions into useful products, which lowers the overall carbon footprint. This fits with efforts around the world to cut down on greenhouse gas emissions and lessen the effects of climate change.

Resource Efficiency

Carbon utilization makes better use of resources and lowers reliance on traditional petrochemical sources by using CO2 as a feedstock. This fits with the ideas of a circular economy, which tries to reduce waste and use resources in a way that lasts longer.

Creation of Value-added Products

When carbon is used, CO2 goes from being a pollutant to a useful resource. Making things like carbon fiber, concrete, and chemicals leads to the production of high-value goods that can be used in many different industries. This helps the economy grow.

Diversification of Energy Sources

Utilizing CO2 in the creation of fuels like methanol or synthetic methane offers a way to store and distribute energy. Diversification helps make energy systems that last longer and work better when things go wrong.

Carbon Capture and Storage (CCS) Complement

Using carbon can go along with traditional efforts to capture and store carbon (CCS). While carbon capture and storage (CCS) focuses on permanently storing CO2, carbon utilization turns CO2 into useful products, adding another level of sustainability.

Challenges

Energy Intensity

A lot of energy can be used in a lot of carbon utilization processes, especially chemical synthesis processes. Making sure that the process is good for the environment overall means balancing the energy used with the carbon saved.

Economic Viability

The ability of carbon utilization technologies to make money depends on several things, such as how much it costs to capture and use carbon and how much the finished products are worth on the market. It can still be hard to get traditional processes to be cost-competitive in some situations.

Scale-up Challenges

It’s hard to figure out how to make carbon utilization technologies work on a larger scale to meet the needs of industry. For implementation to go well, infrastructure, production scale, and how well they fit in with current industrial processes need to be carefully thought out.

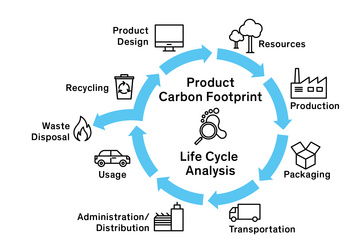

Life Cycle Analysis

To fully understand how carbon utilization processes affect the environment as a whole, it is necessary to do full life cycle assessments. This includes looking at emissions at every stage of a product’s life, from getting the raw materials to throwing them away.

Limited Utilization Options

- Carbon utilization options are not always easy to find in all fields. To find good ways to use something in certain industries, you need to do a lot of research and development that is specific to that industry.

- Waterman Engineers Australia is a leader in developing environmentally friendly engineering solutions, and their work with carbon utilization shows how serious they are about fighting climate change. Waterman Engineers Australia focuses on using cutting-edge technologies to create custom services that use carbon dioxide (CO2) for good purposes.

The company is very good at putting carbon utilization technologies into action, such as capturing CO2 directly from the air and using it in industrial processes. Their knowledge covers a wide range of fields, from making things to making chemicals. They use creative techniques to turn CO2 emissions into useful products.

Waterman Engineers Australia offers services that cover the whole value chain of carbon utilization. This includes figuring out if it’s possible to use carbon-based technologies, making processes more efficient, and making sure that solutions fit in with the way things are done in the industry now. Their all-around approach makes sure that their clients not only reduce their carbon footprint but also get money from things that were once thought of as waste.

Waterman Engineers Australia is a key player in advancing carbon utilization technologies because it focuses on sustainability, innovation, and being environmentally responsible. They help move the world’s economy toward a more circular and sustainable one by providing a wide range of services in this area.

V. Carbon Transportation

A. Carbon Footprint in Transportation

Transportation has been a major source of carbon emissions for a long time, mostly because cars and trucks burn fossil fuels. The carbon footprint in transportation includes all the greenhouse gas emissions that come from making, distributing, and using different types of transportation, like cars, trucks, planes, ships, and trains.

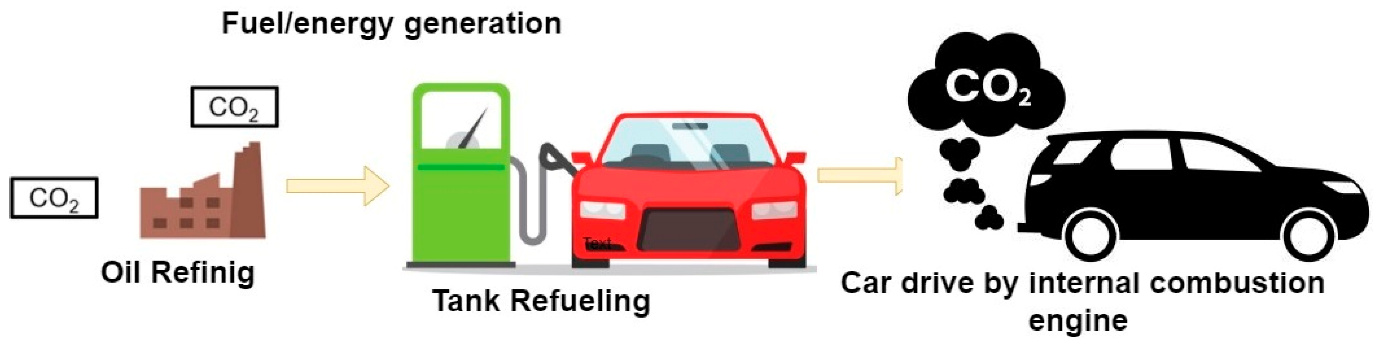

Automobiles and Trucks

- Vehicles with internal combustion engines burn fossil fuels, which releases carbon dioxide (CO2) and other pollutants into the air.

- Processes are used to make cars use a lot of energy, which adds to their overall carbon footprint.

Aviation and Shipping

- A lot of the power that airplanes and ships use comes from fossil fuels, which release a lot of CO2s when they burn.

- The carbon footprint goes all the way through the supply chain, including the making and moving of fuel.

Public Transportation

- Fossil fuel combustion is a source of pollution from public transportation like buses and trains, though usually not as much per passenger as from individual vehicles.

B. Carbon Capture in Transportation

Different plans are being looked into to reduce the carbon footprint of transportation, and carbon capture technologies are getting more attention. Carbon capture in transportation means capturing CO2 emissions that come from burning fuel or using industrial processes that are related to transportation. One way to do this is to use technologies like carbon capture and storage (CCS) in cars or to collect emissions at the point where fuel is made.

Carbon Capture in Vehicles

- Technologies are being worked on to directly capture CO2 from the exhaust systems of cars and trucks. To do this, vehicles need to have capture devices built in that stop CO2 emissions before they reach the air.

- Sorbents, also called absorbents, take CO2 out of the exhaust stream. This CO2 can then be used or stored.

Carbon Capture in Fuel Production

- Carbon capture technologies can be used in fuel refineries to get rid of the CO2 that is released when fossil fuels are processed.

- To make low-carbon or carbon-neutral fuels, the CO2 that is released during the fuel production process has to be captured or balanced out.

C. Sustainable Fuels and Technologies

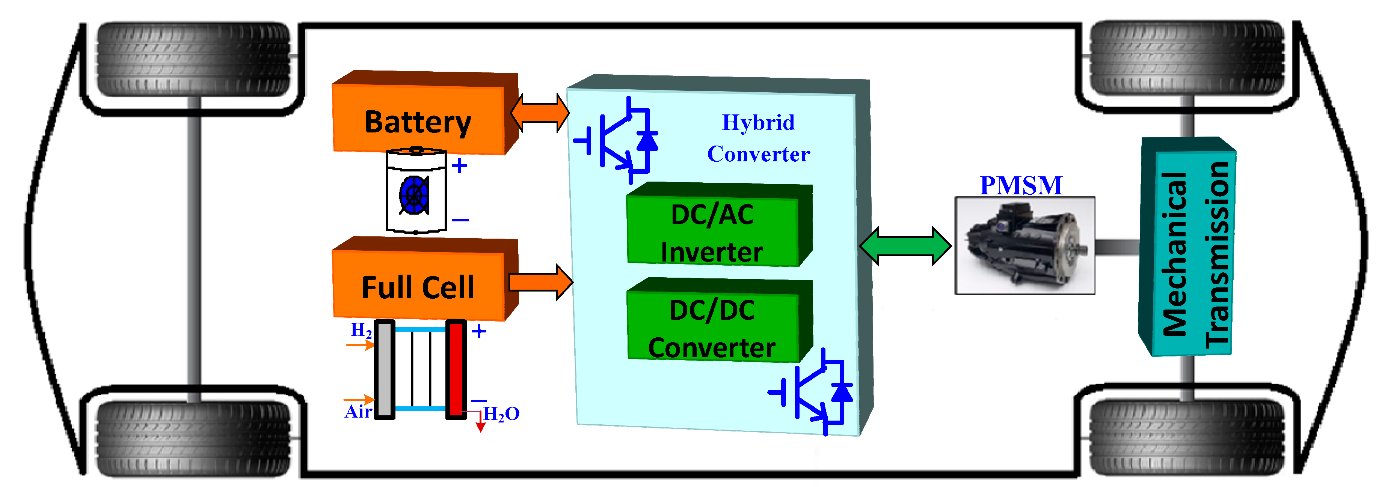

Sustainable fuels and technologies are very important for the transportation sector as it tries to lower its carbon footprint. Electric cars (EVs), biofuels, and hydrogen fuel cells are three popular choices.

Electric Vehicles (EVs)

Electric cars have electric motors that are powered by batteries. This means they don’t need traditional internal combustion engines, which lowers the pollution that comes out of the tailpipe.

Charging the Battery

- During charging, chemical reactions happen inside the battery. These reactions usually involve lithium-ion technology.

Advantages

- EVs don’t put out any pollution when they’re being used, so they clean up the air around them.

- EVs can be charged with electricity that comes from clean sources, which further lowers their carbon footprint.

- Most of the time, electric motors are more efficient than engines that use fuel.

Biofuels

Biofuels are made from organic materials like plants or waste, and they can be used instead of fossil fuels.

Biomass fermentation to make bioethanol or other biofuels from sugars. The process of turning biomass into synthetic fuels, such as biodiesel or synthetic gasoline.

Advantages

- Renewable biomass is used to make biofuels, which reduces our reliance on fossil fuels that are running out.

- If it comes from a sustainable source, the carbon that plants take in during growth balances out the carbon that is released when it is burned.

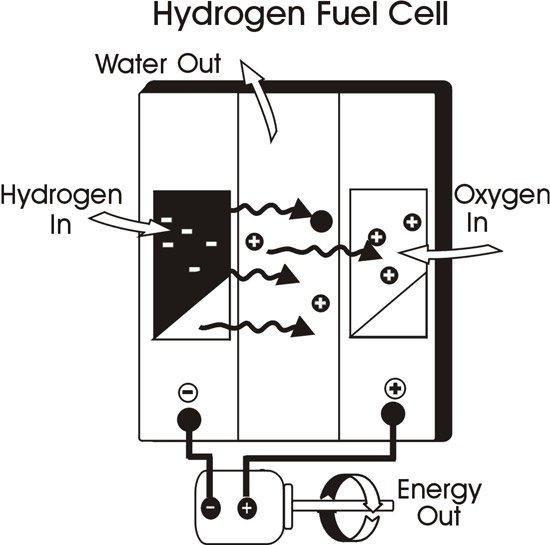

Hydrogen Fuel Cells

Hydrogen fuel cells use the reaction between hydrogen and oxygen to make electricity. As a byproduct, they only give off water vapour.

Electrochemical Reaction

2H2 + O2 → 2H2O + Electricity

Advantages

- Hydrogen fuel cells make electricity without burning anything, so they don’t release any pollution when they’re used.

- Hydrogen can be made from many things, including renewable energy, which makes it a useful fuel that might not even release carbon into the atmosphere.

Challenges and Considerations

Infrastructure Development

For EVs to become widely used, there needs to be a lot of charging stations, especially in places where there aren’t many. In the same way, the use of hydrogen fuel cell vehicles requires the building of a strong network for refueling hydrogen.

Energy Storage and Density

Battery technology needs to get better so that electric vehicles can store more energy, charge faster, and use less energy overall.

Hydrogen storage and transportation are still hard to do efficiently. Researchers are looking into a number of different solutions, such as using liquid hydrogen and advanced composite materials.

Feedstock Availability and Sustainability

Biofuels can last for a long time if they can get the right feedstocks and don’t hurt the environment when they are grown. For biofuels to work, they need to come from sources that are good for the environment.

Which methods are used to make hydrogen affects how long hydrogen fuel cells can last. Green hydrogen, which is made from renewable energy, is better for reducing carbon emissions.

Technological Advancements

Carbon capture technologies need to keep getting better and cheaper so that they can be used in the transportation sector. This can only happen through ongoing research and development.

Consumer Adoption and Awareness

For sustainable transportation technologies to be widely used, consumers need to be educated, made aware, and given incentives to get past problems like high costs and not knowing how to use new technologies.

In order to have a sustainable and low-carbon future, we need low-carbon transportation solutions. Transportation has historically been a big source of carbon emissions, but new technologies and environmentally friendly fuels show promise for reducing these emissions. Electric cars, biofuels, and hydrogen fuel cells are all game-changing technologies that, when used with carbon capture strategies, can help cut transportation’s carbon footprint by a large amount. These technologies have problems that show we need to keep researching, building up infrastructure, and working together to make the world’s transportation system cleaner and more sustainable.

Waterman Engineers Australia sustainable engineering solutions

Waterman Engineers Australia is a leader in providing environmentally friendly engineering solutions, and their services also cover carbon transportation. Because Waterman Engineers Australia knows that transportation is a major source of carbon emissions, they offer specialized services that help make different types of transportation less harmful to the environment.

The company is at the forefront of using cutting-edge technologies and strategies that help cut down on transportation carbon footprints. The goal of Waterman Engineers Australia is to make the transportation sector cleaner and greener. They are working on things like developing carbon capture solutions for vehicles and infrastructure and making the most of sustainable fuels and technologies.

The team at Waterman Engineers Australia plans and builds the infrastructure needed for the switch to sustainable transportation by looking at things from every angle. This includes building charging stations for electric cars, hydrogen refueling stations, and other important parts that are needed for low-carbon transportation solutions to become widely used.

Waterman Engineers Australia is dedicated to protecting the environment, coming up with new ideas, and using the best technology. Because of this, they will play a big role in shaping the future of environmentally friendly transportation. The company makes a big difference in the global effort to build a more sustainable and resilient transportation infrastructure by providing a wide range of services related to all types of carbon transportation.

VI. Carbon Conversion

A. Overview of Carbon Conversion Technologies

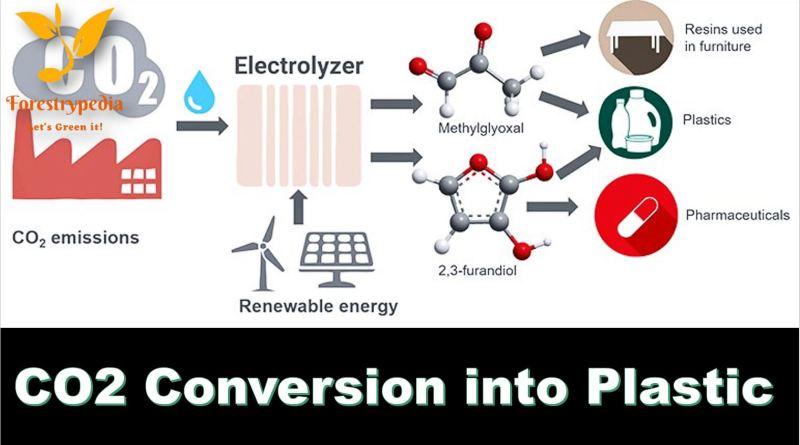

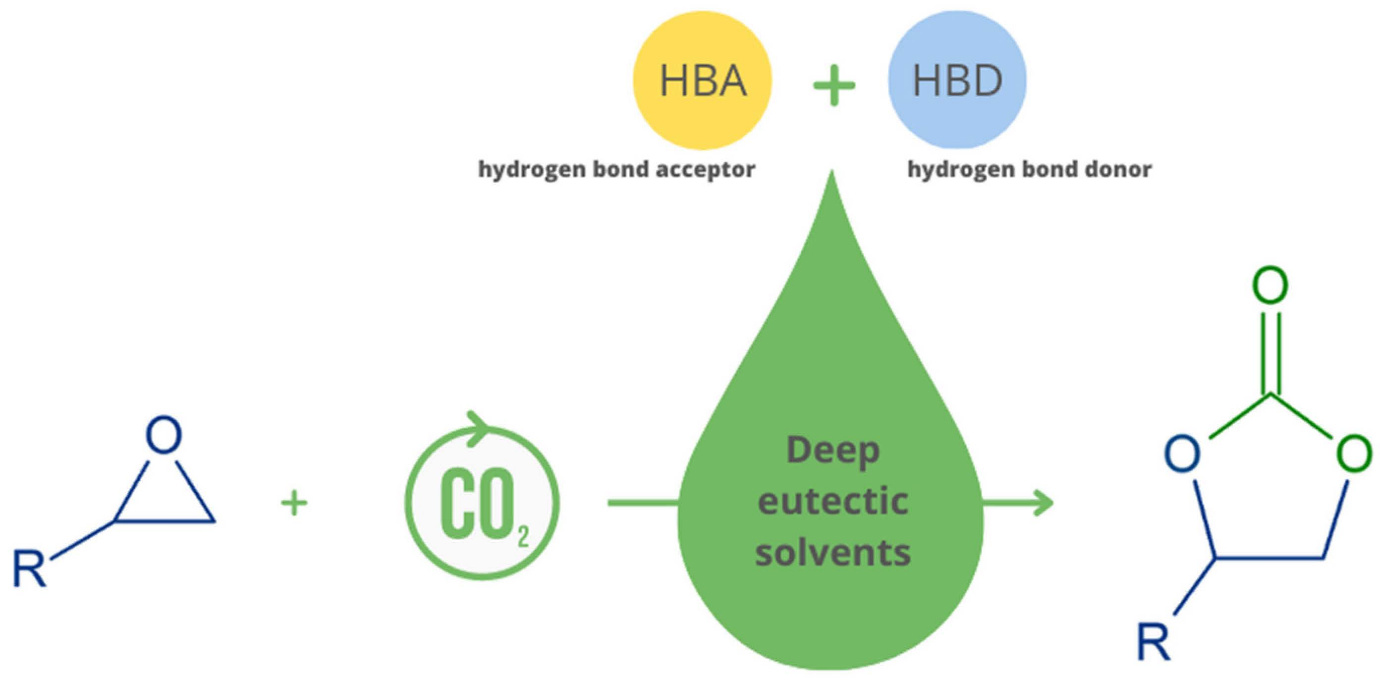

By turning carbon dioxide (CO2) into useful products, carbon conversion technologies are a revolutionary way to deal with carbon emissions. These technologies are very important for creating a circular economy, in which carbon is not seen as waste but as a resource that can be used to help the economy and the environment. The broad definition of carbon conversion technologies includes many new methods for turning CO2 into fuels, chemicals, and building materials.

Direct Air Capture (DAC)

It is possible to get CO2 directly from the air using special technologies in Direct Air Capture. This captured CO2 can be used for different things or stored permanently. Sorbents or absorbents are often used in the chemical reactions that go on in DAC to pick out CO2 from the air.

Carbon Capture and Utilization (CCU)

In the broad category of “Carbon Capture and Utilization,” CO2 emissions from industrial processes are collected and used for goods. Chemical reactions can be used in CCU processes to turn CO2 into fuels, chemicals, or materials.

Artificial Photosynthesis

Artificial photosynthesis is based on the idea that CO2 and water can be turned into energy-rich compounds like hydrogen and hydrocarbons by sunlight. The main reactions use sunlight to change CO2 and water into other substances, just like in natural photosynthetic processes.

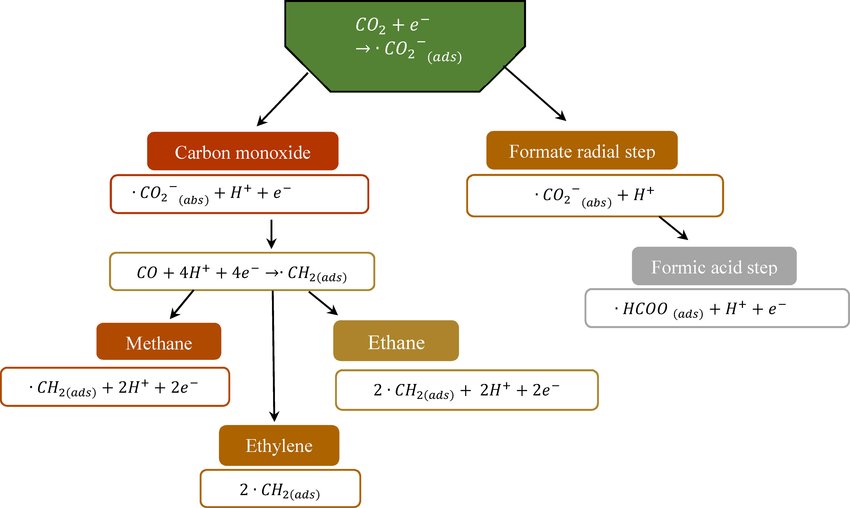

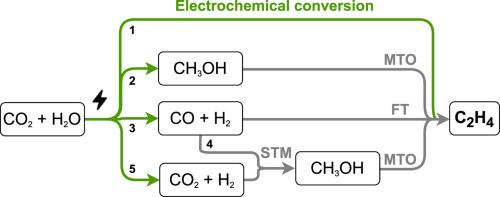

Electrochemical Reduction of CO2

Using electricity to change CO2 into useful chemicals and fuels is called electrochemical reduction. The process is called electrolysis. At the electrode interface, reduction reactions change CO2 into compounds such as formic acid, carbon monoxide (CO), or methane (CH4).

B. Carbon-to-Fuel Conversion

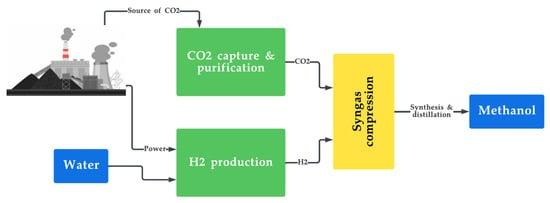

Synthetic Fuels

Synthetic fuels, which are also called electro fuels or e-fuels, are made by using renewable energy to turn CO2 into liquid or gaseous fuels. Synthetic fuels like gasoline, diesel, and aviation fuels are made when CO2 is reduced electrochemically, which is often done with the help of catalysts.

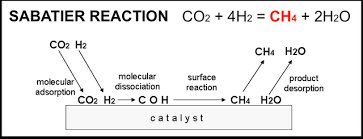

Methane Production

Methane is a main part of natural gas. It can be made by reducing CO2 with hydrogen in a process called the Sabatier reaction.

CO2 + 4H2 → CH4 + 2H2O

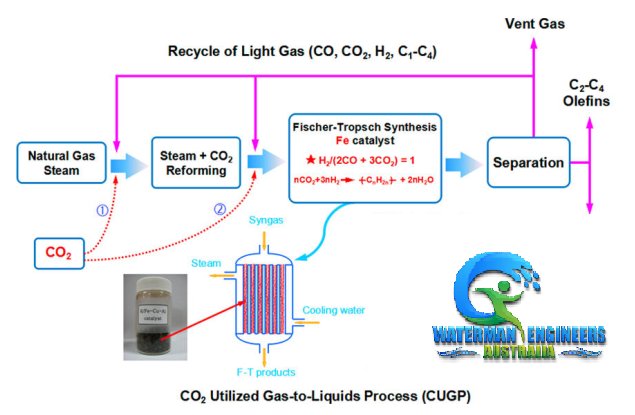

Fischer-Tropsch Synthesis

Through a series of chemical reactions, Fischer-Tropsch synthesis turns CO2 and hydrogen into liquid hydrocarbons. Complex hydrocarbons, like synthetic diesel or jet fuel, are made during the synthesis process.

C. Carbon-to-Chemical Conversion

Methanol Synthesis

A catalytic process can be used to turn CO2 into methanol, a chemical that can be used in many situations.

CO2 + 3H2 → CH3OH + H2O

Ethylene Production

Electrochemical reduction of CO2 or other catalytic processes can be used to make ethylene, which is an important building block in the chemical industry. Ethylene is made through reduction reactions.

Carbonate Formation

By reacting CO2 with metal oxides, carbonates can be made, which are useful in many industrial settings.

CO2 + Metal Oxide → Metal Carbonate

D. Innovations and Emerging Trends

Advanced Catalysts

Research is still going on to make better catalysts that will make carbon conversion reactions more efficient and selective. These catalysts are very important for making certain chemical changes possible.

Photoelectrochemical Systems

Photoelectrochemical systems use light from the sun to power electrochemical reactions that change CO2 into something else. More efficient systems are being made possible by progress in materials science and device design.

Biological Carbon Conversion

Scientists are looking into biological processes, like microbial electrosynthesis and engineered microorganisms, to see if they can turn CO2 into useful materials. These methods use biological systems’ abilities to speed up complicated reactions.

Integration with Renewable Energy

One important trend is the combination of carbon conversion technologies with clean energy sources. This includes combining electrochemical processes with energy from the sun or wind to make products that are carbon-neutral or carbon-negative.

Circular Carbon Economy Initiatives

The goal of circular carbon economy projects is to set up closed-loop systems where CO2 emissions are captured, turned into useful goods, and then reused or recycled. This all-around approach fits with the ideas of sustainability and making the best use of resources.

Scale-Up and Commercialization

As carbon conversion technologies get better, one important trend is for production processes to get bigger and more widely used. Pilot projects and demonstration plants are making it possible to use these ideas on a large scale.

The way people think about and use carbon dioxide has changed a lot because of carbon conversion technologies. These new ideas could help slow down climate change while also making money. For example, they could turn CO2 into synthetic fuels or make useful chemicals and materials. Biological approaches, the use of renewable energy sources, and improvements in catalyst design are all pushing the field of carbon conversion forward and creating a circular and sustainable carbon economy. As long as research and development keep going, putting these technologies on the market could completely change industries and make the future much more sustainable and low carbon.

Pioneering Engineering Solutions

It is Waterman Engineers Australia’s mission to come up with cutting edge engineering solutions that help build a more sustainable future. When it comes to carbon conversion, the company provides specialized services that use the transformative power of carbon dioxide (CO2) to make useful products. Waterman Engineers Australia is a leader in putting cutting-edge carbon conversion technologies into practice, which is a key part of moving towards a circular carbon economy.

Their knowledge covers a wide range of carbon conversion methods, from direct air capture (DAC) to electrochemical reduction and the production of synthetic fuels. Waterman Engineers Australia is dedicated to creating custom solutions that meet the specific needs of businesses that want to turn CO2 emissions into fuels, chemicals, and building materials.

The planning, design, and implementation of carbon conversion systems are all done by Waterman Engineers Australia with an all-around view. To make carbon conversion solutions that work well and last, this includes making processes more efficient, choosing the right catalysts, and adding renewable energy sources. The company’s services promote both environmental sustainability and the economic health of sectors looking for new ways to handle carbon emissions.

Waterman Engineers Australia is a major player in the carbon conversion landscape because it is always coming up with new ideas and striving for technological excellence. The company is very important to the future of industries moving toward a more sustainable and circular carbon economy because it provides a wide range of services in this area.

VII. Carbon Purification

A. Importance of Carbon Purification

Carbon purification is a key part of reducing the environmental problems caused by carbon-containing substances, especially carbon dioxide (CO2). Carbon purification is important for protecting the environment (for example, by lowering greenhouse gas emissions) and making sure of the quality of different industrial processes. By cleaning up carbon, not only is the damage to the environment lessened, but it also opens the door to long-term uses and better resource management.

Greenhouse Gas Emissions Reduction

Carbon purification is an important part of capturing and cleaning up CO2 emissions, so they don’t get released into the air. In line with global efforts to lower greenhouse gas levels, this is an important step toward reducing climate change.

Industrial Process Optimization

In factories, cleaning things that contain carbon makes sure that processes are done well and correctly. For instance, in the chemical industry, clean carbon sources are necessary to make sure that only high-quality products are made without any impurities. Cleaning up carbon makes it possible to use resources in new ways, like making high-purity materials, fuels, and chemicals. Thus, this helps create a circular economy in which carbon is reused in a smart way.

B. Technologies for Carbon Purification

Carbon purification uses a number of different technologies, each one designed for a specific use or environment.

Adsorption

Adsorption is the process by which carbon compounds stick to solid surfaces, usually with the help of activated carbon or other adsorbents. There are physical interactions between the carbon compounds and the adsorbent surface that separate the impurities.

Absorption

Liquids or solvents are used in absorption to selectively break down carbon compounds in a gas stream. There may be chemical reactions between the carbon compounds and the liquid that absorbs them, which makes it easier to separate the impurities.

Membrane Separation

Some carbon compounds can pass through semi-permeable membranes while others are blocked. This is called membrane separation. Molecular size and affinity determine separation, so there aren’t usually any chemical reactions going on.

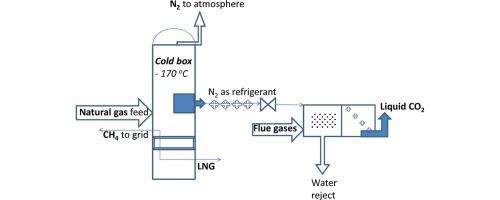

Cryogenic Separation

In cryogenic separation, a stream of gas is cooled to very low temperatures, which makes different carbon compounds condense at different points. Gases change physical phases when they go from a gaseous state to a liquid or solid state based on their temperature.

C. Applications in Various Industries

Water Treatment

- When treating water, carbon purification is used to get rid of organic pollutants like dissolved organic carbon (DOC) and other impurities.

- A method called activated carbon adsorption is often used. In this method, porous carbon materials soak up and remove impurities from water.

- Carbon purification is used in water treatment plants to improve the quality of the water by getting rid of organic matter, colour, and bad tastes or smells.

Air Purification

- Carbon purification is an important part of managing air quality because it captures and lowers airborne pollutants, mainly CO2 and volatile organic compounds (VOCs).

- To get rid of air pollutants, adsorption and absorption technologies are used. These methods usually use activated carbon or other special absorbent materials.

- Carbon purification is used by industries that release VOCs, like chemical manufacturing, to follow air quality rules. Indoor air purification systems also use carbon filters to make the air better.

D. Future Developments in Carbon Purification

Advanced Adsorbents and Absorbents

Advanced materials with better adsorption and absorption capacities are the focus of ongoing research. This includes coming up with new porous structures and adding functional groups to help with selective purification.

Carbon Capture Technologies

New developments in carbon capture technologies aim to make the process of separating and cleaning CO2 emissions from different sources more effective. This includes coming up with cheaper and more energy-efficient ways to capture and use carbon on a large scale.

Smart Membrane Technologies

In order for carbon purification to move forward, smart membrane technologies that can change how permeable they are based on pollutants are needed. This could make separation processes more flexible and use less energy.

Integration with Renewable Energy

Future progress in carbon purification will probably focus on using renewable energy sources for processes that need a lot of power. This could include using solar or wind power to power technologies that clean the air.

Circular Carbon Economy Initiatives

The idea of a circular carbon economy, in which carbon is always being used for something else, will guide future progress. This includes looking into how to clean and reuse carbon efficiently in different industrial processes, which would help the environment and save resources.

Carbon purification is an important part of protecting the environment and running businesses efficiently. As technology keeps getting better, the main goal will be to make carbon purification processes more selective, efficient, and long-lasting. There are exciting changes coming up in the future that will not only help the environment but also make it possible to use carbon resources in a more circular and sustainable way.

Providing Innovative Engineering Solutions

When it comes to coming up with new engineering solutions, Waterman Engineers Australia is the leader. Their services also include carbon purification. Waterman Engineers Australia provides specialized services that use cutting-edge purification technologies because they know how important it is to reduce carbon emissions and make sure the quality of different processes.

Using cutting-edge technologies like adsorption, absorption, membrane separation, and cryogenic separation, the company is great at using a variety of carbon purification methods. Because Waterman Engineers Australia is so good at these techniques, they can make solutions that work for a wide range of industries that need to clean up carbon-containing substances.

Waterman Engineers Australia uses carbon purification methods to improve the quality of water by getting rid of dissolved organic carbon (DOC), organic pollutants, and other impurities. Their solutions help improve water treatment processes in a way that is sustainable and good for the environment.

The company uses cutting edge adsorption and absorption technologies to remove and capture airborne pollutants like carbon dioxide and volatile organic compounds (VOCs) (CO2). This is especially important for industries that release VOCs into the air, making sure they follow air quality rules and improving the air quality in many places.

Waterman Engineers Australia’s dedication to excellence is clear in the way they think about carbon purification. The company stays on the cutting edge of new ideas as the industry changes. New technologies will focus on advanced adsorbents, smart membranes, and combining them with renewable energy. Their services are in line with the ideas of a circular carbon economy, in which carbon is reused and repurposed in an efficient way, leading to a more resource-conscious and sustainable future.

Waterman Engineers Australia is a key player in shaping the future of environmental sustainability and industrial efficiency by providing a wide range of carbon purification services. Their promise to provide customized solutions shows how serious they are about developing technologies that lessen the damage they do to the environment and encourage a more circular and long-lasting use of carbon resources.

VIII. Carbon Recovery

A. Introduction to Carbon Recovery

The process of collecting and reusing carbon-containing substances, mostly carbon dioxide (CO2), from different industrial sources is called carbon recovery. By turning waste carbon emissions into useful resources, this method fits with the ideas of sustainability and the circular economy. Carbon recovery technologies are very important for lowering greenhouse gas emissions, making better use of resources, and making industries more eco-friendly.

B. Recovery from Fertilizer Manufacturing Plants

Process Overview

- Carbon recovery is the process of capturing CO2 that is released when ammonia and urea are made in fertilizer factories.

- The process of making ammonia (NH3) involves reacting nitrogen and hydrogen, which sends CO2 into the air.

- As a byproduct of many chemical reactions, the production of urea also gives off CO2.

Recovery Technologies

Ammonia Stripping

The process removes any ammonia that hasn’t been reacted with, and the remaining gas stream, which is high in CO2, goes through recovery.

Adsorption or Absorption:

Using adsorption or absorption technologies, which often use materials like amine solutions or solid sorbents, you can selectively capture CO2. The recovery process can be physical or chemical, and it can include reactions like amines absorbing CO2 or solid surfaces adsorbing it.

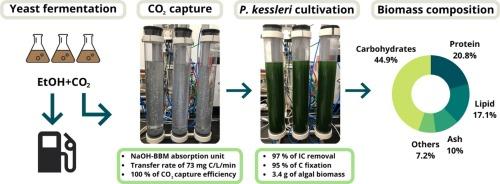

C. Recovery from Breweries

- Because of fermentation processes, breweries make CO2. Breweries use carbon recovery to keep this CO2 from going into the air by collecting it and using it for something else.

- A process called fermentation, in which yeast breaks down sugars, creates CO2.

Recovery Technologies

- The fermentation vessels themselves take in the CO2 that is released during the process.

- CO2 is taken back from the off-gas streams after fermentation.

- The CO2 that is released during fermentation is a pretty pure stream that doesn’t need much treatment, so recovery may be as easy as physical separation.

D. Recovery from Ethanol Distilleries

As a byproduct of fermentation and distillation, ethanol distilleries make CO2. The goal of carbon recovery is to get this CO2 and use it. Yeast turns sugars into ethanol and CO2 during fermentation. Distillation processes make the ethanol even stronger and let out CO2.

Recovery Technologies

- The CO2 that is made during fermentation is either taken in directly or from streams of off-gas.

- It is possible to recover the CO2 that is released during distillation.

Physical separation may be needed for recovery, and the CO2 that is captured could be used in other industries or processes.

E. Challenges and Solutions

High Dilution in Off-Gases

- In some processes, CO2 is released as off-gases that aren’t very concentrated, which makes recovery hard.

- Advanced separation technologies, like membrane systems or advanced adsorption methods, can pick out CO2 even when it’s not present in large amounts.

Energy Intensity of Recovery Processes

- Some recovery processes can use a lot of energy, which can make the operation less environmentally friendly as a whole.

- Energy problems can be solved by using more renewable energy sources, making processes more efficient, and making progress in recovery technologies.

Economic Viability

- The ability of carbon recovery projects to make money could stop them from being widely used.

- Recovery projects can be more successful if they have economic incentives, ways to price carbon, and government policies that support capturing and using carbon.

Integration with Downstream Processes

- Adding recovered carbon to processes further down the line might need changes to the infrastructure.

- The process of integration can go more quickly if you plan for it when you design the facility, make sure everything works together, and look for new ways to use recovered carbon.

Scale-Up Challenges

- When moving from small-scale recovery projects to large-scale industrial uses, it can be hard.

- Large-scale implementation can go more smoothly if it is done in steps, with help from research institutions and by sharing the best ways to do things within the industry.

Carbon recovery is one of the most important ways to cut down on greenhouse gas emissions and make the industrial ecosystem more sustainable. Industries can help create a circular economy where carbon is recovered, reused, and repurposed by working together and using new technologies to solve problems. This will encourage people to be more responsible with the environment and make better use of resources.

Delivering Forward-Thinking Engineering Solutions

When it comes to providing cutting-edge engineering solutions, Waterman Engineers Australia is at the top of the pack, and their services easily extend to carbon recovery. Because Waterman Engineers Australia knows how important it is to turn carbon emissions into useful resources, they offer specialized services that are made to fit the specific needs and opportunities of different industrial processes.

Innovative carbon recovery technologies are used expertly by the company, which focuses on capturing and reusing carbon-containing compounds, with a focus on carbon dioxide (CO2). Their knowledge covers a wide range of fields, and they have dealt with problems related to carbon emissions from ethanol distilleries, breweries, and plants that make fertilizer.

Waterman Engineers Australia uses advanced methods in fertilizer factories, like ammonia stripping, adsorption, or absorption, to get back the CO2 that is released when ammonia and urea are made. Their solutions focus on making recovery processes more efficient while also protecting the environment.

The company uses direct capture from fermentation vessels and post-fermentation capture in breweries to get back the CO2 that was made during the brewing process. By collecting CO2 directly from the fermentation process, Waterman Engineers Australia helps reduce greenhouse gas emissions and opens up the possibility of finding new uses for recovered carbon.

In the same way, Waterman Engineers Australia uses recovery strategies in ethanol distilleries to get back the CO2 that is released during fermentation and distillation. The company offers services that cover the whole carbon recovery value chain, from capturing CO2 to looking for good ways to use the recovered carbon.

Waterman Engineers Australia works on problems related to carbon recovery, such as high dilution in off-gases, high energy use, lack of economic viability, and problems with scaling up. Their method includes using advanced separation technologies, clean energy sources, and careful planning to make sure that carbon recovery projects are both financially viable and successfully carried out.

It’s clear that the company cares about sustainability because it takes a whole-systems approach that includes both finding efficient ways to capture carbon emissions and coming up with new ways to use recovered carbon. Waterman Engineers Australia is a key player in the move to a circular economy, where carbon is not seen as waste but as a valuable resource, because they offer a wide range of carbon recovery services.

Because Waterman Engineers Australia cares about the environment, uses cutting-edge technology, and finds practical solutions, they will play a big role in creating a future where carbon recovery is an important part of environmentally friendly business practices. The company’s services help with the bigger goal of slowing down climate change and making the industrial landscape more resilient and resource efficient.

IX. CO2 Recovery Plant

A. Role and Importance of CO2 Recovery Plants

Carbon dioxide (CO2) recovery plants are very important for protecting the environment, slowing down climate change, and making sure that businesses are environmentally friendly. These plants are made to collect and reuse CO2 emissions from different industrial processes so that they don’t get released into the air. In addition to lowering emissions, CO2 recovery plants play a big role in making the economy better, saving resources, and creating a circular carbon economy.

Climate Change Mitigation

By capturing and stopping the release of CO2, a major greenhouse gas, CO2 recovery plants are very important for slowing down climate change. This fits with efforts around the world to cut down on pollution and lessen the effects of climate change.

Resource Efficiency

By using CO2 for something else, these plants help make better use of resources by recycling something that was once thought of as waste. CO2 can be used for many things, making a closed-loop system that gets the most out of carbon resources.

Circular Carbon Economy

In a circular carbon economy, CO2 is constantly captured, reused, and repurposed. This is made possible by CO2 recovery plants. This circular approach fits with sustainability goals because it uses fewer limited resources and has less of an effect on the environment.

CO2 recovery opens up business opportunities, such as making new markets for CO2 that has been captured and coming up with environmentally friendly ways to do things that make industries that use these technologies more competitive.

Environmental Stewardship

CO2 recovery plants are good examples of environmental stewardship because they do something about how industrial activities hurt the environment. These plants help clean the air and keep the ecosystem healthy by soaking up CO2 emissions.

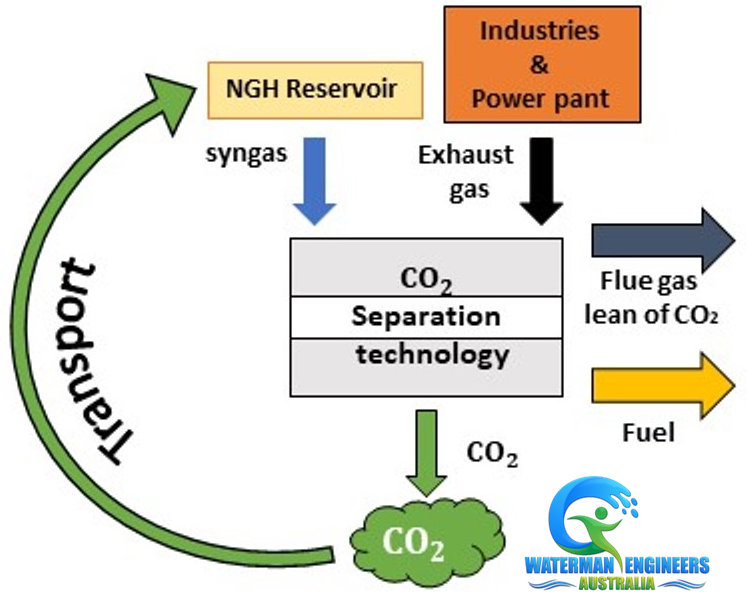

B. Technologies Used in CO2 Recovery Plants

CO2 recovery plants use a range of technologies to collect and separate CO2 from gases that come out of factories. These technologies can be broken down into different groups, each with its own set of uses and industrial settings.

Post-Combustion Capture

- Post-combustion capture is used on flue gases that come out of burning things like power plants and industrial furnaces.

- Solutes that absorb CO2, like amines, pick out CO2 from flue gases.

When CO2 and the solvent react, a stable compound is made. This compound is then separated, letting pure CO2 escape.

CO2+2R−NH2→R−NH3++CO22−

Pre-Combustion Capture

- Pre-combustion capture is used on syngas, which is made when fossil fuels are burned and turned into gas. This is mostly done in chemical manufacturing and power generation using syngas.

- Before CO2 is burned, it reacts with a shift catalyst to make water and a shifted gas.

CO+H2O⇌CO2+H2

Oxy-fuel Combustion

- Oxy-fuel combustion burns fossil fuels in an environment with a lot of pure oxygen, which makes a stream of flue gas that is high in CO2.

- Absorption or adsorption technologies are used to separate CO2 from flue gas.

Like post-combustion capture, reactions with absorption solvents make it easier to separate CO2.

Cryogenic Separation

- In cryogenic separation, the flue gas is cooled down to very low temperatures, which turns CO2 into a liquid.

- The CO2 that has been condensed is then separated from the other gases by distillation or some other method.

Gases change from a gaseous state to a liquid or solid state based on their temperature. This happens without any chemical reactions.

Membrane Separation

- The semi-permeable membranes used in membrane separation only let CO2 pass through while blocking other gases.

- It is planned that the membranes will stick to CO2, which will make separation work well.

Separation is based on molecular size and permeability, so there are no chemical reactions.

C. Applications and Industries Benefiting from CO2 Recovery

CO2 recovery plants are used in many different types of industries, which helps these industries be more sustainable and environmentally friendly. The CO2 that is recovered can be used in different ways, creating a value stream that goes beyond lowering emissions.

Food and Beverage Industry

CO2 that is recovered from fermentation processes in distilleries and breweries is used to make drinks fizzy. Cuts down on the need for CO2 from outside sources, which saves money and is better for the environment.

Greenhouses and Agriculture

Greenhouses get CO2 that has been recovered to help plants grow through photosynthesis. Boosts plant growth and increases crop yields, which leads to higher agricultural productivity.

Chemical Manufacturing

- CO2 is a basic chemical that is used in many chemical reactions to make other chemicals and urea.

- Allows the creation of useful chemicals while lowering the damage that chemical production does to the environment.

Enhanced Oil Recovery (EOR)

CO2 is used in EOR to get more oil out of oil fields that are already mature. Boosts the rate of oil recovery, which extends the life of oil fields and makes the best use of resources.

Carbonation in Concrete Production

CO2 that has been recovered is used to carbonate concrete, which helps the curing process. It makes concrete stronger and lasts longer while also storing CO2 inside the structure.

Pharmaceutical Industry

CO2 is used in pharmaceutical processes, like making medicinal compounds and getting pharmaceutical products out of their bases. Offers a long-lasting source of CO2 for pharmaceutical uses, cutting down on the need for traditional methods of sourcing.

Dry Ice Production

Carbon dioxide is recovered and used to make dry ice, which is used in many fields, such as transportation and food storage. Encourages the production of dry ice as a valuable product that can be used in many industrial settings.

Carbon Capture and Utilization (CCU)

A lot of different CCU processes use CO2, like making synthetic fuels, chemicals, and materials. Helps the circular carbon economy by turning CO2 into useful products, which cuts down on our need for fossil fuels.

Power Generation

Carbon capture and storage (CCS) in power plants is one way that recovered CO2 can be used to make electricity. Boosts cleaner and more environmentally friendly energy production by lowering the carbon footprint of power plants.

Water Treatment and Desalination

CO2 is used to treat water in ways that make it better, like adjusting the pH and causing carbonate to precipitate. Improves the effectiveness of processes used to treat water while utilizing recovered CO2.

Because CO2 recovery plants are so flexible, they can help a lot of different industries. They do this by saving money, using resources more efficiently, and offering long-term alternatives to old ways of doing things. As businesses become more aware of how important it is to cut down on carbon emissions and use environmentally friendly methods, CO2 recovery plants play a bigger part in making businesses greener and more responsible.

Cutting-Edge Engineering Solutions

Waterman Engineers Australia is a leader in providing cutting-edge engineering solutions, and their CO2 recovery plant services fit right in with their other services. Waterman Engineers Australia knows how important it is to reduce carbon emissions and promote environmentally friendly business practices. That’s why they offer specialized services to help different industries use and improve CO2 recovery technologies.

Expertise in Diverse CO2 Recovery Technologies

Waterman Engineers Australia is good at many different CO2 recovery methods, such as pre-combustion capture, post-combustion capture, oxy-fuel combustion, cryogenic separation, and membrane separation. Because they are experts in the field, businesses can pick and use the best technology for their needs, which increases efficiency and reduces damage to the environment.

Tailored Solutions for Different Industrial Settings

Waterman Engineers Australia offers custom CO2 recovery solutions for a wide range of settings because they know that each industry has its own problems and needs. The company offers services that are tailored to the needs of each industry, such as capturing CO2 from power plants, chemical factories, and breweries.

Integration of Advanced Separation Methods

Waterman Engineers Australia is one of the first companies to use cutting edge separation techniques in CO2 recovery processes. This includes using cutting-edge membrane technologies, state-of-the-art absorption solvents, and new ways to separate things using cryogenics. Their method not only captures CO2 efficiently, but it also makes the best use of energy and makes the process more environmentally friendly overall.

Comprehensive Support in Plant Design and Implementation

The company offers full help with the planning, design, and construction of CO2 recovery plants. This includes studying whether the idea will work, making the process more efficient, and choosing the right technologies based on what the client needs for their business. Waterman Engineers Australia’s involvement from the beginning makes sure that CO2 recovery projects are handled in a complete and unique way.

Economic Viability and Cost-Effective Solutions

Waterman Engineers Australia knows that carbon capture technologies can be expensive, so they put a lot of effort into finding solutions that are as cheap as possible. As part of their services, they do cost-benefit analyses, economic feasibility studies, and come up with ways to make their clients’ CO2 recovery projects more profitable.

Sustainable Practices and Circular Economy Integration

The Australian branch of Waterman Engineers actively supports environmentally friendly methods and the addition of CO2 recovery to the circular carbon economy. The company helps businesses use captured CO2 for different purposes, like adding carbonation to drinks, improving oil recovery, or making chemicals. This helps build closed-loop systems that get the most out of carbon resources.

Innovative Applications and Industry-Specific Solutions

The company is clearly dedicated to new ideas as it looks for new ways to use recovered CO2 and solutions that are specific to the industry. This includes helping businesses use CO2 for things like making concrete more carbonated, making medicines, and other uses that make the business world more sustainable and varied.

Continuous Improvement and Adaptation to Emerging Technologies

Waterman Engineers Australia stays ahead of the competition by always changing with the times and following new technologies and business trends. Their dedication to ongoing research and development makes sure that their clients get the most up-to-date information on CO2 recovery, such as better separation methods, more efficient capture, and overall process optimization.

Collaborative Approach and Client-Centric Services

Waterman Engineers Australia takes a collaborative approach, getting to know their clients’ problems and goals by working closely with them. Their services are focused on the client and involve active participation throughout the entire project lifecycle. This builds a partnership that goes beyond implementation and includes ongoing support and improvement.

The work that Waterman Engineers Australia does on CO2 recovery plants shows that they care about cutting edge technology, the environment, and moving businesses toward greener methods. The company is very important to make sure that CO2 recovery is an important part of responsible and sustainable industrial operations in the future. They do this by using their knowledge, custom solutions, and commitment to constant innovation.

X. Waterman Engineers Australia Overview

Waterman Engineers Australia is a top engineering company that is always coming up with new and eco-friendly ways to solve problems. With a dedication to excellence, cutting-edge technology, and a wide range of services, the business has become a major force in shaping the fields of carbon management and environmental sustainability.

A. Overall Recap of Key Points

Diverse Carbon Management Services

Among their carbon management services are carbon capture, storage, utilization, purification, recovery, and conversion. Waterman Engineers Australia offers a wide range of aforementioned services. Their skill is clear when they tailor solutions for different industries, which helps cut down on pollution and make better use of resources.

Cutting-edge Technologies

The company stands out because they are very good at using cutting edge technologies for carbon management. Waterman Engineers Australia is always the first to use the newest technologies in their services, from cutting edge separation methods to new carbon conversion technologies.

Client-Centric Approach

Waterman Engineers Australia focuses on the needs and challenges of each client, working closely with them to learn about their specific issues and needs. This makes sure that the solutions are not only up to date with technology but also fit the needs and goals of each client.

Circular Carbon Economy Integration

The company works hard to make sure that carbon management practices are part of the circular carbon economy. Their services help make closed-loop systems that capture carbon, repurpose it, and use it again and again. This is in line with goals for sustainability and resource efficiency.

Sustainability and Economic Viability

Sustainability and being able to make money are very important to Waterman Engineers Australia. As part of their services, they do cost-benefit analyses, economic feasibility studies, and put in place strategies that make carbon management projects more economically viable.

Innovation and Future-oriented Solutions

Waterman Engineers Australia stays ahead of the curve by doing ongoing research and development to keep up with new technologies and industry trends. Because they are dedicated to new ideas, they can help shape the future of carbon management and sustainable engineering.

B. Future Outlook for Carbon Management

Advancements in Carbon Capture Technologies

Carbon capture technologies will likely get better in the future, with a focus on making them more efficient, using less energy, and looking into new ways to capture carbon.

Circular Carbon Economy Initiatives

Waterman Engineers Australia is ready to play a key role in helping the transition as more and more industries adopt circular carbon economy initiatives. The way they know how to combine carbon capture, utilization, and conversion is in line with the circularity principles.

Renewable Energy Integration

A big trend that will happen is the use of renewable energy sources in carbon management. Utilizing renewable energy for carbon capture and utilization, Waterman Engineers Australia is in a good position to assist businesses in switching to more environmentally friendly methods.

Carbon Management in Emerging Sectors

As carbon management becomes more important across all industries, Waterman Engineers Australia is likely to expand its services into new areas, even those that have high emissions levels now, like heavy industry and transportation.

Policy and Regulatory Landscape

The direction of the industry will likely be determined by how carbon management policies and rules change over time. Because Waterman Engineers Australia is proactive, they can handle changes in regulations and help clients stay in line while improving their carbon management strategies.

Global Collaboration and Knowledge Sharing

Because Waterman Engineers Australia wants to work together and share what they know, they are an important part of the global effort to fight climate change. Partnerships, collaborative projects, and sharing of knowledge are likely to be very important in shaping the future of carbon management.

Overall Conclusion

In conclusion, Waterman Engineers Australia is a leader in the field of carbon management. They provide a wide range of services that deal with the many problems that come with carbon emissions. Their dedication to sustainability, cutting-edge technology, and happy customers makes them a valuable partner for businesses looking for new and custom solutions. As we move toward a future where carbon management is more important, Waterman Engineers Australia is set to continue playing a key role in making the industrial landscape more sustainable and resilient.

Our company is a professional one that works all over the world to set up CO2 production plants and recoveries, as well as specialty gases and machine categories like dry ice machines, among other things. We have more than 10 years of experience in the field of CO2 Plant & Recovery using our own Carbon Capturing Technology. We can supply or service your breweries, distilleries, or other needs for a customised CO2 production plant by recovering raw CO2, cleaning it, turning it into liquid CO2, and storing it.

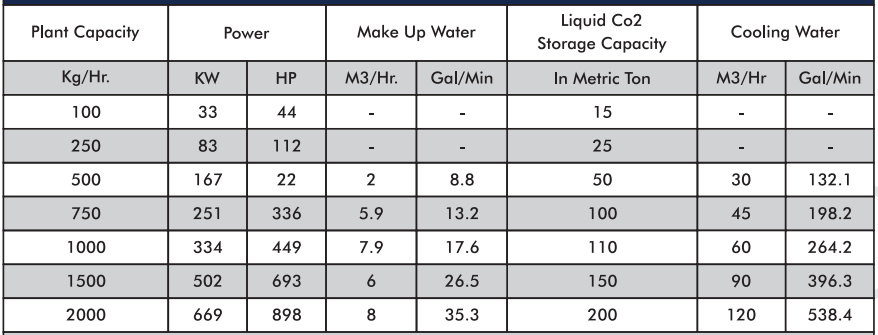

We have a lot of different CO2 production plants with fully automated systems based on our own Carbon Capturing Technology to meet all of our clients’ needs for making a lot of pure CO2s. In this CO2 recovery plant, the continuous process meets the international standards for producing CO2 that is safe for food. In our CO2 Recovery Plants, every step of the purification process is carefully tailored to meet the needs of each customer, taking both technological and financial factors into account. Utility requirements for different capacities CO2 Recovery Plant are given below.

CO2 Recovery System

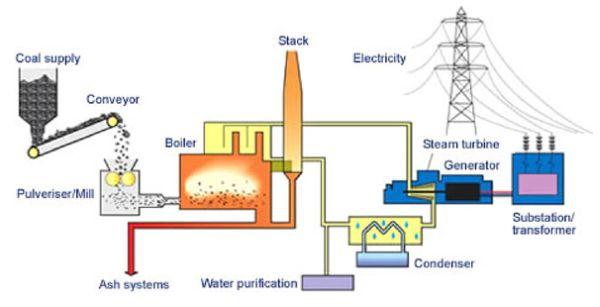

The fermenters release raw gas into the system, which feeds the gas into a foam trap to get rid of foam. Once that’s done, the blower forces the raw gas into the chain of Knockout drums. 1st stage compressor, 2nd stage compressor, 3 intercoolers to get the raw CO2 pressure you want. The compressor puts pressure on the gas, and then the raw CO2 gas goes into the ACF tower’s scrubbing systems.

Aluminum oxide with the help of a pre-water scrubber and dosing options, the air dryer can get the desired moisture level of CO2 that doesn’t smell bad. The gas also goes through a NOx removal tower and an ammonia liquidation system to make liquid CO2. This liquid CO2 is then safely stored in a process vessel until it can be transferred to a mobile tanker.

FAQs

- What does carbon capture mean? Why is it so important?

To slow down climate change, carbon capture means collecting carbon dioxide (CO2) emissions from factories. It is very important for lowering greenhouse gas emissions and dealing with how industrial activities hurt the environment. - What are some of the most important technologies used to capture carbon?

Several technologies are used to separate things: cryogenic separation, membrane separation, oxy-fuel combustion, and post-combustion capture. - How does storing carbon work, and what are the different ways to do it?

Putting CO2 that has been captured underground is what carbon storage means. Geological storage in old oil and gas fields, deep salty aquifers, coal seams, and ocean storage are some of the ways that this can be done. - What is carbon utilization, and how is it not the same as having carbon stored?

Carbon utilization is the process of using captured CO2 for different purposes, like making fuels, chemicals, and materials. It’s not the same as storage, where CO2 is kept underground. - What do the pros and cons of using carbon look like?

One benefit is that CO2 can be used to make something valuable. Some problems include making the system economically viable and able to grow. - For what reasons does Waterman Engineers Australia help with carbon capture projects?

Waterman Engineers Australia has a lot of experience putting different carbon capture technologies to use in different industries. This makes carbon capture projects more efficient and long-lasting. - In terms of carbon storage, what do Waterman Engineers Australia do?