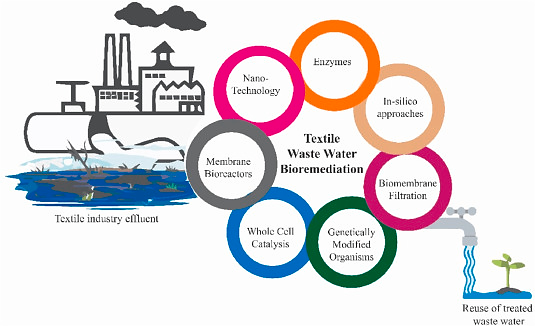

Biological Treatment of Textile Wastewater (Bioremediation)

Overview

In recent decades, a profusion of environmentally friendly strategies and technology, and Caustic recovery plants for textile industry have been developed as people become more aware of how their actions affect the environment. Furthermore, environmental protection rules have become more stringent as a result of social demand. The industry is not immune, and it is transitioning to more sustainable manufacturing practices. Faced with this new paradigm, the textile sector is a hotspot since it not only produces vast amounts of effluents but is also very toxic.

Cotton, wool, synthetic fibres, synthetic dyes, chemicals, and process water are some of the most essential key raw resources in the textile industry, and all these inputs have contributed to the textile industry’s economic diversification. The textile industry can be divided into two basic processes based on fibre production: dry and wet fabric processes. Solid wastes are created mostly in dry processing, whereas liquid wastes are generated primarily in wet processing.

The effluents’ composition is highly varied, with a pH range of 5 to 12, a high chemical oxygen demand (COD) of 10 to 2250 mgO2 L–1, a high biochemical oxygen demand (BOD) of 100 to 3000 mgO2 L–1, suspended particles, heavy metals, and salts, among other physicochemical features. They are highly coloured in terms of dye concentration. Dye concentrations, for example, range from 10 to 250 mg L–1, however, high quantities of 600–800 mg L–1 have been detected, and COD and BOD readings are unusually similar.

Textile production has several issues, including the creation of dyes with improved fixation capability, reduced water consumption, reused water, cost reductions, improved garment finish, and treatment methods, all of which are aimed at making the process more sustainable. As a result, if we are to alleviate the environmental impact of textile discharges, we must take a multifaceted approach to the problem for example using caustic recovery plant for textile effluents.

Principle of Biological Treatment

Principle of Biological Treatment

Biological treatment refers to procedures that utilize the capacities of microbes, plants, or enzymes to remove (either by degradation or sorption) a contaminant from a matrix such as soil, sediment, air, or water, thereby reducing its toxicity and minimizing its negative influence on the environment. Microorganism-based treatments (bacteria, algae, and fungi) are the most common among them. Microorganisms require certain conditions and in-depth knowledge to thrive. The presence of organic components such as dye and a load of bacteria, as well as the temperature, pH, and dissolved oxygen level in the system, all affect degradation performance.

Biological Treatment Processes:

- Aerobic Treatment

- Anaerobic Treatment

- Anoxic/Facultative Treatment

Anaerobic processes employ microorganisms to remove contaminants from wastewater in the presence of sufficient dissolved oxygen, whereas anaerobic methods use bacteria without oxygen to remove pollutants from wastewater.

Microbe selection and enzyme activity determine the efficiency of the biodegradation process. As a result, a vast number of microbes and enzymes have been isolated and tested for dye removal. Separation of potential microorganisms and their use for removal is an important biological component of textile wastewater treatment. Various microorganisms, such as bacteria, fungi, and algae, remove different types of colours contained in textile effluent water.

Fungal Removal of Dyes:

The metabolism of a fungus may adapt to changing environmental conditions. This talent is necessary for their survival. As a result, extracellular and intra-enzyme promote metabolic activity. The textile effluent water digested by enzymes has a variety of hues. Fungal cultures appear to be a beneficial habitat for removing colors from textile effluent water due to enzymes. Enzymes such as lignin peroxidase (LiP), manganese peroxidase (MnP), and laccase aid color breakdown. Colors from textile effluent have been degraded using white-rot fungus and Phanerochaete Chrysosporium. Azo dyes are degraded by white rots fungal cultures. The color Solvent Red 24 can be removed using fungi culture (Lichen Permelia perlata).

Limitations:

The protracted development phase, the need for nitrogen-restrictive conditions, unpredictable enzyme production, and large reactor size are all disadvantages of utilizing white-rot fungi to remove colors from wastewater. When using fungus alone, the system becomes unstable, and after 20 to 30 days, bacteria begin to emerge, and the fungi no longer dominate the system, reducing dye removal.

Algae Removal of Dyes:

Algae are ubiquitous and useful microorganisms for dye removal from textile effluent water. Color is removed from algae via three different processes: dyes are ingested by algae for growth, dyes are converted to no colored products utilizing enzymes, and chromophores are absorbed onto the surface of algae. The processes of biosorption and biodegradation are not the same. Dye molecules migrate from the solution phase to the solid phase (adsorbent) in the biosorption process, whereas enzymes break dye molecules’ bonds in the biodegradation process, allowing the dye molecule to be transformed into various by-products.

Algae decolorizes the pigment by three separate methods. Algae gather algal biomass, CO2, and H2O using chromophores; secondly, algae help in the conversion of chromophore material to non-chromophore material, and thirdly, the resulting chromophore is adsorbed onto algal biomass.

Bacterial Removal of Dyes:

The application of azo-reductase enzymes under anaerobic circumstances for the removal of primarily azo dyes due to the reductive breakdown of azo double bonds began twenty years ago. The necessity of breaking azo bonds (-N=N-) results in a product that is perhaps colorless and toxic-intermediates, which is then handled using anaerobic or aerobic procedures. Biodegradation of colors from textile effluent wastewater has recently been produced utilizing single bacterium cultures such as Alcaligenes faecalis PMS-1, Aeromonas hydrophilia, and Enterobacter sp. EC3.

Limitations:

All operational elements that influence dye degradation by bacteria include dissolved oxygen, temperature, pH of a solution, beginning color extents, dye structure, nitrogen sources, redox mediator, and the amount of electron donor. As a result, each design feature of the biodegradation reactor must be studied in order to ensure effective output and rapid bacterial breakdown.

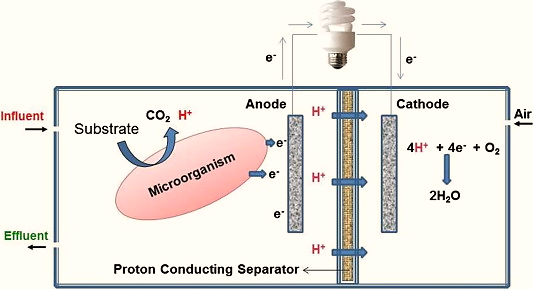

Microbial Fuel Cell (MFC) for Textile Effluent Treatment:

A microbial fuel cell converts chemical potential energy (available organic molecules in wastewater) into electricity through a biological process.

The MFC’s goal is to be a fuel cell that converts chemical potential energy into electrical power using oxidation-reduction reactions. In the MFC process, microorganisms in the anode chamber oxidize various organic substrates of water to generate electrons or protons, which are then transferred to the cathode chamber to consume oxygen. Anaerobic respiring bacteria in an anode may efficiently break down organic materials into carbon dioxide as a product, while also generating electrons and protons.

Advantages:

The direct conversion of organic materials into electrical energy, less excess activated sludge compared to other process technologies, insensitivity to operation environment, even at low temperatures, without any gas treatment, without any energy input for aeration, and widespread application in locations with insufficient electrical infrastructures are all advantages of implementing wastewater treatment to make MFCs.

Limitations:

Microbial fuel cells are rarely used in large-scale businesses due to their limited power output and high investment requirements. Several studies have been undertaken to improve MFC energy generation.

Enzymatic Degradation of Textile Effluent:

Enzymes are the most efficient molecules for sequentially breaking down and degrading complicated compounds. Unspecific cytoplasmic enzymes that operate like azoreductases have been identified in a number of different bacterial species which causes a catalytic reduction event to occur, culminating in the breaking of the azo group’s link (-NN-) and the formation of aromatic amine in colorless water.

Laccase, a phenoloxidase, can degrade waste products from a variety of aromatic compounds. Laccase enzymes are responsible for the breakdown of lignin, which are complex polyaromatic polymers. Laccases are oxidoreductases, also known as multicopper oxidases, that can remove one electron from phenols, polyphenols, and anilines to oxidize them. The laccase enzyme works by using a nonspecific free radical mechanism to degrade azo dyes without producing harmful aromatic amines.

Factors Affecting the Textile Effluent Degradation:

There are various elements that may alter the biodegradation rate of azo dyes due to the extremely variable nature of the biological treatment system, particularly textile effluents. Temperature, pH, and dissolved oxygen are all non-dye-related variables that could influence azo dye and textile effluent biodegradation.

The biodegradability of azo dye wastewater may be influenced by dye-related characteristics such as azo dye class and type, reduction metabolites, dye concentration, dye side-group, and organic dye additives.

Ecological Perspective of Biological Treatment:

Biological treatment employing aerobic bacteria and the activated sludge process (ASP) is particularly environmentally friendly. Because no hazardous chemicals are required, the risk of water contamination is virtually nil. There is no unpleasant odor. Treatment water can be reused for irrigation and fish life, which is difficult with conventional systems. Low levels of non-hazardous sludge are created, with trace amounts of dangerous heavy metals such as lead, chromium, and mercury. Compost fertilizer can be made from sludge.

Biological Treatment Frequently Asked Questions

1) What is biological wastewater treatment process?

The conventional approach, commonly referred to as the biological wastewater treatment method, is a popular and frequently utilised type of treatment. It considers biodegradation bleaching with the help of various microorganisms, including fungi, bacteria, yeasts, and algae.

2) Is Bioremediation a wastewater treatment?

Bacterial bioremediation is commonly employed to clean industrial effluent. Many bacteria, including B. subtilis, pseudomonas, endophytes, and some bacterial strains, are employed for this type of treatment.

3) Which biological treatment method is mostly used for textile industries?

Oxidation processes with chlorine gas. The colour and BOD in the influent can be effectively treated using physico-chemical techniques with coagulation-flocculation.

4) How does bioremediation of wastewater work?

High-toxic chemicals are changed biologically into less-toxic chemicals in bioremediation by microorganisms, which typically uses one type of organism or a group of microorganisms.

5) What are the characteristics of textile in effluent?

The effluent from the textile industry has a high pH value, high levels of suspended particles, chlorides, and nitrates, as well as metals including manganese, sodium, lead, copper, chromium, and iron. It also has a high BOD and COD value. Dark brown also characterises the water.

6) Which enzymes are involved in dye degradation?

The primary ligninolytic enzymes utilised to break down dyes are laccase, manganese peroxidase, and lignin peroxidase. For various fungi, their contributions may differ.